Summary of Contents for VERDER CARBOLITE GERO PF

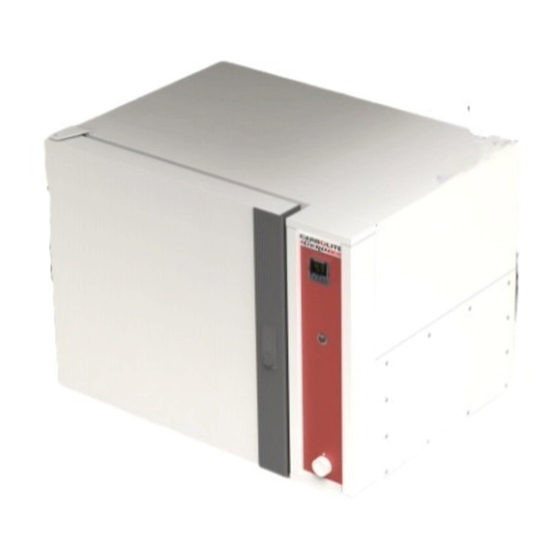

- Page 1 Installation, Operation and Maintenance Instructions 300 °C Peak Fan Convection Oven - PF Model: 200 Litres No Controller PF 200 + No Controller MEN-PF200-006_NOCTRL (18-10-2021)

-

Page 2: Table Of Contents

Contents This manual is for guidance on the use of the Carbolite Gero product specified on the front cover. This manual should be read thoroughly before unpacking and using the furnace or oven. The model details and serial number are shown on the back of this manual. - Page 3 Safety Warning - Refractory Fibre Insulation 6.3 Panel Removal 6.3.1 Side Panel 6.3.2 Internal Element Cover Temperature Controller Replacement Solid-State Relay Replacement Thermocouple Replacement Element Replacement Fuse Replacement 7.0 Fault Analysis Oven Does Not Heat Up Oven Overheats 8.0 Wiring Diagrams WV-11-00 WS-02-06 - Variable Speed Fan WS-02-02...

-

Page 4: Symbols And Warnings

1.0 Symbols and Warnings Switches and Lights Instrument switch: when the instrument switch is operated the temperature control circuit is energised. Door lock indicator: When this lamp is illuminated, the door is locked and cannot be opened. Interior light: when the interior light switch is operated the interior light illuminates. -

Page 5: General Warnings

General Warnings DANGER – Electric shock. Read any warning printed next to this symbol. WARNING: Risk of fatal injury. DANGER – Hot surface. Read any warning printed next to this symbol. WARNING: All surfaces of a product may be hot. DANGER –... -

Page 6: Installation

2.0 Installation Unpacking and Handling Remove the shelves and runners from the packaging before attempting to move the equipment. When unpacking and handling the product, always lift it by its base. Do not use the door or any other projecting cover or component to support the equipment when moving it. - Page 7 Ensure that the product is placed in such a way that it can be quickly switched off or disconnected from the electrical supply. Some models have protruding fan motor housings: these housings must be in an area of good ventilation. Under no circumstances should any objects be placed on top of the product.

-

Page 8: Electrical Connections

Electrical Connections Connection by a qualified electrician is recommended. All models covered by this manual may be ordered for single phase A.C. supply, which may be Live to Neutral non-reversible, Live to Neutral reversible or Live to Live. Check the product rating label before connection. The supply voltage should agree with the voltage on the label and the supply capacity should be sufficient for the current on the label. - Page 9 2- or Black to phase 1 3-phase Black to phase 2 Black to phase 3 (except 2-phase) Light Blue to neutral (except delta) Green/ Yellow to earth (ground)

-

Page 10: Temperature Controller

3.0 Temperature Controller If this product is fitted with a temperature controller, instructions are provided separately. -

Page 11: Operation

4.0 Operation Operating Cycle The product is fitted with an instrument switch. The switch cuts off power to the controllers and elements. The circulation fan will operate when the instrument switch is on. An optional door switch may be fitted. If so, ensure that the door is closed to operate the fans and heating elements. -

Page 12: Temperature Uniformity

Temperature Uniformity Where accurate temperature control of the load is important, use the central part of the chamber and place or distribute the load to allow free air circulation. Do not place loads on the chamber floor: use the bottom shelf. Explosive Vapours Unless your product includes the stoving and curing option, this model is not suitable for drying or heat treatment applications where... -

Page 13: Variable Speed Fan (If Fitted)

Variable Speed Fan (if fitted) If fitted, the variable speed control is fitted in the air circulation fan circuit. A panel mounted rotary dial is used to control the speed. Please note that there is a minimum setting at which the fan motor starts up when the product is switched on. -

Page 14: Door Switch (If Fitted)

4.12 Door Switch (if fitted) If ordered, the door switch will isolate the heating elements and circulation fan. The door switch is operated when the door is opened causing the heating elements and air circulation fan to be switched off. -

Page 15: Maintenance

5.0 Maintenance General Maintenance Preventive rather than reactive maintenance is recommended. The type and frequency depends on the product use; the following are recommended. Maintenance Schedule CUSTOMER QUALIFIED PERSONNEL DANGER! ELECTRIC SHOCK. Risk of fatal injury. Only electrically qualified personnel should attempt these maintenance procedures. Frequency Maintenance Method... - Page 16 Performance Check whether the cooling fans are Cooling Fans (if fitted) working Circulating Fan Visual check to see if it is running (if fitted) Circulating Fan Check bearings and replace if neces- (if fitted) sary Element Circuit Electrical measurement Measure the current drawn on each Power Consumption phase / circuit Shelves...

-

Page 17: Cleaning

5.2.1 Cleaning The product's outer surface may be cleaned with a damp cloth. Do not allow water to enter the interior of the case or chamber. Do not clean with organic solvents. Under no circumstances should any objects be placed on top of the product. - Page 18 In some cases the supply voltage may be outside the range 220-240 V or the 3-phase equivalent, the power limit parameter may be set to a value other than 100%. Do not increase the value to 100%, see section 9.0 for details of power limit settings.

-

Page 19: Repairs And Replacements

6.0 Repairs and Replacements Safety Warning - Disconnection from Power Supply Immediately switch the product off in the event of unforeseen circumstances (e.g. large amount of smoke). Allow the product to return to room temperature before inspection. Always ensure that the product is disconnected from the electrical supply before repair work is carried out. -

Page 20: Panel Removal

6.3 Panel Removal Disconnect the product from the electrical supply. 6.3.1 Side Panel The side panel is located on the right-hand side of the product. To gain access to the products electrical components: 1. Remove all screws holding the panel in place. The bottom of the panel is con- structed in such a way that it will hinge downwards and allow access to electrical components without the need to remove the panel entirely 2. -

Page 21: Temperature Controller Replacement

Temperature Controller Replacement Refer to the controller instructions for more information on how to replace the temperature controller. Solid-State Relay Replacement Disconnect the product from the power supply and remove the appropriate cover as given above. 1. Make a note of the wire connections to the solid state relay, then disconnect them. 2. -

Page 22: Fuse Replacement

Fuse Replacement Fuses are accessed by removal of the appropriate panel, as described in the 'Panel Removal' section. Depending on the model, supply fuses and control circuit fuses may be mounted in their own holders, or may be on a circuit board that contains an EMC filter. -

Page 23: Fault Analysis

7.0 Fault Analysis Oven Does Not Heat Up temperature No power from Check the fuses in the supply controller is supply line The controller shows a very high temperature The temperature sensor has temperature or a controller is broken or has a wiring fault code such as EEE or --- or S.br The SSR could be failing to... -

Page 24: Wiring Diagrams

8.0 Wiring Diagrams WV-11-00 F1, F2 Fuses Filter Instrument Switch Fan Motor Fan Models Only Temperature Controller Thermocouple Solid State Relay Element(s) Live Neutral Earth (GR/Y) (Green+Yellow) -

Page 25: Ws-02-06 - Variable Speed Fan

WS-02-06 - Variable Speed Fan Inverter Fan Motor Potentiometer Supply from Instrument Switch 3-Core 1.5mm2 Screened Cable Live Neutral Earth Cables * Potentiometer may be mounted on the control panel for customer adjustment, or Brown fitted inside, and the fan speed pre-set Blue Green + Yellow... - Page 26 WS-02-02 The variable speed control is wired in series with the fan. The fan activates when the instrument switch is turned on. Instrument Switch Fan Speed Controller Fan Motor Live Neutral Control Circuit...

-

Page 27: Fuses And Power Settings

9.0 Fuses and Power Settings Fuses F1 - F2: Refer to the circuit diagrams. Fitted if supply cable fitted. Internal 38 mm x 10 mm type F fitted on Supply Fitted on board to some types EMC filter circuit board(s) Fuses of EMC filter. -

Page 28: Specifications

10.0 Specifications Carbolite Gero reserves the right to change the specification without notice. Chamber Size Max Temp Max Power Approx Capacity Net Weight (mm) Model (°C) (kW) (kg) Peak Range Ovens - with fans PF 200 10.1 Environment The models listed in this manual contain electrical parts and should be stored and used in indoor conditions as follows: Temperature: 5 °C - 40 °C... - Page 29 Notes Service Record Engineer Name Date Record of Work...

- Page 30 The products covered in this manual are only a small part of the wide range of ovens, chamber furnaces and tube furnaces manufactured by Carbolite Gero for laboratory and industrial use. For further details of our standard or custom built products please contact us at the address below, or ask your nearest stockist.

Need help?

Do you have a question about the CARBOLITE GERO PF and is the answer not in the manual?

Questions and answers