Subscribe to Our Youtube Channel

Summary of Contents for Bush Hog 4810RR1

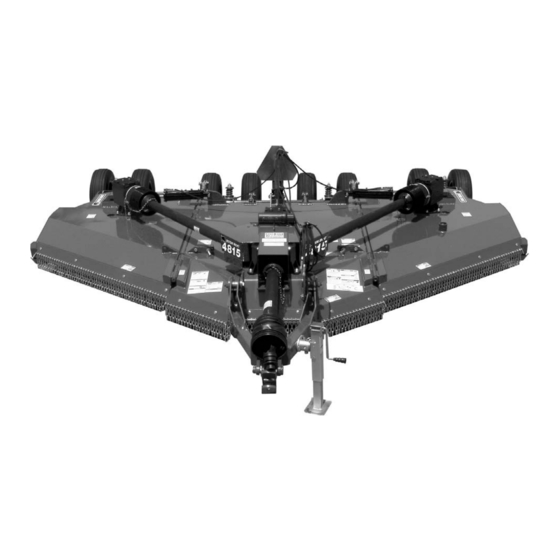

- Page 1 4815RR1,4810RR1 14815RR1,14810RR1 This Manual applies to Models: 4815RR1, 4810RR1, 14815RR1, 14810RR1 FLEX-WING ROTARY CUTTERS / SHREDDERS Published 12/21 Part No. 50076491 © 2021 Alamo Group Inc.

- Page 2 PELIGRO DANGER Si vous ne pouvez pas lire Si no puede leer inglés: antes de poner en l'anglais: avant d'utiliser funcionamiento este equipo, solicite que l'équipement, demandez à une alguien le traduzca los mensajes de personne de vous traduire les seguridad o vaya al sitio web para consultar messages de sécurité...

- Page 5 A Manual canister is provided on the implement where this manual can be properly stored. If you lose or damage this manual a free replacement manual can be obtained from an authorized Bush Hog dealer or by down loading the manual from the Bush Hog website www.bushhog.com...

- Page 6 DEALER to CUSTOMER Pre-Delivery/ Operation Instructions Dealer should inform the Purchaser of this product of Warranty terms, provisions, and procedures that are applica- ble.Dealer should inform Purchaser to review the contents of the Operator’s Manual including safety equipment, safe operation, and maintenance, to review the Safety Signs on the implement (and tractor if possible),and of Pur- chaser’s responsibility to train his/her operators’s in safe operation procedures.

-

Page 7: Table Of Contents

TABLE OF CONTENTS SAFETY SECTION..........................1-1 GENERAL SAFETY INSTRUCTIONS AND PRACTICES ..............1-2 OPERATOR SAFETY ..........................1-3 CRUSHING HAZARDS..........................1-4 CONNECTING OR DISCONNECTING IMPLEMENT SAFETY ............1-5 THROWN OBJECTS HAZARDS ......................1-6 THROWN OBJECTS HAZARD(CONTINUED)..................1-7 RUN OVER HAZARDS..........................1-8 PTO ENTANGLEMENT HAZARDS .......................1-9 MOWER BLADE CONTACT HAZARDS....................1-10 HIGH PRESSURE OIL LEAK HAZARD....................1-10 ELECTRICAL &... - Page 8 CONNECTING THE MOWER TO THE TRACTOR ................4-9 Connecting Mower Tongue to the Tractor ....................4-9 Connecting Mower Hydraulic Lines to the Tractor ................4-10 SETTING THE MOWER ........................4-11 Setting Deck Height ..........................4-12 Setting Deck Pitch..........................4-13 DRIVELINE ATTACHMENT .........................4-14 Driveline Length Check........................4-14 Constant Velocity (CV) Driveline......................4-16 PRE-OPERATION INSPECTION AND SERVICE ................4-17 Tractor Pre-Operation Inspection/Service....................4-18 Mower Pre-Operation Inspection/Service ....................4-18...

-

Page 9: Safety Section

SAFETY SECTION Safety Section 1-1... -

Page 10: General Safety Instructions And Practices

SAFETY GENERAL SAFETY INSTRUCTIONS AND PRACTICES A careful operator is the best operator. Safety is of primary importance to the manufacturer and should be to the owner/operator. Most accidents can be avoided by being aware of your equipment, your surroundings, and observing certain precautions. -

Page 11: Operator Safety

SAFETY OPERATOR SAFETY TO AVOID DEATH OR SERIOUS INJURY DO THE FOLLOWING: • READ, UNDERSTAND and FOLLOW Operator's Manual instructions, Warnings and Safety Messages. • WEAR SAFETY GLASSES with side shields (marked with ANSI Z87), safety shoes, hard hat, hearing protection and gloves when operating or repairing equipment •... -

Page 12: Crushing Hazards

SAFETY CRUSHING HAZARDS 4815/4810/14815/14810 12/21 Safety Section 1-4 © 2021 Alamo Group Inc. -

Page 13: Connecting Or Disconnecting Implement Safety

SAFETY CONNECTING OR DISCONNECTING IMPLEMENT SAFETY 4815/4810/14815/14810 12/21 Safety Section 1-5 © 2021 Alamo Group Inc. -

Page 14: Thrown Objects Hazards

SAFETY THROWN OBJECTS HAZARDS 4815/4810/14815/14810 12/21 Safety Section 1-6 © 2021 Alamo Group Inc. -

Page 15: Thrown Objects Hazard(Continued)

SAFETY THROWN OBJECTS HAZARD (CONTINUED) 4815/4810/14815/14810 12/21 Safety Section 1-7 © 2021 Alamo Group Inc. -

Page 16: Run Over Hazards

SAFETY RUN OVER HAZARD 4815/4810/14815/14810 12/21 Safety Section 1-8 © 2021 Alamo Group Inc. -

Page 17: Pto Entanglement Hazards

SAFETY PTO ENTANGLEMENT HAZARDS 4815/4810/14815/14810 12/21 Safety Section 1-9 © 2021 Alamo Group Inc. -

Page 18: Mower Blade Contact Hazards

SAFETY MOWER BLADE CONTACT HAZARDS HIGH PRESSURE OIL LEAK HAZARD 4815/4810/14815/14810 12/21 Safety Section 1-10 © 2021 Alamo Group Inc. -

Page 19: Electrical & Fire Hazard

SAFETY ELECTRICAL & FIRE HAZARD 4815/4810/14815/14810 12/21 Safety Section 1-11 © 2021 Alamo Group Inc. -

Page 20: Transporting Hazards

SAFETY TRANSPORTING HAZARDS 4815/4810/14815/14810 12/21 Safety Section 1-12 © 2021 Alamo Group Inc. -

Page 21: Hazards With Maintenance Of Implement

SAFETY HAZARDS WITH MAINTENANCE OF IMPLEMENT 4815/4810/14815/14810 12/21 Safety Section 1-13 © 2021 Alamo Group Inc. - Page 22 SAFETY HAZARDS WITH MAINTENANCE OF IMPLEMENT CONTINUED 4815/4810/14815/14810 12/21 Safety Section 1-14 © 2021 Alamo Group Inc.

- Page 23 SAFETY 4815/4810/14815/14810 12/21 Safety Section 1-15 © 2021 Alamo Group Inc.

-

Page 24: Decal Location

SAFETY DECAL LOCATION NOTE: Bush Hog supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Bush Hog cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 25 D587 INSTRUCT Lubrication D549 DANGER Multi Hazard D555 DANGER Shield Missing 91443 IMPORTANT Slip Clutch D559 WARNING Use Bush Hog Genuine Parts D565 DANGER Crushing Hazard D553 WARNING Hydraulic Pressure/Towing D547 DANGER 540 RPM D548 DANGER 1000 RPM D551 WARNING...

-

Page 26: Decal Description

SAFETY DECAL DESCRIPTION DANGER DANGER THROWN OBJECTS HAZARD D549_1 Mower can throw objects up to 300 feet. TO AVOID DEATH OR SERIOUS INJURY to operator or bystanders: STOP mowing if bystanders or traffic come within 300 feet. DO NOT OPERATE with thrown object shielding removed. KEEP thrown object shielding in place and in good condition during operation. - Page 27 SAFETY ENTANGLEMENT HAZARD TO AVOID DEATH OR SERIOUS INJURY: DO NOT operate without guards in place and in good condition. PTO and gearbox guarding are SUBJECT TO WEAR. STAY AWAY and KEEP hands, feet and body AWAY from rotating blades, drivelines and parts that continue to move Tractor PTO Guard after power shut-off.

- Page 28 SAFETY WARNING TO AVOID DEATH OR SERIOUS INJURY FROM HIGH PRESSURE HYDRAULIC OIL LEAKS PENETRATING SKIN: DO NOT OPERATE equipment with oil or fuel leaks. KEEP all hydraulic hoses, lines and connections in good condition and tight before applying system pressure. Relieve hydraulic pressure before disconnecting lines or working on the system.

- Page 29 SAFETY WARNING TO AVOID EQUIPMENT AND GRASS FIRES: CLEAR AWAY grass or debris from slip clutches, gearboxes, drivelines and decks. TO AVOID FIRE IGNITION: DO NOT ALLOW BLADES TO CONTACT rocks,metal or solid objects. D553_3 IMPORTANT D553_4 Required for Standard Pull Type Units. 14"...

- Page 30 SAFETY DANGER TO AVOID DEATH OR SERIOUS INJURY FROM DRIVELINE CONTACT, DRIVELINE SEPARATION OR PTO STUB SHAFT FAILURE: STOP, LOOK and LISTEN for rotating motion before approaching implement. STAY AWAY and KEEP hands, feet and body AWAY from driveline & rotating parts until all moving elements have stopped.

- Page 31 SAFETY 4815/4810/14815/14810 12/21 Safety Section 1-23 © 2021 Alamo Group Inc.

- Page 32 SAFETY WARNING TO AVOID DEATH OR SERIOUS INJURY FROM BLADE ATTACHMENT FAILURE: Torque pan nut (450 ft lbs) and blade nut (600 ft lbs) after first 8 hours of use to ensure proper seating and tightness of components. ALWAYS replace blades in pairs. ALWAYS replace blades with new bolts and nuts.

- Page 33 SAFETY DANGER THROWN OBJECT HAZARD TO AVOID DEATH OR SERIOUS INJURY: DO NOT OPERATE if Thrown Object Shielding is damaged or missing. MAINTAIN Thrown Object Shielding HERE D614 4815/4810/14815/14810 12/21 Safety Section 1-25 © 2021 Alamo Group Inc.

- Page 34 SAFETY PELIGRO DANGER Si vous ne pouvez pas lire Si no puede leer inglés: antes de poner en l'anglais: avant d'utiliser funcionamiento este equipo, solicite que l'équipement, demandez à une alguien le traduzca los mensajes de personne de vous traduire les seguridad o vaya al sitio web para consultar messages de sécurité...

- Page 35 SAFETY 4815/4810/14815/14810 12/21 Safety Section 1-27 © 2021 Alamo Group Inc.

- Page 37 Contents Acknowledgment ......2 Foreword ........2 Safety Alerts.

-

Page 38: Safety Alerts

Safety Alerts Symbol Signal Words This Safety Alert Symbol means: “ATTENTION! Signal words are distinctive words that will typically be STAY ALERT! YOUR SAFETY IS INVOLVED!” found on safety signs on the mower and other worksite equipment. These words may also be found in this The Safety Alert Symbol identifi es important safety manual and the manufacturer’s manuals. -

Page 39: The Industrial/Agricultural Mower

The Industrial/Agricultural Mower Industrial/Agricultural Mower Types Mowers are used for pasture clipping, crop residue shredding, heavy brush cutting, waterways, right-of- Flail ways, roadside or highway mowing. Also, these mowers are used for cutting grass and other growth in public areas such as parks and cemeteries. Boom Rotary Sickle Bar... -

Page 40: Follow A Safety Program

Follow A Safety Program Protect Yourself Wear personal protective clothing and Personal Protective Equipment (PPE) issued to you or called for by job conditions. You must ALWAYS wear safety glasses with side shields. You may also need: — Hard hat —... - Page 41 Follow A Safety Program Avoid Injury From Raised Equipment Avoid Injury From High Pressure Fluid Avoid possible crushing injury from falling mower or Avoid fl uid injection injury due to high pressure fl uid leaks. other raised equipment. High Pressure Fluid Can Inject into the Body Avoid Crushing –...

- Page 42 Follow A Safety Program Be Alert! For Safe Operation Know where to get assistance. Know how to use a fi rst You must be a qualifi ed and authorized operator for aid kit and fi re extinguisher/fi re suppression system. proper operation of your machine.

- Page 43 Follow A Safety Program Some Rules You Must Work By (continued) Keep — Only qualifi ed and authorized individuals may operate Children this equipment. Away from — Never allow children to play on, ride on or operate Equipment the equipment. Children are not qualifi ed to operate this equipment.

-

Page 44: Prepare For Safe Operation

Prepare For Safe Operation Check The Mower And Tractor Equipment Before beginning your work day inspect the machine Walk-Around and have all systems in good operational condition. Inspection WARNING! Prevent possible crushing injury from falling equipment. Hydraulic system or part failure could cause unsupported equipment to fall. - Page 45 Prepare For Safe Operation Know The Work Area Correct unsafe conditions. Do not operate in problem areas where debris and obstacles cannot be removed Before you operate the mower thoroughly inspect or marked. the work area. Walk around the area and inspect the Analyze mowing area to determine: surfaces you will travel on when using the mower.

- Page 46 Prepare For Safe Operation Tractor And Mower Controls Safety Test — Raise and lower mower to check for driveline bottoming out or engagement problems. Start the tractor following the specifi c procedures in the — Check the equipment for excessive vibration and manufacturer’s operator’s manual.

- Page 47 Prepare For Safe Operation Hitching Mower To Tractor Read and Three-point hitch-mounted mowers: Understand Manuals Before — Refer to mower and tractor manufacturers’ manuals. Operating — Place tractor’s hydraulic power lift (rockshaft) selector lever in down position to avoid unexpected movement.

-

Page 48: Start Safely

Start Safely Make The Right Start Mow only in daylight or good artifi cial light conditions. Rotating Blades – Avoid serious injury or death from mower-thrown Keep Away objects or blade contact: — Keep chain shields, fl exible or solid defl ector shields or discharge chutes in place and in good repair. - Page 49 Operate Safely Mower-Thrown Objects (continued) Disc Mowers — When using a disc mower it is Do Not Mow important to know the area to be mowed. If the operator in Reverse has mowed the fi eld before and is familiar with all obstacles that may be present, it is suffi cient to watch ahead of the mower path for any additional objects that may have entered the fi eld.

- Page 50 Operate Safely Under Mount Mower Safety Practices When mowing with an under mount mower: Never Stand — Keep removable discharge chute in place and over on Mower – Keep Away discharge opening. — Never stand on a mower housing when the tractor engine is operating.

- Page 51 Operate Safely Wing And Side Mount Mowers Safety Practices 300 ft (92 m) Raised wing positions reduce shielding protection and Keep Bystanders increases the thrown object and blade contact hazard Away from risks. Mowing Area Avoid possible serious injury or death by thrown objects or blade contact from raising and lowering wings during mowing operations: —...

- Page 52 Operate Safely Uneven Terrain Mowing Safety Practices (continued) Maintain — Use extreme care to maintain control over the Control, Use Low equipment when operating in these conditions. Speeds — Increase tractor stability by adding wheel weights, ballast and increasing wheel spacing to maximum. Refer to operator’s manual for recommendations.

-

Page 53: Park Safely

Park Safely Parking Safety Practices — Use designated or out-of-traffi c areas. — Use fi rm level ground locations. Parking Brake — Set parking brake. — Lower raised equipment to ground. Shut down the mower and tractor using proper equipment shut down practice before dismounting tractor. -

Page 54: Perform Maintenance Safely

Shut Down Safely Dismounting Properly — Never dismount from moving equipment. Wait for — Never jump from any machines. Moving Parts to Stop — Dismount carefully. — Check for slippery steps. — Keep feet and hands away from controls. — Use handholds and steps during dismount. —... - Page 55 Perform Maintenance Safely Prepare Yourself Wear personal protective clothing and Personal Protective Equipment (PPE) issued to you or called for by job conditions. You must ALWAYS wear safety glasses with side shields. You may also need: — Hard hat — Safety shoes —...

- Page 56 Perform Maintenance Safely Prepare The Machine — Securely support, block up, or lock up mower wings with approved locking devices before working near or Stored energy sources (electrical, mechanical, hydraulic, underneath a wing mower. pneumatic, chemical, thermal, etc.) must be controlled —...

- Page 57 Perform Maintenance Safely Perform Maintenance Safely Use Proper Ventilation Make sure the hoists or jacks you use are in good repair. Never use jacks with cracked, bent, or twisted parts. If it is necessary to run an engine in an enclosed area, Never use frayed, twisted or pinched cables.

- Page 58 Perform Maintenance Safely Hydraulic System Hazards When venting or fi lling the hydraulic system, loosen the fi ller cap slowly and remove it gradually. The hydraulic system is under pressure whenever the Never reset any relief valve in the hydraulic system to a engine is operating and may hold pressure even after the pressure higher than recommended by the manufacturer.

- Page 59 Perform Maintenance Safely Avoid Explosion — Observe the polarity of the batteries and connections. — Make the fi nal cable connection to the engine or the WARNING! Avoid possible serious injury from furthest ground point away from the battery. Never explosion.

- Page 60 Perform Maintenance Safely Tire And Wheel Maintenance (continued) Never cut or weld on a wheel with an infl ated tire mounted on it. This could cause explosive WARNING! The types of wheels and tires usually decompression. found on this equipment require special care when Check that the tire size and wheel are correctly matched.

-

Page 61: Final Word To The User

Perform Maintenance Safely Mower Blade Maintenance (continued) — Avoid bending blades. Help prevent mower blades from bending or cracking by avoiding contact with — How are mower blades made? solid objects. Mower blades are intended to cut Mower blades are made of high strength alloy spring grass, shrubs, woody vegetation, and small trees and steel. -

Page 63: Reconocimiento

Contenido Reconocimiento ....... 2 Introducción ........2 Alertas de seguridad . -

Page 64: Alertas De Seguridad

Alertas de seguridad Símbolo Palabras indicativas Este símbolo de alerta de seguridad signifi ca: Las palabras indicativas son palabras distintivas que “¡ATENCIÓN! ¡MANTÉNGASE ALERTA! ¡SU típicamente se encontrarán en letreros de seguridad SEGURIDAD ESTÁ EN RIESGO!” de la cortadora de césped y otros equipos del sitio de trabajo. -

Page 65: Cortadora De Césped Industrial/Para Agricultura

Cortadora de césped industrial/para agricultura Tipos de cortadora de césped industrial/para agricultura Las cortadoras de césped se usan para recortar pasturas, Triturador desmenuzar residuos de cultivos, cortar arbustos, realizar desbroce pesado, cortar la hierba en vías de agua, derechos de paso, costados de caminos o autopistas. Además, estas cortadoras se usan para cortar la hierba y otras plantas en zonas públicas como parques y cementerios. -

Page 66: Cumplimiento Del Programa De Seguridad

Cumplimiento del programa de seguridad Protéjase a sí mismo Use la ropa de protección personal y los equipos de protección personal (PPE) que se le proporcionen o que requieran las condiciones del trabajo. SIEMPRE debe usar gafas de seguridad con escudos laterales. Puede necesitar también: —... - Page 67 Cumplimiento del programa de seguridad Evite las lesiones provocadas por equipos elevados Si un fl uido se inyecta en la piel, debe ser extraído dentro de pocas horas por personal médico Evite posibles lesiones de aplastamiento por caídas de la familiarizado con este tipo de lesión.

- Page 68 Cumplimiento del programa de seguridad ¡Manténgase alerta! Para una operación segura Sepa dónde obtener asistencia. Sepa cómo usar un Usted debe ser un operador cualifi cado y autorizado equipo de primeros auxilios y un extintor de incendios/ para operar la máquina correctamente. Debe comprender sistema de supresión de fuego.

- Page 69 Cumplimiento del programa de seguridad Algunas reglas que debe cumplir al trabajar (continuación) Mantenga — Únicamente personas cualifi cadas y autorizadas a los niños alejados pueden manejar estos equipos. de los equipos — Nunca permita que los niños jueguen en los equipos, viajen en ellos o los hagan funcionar.

-

Page 70: Preparación Para Una Operación Segura

Preparación para una operación segura Revise los equipos de la cortadora de césped y el marcadas; incluya los pernos y sujetadores de las hojas. Nunca enderece o suelde en las hojas. tractor — Asegúrese de que el escudo para objetos que son Antes de comenzar la jornada de trabajo, inspeccione la arrojados se encuentre correctamente instalado y en buen máquina y asegúrese de que todos los sistemas estén en... - Page 71 Preparación para una operación segura Familiarícese con la zona de trabajo Corrija las condiciones no seguras. No opere en áreas con problemas donde no se puedan retirar o marcar los Antes de hacer funcionar la cortadora de césped, residuos y los obstáculos. inspeccione cuidadosamente la zona de trabajo.

- Page 72 Preparación para una operación segura Prueba de seguridad de los controles del tractor y de la cortadora de césped Use el ROPS Arranque el tractor siguiendo los procedimientos y el cinturón de seguridad específi cos del manual del operador del fabricante. Estos procedimientos normalmente incluyen: —...

- Page 73 Preparación para una operación segura Enganche de la cortadora de césped al tractor Lea y asegúrese Cortadoras montadas en enganche de tres puntos: de comprender los — Consulte los manuales de los fabricantes de la manuales antes de comenzar la cortadora y del tractor.

-

Page 74: Arranque Con Seguridad

Arranque con seguridad Cómo realizar un arranque correcto Corte la hierba únicamente con luz diurna o en condiciones de buena luz artifi cial. Hojas giratorias – Manténgase Evite lesiones graves o muerte producidas por objetos arrojados por la cortadora o por el contacto con las hojas: —... - Page 75 Operación con seguridad Objetos arrojados por la cortadora de césped Apague la TDF, espere que las hojas dejen de girar, eleve la cortadora y, después, retroceda. (continuación) Corte desplazándose en sentido de avance. Cortadoras de disco — Cuando se usa una cortadora de disco, es importante conocer la zona donde se va a cortar.

- Page 76 Operación con seguridad Prácticas de seguridad para la cortadora de césped de montaje inferior Nunca se pare sobre la cortadora Cuando se traslada con una cortadora de césped de de césped – montaje inferior: Manténgase alejado — Mantenga la rampa de descarga extraíble en su lugar y por encima de la abertura de descarga.

- Page 77 Operación con seguridad Prácticas de seguridad para cortadoras de 300 ft césped con laterales y montaje lateral (92 m) Mantenga a las personas ajenas Las posiciones elevadas de los laterales reducen la alejadas de la zona protección de los escudos y aumentan los riesgos de de corte objetos arrojados y contacto con las hojas.

- Page 78 Operación con seguridad Prácticas de seguridad para trabajos de corte en terrenos desparejos (continuación) Mantenga — Use extremo cuidado para mantener el control de los el control, equipos cuando trabaja en estas condiciones. desplácese — Aumente la estabilidad del tractor agregando pesos o lastre en las ruedas y aumentando al máximo la separación entre las ruedas.

-

Page 79: Estacionamiento Seguro

Estacionamiento seguro Prácticas de seguridad para el estacionamiento — Use las zonas designadas o alejadas del tránsito. Aplique el freno de — Use lugares con suelo fi rme y nivelado. estacionamiento — Aplique el freno de estacionamiento. — Descienda el equipo de la cortadora de césped hasta el suelo. -

Page 80: Realización De Mantenimiento Con Seguridad

Apagado con seguridad Descenso correcto — Nunca descienda de equipos en movimiento. Espere hasta que las — Nunca baje de una máquina saltando. piezas móviles se detengan — Descienda con cuidado. — Verifi que que no haya peldaños resbaladizos. — Mantenga los pies y las manos lejos de los controles. —... - Page 81 Realización de mantenimiento con seguridad Preparación personal Use la ropa de protección personal y los equipos de protección personal (PPE) que se le proporcionen o que requieran las condiciones del trabajo. SIEMPRE debe usar gafas de seguridad con escudos laterales. Puede necesitar también: —...

- Page 82 Realización de mantenimiento con seguridad Preparación de la máquina Deben controlarse o reducirse las fuentes de energía Prepare los sistemas de la almacenada (eléctricas, mecánicas, hidráulicas, máquina para neumáticas, químicas, térmicas, etc.) al mínimo realizarles servicios practicable antes de realizar cualquier procedimiento de mantenimiento, reparación o servicio.

- Page 83 Realización de mantenimiento con seguridad Use ventilación adecuada Si es necesario hacer funcionar un motor en una zona Retire la llave y cerrada, elimine del área las emanaciones de escape lea el manual de con una extensión del caño de escape. Si no tiene esa mantenimiento extensión, asegúrese de abrir las puertas y dejar entrar aire del exterior.

- Page 84 Realización de mantenimiento con seguridad Riesgos del sistema hidráulico Cuando ventila o llena el sistema hidráulico, afl oje la tapa de llenado con lentitud y retírela gradualmente. El sistema hidráulico se encuentra bajo presión siempre Nunca restablezca una válvula de alivio del sistema que el motor está...

- Page 85 Realización de mantenimiento con seguridad Evite explosiones — Asegúrese de que las máquinas no se estén tocando. — Observe la polaridad de las baterías y conexiones. ¡ADVERTENCIA! Evite posibles lesiones graves por — Realice la conexión fi nal de cable al motor o al punto explosiones.

- Page 86 Realización de mantenimiento con seguridad Mantenimiento de neumáticos y ruedas (continuación) Evite la explosión ¡ADVERTENCIA! Los tipos de ruedas y neumáticos de los neumáticos que generalmente se encuentran en estos equipos requieren cuidados especiales al realizar servicios para evitar lesiones graves o la muerte. No infl e los neumáticos por encima de la presión No infl e neumáticos con gases infl amables o con sistemas recomendada.

-

Page 87: Palabras Fi Nales Para El Usuario

Realización de mantenimiento con seguridad Mantenimiento de las hojas de la cortadora — Evite doblar las hojas. Contribuya a prevenir que las hojas de la cortadora se doblen o rajen evitando el (continuación) contacto con objetos sólidos. Las hojas de la cortadora —... -

Page 89: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1... - Page 90 INTRODUCTION We are pleased to have you as a Bush Hog customer. Your Rotary Cutter has been carefully designed with care and built with quality materials by skilled workers to give maximum service with minimum down time. This manual is provided to give you the necessary operating and maintenance instructions for keeping your rotary cutter in top operating condition.

-

Page 91: Equipment Specifications

INTRODUCTION NOTE: All references made in this manual to right, left, front, rear, top or bottom are as viewed facing the di- rection of forward travel with implement properly attached to tractor. The Models 4815/14815 Rotary Cutter consists of a center unit with two variable position wings together hav- ing a cutting width of 15 feet (4.6m). -

Page 92: Key Operation Points

• If Tractor engine is lugging down, shift tractor to a lower gear • ALWAYS OPERATE WITH THE WING HYDRAULIC CYLINDER CONTROL VALVES IN A FLOAT POSITION. • For maximum performance and service life, Always use Genuine Bush Hog replacement parts. Operating Noise Level/Sound Pressure The sound levels at the operator's ear from the attached machine (rotary cutter) are at least 10 dB (A) below the levels from typical Agricultural tractors used to power and transport this machine. - Page 93 INTRODUCTION 4815/4810/14815/14810 12/21 Introduction Section 2-5 © 2021 Alamo Group Inc.

- Page 94 INTRODUCTION 4815/4810/14815/14810 12/21 Introduction Section 2-6 © 2021 Alamo Group Inc.

-

Page 95: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1... -

Page 96: Assembly

ASSEMBLY 4815/4810/14815/14810 12/21 Assembly Section 3-2 © 2021 Alamo Group Inc. -

Page 97: Tongue

ASSEMBLY Tongue During shipping tongue is tilted back to- ward unit.Roll tongue down into working position. Pin jackstand to tongue. Hose Holder Attach the Hose Holder to the mounting lug on the inside left strut of the tongue. Use the 5/8” x 2” bolt,5/8” nut and flat- washer provided. - Page 98 ASSEMBLY 4815/4810/14815/14810 12/21 Assembly Section 3-4 © 2021 Alamo Group Inc.

- Page 99 ASSEMBLY 4815/4810/14815/14810 12/21 Assembly Section 3-5 © 2021 Alamo Group Inc.

- Page 100 ASSEMBLY 4815/4810/14815/14810 12/21 Assembly Section 3-6 © 2021 Alamo Group Inc.

-

Page 101: Hydraulics

ASSEMBLY HYDRAULICS All versions of the 4815/14815/4810/14810 are shipped from the factory with the plumbing attached. Be sure to check fittings prior to use, to make sure they are tight. Fittings for attaching to the tractor remotes or inde- pendent valves should be purchased locally to fit the application. Plumb hydraulic cylinders as shown, (Hy- draulic Hoses are supplied for attachment to three tractor remotes.) Plugs are supplied to adapt value for either an open or closed center tractor hydraulic system. -

Page 102: Driveline Attachment To Implement

ASSEMBLY DRIVELINE ATTACHMENT TO IMPLEMENT CV DRIVELINE 1. Secure the opposite end to the power divider gearbox using the tapered pin and locknut. Tighten nut to 30 ft. lbs. 2. Install driveline with the CV body attaching to the tractor PTO. 3. - Page 103 ASSEMBLY 4815/4810/14815/14810 12/21 Assembly Section 3-9 © 2021 Alamo Group Inc.

- Page 104 ASSEMBLY IMPORTANT: Scan this QR Code with your smart phone to link to the ADMA Driveline Safety Manual for more information on the safe use of a driveline during normal operation and maintenance. Or type in your internet browser the following web address: www.algqr.com/dme Ops-0009-MISC 4815/4810/14815/14810...

-

Page 105: Operation Section

OPERATION SECTION Introduction Section 4-1... - Page 106 BUSH HOG 4815/14815/4810/14810 ROTARY MOWER OPERATION INSTRUCTIONS Bush Hog rotary mowers are manufactured with quality material by skilled workers. These mowers are designed to cut grass, weeds, small brush and other vegetative material up to 4-1/2” diameter in areas such as pastures and along highway right-of-ways.

-

Page 107: Operator Requirements

OPERATION 1. OPERATOR REQUIREMENTS Safe operation of the unit is the responsibility of a qualified operator. A qualified operator has read and understands the implement and tractor Operator’s Manuals and is experienced in implement and tractor operation and all associated safety practices. In addition to the safety messages contained in this manual, safety signs are affixed to the implement and tractor. -

Page 108: Tractor Requirements

OPERATION 2. TRACTOR REQUIREMENTS The tractor used to operate the mower must have the power capacity to lift, pull, and operate the Power Take Off (PTO) at the mower’s rated speed while traveling at a ground speed between 2 and 5 MPH. Operating the mower with a tractor that does not meet the following requirements may cause tractor or mower damage and be a potential danger to the operator and passersby. -

Page 109: Tractor Horsepower

OPERATION 3. Tractor Horsepower The horsepower required to operate the mower depends on several operating factors including the vegetation to be cut, terrain condition, operator experience, condition of the mower and tractor, and others. For most mowing conditions, the 4815/4810 mower requires a tractor with a minimum of 70 HP. Operating the mower with a tractor that does not have adequate power may damage the tractor engine.Exceeding 120 HP may cause mower damage by overpowering the unit in heavy cutting conditions. -

Page 110: Tire Spacing

OPERATION Tire Spacing The tire spacing of the tractor must be sufficient to maintain stability on the type of terrain where it is intended to be operated and for the type of implement that is being operated. Always refer to the tractor Operator’s Manual or consult the tractor’s authorized dealer for instructions on sufficient tire spacing or to change tractor tire spacing. - Page 111 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-7 © 2021 Alamo Group Inc.

- Page 112 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-8 © 2021 Alamo Group Inc.

- Page 113 OPERATION 6. CONNECTING THE MOWER TO THE TRACTOR Use extreme caution when connecting the mower to the tractor. The mower should be securely resting at ground level or setting on blocks. Keep hands and feet from under the mower deck and clear of pinch points between the tractor hitch arms and mower pins.

- Page 114 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-10 © 2021 Alamo Group Inc.

- Page 115 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-11 © 2021 Alamo Group Inc.

- Page 116 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-12 © 2021 Alamo Group Inc.

- Page 117 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-13 © 2021 Alamo Group Inc.

- Page 118 OPERATION IMPORTANT: Scan this QR Code with your smart phone to link to the ADMA Driveline Safety Manual for more information on the safe use of a driveline during normal operation and maintenance. Or type in your internet browser the following web address: www.algqr.com/dme Ops-0009-MISC 4815/4810/14815/14810...

- Page 119 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-15 © 2021 Alamo Group Inc.

- Page 120 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-16 © 2021 Alamo Group Inc.

- Page 121 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-17 © 2021 Alamo Group Inc.

- Page 122 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-18 © 2021 Alamo Group Inc.

- Page 123 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-19 © 2021 Alamo Group Inc.

- Page 124 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-20 © 2021 Alamo Group Inc.

- Page 125 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-21 © 2021 Alamo Group Inc.

- Page 126 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-22 © 2021 Alamo Group Inc.

- Page 127 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-23 © 2021 Alamo Group Inc.

- Page 128 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-24 © 2021 Alamo Group Inc.

- Page 129 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-25 © 2021 Alamo Group Inc.

- Page 130 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-26 © 2021 Alamo Group Inc.

- Page 131 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-27 © 2021 Alamo Group Inc.

- Page 132 OPERATION 10.3 Operating the Mower Wings Wings are positioned with hydraulic cylinders. It is recommended that the tractor be equipped with three hydraulic ports or a 3-spool control valve be used so that each section can be controlled independently. Ensure the hydraulic cylinders and lines are filled with oil by holding the valve control levers in the raised position until the cylinders fully retract (wings) and extend (center).

- Page 133 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-29 © 2021 Alamo Group Inc.

- Page 134 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-30 © 2021 Alamo Group Inc.

- Page 135 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-31 © 2021 Alamo Group Inc.

- Page 136 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-32 © 2021 Alamo Group Inc.

- Page 137 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-33 © 2021 Alamo Group Inc.

- Page 138 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-34 © 2021 Alamo Group Inc.

- Page 139 OPERATION 11.4 PTO RPM and Ground Speed Ground speed for mowing will depend upon the height, type, and density of vegetation to be cut. Recommended speed for efficient mower performance is between 2 and 5 mph(3-8 kph). Operate the mower at its full rated PTO speed to maintain blade speed for a clean cut.

- Page 140 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-36 © 2021 Alamo Group Inc.

- Page 141 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-37 © 2021 Alamo Group Inc.

- Page 142 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-38 © 2021 Alamo Group Inc.

- Page 143 OPERATION 11.6 Right of Way (Highway) Mowing • USE DOUBLE CHAIN GUARDS for highway, right-of-way, parks, greenbelt mowing, or all other mowing where human dwellings, vehicles, or livestock could be within 300 feet of the mower. • No shielding is 100% effective in preventing thrown objects. To Reduce Possibility of Injury: 1.

- Page 144 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-40 © 2021 Alamo Group Inc.

- Page 145 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-41 © 2021 Alamo Group Inc.

- Page 146 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-42 © 2021 Alamo Group Inc.

- Page 147 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-43 © 2021 Alamo Group Inc.

- Page 148 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-44 © 2021 Alamo Group Inc.

- Page 149 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-45 © 2021 Alamo Group Inc.

- Page 150 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-46 © 2021 Alamo Group Inc.

- Page 151 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-47 © 2021 Alamo Group Inc.

- Page 152 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-48 © 2021 Alamo Group Inc.

- Page 153 OPERATION 15. TROUBLE SHOOTING GUIDE Problem Possible Cause Remedy Excessive Vibrations Check Gearbox bolts. Tighten if loose. Check for loose nuts on Tighten if loose. Blade holder and Blades Check for bent output shaft. Replace shaft if bent. If shaft is bent oil will normally leak from the bottom seal.

- Page 154 OPERATION 4815/4810/14815/14810 12/21 Operation Section 4-50 © 2021 Alamo Group Inc.

- Page 155 MAINTENANCE SECTION Maintenance Section 5-1...

- Page 156 MAINTENANCE HAZARDS WITH MAINTENANCE OF IMPLEMENT 4815/4810/14815/14810 12/21 Maintenance Section 5-2 © 2021 Alamo Group Inc.

- Page 157 MAINTENANCE HAZARDS WITH MAINTENANCE OF IMPLEMENT CONTINUED 4815/4810/14815/14810 12/21 Maintenance Section 5-3 © 2021 Alamo Group Inc.

- Page 158 MAINTENANCE NOTE: Some guards and shields have been removed from the illustrations and pictures for instructional clarity. DO NOT operate implement with out all shields and guards in place and in good condition. Lubrication Do not let excess grease collect on or around parts, particularly when operating in sandy areas. The accompanying illustration shows lubrication points.

- Page 159 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-5 © 2021 Alamo Group Inc.

- Page 160 MAINTENANCE CENTER & WING GEARBOXES The gearboxes have been filled with lubricant to the proper level prior to shipment. However, you should check the oil level before each use. The gearbox should not require additional lubricant unless the box is cracked or a seal is leaking. Add EP80W-90 or EP85W-140 oil, if necessary, to bring oil level to check plug located on side of housing.

- Page 161 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-7 © 2021 Alamo Group Inc.

- Page 162 MAINTENANCE CAT IV WING DRIVELINE SHIELDS To remove the main inner driveline shield, Remove the locking screws. Align the bearing tabs with the cone pockets. FIGURE Mnt-0026. Remove the half-guard and remove the bearing ring. FIGURE Mnt-R-0012. Inspect the driveline shield for worn areas or cracks. If the shield has any dents or cracks, replace the Shield. While the Shields are off, examine the Driveline for signs of abnormal wear, bent or twisted shafts, or cracks in the shafts or tubes.

- Page 163 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-9 © 2021 Alamo Group Inc.

- Page 164 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-10 © 2021 Alamo Group Inc.

- Page 165 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-11 © 2021 Alamo Group Inc.

- Page 166 MAINTENANCE Avoid personal injury. Blade and/or blade carrier removal should be done only with the tractor engine shut off, key removed, in neutral, parking brake on, PTO disengaged, and the cutter blocked in the raised position. Blade Bolt Inspection Inspect Blade Bolt Head daily for wear as followed: Inspect the Blade Bolt Heads daily for abnormal wear.

- Page 167 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-13 © 2021 Alamo Group Inc.

- Page 168 MAINTENANCE TIRES AND WHEELS Before working on any tires and wheels make certain the Cutter is jacked up high enough and securely supported. When installing laminated or airplane tires, be sure the flat side of the lug nut is against the Wheel. When installing Sectional Tires and Wheels note the direction of travel and the curvature of rubber segments in the tire (See Assembly Section).

- Page 169 MAINTENANCE HIGH PRESSURE OIL LEAK HAZARD HYDRAULIC HOSES Replace pinched and broken Hydraulic Hoses at once. Tighten any Hydraulic Fitting with fluid leaking from it. If fluid still leaks, loosen the fitting, apply a pipe thread compound to the threads and tighten. Care must be exercised when tightening Hydraulic Fittings.

- Page 170 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-16 © 2021 Alamo Group Inc.

- Page 171 MAINTENANCE 4815/4810/14815/14810 12/21 Maintenance Section 5-17 © 2021 Alamo Group Inc.

- Page 172 MAINTENANCE PROPER TORQUE FOR FASTENERS The chart lists the correct tightening torque for fasteners. When bolts are to be tightened or replaced, refer to this chart to determine the grade of bolts and the proper torque except when specific torque values are assigned in manual text.

Need help?

Do you have a question about the 4810RR1 and is the answer not in the manual?

Questions and answers