Advertisement

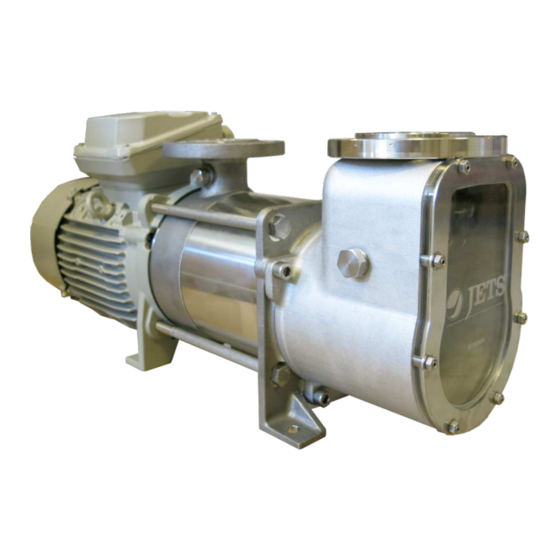

ets™ 25MBA Vacuumarator™ pump

Product No. 200025004

Vacuumarator™ pumps are the most compact efficient and reliable

vacuum generators available for vacuum sanitary systems. The

pump creates vacuum, macerates sewage and discharges in one

single pass operation.

eatures:

● Highly efficient in transporting wastewater

● Small footprint and low weight allows for quick and flexible

installation

● In line installation - direct discharge to sewer, STP (Sewage

Treatment Plant) or collecting tank

● Multiphase design - pumps any combination of air, black and

grey water

● Low energy consumption

● High quality – low lifecycle cost

Technical Data

Capacity

...................................

Back Pressure

......................................................................

Outside imensions

..................................

Connection Inlet

..............................................................................

Connection Outlet

...........................................................................

Protection Class

...............................................................................

Insulation Class

..............................................................

uty

...........................................................................................

Ambient Temperature Range

Humidity

.............................................................................

Approvals

..............................................................

Net Weight

..................................................................................

Operating Data

Frequency

....................................................................................

Voltage

................................................................................

Nominal Current

.........................................................................

Speed

...........................................................................

Power Output

...........................................................................

Power Factor

.......................................................................

Efficiency

.....................................................................................

Heat issipation

...............................................................

Disclaimer

Note: Our products and services are offered and sold subject to Jets

Vacuum AS' General Sales Conditions, copies of which will be

furnished upon request. Information provided herein is solely for

information purposes, does not constitute any warranty or

representation of any kind and is subject to change without notice.

We strive to reproduce product colors reasonably accurate. Without

prior written approval, this document or any part of may not be

reproduced in any form. Jets™, Vacuumarator™, Helivac™, VC™,

VO ™, CVS™ and Softsound™ are trademarks and/or registered

trademarks of Jets. © Jets AS. All rights reserved.

1

Tel. +47 70 03 91 00

www.jetsgroup.com

oc. Rev.: 22 (2021-06-08)

26 m³/h (ACMH) at 500 mbar abs. 60 Hz

(50% Vacuum)

702 x 198 x 278 mm (LxWxH)

155(F) to 130(B)

.............................................

+0 °C - 55 °C

Class F / 95%

Motor - CSA Approved

// Δ198-218 V

CCW // 3435 rpm

// 0.88 cos ɸ

Approx. 0.6 kW

Max. 0.3 bar

N50

N32

IP 55

S1-100%

66.50 kg

// 60 Hz

// 12.9 A

// 3.45 kW

// 84.5%

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Jets 25MBA

- Page 1 ● In line installation - direct discharge to sewer, STP (Sewage Disclaimer Treatment Plant) or collecting tank Note: Our products and services are offered and sold subject to Jets ● Multiphase design - pumps any combination of air, black and Vacuum AS’ General Sales Conditions, copies of which will be grey water furnished upon request.

- Page 2 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004...

-

Page 3: Additional Components

Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Components 26.2 Ball Bearing ..............038213500 Macerator Alignment Tool 25MBA ......... 816100118 Cover ................023280050* Motor ................031002504 O-ring ................037219260* 60 Hz Δ198-218 V Suction Chamber, Complete ........023280041* * Component s avaliable as replacement parts. -

Page 4: Dimension Drawings

25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Dimension Drawings Measurements given in mm. - Page 5 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 unction and Principle Description Flap Valve: Facilitates flow into the pump, seals vacuum in the pipes and prevents backflow. Macerator: The macerator grinds any solids to a fine pulp.

-

Page 6: Pre-Installation

Rev.: 22 (2021-06-08) Product No. 200025004 Pre-Installation The following installation information is only applicable for single pump installations. If a Vacuum Unit is supplied by Jets Vacuum AS, please refer to the Vacuum Unit information. Installation Site Considerations 1. Installation space requirements can be determined from the dimension drawing. - Page 7 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Installation Steps 1. o not remove the protective covering on the pumps inlet and outlet until connecting the pipes. 2. Flush the piping system and any connections to the pump to ensure that all foreign objects have been removed prior to connection.

-

Page 8: Operation

Mineral scale build-up, if left untreated, may affect the performance of the pump. To treat mineral scale build-up, it is necessary to flush a suitable descale solution through the pump. Jets™ descale products are recommended. Annual Descaling of the Vacuumarator™ Pump 1. - Page 9 Caution: Never use automotive antifreeze (ethylene glycol) in the system. Note: Failure to adequately protect the pump from damages may result in void of your warranty coverage. Jets Vacuum AS reserves the right to deny any warranty claim submitted if the claim is caused by freezing damage.

- Page 10 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Service and Maintenance - Disassembly Instructions Turn off and disconnect the power to the pump. Empty the pump of wastewater. 3.2 Warning Never work on the equipment when mains power is applied.

- Page 11 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Remove the four screws (M5x12) Remove the stationary knife from securing the stationary knife in place. the assembly. Remove the four stay bolts ℺.

- Page 12 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Remove the flange ⅁. Remove the rotating part of the shaft seal (21B). Important: o not touch ceramic surfaces on the shaft seal. Residue will affect operation.

- Page 13 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Remove the two ball bearings (26.1) and (26.2) from the shaft (26), using a bearing puller. Service and Maintenance - Assembly Instructions ●...

- Page 14 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Place the O-ring ℯ in the guiding Place the O-ring (39) and the flange (38), secure the nut (37). strip on the cover...

- Page 15 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Position the O-ring ℻ on the Position the rotor ℼ on the shaft. pressure chamber. Fit the rotor housing ℽ. Insert the O-ring ℻.

-

Page 16: Troubleshooting

25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Position the suction chamber ℰ. Secure the suction chamber by tightening the four hex screws ℱ in a cross formation. Remove the service jig and place the pump on a flat horizontal surface. - Page 17 25MBA Vacuumarator™ pump Tel. +47 70 03 91 00 www.jetsgroup.com oc. Rev.: 22 (2021-06-08) Product No. 200025004 Low vacuum or the pump is Lack of liquid in the pump. Fill the pump with water. Check for leakage and repair.

Need help?

Do you have a question about the 25MBA and is the answer not in the manual?

Questions and answers