Table of Contents

Advertisement

Quick Links

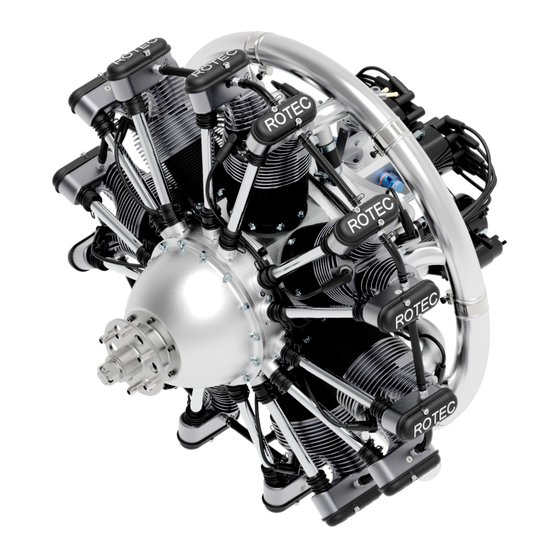

ROTEC

AEROSPORT

RADIAL ENGINE

OPERATIONS MANUAL

ROTEC AEROSPORT PROPRIETARY INFORMATION THIS DOCUMENT IS PROPRIETARY PROPERTY

OF ROTEC AEROSPORT PTY LTD. IT IS NOT TO BE COPIED OR REPRODUCED IN ANY MANNER,

NOR SUBMITTED TO OTHER PARTIES FOR EXAMINIATION WITHOUT PRIOR WRITTEN APPROVAL.

Date Published

Revison Published

Rotec Aerosport

Radial Engine Operations Manual

10

08

2017

15

04

2007

www.rotecaerosport.com

Version

V3

Advertisement

Table of Contents

Need help?

Do you have a question about the AEROSPORT R2800 and is the answer not in the manual?

Questions and answers

what is the minimum battery capacity for starting properly the rotec 3600?