Summary of Contents for RHINO RMCS – 2303

- Page 1 DC Servo Drive for Rhino Encoder DC Servo Motor (Model No : RMCS – 2303) Operating Manual v1.0...

-

Page 2: Table Of Contents

Contents Introduction – Salient Features ........................ 3 Technical specifications and Pin description .................... 4 Description of the three modes of Operation and Slave ID settings ............5 How to use the drive: ..........................7 Steps to configure the Drive using Modbus Poll Software : ..............7 STEP 1: Hardware Connection ...................... -

Page 3: Introduction - Salient Features

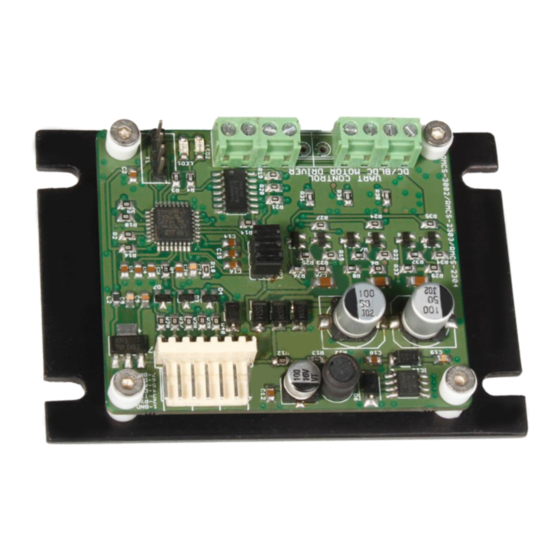

Introduction – Salient Features Rhino Motion Controls RMCS-2303 with UART ASCII is a high performance dc servo drive (10–30 V DC) designed for optimized operation of Rhino DC Servo motors with encoder feedback. This is an amazing cost effective solution to provide closed loop servo control for various applications. -

Page 4: Technical Specifications And Pin Description

Technical specifications and Pin description Supply Voltage and Current Specification Units Comments Supply Voltage Volts DC Between +Ve and GND Phase Current Amps Peak 5 Amps per phase Pin description of the drive is as per below image: Pin No. Description Pin No. -

Page 5: Description Of The Three Modes Of Operation And Slave Id Settings

Mode 1 Digital Speed control mode with direction control : In this mode the speed and direction of the Rhino DC servo motor is settable / controllable via a Computer / Arduino Controller board / any other Modbus ASCII compatible device. - Page 6 The three jumpers JP1, JP2 and JP3 can be set in the configuration as per the below table to provide a physical slave address to the drive. In the below table a value of ‘0’ corresponds to a state where the jumper is not connected and a value of ‘1’...

-

Page 7: How To Use The Drive

PC with Modbus Poll software. ( The modbus poll software can be downloaded from the link - https://www.modbustools.com/download.html RMCS-2303 UART ASCII Encoder DC Motor Driver https://robokits.co.in/motor-drives-drivers/encoder-dc-servo/rhino-industrial-encoder-dc-motor-driver-50w- with-uart-ascii-compatible-10-to-30-v-10a Encoder DC Servo Motor ( any of the below motors would work with the drive) https://robokits.co.in/rhino-planetary-encoder-dc-servo... -

Page 8: Step 1: Hardware Connection

STEP 1: Hardware Connection The hardware connections need to be setup between the motor, drive and PC as per the below block diagram and the pin out tables provided below. The potentiometer connections need to be provided only to run the driver and motor in Mode0 analog speed control mode. - Page 9 CP2102 Pin outs Drive Pin outs Description Pin No. Voltage Divider Pin outs 3.3V Signal Potentiometer Pin outs 5 V DC Output Signal 3.3 V DC Page | 9...

-

Page 10: Step 2: Connect Modbus Uart Ascii Drive With Modbus Poll Software

STEP 2: Connect Modbus UART ASCII Drive with Modbus Poll Software Once the Modbus Poll software is installed and the CP2102 is connected, please run the Modbus Poll software. Proceed to the Connection Tab on the screen and click the same as per below image. Then click on the connect tab which will open the connection settings as per the next image. - Page 11 Please make sure the connection setup settings are as per above for all parameters including the parity and stop bit. Once the OK button is pressed in the connection setup, the screen should show connected and it should be as per below image. This concludes STEP 2 of the configuration procedure.

-

Page 12: Step 3: Set Slave Id In Modbus Poll Software To Send And Receive Data

Step 3: Set slave ID in Modbus Poll Software to send and receive Data Read/Write Definition: Right Click on the Table shown on the home screen of Modbus Poll software. It should pop up a menu as per below image. Change screenshot Now select the first option Read / write Definition. - Page 13 Slave ID: As per jumper setting as shown on page 4. Function: Select Function as 03 Read Holding registers (4x). Select quantity as 2. Select Display as “Hex”. Once all settings are done, click on apply then select ok. You should receive data in the main table as per below image. The procedure to set Slave ID through software setting is explained below with images.

- Page 14 Then with power reset also remove all the three jumpers and enter Slave ID 247 as per below image. Then your drive is connected with Modbus Poll Software and Slave ID is 247. This concludes STEP3 of the configuration procedure. Page | 14...

-

Page 15: Step 4: Go To Function

Step 4: Go to Function This step is to understand the procedure to write the data to the drive to run it as per the requirement. Go to Functions tab on the home screen and click on “06: Write Single Register” as per the below image. It should open up a screen as per below image. - Page 16 This pop Window enables us to write data in HEX value to the drive in different Address Registers. Eg. When we write HEX value 0101 in the Address register 2 with a slave ID 7, this command will enable the Digital speed control mode of the drive.

-

Page 17: Step 5: Set The Lines Per Rotation As Per The Encoder And Motor Specifications

STEP 5: Set the Lines per rotation as per the encoder and motor specifications Lines per rotation concept is very important for Position Control mode. We have two types of quad encoders for Rhino DC Servo Motors which are : High Precision encoder ... - Page 18 Go to Functions tab on the home screen and click on “06: Write Single Register” as per the below image. Send lines per rotation Hex value to address 10. For High Precision encoder motor lines per rotation is 334 so send Hex value 14E (334) to address 10 as per below image. This concludes STEP 5 of the configuration procedure.

-

Page 19: Step 6: Program The Drive To Run In Any One Of The Three Modes

STEP 6: Program the drive to run in any one of the three modes: Mode0 - Analog Control Mode Mode1 - Digital Speed Control Mode Mode2 - Position Control Mode Mode 0 –Analog Control Mode For analog control mode we need to have the proper hardware connections as per STEP 1 and set the values in address 2 as per below table which is described from point no. - Page 20 After receiving response OK in the window, we need to enable motor. Send Hex value 0001 to address 2 as per below image to enable the motor. For analog mode connect external potentiometer to change speed of motor. Connect enable (Pin 4) of drive to GND (Pin 8) to enable motor in analog mode. User can change direction of motor in analog mode to connect the Direction (Pin 6) to the GND (Pin 8).

-

Page 21: Mode 1 - Digital Speed Control Mode

Mode 1 – Digital Speed Control Mode For digital speed control mode the register values need to be set as per the below table. (The procedure for same along with screenshots is provided after the table) refer below table settings and procedure is also explained below from point b. - Page 22 Now we need to set speed in digital speed control mode. The Speed is as per rpm of base motor. Eg. For a base motor with 18,000 rpm and the gear ratio of 180, the motor at maximum rpm would be 100 rpm at output shaft.

- Page 23 To change direction of motor send Hex value 0109 to address 2 as per below image. To stop motor send Hex value of 0 to address 2 as per below image. This concludes the settings for Mode1. The Gain and acceleration of the motor can be set as per described in Apendix 1. If you intend to use the motor in Mode1 as described above, please skip to Step 7 to save settings.

-

Page 24: Mode 2 - Position Control Mode

Mode 2 – Position Control Mode For position control mode the register values need to be set as per the below table. (The procedure for same along with screenshots is provided after the table) refer below table settings and procedure is also explained below Slave ID Address... - Page 25 User can set position of motor as per requirement. For 334 lines per rotation user need to send Hex value 538 (Decimal value is 1336) to address 16 for 1 rotation of encoder as per below image. To understand lines per rotation concept refer page 16.

- Page 26 To set encoder at initial position send Hex value 0000 to address 16 as per below image. The procedure to set 1 rotation at output shaft of motor is explained below with images. Refer Page 14 for calculations. For one rotation at output shaft (334 lines per rotation) Hex value is 1D5B0 (120240 decimal value).

- Page 27 Send Hex value 1 to address 18 as per below image. Then enable the motor by sending Hex value 0201 to address 2. Motor takes one rotation at output shaft. By this method user can set motor at any position. This concludes the settings for Mode2.

-

Page 28: Step 7: Save And Reset Settings In Drive

STEP 7: Save and Reset settings in Drive To save settings in drive send Hex value 07FF to address 0. If user saves setting in drive then user just need to power up drive then motor will run according to saved setting. Users don’t need to connect the drive through software again to run the motor. - Page 29 Appendix 1 In this section we describe all the MODBUS register and additional settings like gain and acceleration to optimize the motor driving parameters depending on the load and application of the motor. However, we would recommend to change the advanced settings after gaining some experience in using the drive. Also please test the changed settings in actual use case before finalizing same to make sure drive performs as per requirement.

-

Page 30: Brief Description Of All Configuration Registers

Brief Description of all configuration registers. A brief decription of the procedure to use the registers to configure the drive is provided below for registers listed in the above table Register 1: This register shows device address. Its default value is 0007 where 00 shows mode is disabled & 07 is slave ID. - Page 31 Register 2: This Register is Input Control Byte. It is already explained in STEP 6 Register 3: This register is Input Mode Byte. It is related to register 2. Refer below image for understanding its default Hex value is 2000 where 2 is Input control byte register and 00 shows it is in mode 0. As per below image when user sends Hex value 0100 in register 2 to enable mode 1 then register 3 value becomes 2001 where 2 is register 2 and 01 is mode 1.

- Page 32 Register 4: This register is for Velocity Proportional gain (P gain parameter). Its default value is FF20 (-224). User can change this value as per requirement. Refer below method to change Velocity proportional gain of motor. Eg. Hex value FF4C (-180) send to register 4 to set velocity proportional gain of motor to 180 as in below image. Register 6: This register is for Velocity Integral gain (I gain parameter).

- Page 33 Register 10: This register is for setting of lines per rotation. It is already explained in STEP 5 of document Register 12: This register is for setting of acceleration. Its default Hex value is 4E20 (20000).User can change this value as per requirement. Eg. Hex value 2710 (10000) is send to register 12 to set acceleration of motor to 10000. Register 14: This register is used to set speed of motor.

- Page 34 For example if user set one rotation of encoder (1336 = 4 x 334 lines per rotation) then position feedback of encoder is Hex value 538 (334 x 4 = 1336). From register 20 user can read LSB position of motor and from register 22 user can read MSB position of encoder.

- Page 35 Then user can read feedback of motor speed as per below image. Page | 35...

-

Page 36: Troubleshooting

Troubleshooting: Timeout Error: When slave address is not set. Set slave ID. Byte Missing Error: Check Connections and reset power. Check Jumpers connection as per slave ID. If no jumper is connected then default slave ID is 7. ...

Need help?

Do you have a question about the RMCS – 2303 and is the answer not in the manual?

Questions and answers