Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for molex FA2

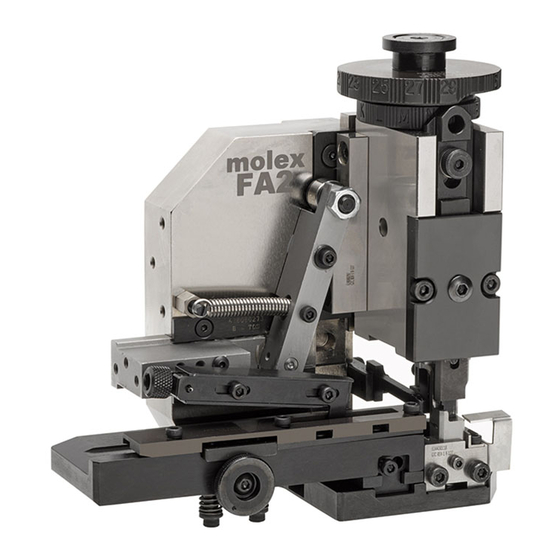

- Page 1 FA2 Applicator FA2 CRIMP APPLICATOR General Description, Setup and Operating Instructions Document No. 63808-0200 Start-Up Guide Page 10 UNCONTROLLED COPY Doc. No: TM-638080200 Release Date: 02-08-18 Page 1 of 33 Revision: B2 Revision Date: 05-04-18...

- Page 2 FA2 Applicator UNCONTROLLED COPY Doc. No: TM-638080200 Release Date: 02-08-18 Page 2 of 33 Revision: B2 Revision Date: 05-04-18...

-

Page 3: Safety Warnings And Information

Keep this manual available when using this tool. Replacement manuals are available for download at www.molex.com. SAFETY ALERT SYMBOL This symbol is used to call your attention to hazards or unsafe practices that could result in an injury or property damage. - Page 4 Installation of crimp presses with other-than-standard shut heights can cause tool breakage. It is advisable to perform a check of the shut height before installation. Molex will not be liable for any damages as a result of applicator installation in a crimp press with an incorrectly set shut height.

-

Page 5: Table Of Contents

FA2 Applicator Table of Contents Safety Warnings and Information ..........................3 Section 1 – General Description ............................ 6 Description..............................6 Features ..............................6 General Applicator Parts Identification (Mechanical Feed) ................ 7 General Applicator Parts Identification (Air Feed) ..................8 Applicator Tooling Identification ......................... 9 Section 2 –... -

Page 6: Section 1 - General Description

Section 1 – General Description 1.1 Description The FA2 applicator fits in the Molex TM-2000, TM-3000 and TM-4000 Universal Presses and in most industry-standard crimp presses with 135.8mm (5.346”) shut height and 3-point base plate mounting to the press bolster. -

Page 7: General Applicator Parts Identification (Mechanical Feed)

FA2 Applicator 1.3 General Applicator Parts Identification (Mechanical Feed) Indicates manual page number for more information LUG BOLT FEED CAM PUNCH COVER POSITION ADJUSTING KNOB FEED PAWL TRACK SCRAP CHUTE TRACK ADJUSTING SCREW TERMINAL GUIDE DRAG BRAKE KNOB DRAG BRAKE... -

Page 8: General Applicator Parts Identification (Air Feed)

FA2 Applicator 1.4 General Applicator Parts Identification (Air Feed) Indicates manual page number for more information LUG BOLT SPEED CONTROL (FORWARD STROKE) SPEED CONTROL (BACK STROKE) PUNCH COVER ADJUSTING SCREW (BACK STROKE) FEED PAWL TRACK SCRAP CHUTE TRACK ADJUSTING POSITION... -

Page 9: Applicator Tooling Identification

FA2 Applicator 1.5 Applicator Tooling Identification Tooling component used on some applicators FEED CAM (NOT USED ON AIR FEED APPLICATORS) TERMINAL HOLD DOWN CONDUCTOR PUNCH CONDUCTOR STUFFER BLADE AND SPRING INSULATION PUNCH INSULATION STUFFER AND SPRING FRONT PLUNGER STRIKER PUNCH... -

Page 10: Section 2 - Start-Up Guide

T-shape universal ram mounting Confirm Terminal, Wire and Tool Use the applicator’s ATS document to confirm the applicator is compatible with Molex terminal part number and selected wire (conductor size and insulation diameter). Set Up Applicator for Wire Processing (If Applicable) o As shipped, Molex applicators are set up for bench crimping. - Page 11 FA2 Applicator Inspection Measure crimp characteristics as specified in the ATS and adjust accordingly. Ready for Production Visual Inspection of Crimped Terminals Examples Improper Wire Preparation Optimal Crimp Measurement of Crimp Height Note: Do not measure extrusions. Application Tooling Support Phone: (402) 458-TOOL (8665) E-Mail: applicationtooling@molex.com...

-

Page 12: Section 3 - Troubleshooting

FA2 Applicator Section 3 – Troubleshooting 3.1 Applicator Troubleshooting Note: ATS refers to the Application Tooling Specification document for the applicator. Symptom Cause Solution See Page Terminal strip bent or damaged Replace terminals — Terminal strip pulled tight from reel... - Page 13 FA2 Applicator Symptom Cause Solution See Page Verify insulation diameter is within Wire insulation diameter too small Insulation crimp too specification loose (poor strain Wrong insulation cam setting Adjust insulation cam for tighter crimp 15-16 relief) Worn or damaged tooling...

-

Page 14: Section 4 - Setup And Operation

This applicator must be installed in a crimp press with a standard 135.80mm (5.346”) press shut height. Shut height should be verified with a calibrated shut height gauge. Molex offers a shut height gauge (Order No. 63800-7900). 4.1 Applicator Installation and Removal RAM STORAGE SCREW BASE PLATE 2. -

Page 15: How To Make A Crimp

5. Evaluate the crimp for any necessary adjustments. Note: Molex recommends performing a setup with the crimp height cams at their loosest setting (A, 1) to verify that the feed and cutoff are functioning properly. This will help prevent tooling damage. -

Page 16: Track Guide Setup And Adjustment

CONDUCTOR ADJUSTING CAM Figure 4.3.1 Note: Due to the large variety of insulation wall thicknesses, materials and diameters, Molex does not always specify insulation crimp height. For each different wire type, insulation crimp height can be measured, recorded and inspected as a quality indicator. - Page 17 FA2 Applicator Track Guides The applicator’s terminal track uses two adjustable guides. See Figure 4.4.1: Feed Pawl Guide: The slot in the feed pawl guide is aligned to pilot holes in the terminal carrier strip and provides feed pawl guidance. See Figure 4.4.2.

-

Page 18: Loading And Unloading Terminals In The Applicator Track

DO NOT remove the applicator back frame from the base plate. The back frame of this applicator is NOT doweled to the base plate. If the back frame screws are loosened, then the applicator will need to be returned to Molex for realignment. M3 SCREW (3) -

Page 19: Terminal Feed Adjustments

FA2 Applicator 8. For air feed applicators, turn the press air valve on and off so the feed pawl retracts and feeds the terminal to a centered position over the anvils. CARRIER STRIP AGAINST TRACK LIP PUSH IN TERMINAL STRIP... - Page 20 FA2 Applicator HOLD LEVER M3 SCREW DOWN FEED PAWL IN POSITION ADJUSTING FORWARD POSITION KNOB CORRECT INCORRECT INCORRECT INCREASED Feed Adjustment: Air Feed Applicators DECREASED FEED DRAG BRAKE ON Figure 4.6.1 FEED Air feed applicators use an air cylinder to push terminals through the applicator track. The back stroke of the feed cycle is adjusted to the specific terminal pitch.

- Page 21 FA2 Applicator Air Feed Back-Stroke Adjustment After adjusting the forward stroke of the feed cycle, follow these steps to adjust the back-stroke position of the feed cycle. See Figure 4.6.3. 1. Load terminals in the track, and make sure the drag brake is on (dot facing down).

-

Page 22: Terminal Track Position Adjustment

FA2 Applicator 4.7 Terminal Track Position Adjustment The terminal track should be adjusted only to correct the size of crimp bellmouth and terminal cut-off tab. A 2.5mm hex wrench is used for adjustment. Caution: Always disconnect press power before installing or removing tooling. -

Page 23: Crimp Tooling Installation And Removal

FA2 Applicator 4.8 Crimp Tooling Installation and Removal Removal and Installation of Upper Tooling (Punches) Caution: Always disconnect press power before installing or removing tooling. Caution: DO NOT operate the applicator without guards in place. Upper Tooling Removal 1. Disconnect power to the press. - Page 24 FA2 Applicator Upper Tooling Alignment Upper tooling is mounted in a precision-machined pocket and should not require further alignment. However, it is a good practice to hand-cycle the applicator after installing the upper tooling to ensure correct fit. Note: If the punches or anvils are installed in the incorrect order or are incorrectly matched, there will be a tooling crash.

-

Page 25: Wire Stop Setup And Adjustment

FA2 Applicator 4.9 Wire Stop Setup and Adjustment For automatic wire processing machines, the wire stop can be used to assist in stripping the terminal from the punches. However, in certain circumstances, the wire stop may need to be removed when running on an automated machine. - Page 26 FA2 Applicator 10. While holding the wire stop assembly against the spacer, tighten the M5 screw on the side of the applicator frame. 11. Remove the spacer from the applicator and discard. Wire Stop Adjustment STRIP LENGTH Use the following steps to determine if a wire stop adjustment is...

-

Page 27: Wire Processing Setup And Feed Cam Orientation

If the wire stop must be removed from the workspace, then it can be flipped around and mounted backward in its location to prevent its loss. Many of the FA2 applicators have a cut-off retainer where the cutting insert can be removed to allow the wire processor to chop the scrap carrier strip. ... -

Page 28: Bend Adjust Dial

FA2 Applicator 7. Position the cam in the desired orientation for feeding, and reinstall the M4 screws. 8. Push the feed pawl slide toward the ram so the feed pivot lever is vertical, and install the ram in the applicator. -

Page 29: Section 5 - Maintenance

2. Grease the ram with a multipurpose synthetic lubricant with Teflon or an equivalent. If using a grease gun, stop when the grease begins to show at the top of the applicator frame. Molex ships applicators greased with Synco Super Lube ® ®... -

Page 30: Section 6 - Service Parts

FA2 Applicator Section 6 – Service Parts Basic Applicator Note: General replacement parts shown. Refer to ATS document for terminal-specific tooling and service parts. FEED PAWL SPRING 63600-5400 DRAG BRAKE 63808-0259 FEED PAWL 63808-0274 TRACK LOCKING SCREW 63600-5726 DRAG BRAKE SPRING... -

Page 31: Feed Pawl Spring Replacement

FA2 Applicator 6.1 Feed Pawl Spring Replacement The applicator must be removed from the press for this procedure. 1. For mechanical feed applicators, remove the ram from the applicator. 2. For air feed applicators, extend the air cylinder. 3. Back up the feed position by removing the ram from the applicator. For air feed applicators, extend the air cylinder. -

Page 32: Accessories

FA2 Applicator 6.2 Accessories For terminals that require lubrication for crimping, terminal oiler 63801-7240 is available. See document ATS- 638017240 for more details. 6.3 Contact Us Application Tooling Support Phone: (402) 458-TOOL (8665) E-Mail: applicationtooling@molex.com Website: www.molex.com/applicationtooling UNCONTROLLED COPY Doc. No: TM-638080200... -

Page 33: Section 7 - Crimp Quality

This handbook can be downloaded from the Molex website (www.molex.com), or contact your local Molex sales engineer. Molex is a registered trademark of Molex, LLC in the United States of America and may be registered in other countries; all other trademarks listed herein belong to their respective owners.

Need help?

Do you have a question about the FA2 and is the answer not in the manual?

Questions and answers