Table of Contents

Advertisement

Quick Links

Table of Contents

................................................................................................................................

....................................................................................................................................

.................................................................................................................................

....................................................................................................................................

..................................................................................................................................

......................................................................................................................................

....................................................................................................................................

..................................................................................................................................

.......................................................................................................................................

.................................................................................................................................

..................................................................................................................................

.................................................................................................................................

13.0.3 Working parameters

................................................................................................................................

..................................................................................................................................

.......................................................................................................................................

MDO_P1P44F-010: Operator Manual

.....................................................................................................

.........................................................................................................................

.............................................................................................................................

...............................................................................................................

.........................................................................................................

..................................................................................................................

...............................................................................................................

............................................................................................................................

...........................................................................................................................

...........................................................................................................

.................................................................................................

......................................................................................................................

..........................................................................................................

.....................................................................................................

..........................................................................................................

.................................................................................................

.............................................................................................................

.......................................................................................................

............................................................................................................

.................................................................................................

.......................................................................................................

.......................................................................................................

.............................................................................................................

.......................................................................................................

........................................................................................................

..................................................................................................................

.......................................................................................................

............................................................................................................

.............................................................................................................

..............................................................................................................

.......................................................................................................

.............................................................................................

..................................................................................

1/2

1

2

2

2

3

3

3

3

3

3

5

8

8

9

10

12

12

13

14

15

16

20

21

22

23

25

25

26

26

28

29

32

32

33

35

35

35

36

37

38

39

43

45

45

47

47

48

49

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for QEM MDO P1P44F-010

-

Page 1: Table Of Contents

MDO_P1P44F-010: Operator Manual Table of Contents MDO_P1P44F-010: Operator Manual ..................... 1. Informations ..........................1.1 Release ............................ 1.1.1 Specifications/Copyright ..................... 2. General features ......................... 2.1 Description ..........................2.2 Workings ..........................2.3 Options ............................ 2.4 Features ..........................2.5 Executable working ....................... 3. Hardware ............................3.1 Function and LED keys ......................3.2 Symbols and keys ........................ - Page 2 MDO_P1P44F-010: Operator Manual 16.1 Alarms list .......................... 16.2 Messages ..........................17. Diagnostic ..........................17.1 CPU DATA ........................... 17.2 Digital inputs ........................17.3 Digital outputs ........................17.4 Encoder counters ......................17.5 Analog outputs ........................17.6 Analog inputs ........................17.7 Communication with RMC1S modules ................18. Assistance ..........................Request for assistance ....................... Repair ............................

-

Page 3: Mdo_P1P44F-010: Operator Manual

MDO_P1P44F-010: Operator Manual MDO_P1P44F-010: Operator Manual 1/55... -

Page 4: Informations

QEM has no assurances or guarantees on the content and specifically disclaims any liability inherent in the guarantees of eligibility for any particular purpose. The information in this document is subject to change without notice. QEM does not take any responsibility for any errors that may appear in this document. -

Page 5: General Features

MDO_P1P44F-010: Operator Manual 2. General features 2.1 Description The J1-P44-FB20 innstrument with the P1P44F-010 software, it's suitable for automating a machine type: “cutter for stone processing”. 2.2 Workings single cut tile cutting tilt cut profiling drawing profiles with Mini Cad inside profile drawings with Cad on PC and importing on the instrument with “ Profile Importer 8” program with USB or LAN key table flattening with parameters, you can define whether the inclined cut will be done with the tilt of the beam, or with the tilt of the disk... - Page 6 MDO_P1P44F-010: Operator Manual Profiling Flattening 4/55...

-

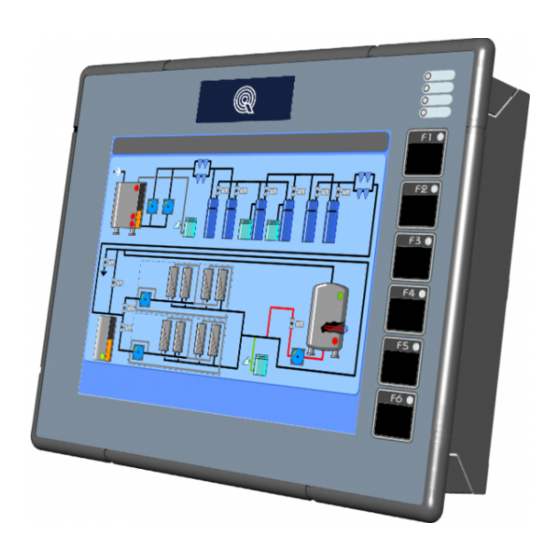

Page 7: Hardware

MDO_P1P44F-010: Operator Manual 3. Hardware J1-P44-FB20 5/55... - Page 8 MDO_P1P44F-010: Operator Manual J1-P44-FB20 J1-P44-Fx:Installation and Maintenance Manual 6/55...

- Page 9 MDO_P1P44F-010: Operator Manual RMC-1SC01E1/DP1/24Vdc RMC-1SC01:Installation and Maintenance Manual 7/55...

-

Page 10: Function And Led Keys

MDO_P1P44F-010: Operator Manual 3.1 Function and LED keys Icon Function Icon Function Start Cycle Semi-automatic = ON Active semi-automatic Stop Cycle Alarm = ON Alarm Restart Exit - - - - - - - - - - - - - - - - - - - - - - - - - - - -... -

Page 11: Startup

MDO_P1P44F-010: Operator Manual 3.3 Startup The instrument waiting the input to be activated “activated auxiliaries” to automatically go to the next page START Important: pressing the button you can navigate the HMI, with the machine stationary HOMING for exit MAIN MENU These are the 24 Volt dc power supplies of the RMC1S modules, limit switches, encoders, relays, etc. -

Page 12: Main Menu

MDO_P1P44F-010: Operator Manual 4. Main menu 10/55... - Page 13 MDO_P1P44F-010: Operator Manual 11/55...

-

Page 14: Homing

MDO_P1P44F-010: Operator Manual 5. Homing Axis enabled for homing procedure Homing OK Axis not enabled for homing procedure Homing not OK Delta error compared to previous homing ALWAYS homing before moving to the MANUAL page. If homing is missing, it affects the functionality of the machine. 5.1 Homing procedure Activate the MANUAL Check that there are no ALARMS... -

Page 15: Error Delta

MDO_P1P44F-010: Operator Manual 5.2 Error Delta This data indicates the Error Delta compared to previous homing, with this value you can easily check if an encoder is good or is broken. Procedure: Execute an homing Move the axis in manual, numerous times forward and backward Then, without turning off... -

Page 16: Machine Datas

MDO_P1P44F-010: Operator Manual 6. Machine datas MAIN MENU SECURITY QUOTE setting Setting Minimum location Z Automatic setting Minimum location Z Diameter and RPM setting Disk diameter Disk RPM AL : Maximum current setting Current Disk Absorption Disk thickness setting WR : Early warning threshold setting Out-of-clutter position Parking position Tool change position... -

Page 17: Bottom Bar

MDO_P1P44F-010: Operator Manual 7. Bottom bar : Active Stateflow Alarm : Off Stateflow Alarm : EV water deactivates : EV active water Ø : Current diameter RPM : Set the desired rounds MIN RPM : Minimum setable value SPINDLE RPM MAX RPM : Maximum setable value If the WRN symbol appears above the current absorption 99999 A Instantaneous absorption of spindle current. -

Page 18: Manual/Semi-Automatic

MDO_P1P44F-010: Operator Manual 8. Manual/Semi-Automatic 16/55... - Page 19 MDO_P1P44F-010: Operator Manual Out-of-clutter position Parking position Tool change position Reset Relative Position ABSOLUTE TARGET POSITION TARGET POSITION SET INCREMENTAL TARGET POSITION 0 TARGET POSITION Disk Compensation 17/55...

- Page 20 MDO_P1P44F-010: Operator Manual Minimum Z Position Z Minimum Position Self-Learning X positions self- X START Cut X END Cut position learning Position Single Pass Greek cutting Cut Depth 18/55...

- Page 21 MDO_P1P44F-010: Operator Manual Set dati del taglio a greca (max 10) % Reducing the speed of the first cut Forward lowered Backward lowered (X- (X+) Last Cut Direction % Reducing the speed Last lowered depth of the last cut 19/55...

-

Page 22: Semi-Automatic Execution

MDO_P1P44F-010: Operator Manual 8.1 Semi-Automatic Execution Check that you are in manual F4 → external START key (I10) or F1 the axis reaches the set dimension or single-cut is executed. 20/55... -

Page 23: Reset Axes

MDO_P1P44F-010: Operator Manual 9. Reset axes The reset axes function reset RELATIVE quotas Check you're in manual mode : hold to reset the X-axis count : hold to reset the Y-axis count : hold to reset the Z-axis count F6 - Exit from the page 21/55... -

Page 24: Restart Working

MDO_P1P44F-010: Operator Manual 10. Restart working The restart function restarts the loaded working from the beginning Check that you're in manual mode Check that you're on one of the work pages in case of cutting slabs in case of profiling OK - : press to confirm the restart and exit the page F6 - Exit from the page without confirmation 22/55... -

Page 25: Muliple Cuts/Automatic

MDO_P1P44F-010: Operator Manual 11. Muliple Cuts/Automatic 23/55... - Page 26 MDO_P1P44F-010: Operator Manual 24/55...

-

Page 27: Without Table Rotation

MDO_P1P44F-010: Operator Manual 11.0.1 Without table rotation 1 Current positions and axis target dimensions 2 Current work step 3 Size of the cut (Y) 4 Number of cuts to be execute 5 Pieces counter 6 Cuts list scroll (1-10) 7 Working parameters 8 Cutting Depth (Z) 11.0.2 With table rotation 1 Current positions and axis target dimensions... -

Page 28: Y-Axis End Position Page

MDO_P1P44F-010: Operator Manual 11.0.3 Y-axis end position page Pressing on the measurement the instrument calculates and shows the position of the Y-axis at the end of all moves written in the work schedule + all blade thicknesses. 11.0.4 Axes parameters WITHOUT TABLE ROTATION WITH TABLE ROTATION Self-learning positions X1 + X2 = Table (W) to 0°…..X3 + X4 = Table (W) to 90°... - Page 29 MDO_P1P44F-010: Operator Manual Self-learning position Y2 = Start position with Table (W) to 90° Start of cut X End of cut X Immediate position : 0° Quick Move the Table Immediate position : 90° Immediate position set Input data set Last Cut Direction 0 ~ 10 Forward lowered...

-

Page 30: Working Parameters

MDO_P1P44F-010: Operator Manual 11.0.5 Working parameters POSITIVE The piece thickness is made with Y that NEGATIVE The piece thickness is made with Y that increment decrements Y DIRECTION X+ Forward only BILATERAL to greek CUT DIRECTION SINGLE one pass TO LOWERED multi-pass CUT TYPE Z lift when X is in the FORWARD POSITION X and Z come out TOGETHER from the slab... -

Page 31: Tilted Cuts/Automatic

MDO_P1P44F-010: Operator Manual 12. Tilted Cuts/Automatic 29/55... - Page 32 MDO_P1P44F-010: Operator Manual H axis without ENCODER 30/55...

- Page 33 MDO_P1P44F-010: Operator Manual 1 Current positions and axis target dimensions 2 Current work step 3 Size of the cut (Y) 4 Number of cuts to be execute 5 Pieces counter 6 Cuts list scroll (1-10) 7 Working parameters 8 Cutting Depth (Z) 9 Settable cut angle (I) Axes parameters - see Multiple Cuts H axis with ENCODER...

-

Page 34: Y-Axis End Position Page

MDO_P1P44F-010: Operator Manual 12.0.1 Y-axis end position page Pressing on the measurement the instrument calculates and shows the position of the Y-axis at the end of all moves written in the work schedule + all blade thicknesses. 12.0.2 Working parameters POSITIVE The piece thickness is made with Y that NEGATIVE The piece thickness is made with Y that increment decrements... -

Page 35: Flattening

MDO_P1P44F-010: Operator Manual 13. Flattening 1 Current positions and axis target dimensions 2 Current work step 3 Surface and step width 4 Increment and depth of the cut 5 Parking at the end of working 33/55... - Page 36 MDO_P1P44F-010: Operator Manual 34/55...

-

Page 37: Working Parameters

MDO_P1P44F-010: Operator Manual 13.0.1 Working parameters Y width Total width of the part to be flattened. Y step The value of the pitch that covers the Y axis after each cut. Z depth Cut Depth. Used if lowered cut is set. Z step The value of the step that covers the Z axis with each pass. -

Page 38: Programming And Executing Profiles

MDO_P1P44F-010: Operator Manual 14. Programming and executing profiles 36/55... -

Page 39: Program List Filtering

MDO_P1P44F-010: Operator Manual 14.1 Program list filtering Using the program list filter you can quickly view the desired program, without scrolling through the entire list. The system has two types of filtering that can be combined together: Program Description Filter Program Type Filter What's a “Program type”... -

Page 40: Profiles

MDO_P1P44F-010: Operator Manual 14.2 Profiles 38/55... -

Page 41: Profiles - Cad

MDO_P1P44F-010: Operator Manual 14.2.1 Profiles - CAD Z0 = origin Repeat Shape Mirror Shape Y Coordinate = 0 Zoom in Zoom out Fit to screen Scroll to choose the stroke you want Insert a Delete a Stroke Add a stroke stroke stroke properties 39/55... - Page 42 MDO_P1P44F-010: Operator Manual Stroke types Absolute Incremental final coordinates are absolute relative to final coordinates are relative to the end of the origin the previous stroke 40/55...

- Page 43 MDO_P1P44F-010: Operator Manual LINE Insert final coordinates Insert Y coordinate TANGENT LINE Insert Z coordinate Insert L = length Enter the end coordinates and radius MINIMUM it's the least radius possible ARC WITH clockwise RADIUS anticlockwise Choosing the direction of the curve clockwise OR anticlockwise short arc OR...

- Page 44 MDO_P1P44F-010: Operator Manual Insert the coordinates of the endpoint and midpoint ARC FOR 3 POINTS Insert the coordinates of the endpoint TANGENT Stroke movement without cuts. Enter end point coordinates TRANSFER The software automatically corrects the undercut set. 42/55...

-

Page 45: Profiles - Parameters

MDO_P1P44F-010: Operator Manual 14.2.2 Profiles - parameters 43/55... - Page 46 MDO_P1P44F-010: Operator Manual Size of the solid. As an option, you can enter Over Material on the profile the size of the solid. This will be grayed out in the Cutting direction Y-axis increment CAD pages of working preview. only to X+ direction Bilateral cut Preview cuts...

-

Page 47: Execution

MDO_P1P44F-010: Operator Manual 15. Execution 15.1 Program execution Choose and select the program to preview 45/55... - Page 48 MDO_P1P44F-010: Operator Manual 46/55...

-

Page 49: Profile Execution

MDO_P1P44F-010: Operator Manual 15.1.1 Profile execution 1 Current positions and axis target dimensions 2 Running shape 3 Working parameters 4 Preview of the drawn shape 15.1.2 Axis parameters Self-learning of X1 + X2 positions = Software limit switch of cutting Input lowered data set Last cut direction 0 ~ 10 Forward lowered (X+) -

Page 50: Working Parameters

MDO_P1P44F-010: Operator Manual 15.1.3 Working parameters SINGLE one pass TO LOWERED multi-pass CUT TYPE The disk goes to PARKING at the end of the The axes STOPPED when the cycle is end cycle END CYCLE The following symbols are view-only They are programmed in the appropriate parameter pages. POSITIVE The next cut is done with Y that NEGATIVE The next cut is made with Y that increments... -

Page 51: Alarms

MDO_P1P44F-010: Operator Manual 16. Alarms Clear all alarms The alarms block all machine operations. Alarm Cause Solution Emergency Stop for emergency switch Y axis limit switch FW The Y-axis has encountered the forward limit switch Y axis limit switch BW The Y-axis has encountered the backrward limit switch Z axis limit switch UP The Z-axis has encountered the up limit switch Z axis limit switch DOWN... -

Page 52: Alarms List

MDO_P1P44F-010: Operator Manual 16.1 Alarms list to clear the alarms list 16.2 Messages The messages do not block machine operations. Message Cause Solution PLEASE WAIT… Data is being processed PATH ERROR Error calculating axis path The tool is too wide ERR: TILTED DISK Disk tilt is not compatible with the current working Correct tilt X OVER MAX LIMIT... -

Page 53: Diagnostic

MDO_P1P44F-010: Operator Manual 17. Diagnostic PASSWORD:462 INPUTS OUTPUTS 51/55... -

Page 54: Cpu Data

MDO_P1P44F-010: Operator Manual COUNTERS ANALOG OUTS ANALOG INP. CANBUS 17.1 CPU DATA Fw name : firmware code and checksum Task time : average time of CPU cycle Maximum Time and Minimum Time registered limits CPU time : total CPU time in RUN state (hh:mm) 52/55... -

Page 55: Digital Inputs

MDO_P1P44F-010: Operator Manual 17.2 Digital inputs Status of digital inputs = OFF INPUTS = ON Previous page Next page 17.3 Digital outputs Status of digital outputs = OFF = ON OUTPUTS Previous page Next page Press to switch to output force mode Press the output that you want to activate. -

Page 56: Analog Outputs

MDO_P1P44F-010: Operator Manual 17.5 Analog outputs ANALOG OUTS Analog outputs voltage 17.6 Analog inputs ANALOG INP. Analog inputs read 17.7 Communication with RMC1S modules CANBUS Status of communication with RMC1S modules. 54/55... -

Page 57: Assistance

4. Request a quote for repair; if not required, the cost will be calculated in the final balance. Documento generato automaticamente da Qem Wiki - https://www.qem.eu/doku/ Il contenuto wiki è costantemente aggiornato dal team di sviluppo, è quindi possibile che la versione online contenga informazioni più...

Need help?

Do you have a question about the MDO P1P44F-010 and is the answer not in the manual?

Questions and answers