Advertisement

Table of Contents

Advertisement

Table of Contents

Summary of Contents for ASGCO BC-2

- Page 1 BC-2™ with Bolt-Up Tensioner System ™ INSTALLATION, OPERATION & MAINTENANCE INSTRUCTION Need Solutions... ask... ASGCO ® to improve efficiency, safety and productivity? www.asgco.com 800.344.4000 | info@asgco.com| EM: 610.821.0210 © 4/2021 Copyright ASGCO “Complete Conveyor Solutions” ®...

-

Page 2: Safety First

Failure to observe all instructions could result in serious injury. It is the owner’s responsibility that the owner and each operator read and be familiar with this manual. Please contact our ASGCO engineering Department at 1.800.344.4000 if you have further questions or are unsure of these procedures. -

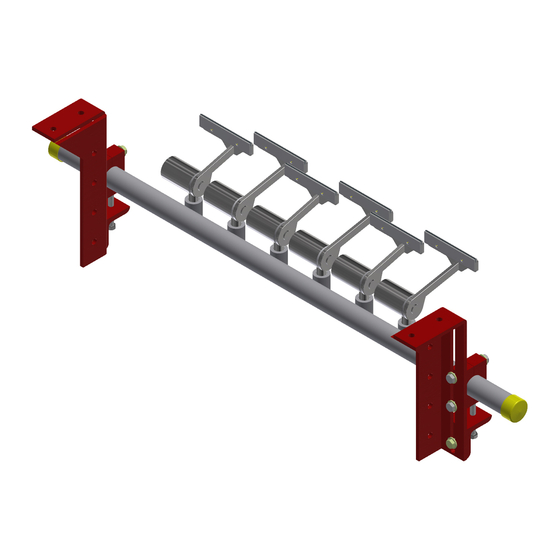

Page 3: Overall View

XX - BELT WIDTH 30”, 36” or 72” OVERALL VIEW The BC-2™ is a Secondary Belt Cleaner designed to be installed on the return side of the belt. Identify and become familiar with all the parts. Ensure all parts have been included. If mounting structure is not available, additional steel may have to be added. - Page 4 1. DETERMINE CLEANER LOCATION Although BC-2 is a secondary cleaner and as such should be located on the return side of the belt after the belt leaves contact with the head pulley, this system is designed that it will function at the 6 o’clock position on the pulley as shown below.

-

Page 5: Mounting Brackets

BC-2™ INSTALLATION 3. MOUNTING BRACKETS Insert the tube with attached blades through the chute cut outs. Determine the desired position of the mounting brackets. Attach the mounting brackets to the chute wall by welding or bolting through the mounting holes along the mounting brackets’ length, or to the conveyor frame using the two holes on top of each mounting bracket. -

Page 6: Operation

BC-2™ INSTALLATION 5. ARM TO TUBE INSTALLATION With mounting brackets bolted or welded in place, insert the tube through the chute cut outs. Arms should be inserted into the mounting tube, alternating short and long arms. On belt widths that have odd numbers of arm modules, more short arms will be included than long arms. - Page 7 BC-2™ INSTALLATION OPERATION CONT. Adjust the short arms up so that the tips contact the belt. Tighten all set screws and jam nuts completely. Ensure the blade tip is contacting the belt and then tighten lock nuts on the blade tips.

- Page 8 BC-2™ MAINTENANCE AFTER ONE DAY OF OPERATION Inspect the cleaner for proper belt cleaning and operation. WEEKLY Frequent inspection is the key to proper belt cleaning and easy Scraper servicing. Weekly inspec- tions are recommended, but actual service frequency may vary widely depending on various plant operating conditions.

- Page 9 BC-2™ TROUBLE SHOOTING Problem Solution Excess vibration of the scraper. Make certain all bolts are tight. If the belt is non-reversing, rotate the blade about 5° degrees in the direction of the belt movement. Excess carryback. Check for proper Scraper tension. Put additional tension on cleaner.

Need help?

Do you have a question about the BC-2 and is the answer not in the manual?

Questions and answers