Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Lapple FIBRO FIBROTOR EM.NC Series

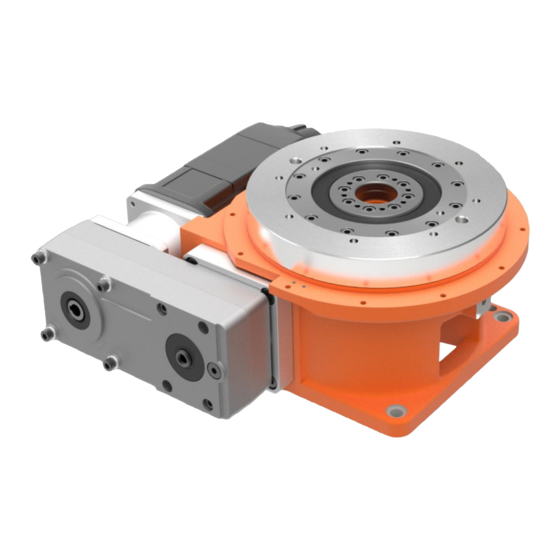

- Page 1 TRANSLATION OF THE ORIGINAL ASSEMBLY AND OPERATION MANUAL FIBROTOR EM.NC...

- Page 3 1 INTRODUCTION 1.1 DEFINITION Rotary table FIBROTOR EM.NC Type: Item number: Serial number: Dimensions drawing: Year of manufacture: Order number: This document has been created by FIBRO GmbH Rotary Table Division Postfach 11 20 D-74183 Weinsberg Weidachstrasse 41 - 43 D-74189 Weinsberg Service rtservice@fibro.de...

- Page 4 1 INTRODUCTION 1.1 DEFINITION 4 | 60 FIBROTOR...

-

Page 5: Table Of Contents

1 INTRODUCTION 1.1 DEFINITION Contents Introduction .........................9 1.1 Definition ......................9 1.2 Intendeduse ......................9 1.3 Improper use .......................9 1.4 Applicable documents..................10 1.5 Structure......................10 1.5.1 Bearing....................10 1.5.2 Middle throughlet................. 10 1.5.3 Direction of rotation................10 1.5.4 Service life .................... 10 1.5.5 Cam drive ..................... - Page 6 1 INTRODUCTION 1.1 DEFINITION Transport ........................27 4.1 Important safety guidelines ................27 4.2 Packaging and weight ..................28 4.3 Transport damages ..................28 4.4 Interim storage ....................28 4.5 Permitted equipment and auxiliary devices for the transport....29 4.6 Transport locks ....................29 4.6.1 Unpacking and transporting of the rotary table ......

- Page 7 1 INTRODUCTION 1.1 DEFINITION 10 Shutdown ........................45 10.1 Important safety guidelines ................45 10.2 Temporary shutdown ..................45 10.3 Permanent shutdown ..................46 11 Disassembly and disposal ................... 47 11.1 Important safety guidelines ................47 11.2 Disposal of components ................. 48 12 Service and spare parts ..................

- Page 8 1 INTRODUCTION 1.1 DEFINITION 8 | 60 FIBROTOR...

-

Page 9: Introduction

1 INTRODUCTION 1.1 DEFINITION Introduction Definition Rotary table Rotary table: The rotary table is a partly completed machine in the sense of European Guideline 2006 / 42 / EG, Art. 1g and 2g. Intendeduse The purpose of the rotary table is to be mounted in other machines or in other partly completed machinery or equipment, or to be assembled with them. -

Page 10: Applicable Documents

1 INTRODUCTION 1.4 APPLICABLE DOCUMENTS Applicable documents Along with this manual, other applicable documents are necessary for the safe operation of the machine. The data in these documents must be observed. Instruction for the assembly of a partly completed machine according to Guideline 2006/42/EG ... -

Page 11: Positioning

1 INTRODUCTION 1.5 STRUCTURE 1.5.6 Positioning Positioning is achieved through the NC control system with position rule capture via encoder. In the positioned condition the cam is stopped play-free by an electric brake. In the event of high tangential forces, a hydraulic table top clamping can be used (greater rigidity, relief of the gearbox parts). -

Page 12: Indirect Measuring System (Standard Design)

1 INTRODUCTION 1.5 STRUCTURE _________________________________________________________________ _________________________________________________________________ Fig. 1 Holding brake Magnet Membrane transmission spring Anchor plate Flange Friction lining 1.5.10 Indirect measuring system (Standard design) The encoder is arranged in the worm shaft axis. The tolerances of the worm rolling gearbox are included in the measurement. -

Page 13: Cable Colours And Connections

1 INTRODUCTION 1.6 WARRANTY 1.5.14 Cable colours and connections Function Core colour Signal 1 Brown \Signal 1 Green \Signal 2 Pink Signal 2 Grey Brown-Green White-Green Sensor +5V Blue Sensor 0V White Signal 0 \Signal 0 Black _________________________________________________________________ _________________________________________________________________ Fig. -

Page 14: Translation Of The Original Maintenance And Operation Manual

1 INTRODUCTION 1.7 TRANSLATION OF THE ORIGINAL MAINTENANCE AND OPERATION MANUAL Translation of the Original maintenance and operation manual This manual is the translation of the original maintenance and operation manual and is part of the scope of delivery. This manual describes the operation of the machine and contains important information about its intended use. -

Page 15: Definitions Of Terms

1 INTRODUCTION 1.8 DEFINITIONS OF TERMS The code charts used in this manual have the following meaning: DANGER designates a hazardous situation which, if not prevented, can lead to death or serious injury. WARNING designates a hazardous situation which, if not prevented, can lead to death or serious injury. CAUTION designates a hazardous situation which, if not prevented, can lead to light to medium-level injuries. - Page 16 1 INTRODUCTION 1.8 DEFINITIONS OF TERMS 16 | 60 FIBROTOR...

-

Page 17: Safety

2 SAFETY 2.1 BASIC SAFETY INSTRUCTIONS Safety BASIC SAFETY INSTRUCTIONS Most accidents during work with machines are due to disregarding the basic safety instructions. Perceiving a possible hazard can prevent an accident before it occurs. If there are hazards, the safety information on the rotary table and in this document provides warnings about these hazards. -

Page 18: Due Diligence Of The Operator

2 SAFETY 2.1 BASIC SAFETY INSTRUCTIONS 2.1.1 Due diligence of the operator The rotary table is designed and manufactured according to the state of the art. The requirements for ensuring the safety and protection of health have been fulfilled. However, this safety can be achieved in operational practice only when all necessary measures in this respect have been taken. -

Page 19: Personnel Requirements

2 SAFETY 2.2 QUALIFICATION OF THE PERSONNEL 2.1.2 PERSONNEL REQUIREMENTS The following safety instructions must be observed in all operations on the rotary table. Their violation can cause serious injuries or death. All persons working on and with the rotary table must: •... -

Page 20: Safety Devices On The Machine

2 SAFETY 2.3 SAFETY DEVICES ON THE MACHINE Safety devices on the machine The rotary table is designed for mounting in other machines or for assembly with other machines. FIBRO GmbH has no control over the intended use of the machine. The operator is responsible for the safety devices for operation of the machine. -

Page 21: Technical Description

3 TECHNICAL DESCRIPTION 3.1 GENERAL TECHNICAL DATA Technical description General technical data The technical data of the rotary table depend on the contract. A name plate with number, year of manufacture and type is fixed on the rotary table. __________________________________________________________________________ __________________________________________________________________________ Fig. -

Page 22: Sealing Air (Optional)

3 TECHNICAL DESCRIPTION 3.4 SEALING AIR (OPTIONAL) Sealing air (optional) The rotary table has a connection for the sealing air between the housing and the table top (for position and connection thread see the dimensional drawing). The necessary compressed air must be provided by the supply facilities of the operator. -

Page 23: Cam Roller Gearbox

3 TECHNICAL DESCRIPTION 3.7 ADDITIONAL COMPONENT ASSEMBLIES AND ACCESSORIES 3.6.2 Cam roller gearbox The operation is generated from the drive motor via a gearbox and cam drive to the table top. The cam rollers are pretensioned on both sides on the operating cam. The table top is held in an exact play-free position by the operating cam and the cam rollers. -

Page 24: Connection Diagram Table Top Clamping

3 TECHNICAL DESCRIPTION 3.7 ADDITIONAL COMPONENT ASSEMBLIES AND ACCESSORIES _________________________________________________________________ _________________________________________________________________ Fig. 6 Hydraulic table top clamping The clamping should never be activated during the rotation motion of the table top (also not at emergency stop!). The rotary table should never start against closed clamping. This leads to damages. - Page 25 3 TECHNICAL DESCRIPTION 3.7 ADDITIONAL COMPONENT ASSEMBLIES AND ACCESSORIES Settings: 5 bar clamping control released S3: 64 bar control clamped _________________________________________________________________ _________________________________________________________________ Fig. 7 Connection diagram table top clamping FIBROTOR 25 | 60...

-

Page 26: Functional Diagram Table Top Positioning

3 TECHNICAL DESCRIPTION 3.7 ADDITIONAL COMPONENT ASSEMBLIES AND ACCESSORIES 3.7.2.1 Functional diagram table top positioning Initial position: The table top is in any position _________________________________________________________________ _________________________________________________________________ Fig. 8 Functional diagram table top positioning ... -

Page 27: Transport

4 TRANSPORT 4.1 IMPORTANT SAFETY GUIDELINES Transport Important safety guidelines Suspended loads Dimensioned load suspension device that are too weak can break. The suspended loads can swing. The lifting equipment and the load suspension devices must correspond to the regulations and should be designed for the weight of the components, including the packaging. -

Page 28: Packaging And Weight

4 TRANSPORT 4.2 PACKAGING AND WEIGHT Packaging and weight For shipping by truck, the rotary table is secured with transport locks and packaged in foil. For shipping by sea the rotary table is secured at FIBRO GmbH with transport locks and packaged in a wooden box. -

Page 29: Permitted Equipment And Auxiliary Devices For The Transport

4 TRANSPORT 4.5 PERMITTED EQUIPMENT AND AUXILIARY DEVICES FOR THE TRANSPORT Permitted equipment and auxiliary devices for the transport The unloading of the boxes and their transport to the installation site can be performed with an overhead crane. Use crossbars. Fig. -

Page 30: Return Shipping

4.7 RETURN SHIPPING Damage to components. Never lift the rotary table suddenly with a jerk. 5. Hook the belts onto the attachment eyes and lift the rotary table from the box while observing the safety instructions and transport regulations. 6. Transport the rotary table in compliance with the safety instructions and transport regulations. -

Page 31: Assembly

5 ASSEMBLY 5.1 IMPORTANT SAFETY GUIDELINES Assembly Important safety guidelines Incorrect installation The assembly work should be performed by qualified personnel only. Work on the power supply line connections should be performed by qualified electricians only. A check must be carried out to ensure that the power supply frequency and voltage correspond with the data in the technical specification. -

Page 32: Modifications And Alterations

5 ASSEMBLY 5.4 MODIFICATIONS AND ALTERATIONS Transport the rotary table to the assembly site in compliance with the safety instructions and transport regulations. Sagging load. Do not hold between the rotary table and the installation surface. Crushing of hands or fingers. ... -

Page 33: Commissioning

6 COMMISSIONING 6.1 IMPORTANT SAFETY GUIDELINES Commissioning Important safety guidelines The rotary table is designed for mounting in other machines or for assembly with other machines. FIBRO GmbH has no control over the intended use of the rotary table. The commissioning is a responsibility of the operating company. Prior to the commissioning Prior to the commissioning, visual inspection of the rotary table has to be performed. - Page 34 7 OPERATION 6.2 PRIOR TO THE COMMISSIONING 34 | 60 FIBROTOR...

-

Page 35: Operation

7 OPERATION 7.1 IMPORTANT SAFETY GUIDELINES Operation Important safety guidelines Inadmissible operating parameters / software. The change of the operating parameters leads to a change in the system behaviour of the rotating or moving parts of the rotary table. The use of a controller with unlicensed software creates a risk for the safety of the rotary table. -

Page 36: Path Of Motion

7.5 ROTARY TABLE - TURNING ON AND OPERATION 7.4.2 Path of motion Electric holding brake is ventilated (de-energised). During the dividing procedure by a servo motor the acceleration and deceleration time must be observed. (NC controlled) If the NC rotary table has reached the target position, the worm shaft is stopped by the holding brake. -

Page 37: Faults

8 FAULTS 8.1 IMPORTANT SAFETY GUIDELINES Faults Important safety guidelines Unauthorised personnel Any personnel that has not been adequately trained does not have the necessary authorisation to localise faults or correct errors. Any defects may only be corrected by FIBRO Customer Service or by members of staff from the operating company who are trained and authorised for performing the respective activity. - Page 38 9 REPAIR 8.2 CUSTOMER SERVICE 38 | 60 FIBROTOR...

-

Page 39: Repair

9 REPAIR 9.1 IMPORTANT SAFETY GUIDELINES Repair Important safety guidelines Unauthorised personnel The personnel of the operator may perform only the maintenance work described in this manual. This personnel must be trained and authorised for performing these activities. The action area of the moving machine parts must be secured. All other work and repairs must be performed by FIBRO personnel only. -

Page 40: Maintenance Work

9 REPAIR 9.2 MAINTENANCE WORK Maintenance work The following activities are considered maintenance work: • Inspection • Maintenance / cleaning • Repair 9.2.1 Inspections Daily before the start of the work shift: • Inspection of the essential functional units. • Inspection of the air pressure on the manometer. -

Page 41: Long-Term Lubrication

9 REPAIR 9.2 MAINTENANCE WORK When maintaining the rotary table, the following must be ensured: • all work steps are performed in the specified order. After the maintenance work has been completed, it must be checked whether • the work has been performed completely. •... -

Page 42: Lubrication Plan

9 REPAIR 9.2 MAINTENANCE WORK 9.2.2.3 Lubrication plan _________________________________________________________________ ________________________________________________________________ Fig. 11 Lubrication plan Lubricant rotary indexing table + Lubricant rolling bearing Lubricant gearbox Lubricant rolling bearing Motor brake control 9.2.2.4 Lubricants Lubricant rotary table: The following synthetic oils are permitted for the rotary table: Manufacturer / supplier Designation... -

Page 43: Filling Quantities

9 REPAIR 9.2 MAINTENANCE WORK + Lubricant rolling bearing The following synthetic greasesare permitted for the rolling bearing: Manufacturer / supplier Designation Arcanol MULTITOP ARAL Aralub HLP2 Discor 8 – EP 2 ESSO Beacon 325 KLÜBER Isoflex NCA 15 MOBIL Mobiltemp SHC 32 SHELL AERO Shell Grease 16 or 7... -

Page 44: Repair

9 REPAIR 9.2 MAINTENANCE WORK (1) Rundtisch (4) Getriebe ER.10 0,03 l ER.11 T02 0,10 l ER.11 >T02 0,06 l ER.12 0,17 l Getriebe ist ER.13 T02 0,25 l wartungsfrei ER.13 >T02 0,4 l ER.15 0,6 l ER.16 1,1 l ER.17 2,5 l 9.2.3... -

Page 45: Shutdown

10 SHUTDOWN 10.1 IMPORTANT SAFETY GUIDELINES Shutdown 10.1 Important safety guidelines Restoring the power supply The restoration of the energy supply to a shut-down machine can lead to unexpected start. In order to shut down the machine, it must be turned off from the main switch and secured against unintended starting. -

Page 46: Permanent Shutdown

10 SHUTDOWN 10.3 PERMANENT SHUTDOWN 10.3 Permanent shutdown For permanent shutdown and decommissioning: • Turn off the machine in a proper manner. • Secure the machine against unintentional restarting. • Put a warning sign on the machine that shows clearly that it is permanently out of operation. -

Page 47: Disassembly And Disposal

11 DISASSEMBLY AND DISPOSAL 11.1 IMPORTANT SAFETY GUIDELINES Disassembly and disposal 11.1 Important safety guidelines The rotary table should be disassembled by specialised personnel of FIBRO GmbH only. Disassembly by personnel of the operator is prohibited. Unauthorised personnel In the process of disassembly and during transportation, parts can tilt or fall. Loads can swing or fall down. -

Page 48: Disposal Of Components

11 DISASSEMBLY AND DISPOSAL 11.2 DISPOSAL OF COMPONENTS 11.2 Disposal of components Dispose of the components in a proper manner! The improper disposal of components can cause damage to the environment and is subject to criminal prosecution. The components have to be disposed of in accordance with the applicable local and regional laws and guidelines. -

Page 49: Service And Spare Parts

12 SERVICE AND SPARE PARTS 12.1 SERVICE Service and spare parts 12.1 Service You can reach our customer service Monday to Friday from 07:00 am to 5:00 pm under the Service number +49 (0) 7134 - 73-243 or under rtservice@fibro.de Outside the times stated, a recorded message with additional information is available. -

Page 50: Spare Parts Ordering

12 SERVICE AND SPARE PARTS 12.3 SPARE PARTS ORDERING 12.3 Spare parts ordering When ordering spare parts, please provide the following data: • Name, address, shipping address • Exact designation of the equipment (take serial number from the name plate) •... -

Page 51: Declaration Of Incorporation

13 DECLARATION OF INCORPORATION 13.1 DECLARATION OF INCORPORATION Declaration of incorporation 13.1 Declaration of incorporation in accordance with EU machinery directive 2006/42/EC (Annex II B) The manufacturer FIBRO GmbH Weidachstr. 41-43 D-74189 Weinsberg We herewith declare, that the incomplete machine described below Product description Rotary table type: FIBROTOR EM.NC... - Page 52 13 DECLARATION OF INCORPORATION 13.1 DECLARATION OF INCORPORATION 52 | 60 FIBROTOR...

-

Page 53: Index

14 INDEX 14.1 LIST Index 14.1 List Inspection ............. 40 Installation requirements ......31 Intended use ..........9 Interim storage..........28 Accident prevention regulations ..18, 27 Additional component assemblies ..10, 23 Assembly......... 17, 27, 31 Linear axis ............ 27 Load suspension devices ....27, 29 Long-term lubrication ........ - Page 54 14.1 LIST synthetic greases ........43 synthetic oils..........43 Reference point switch......11, 36 synthetic viscous oils ........42 Remaining risks........... 20 Repair ......17, 18, 19, 39, 40, 44 Return shipping ........... 30 Return to operation ......33, 45 Table top clamping ......23, 24, 25 Rolling bearings ......

-

Page 55: Personal Notes

15 PERSONAL NOTES 15.1 NOTES Personal notes 15.1 Notes ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------ FIBROTOR 55 | 60... - Page 56 15 PERSONAL NOTES 15.1 NOTES 56 | 60 FIBROTOR...

-

Page 57: Annex

16 ANNEX 16.1 WIRING GUIDELINES Annex 16.1 Wiring guidelines FIBROTOR 57 | 60... - Page 58 16 ANNEX 58 | 60 FIBROTOR...

-

Page 59: Other Documents

16.2 OTHER DOCUMENTS 16.2 Other documents Technical specification Dimensional drawing(s) Connection diagram FIBROTOR 59 | 60...

Need help?

Do you have a question about the FIBRO FIBROTOR EM.NC Series and is the answer not in the manual?

Questions and answers