Table of Contents

Advertisement

Quick Links

Hoffman

Installation & Operating

Instructions

CAUTION

Failure to read and understand the accompa-

nying instructions and diagrams prior to

energizing the sequencer may result in permanent

damage to the sequencer.

General

The Class II 890-DSQ microcontroller based universal sequencer

provides a fully programmable platform to sequence multiple

loads using SPDT relay closures. The multiple loads may consist

of condenser fan motors, heating elements, compressors or other

sequencing applications. The 890-DSQ Sequencer's veratility

includes a wide range of input and output options. This universal

sequencer can use 1) up to six (0-5 Vdc) temperature / pressure

sensor inputs or 2) a single 0-10 VDC input. The sequencer has

three 0-10 VDC, EC motor speed control outputs which can be

reconfigured as three 10 - 0 VDC motor speed outputs. There are

also three, 17.5 volt (80Hz) PWM EC motor speed control outputs,

a +5 Vdc output to power the pressure sensors, when used, and up

to six 24 VAC fixed staged outputs, with an additional six 24 VAC

fixed staged outputs available on a separate expansion board (total

of 12 fixed relay output stages).

The 890-DSQ can be setup as a traditional sequencer or as a true

continuous vernier sequencer, when using continuously variable

EC motors or SCRs as the (VS) variable stage. The sequencer can

be operated locally, using the 5 push buttons and the information

shown on the LCD screen or remotely using a Modbus RTU master

control.

The 890-DSQ Series sequencers require 24 VAC (1 VA) to

power the control.

IMPORTANT: When using the 890-DSQ Sequencer, select a

transformer to meet the requirements of all the 24 VAC compo-

nents being used.

Introduction

The 890-DSQ Series sequencer is typically used, in an A/C

system, to sequence multiple condenser fan motors, on and off,

to provide low ambient condenser control. The 890 has up to six

temperature or pressure inputs that are used to sequence up to 12

fixed speed condenser fan motors or other loads.

A unique feature is that the 890 also provides PWM, and either

a 0-10 VDC or 10-0 VDC outputs that are used to drive variable

speed EC fan motors. When the variable speed fans are present,

the sequencer intelligently modifies the output to the variable

speed fans so that, as the additional fixed speed fans are sequenced

on or off, the overall effect is that the total fan outputs' airflow

varies continuously over the entire range.

For example, when the next fixed speed fan is turned on, the

variable speed fans drop in rpm to compensate for the additional

|

Controls

890-DSQ Series Microprocessor

Based Universal Sequencer

fan. As the input continues to go up, the variable speed fans in-

crease speed until the next fixed speed fan turns on, at which point

the varible speed fan drops in rpm again. This process works in

reverse as the input decreases. Hystesesis is also provided so that no

short cycling of the fixed speed fans occur.

Setpoint Values

The 890-Series sequencers can utilize up to 2 sets of setpoint

values, a primary set and a secondary set. Each set can utilize a

maximum of 12 stage turn on and turn off values (24 set points).

The primary set of setpoint values is the set typically used. The

secondary set of setpoint values can be used, on demand, whenever

the sequencer's "2ND" input terminal is connected to the adjacent

"GND" terminal thru an external contact closure.

Description

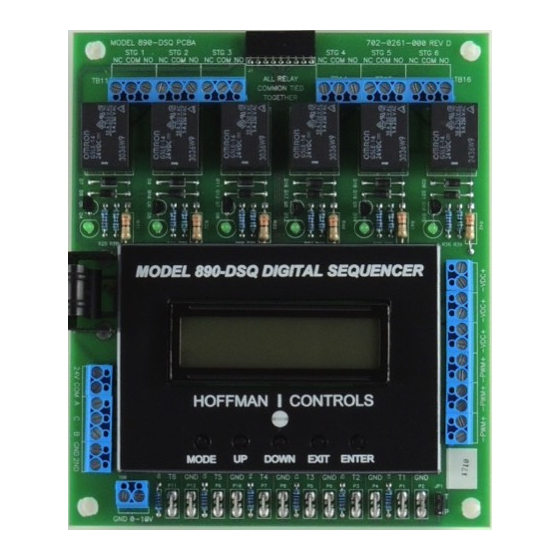

The 890 Control consists of a Kydex covered PCB, on stand

offs, with a 32 character LCD display and five push buttons. The

sequencer can be manually operated by following the LCD's menu

system and selecting the available options, parameters and numer-

ical values, using the 5 push buttons. The LCD display routinely

shows a Home Screen and, when selected, up to 5 mode screens

and a small number of additional menu and submenu screens.

The LCD's Home Screen always displays the number of fixed

relay output stages that are turned on and the currently used

input's value (temperature, pressure or 0-10 VDC). When the VS

(variable stage) option is selected, the Home Screen also displays

a speed index (percent) of the continuously variable stage's EC

motors speed or SCRs total output current, along with a number

representing the total of all the relay stages and effective variable

stages (see Mode 1.2, page 4) that are turned on.

Due to the availability of various speed EC motors, the

displayed EC motor speed is shown as a speed index, which is

the percent of full speed (10%, 50%, 76% etc.) that the motor is

operating at. For example: a 1075 rpm EC motor showing a speed

index of 75 (%) would be running at 806 rpm.

The five push buttons (MODE, UP, DOWN, EXIT and

ENTER) allow the installer to change 1) the number of output

stages used, 2) the number of inputs used along with the input

type (temperature, pressure or 0-10 VDC), 3) the selection of the

used output stage's individual (primary & secondary) setpoint

values, 4) the selection of the output stage's activation modes

[LIFO, FIFO or Binary Encode] and 5) the three scaling percent-

ages, used to match the sequencer's PWM and VDC output

signal's parameters, to the variable stage EC motors' input signal's

specifications.

The 890-DSQ Sequencer is available in 4 or 6 fixed stage

models, with each model having an additional "variable stage

output". The variable stage output concists of the "PWM" and

"VDC" outputs and their associated "GND" terminals. There are

three sets of "VDC" outputs and associated "GND" terminals and

three sets of "PWM" (17.5 volt, 80 Hz) outputs and their associ

1

Advertisement

Table of Contents

Summary of Contents for Hoffman Controls 890-DSQ Series

- Page 1 SCRs total output current, along with a number control. representing the total of all the relay stages and effective variable The 890-DSQ Series sequencers require 24 VAC (1 VA) to stages (see Mode 1.2, page 4) that are turned on. power the control.

-

Page 2: Operating Methods

Table 1, on pages 14 & 15, to the Operating Methods 890-DSQ Series sequencer's internal data registers The sequencer communicates via a 3 wire Modbus RTU connection to the Modbus RTU master computer. All of the 890-DSQ Sequencer's options,... -

Page 3: Operating Modes

Pressing the EXIT button, at any time, causes the control to return immediately to the Home Screen. However, any options or value changes that were not saved, by previously pressing the ENTER button, will be lost. Remote Operation Remote operation is accomplished by using a Modbus RTU master computer to communicate with the 890-DSQ Sequencer via the Modbus 3 wire connection. - Page 4 An 890-DSQ Operating Modes Chart (Figure 8, page 13) is provided to allow the operator to track his/her progress thru the various LCD's screens. The Operating Modes Chart's information is viewed starting from the Home Screen, located at the top center of the chart, and continuing counter clockwise around the chart.

- Page 5 or KW capacity. Typical ratios are 1.5 to 2.0 for 4 to 6 stage When the number of inputs used is set to "0", the 0-10 applications respectively. VDC input is used instead of the six 0-5 VDC temperature or pressure sensor inputs.

- Page 6 MODE 4: Change Secondary Setpoints the UP or DOWN buttons until the desired hysteresis value, The 890-DSQ Series sequencers include a second set of setpoints used by all the selected (fixed) relay stages, is displayed on the that can be stored and used when an application determined condi- LCD screen's second line.

- Page 7 secondary setpoint values are identical to the options used to set the stage to turn off. FIFO mode promotes even load operation primary setpoint values in MODE 3 above. Therefore, follow the (wear) by using each stage an equal amount of time, on average, MODE 3 instructions, when the number "2"...

-

Page 8: Installation

NOTE: Temperature and pressure sensors can not be used together, as inputs, on the same sequencer. The 890-DSQ Series sequencers may be installed using a range 9. The 890-DSQ Sequencer is designed for low voltage (24 VAC) of inputs, staged relay outputs, and continuously variable EC operation, including the 24 VAC relay stage output loads. -

Page 9: Modbus Operation

buttons at once. The 890's LCD will display what appears to be the Home Screen (Figure 1, page 3) and the relays stages may start turning on, depending on the sequencer's selected setpoint values. However, the installer can now change the simulated temperature shown on the LCD screen's second line. - Page 10 MODEL 890-ASQ PCBA 702-0261-000 REV C STG 1 STG 2 STG 5 STG 6 COM NO DOWN EXIT ENTER MODE T6 GND T5 GND T4 GND T3 GND T2 GND 0-10V...

- Page 11 MODEL 890-ASQ PCBA 702-0261-000 REV C STG 1 STG 2 STG 5 STG 6 COM NO DOWN EXIT ENTER MODE T6 GND T5 GND T4 GND T3 GND T2 GND 0-10V...

- Page 12 TB10 -PWM+ -PWM+-PWM+ -VDC+ -VDC+ -VDC+...

- Page 14 REGISTER REGISTER 16 BIT REGISTER FUNCTION NUMBER TYPE EC motor or SCR Turn-On Temp,PSI or Volts. (All values times 10) Read & Write Stage 1 On Temp(°F),PSI or Volts. (All values times 10) Read & Write Stage 2 On Temp(°F),PSI or Volts. (All values times 10) Read &...

- Page 15 REGISTER REGISTER 16 BIT REGISTER FUNCTION NUMBER TYPE Stage 11 On Temp(°F), PSI or Volts [Secondary Setpoint] (All values times 10) Read & Write Stage 12 On Temp(°F), PSI, Volts [Secondary Setpoint] (All values times 10) Read & Write Stage 1 Off Temp(°F), PSI, Volts [Secondary Setpoint] (All values times 10) Read &...

-

Page 16: Operating Tips

Re-calibration (con't) Operating Tips settings and numerical values made available by each The speed at which the LCD screen's values change is variable. mode, menu and submenu screen. Follow the Operating Holding the UP or DOWN button down causes the dislayed value Methods and Operating Modes sections (pages 2 thru 5) to change slowly at first and then speed up noticably.

Need help?

Do you have a question about the 890-DSQ Series and is the answer not in the manual?

Questions and answers