Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Plasma 703-1-0

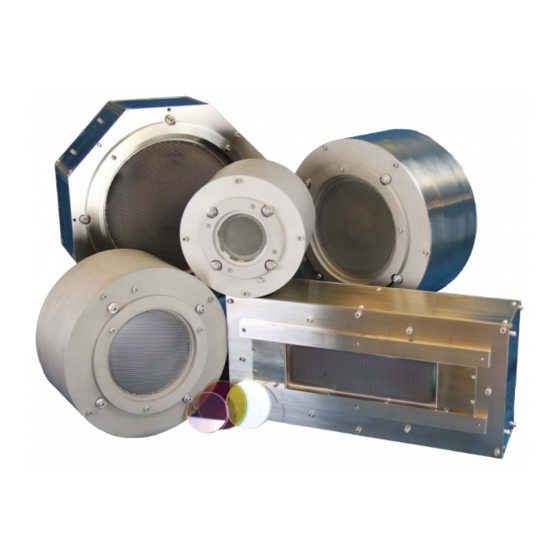

- Page 1 ION BEAM RF SOURCES MANUAL ESTABLISHED 2003...

- Page 2 Thank you for purchasing an ion beam source from Plasma Process Group! We want your new source to operate safely. Anyone who installs or operates this equipment should read this publication (and any other manuals) before installing or using the ion beam source, neutralizer and power supply.

- Page 3 Many issues can be solved over the phone or email. In the event hardware needs to be returned, all equipment, including warranty, returned to Plasma Process Group (PPG) requires a return authorization (RA) number. Our support team will provide a return request form with instructions to start the process.

- Page 4 Warning Statements This manual uses these symbols to indicate potential hazards. ALERT - This symbol is used for tips and other pointers. WARNING This symbol illustrates a electrical shock hazard. Warning- Risk of Injury to Persons This symbol is used to warn of a heavy lift operation. CAUTION This symbol is used to alert of a potential risk to person or equip- ment.

-

Page 5: Table Of Contents

Table of Contents Chapter 1: Getting Started Section 1.1: Terminology Section 1.2: Overview Chapter 2: Installation Section 2.1: General Requirements Section 2.2: Layout Section 2.3: Unpacking Section 2.4: Source Installation Chapter 3: Specifications Section 3.1: Specifications for RF Neutralizer (RFN) Section 3.2: Specifications for 6 cm RF Section 3.3: Specifications for 12 cm RF Section 3.4: Specifications for 16 cm RF... -

Page 6: Chapter 1: Getting Started

ION BEAM RF SOURCES MANUAL Chapter 1: Getting Started Ion beam technology was developed at NASA in the 1960s as a means of producing thrust on spacecraft. Today, ion beam sources are used on vacuum systems for depositing precise thin film coatings of oxides, diamond-like carbon, and other useful materials on optical and mechanical components. - Page 7 The RF antenna will then excite free electrons causing ionization of the process gas. A plasma is then created inside the discharge chamber. A plasma is an electrically conductive gas where the density of ions and electrons are approximately equal.

-

Page 8: Section 1.2: Overview

±2500 V. The oscillating field will excite free electrons that can ionize the process gas and sustain a plasma discharge (ions and electrons). Ions created in the discharge chamber that drift towards the grids are then accelerated to high velocities with electrostatic potential applied to the grids. The screen grid is biased positive, the accelerator grid is biased negative and the decelerator grid is grounded. - Page 9 Electrons from the neutralizer do not recombine with source ions, rather they provide space-charge- neutralization for the downstream plasma. Under normal operation, the neutralizer will emit between 125% to 200% of the measured beam current. In this fashion substrates or targets downstream will not suffer damage due to arcing or surface charging.

- Page 10 ION BEAM RF SOURCES MANUAL Chapter 1: Getting Started The source and RFN are both controlled using the I-BEAM power supply. The I-BEAM supply is connected to the source, RFN and it will monitor the source matching network controller. There are three modes of control.

-

Page 11: Chapter 2: Installation

ION BEAM RF SOURCES MANUAL Chapter 2: Installation Please contact us with any concerns or issues that arise during the installation of the source. Each source and vacuum system are unique and present challenges. Section 2.1: General Requirements Vacuum system The source will require a modest vacuum system capable of handling some gas flow. -

Page 12: Section 2.2: Layout

ION BEAM RF SOURCES MANUAL CHAPTER 2: Installation Safety The I-BEAM power supply has a switch closure interlock that needs to be interfaced with the facilities. Industry standard is to safe guard the power supply and only allow for the source to be run when the vacuum pumping station is ready, gas and coolant flows are nominal. -

Page 13: Section 2.3: Unpacking

ION BEAM RF SOURCES MANUAL CHAPTER 2: Installation Section 2.3: Unpacking We take extra care in packaging our equipment for shipment. Please inspect all containers for any shipping damage. Send us a photo of the shipping container if there are any issues. Handle all equipment with care. Personal protection Eye protection should always be worn. -

Page 14: Section 2.4: Source Installation

ION BEAM RF SOURCES MANUAL CHAPTER 2: Installation Section 2.4: Source Installation The installation of a flange mount or extension mount source styles are straightforward, as the source body is mounted to the vacuum flange. An internal mount source differs from the flange mount sources in a few respects;... - Page 15 ION BEAM RF SOURCES MANUAL Chapter 2: Installation Internal mount Step 3A: Place the source body inside the chamber and position it to line up with the feed-through connections. Secure it loosely for now. Step 3B: Connect the gas line from the feed-through to the source. Step 3C: Connect the DC power leads from the feed-through to the source.

- Page 16 ION BEAM RF SOURCES MANUAL Chapter 2: Installation Step 6: It is good practice to ensure the spring tabs are connected. For sources with molybdenum grids, perform a continuity test between the pins of the feed-through and each grid. Use a multimeter (preferably with an audible continuity test tone) with a fine wire probe.

- Page 17 ION BEAM RF SOURCES MANUAL Chapter 2: Installation Step 11: Follow the I-BEAM power supply manual to complete installation of the power supply and its connec- tions. Connect the interlocks as required. Pump down the vacuum chamber. Leak check all vacuum ports that have been affected. Step 12: Step 13: Slowly open the coolant water valve.

-

Page 18: Chapter 3: Specifications

ION BEAM RF SOURCES MANUAL Chapter 3: Specifications Each ion beam source will have a range of operating conditions that it can achieve under typical running conditions. The data in this chapter are typical and have been optimized for proper operation. Critical parameters for the source will be the beam current (number of ions leaving the source), beam voltage (ion energy) and accelerator voltage. -

Page 19: Section 3.2: Specifications For 6 Cm Rf

CHAPTER 3: Specifications ION BEAM RF SOURCES MANUAL Section 3.2: Specifications for 6 cm RF 6 cm RF ion beam source Dimensions and weight: 3.6kg NOMINAL PERFORMANCE DATA - USING ARGON @ 8 SCCM BEAM ACCELERATOR RF POWER NEUTRALIZER Current (mA) Forward (W) Reflected (W) Emission (mA) Voltage (V) Current (mA) Voltage (V) 1000... -

Page 20: Section 3.3: Specifications For 12 Cm Rf

CHAPTER 3: Specifications ION BEAM RF SOURCES MANUAL Section 3.3: Specifications for 12 cm RF 12 cm RF ion beam source Dimensions and weight: 6.8 kg NOMINAL PERFORMANCE DATA - USING ARGON @ 10 SCCM BEAM ACCELERATOR RF POWER NEUTRALIZER Current (mA) Forward (W) Reflected (W) Emission (mA) Voltage (V) Current (mA) Voltage (V) -

Page 21: Section 3.4: Specifications For 16 Cm Rf

CHAPTER 3: Specifications ION BEAM RF SOURCES MANUAL Section 3.4: Specifications for 16 cm RF 16 cm RF ion beam source Dimensions and weight: 7.7 kg NOMINAL PERFORMANCE DATA - USING ARGON @ 18 SCCM BEAM ACCELERATOR RF POWER NEUTRALIZER Current (mA) Forward (W) Reflected (W) Emission (mA) Voltage (V) Current (mA) Voltage (V) -

Page 22: Section 3.5: Specifications For 23 Cm Rf

CHAPTER 3: Specifications ION BEAM RF SOURCES MANUAL Section 3.5: Specifications for 23 cm RF 23 cm RF ion beam source Dimensions and weight: 22 kg NOMINAL PERFORMANCE DATA - USING ARGON @ 20 SCCM BEAM ACCELERATOR RF POWER NEUTRALIZER Current (mA) Forward (W) Reflected (W) Emission (mA) Voltage (V) Current (mA) Voltage (V) -

Page 23: Section 3.6: Specifications For Linear Rf

CHAPTER 3: Specifications ION BEAM RF SOURCES MANUAL Section 3.6: Specifications for Linear RF 6x22 and 6x30 cm RF ion beam source Dimensions and weight: 11.9 kg NOMINAL PERFORMANCE DATA - USING ARGON @ 20 SCCM BEAM ACCELERATOR RF POWER NEUTRALIZER Current (mA) Forward (W) Reflected (W) Emission (mA) Voltage (V) -

Page 24: Section 3.7: Power Supply Specifications

Size (w x h x d): 19” x 7” x 20” weight: 23.1 kg I-BEAM POWER SUPPLY CONFIGURATIONS MODEL BEAM CURRENT BEAM VOLTAGE RF GENERATOR interface box IBOX 703-1-0 600 mA 1500 V 500 W 703-1-1 600 mA 1500 V... -

Page 25: Chapter 4: Operation

ION BEAM RF SOURCES MANUAL Chapter 4: Operation With the ion beam source installed in the vacuum chamber as described in the previous chapters, it is now ready for operation. This chapter will describe nominal operation of the source. Section 4.1: Quick Start Sequence Step 1: Pump down The ion beam source requires a high vacuum environment for proper operation. - Page 26 ION BEAM RF SOURCES MANUAL Chapter 4: Operation Step 3: Turn on the water cooling. Turn on the cooling water to the source and test the flow switch interlock. Check the flow rate to ensure 1 L/min is achieved. The flow rate will vary with facilities but should not be less than 0.5 L/min. TIP - Best practice is to connect the water flow interlock in series to the power supply interlock.

- Page 27 ION BEAM RF SOURCES MANUAL Chapter 4: Operation CAUTION The power supply will accept commands that may cause operating issues with the source. Please examine the typical source data in the Chapter 3 - Specifications of this manual. Step 5: Select MODE of operation for the source. Study the table below and select the mode of operation by pressing the MODE button on the power supply.

- Page 28 ION BEAM RF SOURCES MANUAL Chapter 4: Operation Step 7: Turn the source on and allow it to warm-up Turn on the source by pressing the SOURCE button. When the SOURCE button is pressed, the power supply will begin to start the RFN by applying RF power while the start / run relay is toggled (you may hear a light clicking sound from the RFN Matching Network).

-

Page 29: Section 4.2: Additional Resources

ION BEAM RF SOURCES MANUAL Chapter 4: Operation Step 9: Neutralizer operation When the BEAM button is pressed, the neutralizer emission current will change. If the power supply is in MANUAL mode, the emission current is determined by the settings in the neutralizer module. If the power supply is in LOCAL (or REMOTE) mode, the emission current will adjust to the E/B ratio (emission current to beam current ratio). -

Page 30: Chapter 5: Advanced Operation

Extraction and acceleration of plasma ions. The plasma created in the discharge chamber will contain ions and electrons. To extract just the ions, a grid assembly is connected and exposed to the plasma. The grids are electrodes separated from each other by roughly one millimeter. - Page 31 The decelerator grid potential is held at ground (0 V). If the decelerator grid was removed, the electrostatic potential in the downstream plasma environment (within a few mm of the accel grid) is approximately zero be- cause this downstream plasma is in contact with the grounded vacuum chamber. After passing the accelerator grid, the ions are then slowed down (decelerated) by the potential difference between the accel and decel grids (which is just the accelerator voltage).

- Page 32 ION BEAM RF SOURCES MANUAL Chapter 5: Advanced Operation Beamlet focusing example The beamlets will combine and form a larger broad beam. The broad beam can then be shaped by the grid assembly and its geometry. For flat grids, such as graphite, the broad beam will diverge at the half angle (α). However, if the grid assembly is dished, such as molybdenum, the beam shape can be tailored for a specific application.

- Page 33 These electrons can create additional ions or be collected at the screen grid (or any surface in contact with the screen grid). Unless there is a plasma leak, discharge electrons will stay confined in the discharge chamber. These electrons will be repelled by the negative potential on the accelerator grid and cannot escape as the gas isolator and discharge chamber are non conductive.

- Page 34 ION BEAM RF SOURCES MANUAL Chapter 5: Advanced Operation Electron Backstreaming continued In the example graph below the accelerator voltage of a 23 cm RF ion source was systematically lowered while the power supply is in LOCAL mode. The power supply adjusts the RF power as needed to keep the beam current at the requested level (in this case, 1000 mA).

- Page 35 ION BEAM RF SOURCES MANUAL Chapter 5: Advanced Operation Accel Current, Voltage and Charge Exchange Ar + Ar + Ar slow fast slow fast Charge exchange reaction Charge exchange reaction is the process whereby a fast moving ion (created by the source) will encounter a slow moving neutral (unused source gas).

-

Page 36: Section 5.2: Source Ignition

ION BEAM RF SOURCES MANUAL Chapter 5: Advanced Operation Section 5.2: Source Ignition RFN and Source Ignition The ionization process inside the RFN or discharge chamber of the source may begin immediately when RF power is applied to the its RF coil. For these situations, the RFN or source has self started by using free electrons in the gas and oscillating these electrons in the RF field to create ions. - Page 37 In idle mode, if the beam current is greater than the start detect current (START DETECT I), the source is considered to be started and a plasma exists. This parameter is usually set to 5 mA and represents a threshold whereby if the detected current on the beam supply is greater than this value, the source is considered to be started and a plasma exists.

-

Page 38: Section 5.3: Source Ignition Sequence

6) During any time while the beam voltage is at the BV IDLE setting, if the beam current is above the “Start Detect” level (default value is 5 mA), the I-Beam considers the plasma in the source to be started and will... -

Page 39: Section 5.4: Technical Tips

ION BEAM RF SOURCES MANUAL Chapter 5: Advanced Operation proceed to adjust the RF power to the IDLE POWER setting. 7) The source should be allowed to warm up for 20 minutes prior to turning the beam on. Turning on the beam - too early 8) If the beam button is pressed when the I-Beam believes the source has NOT yet started, an alarm will occur, and the beam switch will turn back off. - Page 40 ION BEAM RF SOURCES MANUAL Chapter 5: Advanced Operation At each gas flow setting, record the RF power required to produce the desired beam current (e.g. 600 mA). If the source can run at 50% of the flow, the RF power will be at a high setting. As the gas flow increases, the RF power will start to drop and the accelerator current will increase.

- Page 41 ION BEAM RF SOURCES MANUAL Chapter 5: Advanced Operation Impingement damage can occur when ions strike a grid directly. The most common mechanism for this is when the accelerator grid holes become unevenly coated near the edge of the grid. The beamlets will then steer and strike the decelerator grid.

-

Page 42: Chapter 6: Maintenance

ION BEAM RF SOURCES MANUAL Chapter 6: Maintenance General guidelines are provided here for the more common items that will require service on the ion source. The time between maintenance will vary as this can be system or process specific. The most common item that will require service are the molybdenum grids. -

Page 43: Section 6.2: Schedule

ION BEAM RF SOURCES MANUAL Chapter 6: Maintenance Additional supplies • Assembly drawings • Acrylic grid assembly jig for alignment and re-assembly of the grids. We recommend setting up processes and procedures for proper logging of the maintenance and documentation of measurements performed. It is important to keep track of the following information. •... -

Page 44: Section 6.3: Common Wear And Tear

RFN manual. Unexpected events Occasionally the source might experience an unexpected event such as ignition of a plasma near the RF antenna and behind the discharge chamber (i.e. under high pressure environment). In most cases, this event will produce a flash coating that is electrically conductive onto the backside of the discharge chamber and other... -

Page 45: Section 6.4: Recommended Spare Parts

ION BEAM RF SOURCES MANUAL Chapter 6: Maintenance cleaned and rebuilt to remove the conductive coating on all insulative surfaces. The source should then be fully tested to ensure its operation is stable. Standard cleaning procedure Most items can be cleaned using a media blast cabinet with 150 grit alumina media. Media blast is the most common technique for cleaning. -

Page 46: Chapter 7: Troubleshooting

It is important to be aware of the electrical nature of the ion beam source. Most issues arise from electrical shorting or openings that disrupt proper operation. These issues may not present themselves easily, say with a multi-meter, as it may be a plasma short or an open connection that creates the issue. This chapter is divided into: •... -

Page 47: Section 7.1: Common Issues And Quick Fixes

ION BEAM RF SOURCES MANUAL Chapter 7: Troubleshooting Section 7.1: Common Issues and Quick Fixes This page is a punch list or quick check for common items that may be inhibiting the source from normal operation. They are presented in the order of installation, startup and beam on. Installation RF cables going to the wrong component. -

Page 48: Section 7.2: Power Supply Error Codes

Output of module 1. Electrical short: Check electrical connections. non fatal is higher than 2. Plasma short: Check the source and feed-through for electrical wire requested. proximity problems or coated insulators. 3. Gas flow is too high: Check gas flow level. - Page 49 Beam I dropped beam during operation. below start-detect 2. Momentary RF circuit disturbance - probably a plasma leak: Check for setting gaps between grid assembly and mounting hardware. 3. Tuning Issues: RF power ramped down too far during idle mode (overshot).

- Page 50 The detect threshold value (START DETECT I) is usually set to 5mA. This means if the beam current drops below 5 mA, error -71- is activated, indicating plasma is no longer present. It is a Fatal alarm, so it turns the ion source off and stops process.

-

Page 51: Section 7.3: Rf Neutralizer (Rfn) Errors

ION BEAM RF SOURCES MANUAL Chapter 7: Troubleshooting Section 7.3: RF Neutralizer (RFN) Errors It can be advantageous to view the RFN as it attempts to start. Use a silicon wafer as a mirror if necessary. The table below covers the tuning and starting of the RFN. The possible solutions are presented with the highest probability being first. - Page 52 ION BEAM RF SOURCES MANUAL Chapter 7: Troubleshooting The table below covers the starting and running of the RFN. The possible solutions are presented with the highest probability being first. RFN TROUBLESHOOTING TABLE PROBLEM DESCRIPTION POSSIBLE PROBLEMS AND SOLUTIONS Emission current normal, but 1.

-

Page 53: Section 7.4: Starting The Source

Step 3. Once START POWER is achieved, the power supply will pulse the beam and accel grids to the BV PULSE setting, and cycle between BV PULSE and BV IDLE. • Step 4. The pulse draws free electrons from the RFN in through the grids, to help start plasma in the discharge chamber. •... -

Page 54: Section 7.5: Turning On The Beam

1. Backstreaming electrons gave false plasma detection indication. Increase zero immediately after START DETECT CURRENT setting. accel voltage rises. Source 2. Discharge chamber not installed or plasma ignition was near RF antenna. discharge is dark after beam Inspect source interior for plasma short. is on. -

Page 55: Section 7.6: Additional Resources

1. Accel grid is electrically shorted. Check accelerator connections. Look for normal. signs of plasma shorts inside the source, coated insulators and electrical lead wire proximity issues. Spring tab may be bent. 2. Damaged accelerator grid. Inspect accelerator grid for delamination or proximity issues to the screen or decel grids. -

Page 56: Chapter 8: Parts And Drawings

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Please see our website for spare parts and the latest mechanical drawings. Complete assembly drawings are provided to customers (through our website). The drawings provided in this chapter are for a quick reference only. -

Page 57: Section 8.2: Part Numbers For Rfn

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Section 8.2: Part Numbers for RFN This section contains part numbers and drawings for the RF neutralizer. Dimensions are in inches. RFN PARTS PART NUMBER DESCRIPTION 504424B RFN assembly 504425B Gas isolator assembly for RFN 504687A RFN refurbish kit - includes collector... -

Page 58: Section 8.3: Part Numbers For 6 Cm Rf Source

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Section 8.3: Part Numbers for 6 cm RF Source This section contains part numbers and drawings for the 6 cm RF source. Dimensions are in inches. 6 CM RF SOURCE PARTS PART NUMBER DESCRIPTION 06RF... - Page 59 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Flange mount interface kit part number 505865A. ...

- Page 60 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Internal mount interface kit part number 505864A. ...

-

Page 61: Section 8.4: Part Numbers For 12 Cm Rf Source

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Section 8.4: Part Numbers for 12 cm RF Source This section contains part numbers and drawings for the 12 cm RF source. Dimensions are in inches. 12 CM RF SOURCE PARTS PART NUMBER DESCRIPTION 12RF08... - Page 62 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Flange mount interface kit part number 504904A. ...

- Page 63 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Internal mount interface kit part number 504905A. ...

-

Page 64: Section 8.5: Part Numbers For 16 Cm Rf Source

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Section 8.5: Part Numbers for 16 cm RF Source This section contains part numbers and drawings for the 16 cm RF source. Dimensions are in inches. 16 CM RF SOURCE PARTS PART NUMBER DESCRIPTION 16RF08... - Page 65 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Flange mount interface kit part number 504901A. ...

- Page 66 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Extension flange mount interface kit part number 504902A. ...

- Page 67 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Internal mount interface kit part number 504903A. ...

- Page 68 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Flange mount interface kit part number 505037A. ...

-

Page 69: Section 8.6: Part Numbers For 23 Cm Rf Source

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Section 8.6: Part Numbers for 23 cm RF Source This section contains part numbers and drawings for the 23 cm RF source. Dimensions are in inches. 23 CM RF SOURCE PARTS PART NUMBER DESCRIPTION 23RF... - Page 70 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Flange mount interface kit part number 507226A. ...

- Page 71 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Internal mount interface kit part number 507178A. ...

-

Page 72: Section 8.7: Part Numbers For 6X22 Cm Rf Source

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Section 8.7: Part Numbers for 6x22 cm RF Source This section contains part numbers and drawings for the 6x22 cm RF source. Dimensions are in inches. 6X22 CM RF SOURCE PARTS PART NUMBER DESCRIPTION 06x22RF... -

Page 73: Section 8.8: Part Numbers For 6X30 Cm Rf Source

ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Section 8.8: Part Numbers for 6x30 cm RF Source This section contains part numbers and drawings for the 6x30 cm RF sources. Dimensions are in inches. 6X30 CM RF SOURCE PARTS PART NUMBER DESCRIPTION 06x30RF... - Page 74 ION BEAM RF SOURCES MANUAL Chapter 8: Parts and Drawings Internal mount interface kit part number 505890A. The same interface kit works for the 6x22 cm and the 6x30 cm sources. ...

-

Page 75: Appendix A: Cleaning Guide

ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide The item on the source that requires the most maintenance is the grid assembly as it quickly becomes coated with process material. Occasionally, source insulators and the source discharge chamber will require cleaning. In other rare cases, the RF antenna may require cleaning. - Page 76 ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide C. Grid Cleaning: Media blast the grids using Aluminum Oxide 150 grit media and a pressure no greater than 40 PSI. Also, observe the following: • Inspect the condition of the hoses and nozzle before use.

- Page 77 ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide E. Final Clean: Fill a 5-gallon ultrasonic tank with hot water and add 75 mL of Micro90 brand detergent cleaner as recommended by the manufacturer. Place grids into ultrasonic bath for 20 minutes. Remove grids and rinse thoroughly in hot water filtered to 3 microns.

-

Page 78: Section A.2: Reassemble

ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide Section A.2: Reassemble Confirm all hardware with drawing On a clean assembly surface, begin reassembly of the grids, spacers, insulators, and hardware following the assembly drawing for the appropriate part number. Confirm all spacing washers are accurate thicknesses by using a micrometer to measure each one before installation. - Page 79 ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide Center the insulator and washer on the screw and place in the assembly jig as shown. Face each screw upwards. Place the decel grid over the screws (hat side down), and line up the serial number and strap with the markings on the fixture.

- Page 80 ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide Align the accel grid serial number with the decel grid and align the accel strap with the markings on the template. Place onto the insulators. Add the accel grid to the stack. Place the ceramic insulator and metal washers over the screws.

- Page 81 ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide Install the screen grid strap. Clean 4 alignment pins with isopropyl alcohol. Add final washer and hex nuts to the posts, but do not tighten them yet. Add the final hardware. Place the alignment pins into the alignment holes, all the way down into the jig, rotating while inserting.

-

Page 82: Section A.3: Electrical Testing

ION BEAM RF SOURCES MANUAL Appendix A: Cleaning Guide Before installing into the mounting plates, use the pin-end of a micrometer to measure grid spacing between the screen and accel grid. Install the mounting plates and tighten. Check the grid spacing again. If it has changed, then remove the mounting plates and add a washer of appropriate thickness to each mounting plate stack to eliminate the spacing change. - Page 83 Plasma Process Group Since its founding in 2003, Plasma Process Group has consistently provided the highest quality service and equipment to the ion beam industry. We offer innovative new designs and industry standard products compatible with legacy equipment. EQUIPMENT We provide a wide array of ion beam products ranging from turnkey sputter coating systems through stand alone ion beam source and power supply packages.

Need help?

Do you have a question about the 703-1-0 and is the answer not in the manual?

Questions and answers