Summary of Contents for Movacolor MIX50

- Page 1 Mixer Manual MIX50, MIX100, MIX PHA, MIX BHA, MIX BH Manual revision : rev.02 Language : ENG Date : October 2019...

-

Page 2: Table Of Contents

Index 1 Introduction Symbols Terms Transport Receipt Disclaimer Manual description 2 General information Safety Certification Operating environmental conditions 3 Overview Mixers 4 Water-cooled setup 5 Mixer component overview 6 Mechanical installation Remove mixing blades 7 Electrical installation 8 Maintenance Periodically check Spare parts Options APPENDIX A: Technical specifications... -

Page 3: Introduction

Transport To protect the Movacolor unit against damage during transport, the unit is packed in a cardboard box filled with polyurethane foam. Delivery terms are Ex-Works Sneek, The Netherlands. Buyer is responsible for the transport. Movacolor cannot be held liable for any damage during transport. -

Page 4: General Information

Ensure that all parts are securely fixed to the extruder, injection molding machine or machine support. Always switch off the Movacolor control cabinet and disconnect the mains power plug from electrical power before performing maintenance. Dangerous voltages are present inside the control cabinet for up to 2 minutes after it has been switched off. -

Page 5: Overview Mixers

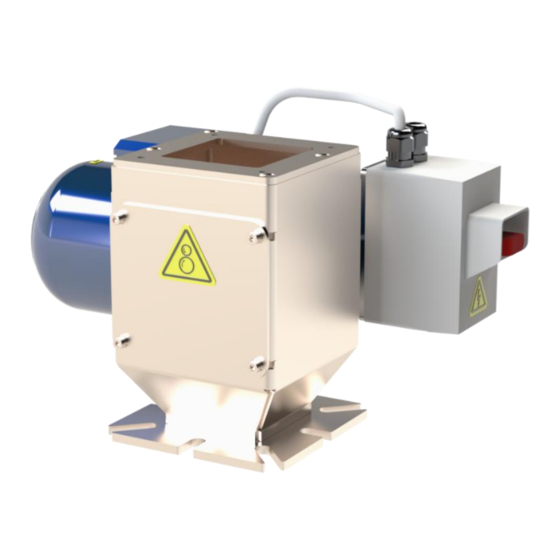

3 Overview Mixers Name Specifications Image • Mixer only MIX50 • Flange hole: square45mm • Mixer only • MIX100 Flange hole: square 90mm • Mixer neckpiece • Water cooled insert • Flange hole: square 45mm • MIX BH 1 or 2 dosing devices •... -

Page 6: Water-Cooled Setup

4 Water-cooled setup Only applicable for MIX PHA, MIX BH and MIX BHA The two air vents of the neckpiece can be left open but the preferred configuration is to connect one of the vents to the suction side of the drying system (see diagram). In that case it is advised to use a valve to minimize airflow either in or out the left open vent. -

Page 7: Mixer Component Overview

5 Mixer component overview MIX50 / MIX100 MIX BH MIXBHA / MIXPHA Mixer housing Mixer neckpiece Mixing blades Cover plate Bolts and washers to secure cover plate Normal top plate De-airing top plate Not available Water cooled insert Motor / reducer... -

Page 8: Mechanical Installation

6 Mechanical installation packed because of the weight. In case of a PHA or BHA mixer the neckpiece and motor reducer with blades are separately • Mount the neckpiece to the injection molding machine or extruder • Place the motor reducer with mixing blades in the neckpiece of the mixer and tighten the 4 hexagonal bolts and washers with a wrench as shown in the picture. -

Page 9: Electrical Installation

7 Electrical installation • The mixer needs a 3 phase power connection with a voltage of 400 Vac (other voltages on special request) • The mixer will be delivered with a combined Main switch / thermal motor safety switch and cable between the motor reducer and main switch. -

Page 10: Maintenance

Bolt to fasten mixer blade + locking ring MIXSPIERING Options Optional a motor start stop system can be connected to the MIX50 or MIX100 With this start/stop system the mixer motor can be activated during material dosing only. Item Description... -

Page 11: Appendix A: Technical Specifications

APPENDIX A: Technical specifications MIX0HEAT400 Motor reducer Type: BS03-34V/D08MA4/SP H1 IV/C Motor power: 0,55 kW Rotation speed sec. axes: 74 RPM Moment: 53 Nm 1,05 Color: RAL 7031 Weight: 6,9 kg Motor Voltage: 400V Y Frequency: 50 Hz Nom. current at 400 V Y: 1,6 A Cos φ: 0,75... - Page 12 MIX0HEAT480 Motor reducer Type: BS03-34V/D08MA4/SP H2 IV/C Motor power: 0,55 kW Rotation speed sec. axes: 68 RPM Moment: 53 Nm 1,05 Color: RAL 7031 Weight: 6,9 kg Motor Voltage: 480V Y Frequency: 60 Hz Nom. current at 480 V Y: 1,54 A Cos φ: 0,75...

-

Page 13: Appendix B: Dimensional Drawings

APPENDIX B: Dimensional drawings Mixer manual... - Page 14 Mixer manual...

- Page 15 Mixer manual...

-

Page 16: Appendix C: Declaration Of Incorporation

In case of alteration of the Partly Completed machine, not agreed upon by us, this declaration will lose its validity. Partly completed machine : Mixers with the following designation: MIX50, MIX100, MIXBH, MIXBHA, MIXPHA And any accessories to the respective designation covered by these directives Year:...

Need help?

Do you have a question about the MIX50 and is the answer not in the manual?

Questions and answers