Summary of Contents for Addie Water Systems 2500

- Page 1 MODEL 2500 & 1500 Service Manual IMPORTANT: Fill in pertinent information on page 2 for future reference.

-

Page 2: Job Specification Sheet

MODEL 2500 & 1500 MODEL 2500 & 1500 Job Specification Sheet * JOB NO. _________________________________________________________ * MODEL NO. _______________________________________________________ * WATER TEST _____________________________________________________ * CAPACITY PER UNIT ____________ MAX. __________ PER REGENERATION * MINERAL TANK SIZE DIA. ________________ HEIGHT ___________________ * BRINE TANK SIZE &... -

Page 3: Installation Instructions

MODEL 2500 & 1500 Installation Instructions The water softener should be installed with the inlet, outlet and drain connections made in accordance with manufacturer’s recommendations and to meet applicable plumbing codes. 1. Remove control box cover. 2. Make “Time of Day” setting and set “Skipper Wheel.” (See time control instructions.) 3. -

Page 4: Timer Setting Procedure

MODEL 3200 TIMER Timer Setting Procedure How To Set Days On Which Water Conditioner Is To SERVICE 24 HR. GEAR POSITION Regenerate: MANUAL REGENERATION KNOB INDICATOR Rotate the skipper wheel until the number “1” is at the red pointer. Set the days that regeneration is to occur by sliding tabs on the skipper wheel outward to expose trip fingers. - Page 5 MODEL 3200 TIMER Regeneration Cycle Program Setting Procedure (Rapid Rinse) White Drive Cam and Brine Valve Cam How to Set The Regeneration Cycle Program: PROGRAM BRINE & RINSE WHEEL FOR SECTION The regeneration cycle program on your water conditioner CONTROL OF (2 MIN.

- Page 6 MODEL 3200 TIMER Regeneration Cycle Program Setting Procedure (Brine Tank Refill Separate From Rapid Rinse — STF) Black Drive Cam and Brine Valve Cam How to Set The Regeneration Cycle Program: PROGRAM BRINE & RINSE WHEEL FOR SECTION The regeneration cycle program on your water conditioner CONTROL OF (2 MIN.

-

Page 7: Water Conditioner Flow Diagrams

MODEL 2500 & 1500 Water Conditioner Flow Diagrams BRINE VALVE 1. SERVICE POSITION FLOW CONTROL Hard water enters unit at valve inlet and flows down thru the mineral in the mineral tank. Conditioned water enters center tube thru the bottom distributor —... - Page 8 MODEL 2500 & 1500 Water Conditioner Flow Diagrams (Cont’d.) 4. SLOW RINSE POSITION 5. RAPID RINSE & BRINE TANK FILL BRINE VALVE BRINE VALVE FLOW FLOW CONTROL CONTROL DRAIN DRAIN INLET INLET MINERAL MINERAL TANK TANK BRINE BRINE TANK TANK Hard water enters unit at valve inlet —...

- Page 9 Notes Page 9 Printed in U.S.A.

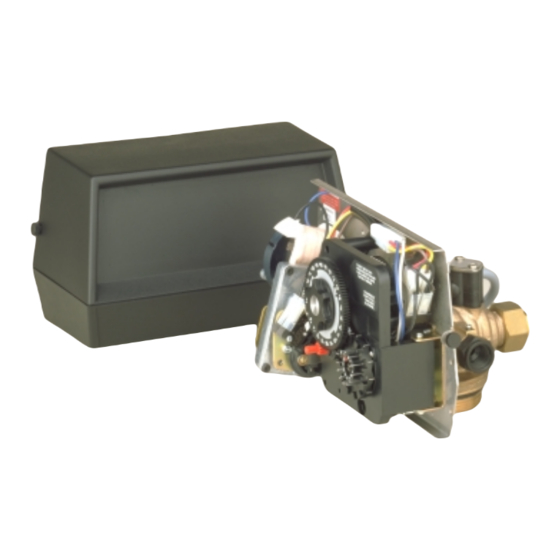

- Page 10 MODEL 2500 & 1500 Control Valve Drive Assembly (See opposite page for parts list) Page 10 Printed in U.S.A.

- Page 11 MODEL 2500 & 1500 Control Valve Drive Assembly Parts List Item No. Quantity Part No. Description 1 ... 1 ... 14884 ....Back Plate - Stainless Steel 1 .

- Page 12 MODEL 2500 Control Valve Assembly (See opposite page for parts list) Page 12 Printed in U.S.A.

- Page 13 MODEL 2500 Control Valve Assembly Parts List Item No. Quantity Part No. Description 1 ... . 1 ... . . 11212 ....Valve Body 2 .

- Page 14 MODEL 1500 & 1500 SM Control Valve Assembly (See opposite page for parts list) 19 20 Page 14 Printed in U.S.A.

- Page 15 MODEL 1500 & 1500 SM Control Valve Assembly Parts List Item No. Quantity Part No. Description 1 ... 1 ... 10729 ....Valve Body - Side Mount 1 .

- Page 16 MODEL 3200 TIMER Timer Assembly (See opposite page for parts list) Page 16 Printed in U.S.A.

- Page 17 MODEL 3200 TIMER Timer Assembly Parts List Item No. Quantity Part No. Description 1 ... 1 ... 13870 ....Timer Housing 2 .

- Page 18 1600 Series Brine System Assembly 20 - 21 PARTS LIST Item No. Quantity Part No. Description 1 ... 1 ... . .10328 ... . . 90° Elbow - 1/4 Pipe Thd. to 3/8 Tube 2 .

- Page 19 MODEL 2500 & 1500 Service Instructions PROBLEM CAUSE CORRECTION Softener fails to regenerate. Electrical service to unit has been Assure permanent electrical service interrupted. (check fuse, plug, pull chain or switch). Timer is defective. Replace timer. C. Power Failure C. Reset Time of Day.

- Page 20 MODEL 2500 & 1500 Service Instructions (Cont’d.) PROBLEM CAUSE CORRECTION Excessive water in brine tank. Plugged drain line flow control. Clean flow control. Plugged injector system. Clean injector and screen. C. Timer not cycling C. Replace timer. Foreign material in brine valve.

- Page 21 MODEL 2500 & 1500 Seal and Spacer Replacement 1. Remove electrical plug from outlet, turn off water supply to valve and relieve water pressure. 2. Remove control box cover. 3. Disconnect the brine line, from the injector housing to the brine valve (if your unit has timed brine tank fill).

- Page 22 MODEL 2500 & 1500 Seal and Spacer Replacement (Cont’d.) Special Tool To Remove Spacers Special Tool To Replace Spacers And Seals Spacer Removing Spacer From Replacing Spacer Valve Body. In Valve Body. FIGURE 3 FIGURE 4 9. Alternately remove the remaining seals and spacers in accordance with steps No. 6 and 8.

- Page 23 MODEL 2500 & 1500 Seal and Spacer Replacement (Cont’d.) Special Tool Seal Placing Seal In Brass Sleeve Removing Special Tool From Valve Of Special Tool. Body After Inserting Seal. FIGURE 5 FIGURE 6 15. While the tool is still in the valve, press another seal into the inside diameter of the exposed brass sleeve end.

- Page 24 MODEL 2500 & 1500 Piston Assembly Replacement LINE TO BRINE VALVE PISTON ASSEMBLY END PLUG PISTON SPECIAL SPRING PIN ROLL PIN CAPSCREWS 1. Turn off water supply to the valve and relieve water pressure. 2. Cycle the valve until the piston is in the service position (piston rod all the way out).

- Page 25 MODEL 2500 & 1500 Typical Top Mounting Installation MANUAL SHUTOFF 3-WIRE SERVICE CORD DRAIN BRINE LINE RESIN TANK BRINE TANK TYPICAL CONTROL VALVE INFORMATION Slow Rinse Brine Draw Tank Size Rate (gpm) Rate (SPM) Dia. Injector @ 40 PSI @ 40 PSI B.L.F.C.

- Page 26 MODEL 2500 & 1500 Wiring Diagram for Valve Drive Motor and Timer VALVE MOTOR TIMER MOTOR PROGRAM WHEEL PROGRAM RE-SET SWITCH DRIVE CAM SWITCH RAPID RINSE BLACK SERVICE CAM SWITCH SERVICE CAM RAPID RINSE BRINE TANK SERVICE FILL BRINE BRINE &...

-

Page 27: Service Assemblies

1 ..15168 ..Piston 2500 1 ..14452 ..Piston Rod, 2500 1 ..14309 ..Retainer, Piston Rod 60091 . - Page 28 P/N 15856 Rev. 1 1/99 Printed 7/99...

Need help?

Do you have a question about the 2500 and is the answer not in the manual?

Questions and answers