Summary of Contents for Honeywell CBU145-50A-042

- Page 1 CBU145 Compact Booster Unit - double pump To ensure the quality of potable water according to EN1717 Instructions...

-

Page 2: Table Of Contents

4. Technical data ...................10 16. Proof of Maintenance ...............25 4.1 Construction dimensions ..............11 4.2 Noise expectancy values ..............11 4.3 Authorised environmental conditions ..........11 5. Shipping ....................12 5.1 Check condition upon delivery ............12 5.2 Transportation ..................12 Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 3: Safety Guidelines

The basis for safe and error-free operation of the compact booster unit is knowledge of the instructions for safety and operation in this manual. 1.6.1 Mechanical residual dangers During normal operation, no danger is threatened from mechanical compon- ents. EN1H-1375GE23 R1014 - Translation of original Honeywell GmbH... -

Page 4: Residual Dangers Pertaining To Fluids

- Hazard to persons caused by electrical, thermal, mechanical, and chemical influences - Loss of important product functions - Failure to perform required maintenance and service measures - Environmental hazard caused by leakage of hazardous substances Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 5: Basic Safety Measures

1.11 Requirements for operating personnel compact booster unit. 1.11.1 Operating personnel Parts and special equipment not delivered by Honeywell are also not autho- This compact booster system may only be asembled, started, operated, rised by Honeywell for use. maintained, and shut down by persons who have been trained, instructed and authorised to do so. -

Page 6: General Information

Instructions for the pressure switch In order to maintain the warranty, in the event of damage immediately Instructions for the throttle valve contact the nearest Honeywell service centre. Instructions for the membrane pressure vessel 2.1 Conformity with the following norms... -

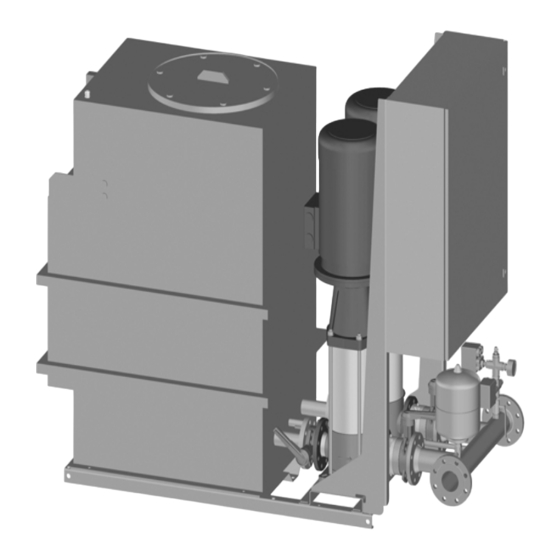

Page 7: Description

3.3 Version The Compact Buster Unit comprises the following modules, that can be Honeywell Compact Booster Unit - double pump CBU145 as a safety device disassembled (for example for transport purposes). to separate potable water from category 5 fluids according to DIN EN 1717 •... -

Page 8: Function

• Water shortage Figure 2: CBU145 Inlet side • Switch to position manual/automatic • Buffer tank overflow • Remote actuation via remote on/off • Collective error message • Separation of potable water Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 9: Mode Of Operation

(default 90 °C) to protect the pump against overheating when operated without a minimum amount discharge. Temperature monitoring is activated in the automatic and manual modes. EN1H-1375GE23 R1014 - Translation of original Honeywell GmbH... -

Page 10: Technical Data

Type 18 m /h (5,0 l/s) 36 m /h (10,0 l/s) Δp Δp [m3/h] Inlet Pump [bar] [bar] [bar] [bar] [bar] [bar] [kW] CBU145-50A-042 DN50 7,29 CBU145-50A-052 DN50 10,07 CBU145-50A-063 DN50 10,07 CBU145-50A-074 DN50 13,6 CBU145-50A-085 DN50 11,2 13,6 CBU145-50A-095... -

Page 11: Construction Dimensions

4.1 Construction dimensions ±10 DN100 ±10 max ±10 Type Weight [kg] CBU145-50A-042 G2" DN50 1372 1720 2000 CBU145-50A-052 G2" DN50 1372 1720 2000 CBU145-50A-063 G2" DN50 1372 1720 2000 CBU145-50A-074 G2" DN50 1372 1720 2000 CBU145-50A-085 G2" DN50 1372 1720... -

Page 12: Shipping

2. In the case of transport damage estimate the extent, document the Danger for persons, near-by systems and the the environment that damage and notify Honeywell immediately in writing. arises from the non-intented use of the compact booster unit. 5.2 Transportation Operate the compact booster unit only as intended. -

Page 13: Inspection Before Assembly

6.9 Installing valves All additional valves in the terminal lines such as sliders, water meters and check valves have to be dimensioned according to the values stipulated by the competent water distribution company. EN1H-1375GE23 R1014 - Translation of original Honeywell GmbH... -

Page 14: Electrical Connection

The clamps are labelled in the diagram and in the cabinet. Forward alert messages to the control unit. Potential-free collective error message can be created by looping throu- gh of potential-free single messages. Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 15: Standby Indicator

6.11 Standby indicator 7.3 Initial operation The system standby mode has to be registered by the operator or their The initial start-up should be performed by Honeywell technical staff. contractors at the responsible authority (most commonly WVU or factory Caution inspectorate). -

Page 16: Settings

1. Secure the shut-off valves of the in and output against being closed. 2. Operate the main switch to supply the system with voltage. - The green light goes on to signal standby mode. Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 17: Maintenance

Maintenance should be performed by Honeywell technical staff. Inappropriately maintained compact booster unit • If necessary contact the service department at Honeywell. The proper function of the compact booster unit can no longer be Performance of tasks only by qualified personnel (see section 1.11). -

Page 18: Monitoring Operation

Check the batteries yearly, replace if necessary. Observe the manufacturer`s manual on how to use the rechargable backup battery. Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 19: Maintenance

9. Troubleshooting 8.3 Maintenance Maintenance should be performed by Honeywell technical staff. During the warranty period consult the manufacturer before performing Alterations or modifications of the system are only permitted with the maintenance work on the system (only work that is required for start-up consent of the manufacturer. -

Page 20: Possible Causes / Elimination

The refilling is too large, odour trap is Check the refilling, check if the odour ------------------------ clogged trap is clogged, clean if necessary Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 21: Shut-Down, Restart

2. Separate the pump materials for example according to: - Metal - Plastic - Electronic junk - Grease and lubricants 3. Dispose according to local regualtions or have them disposed of accor- ding to regulations. EN1H-1375GE23 R1014 - Translation of original Honeywell GmbH... -

Page 22: Spare Parts

Motitec 4006 DN80 0904137 Pressure switch MCS 22 alle 0904106 Solenoid valve 1/2" alle 0904107 Float valve DN50, DN65 VR170-2A DN80 VR170-21/2A Float switch alle 0904116 Spare parts for older models on request Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 23: Start-Up Protocol

14. Start-up protocol The following so-called Honeywell Compact Booster Unit was commisioned today by the signatories, authorised Honeywell customer service staff, and this protocol was written. 1 Compact booster unit Series ..................Size ..................Serial number ..................Order number .................. -

Page 24: Declaration Of No Objection

The following safety precautions regarding rinsing medium, residual fluids and their disposal are required: .................................................................. We ensure that the above information is correct and complete and delivery will be made according to statutory requirements............................................City, date and signature Address Company stamp Honeywell GmbH Translation of original - EN1H-1375GE23 R1014... -

Page 25: Proof Of Maintenance

This compact booster unit is subject to the standards for drinking water and guidelines for maintenance therein, and have to be maintained regularly by qua- lified personnel and the results have to be documented. Date Operating company Name Signature EN1H-1375GE23 R1014 - Translation of original Honeywell GmbH... - Page 26 Automation and Control Solutions Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell GmbH Honeywell Technologies Sàrl, Z.A. La Pièce 16, Hardhofweg 1180 Rolle, Switzerland by its Authorised Representative Honeywell GmbH 74821 MOSBACH MU1H-1375GE23 R1014...

Need help?

Do you have a question about the CBU145-50A-042 and is the answer not in the manual?

Questions and answers