Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hafco Metalmaster HM-32B

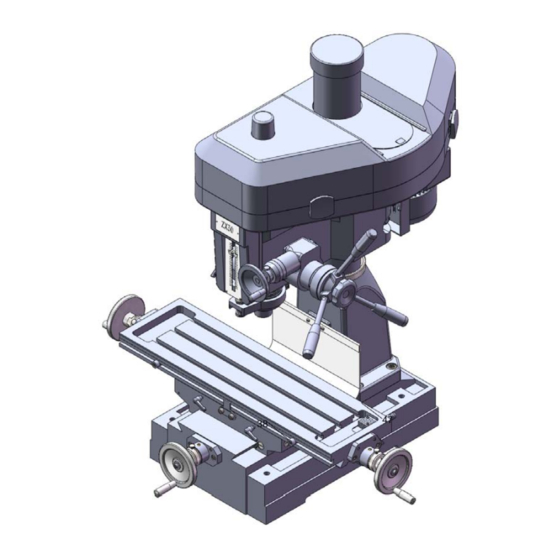

- Page 1 INSTRUCTION MANUAL DRILLING AND MILLING MACHINE HM-32B...

-

Page 2: Specification

Thank you for purchasing the DM30 ComplexMachine.If properly cared for and operated,this machine can provide you with years of accurate service.Please read this manual carefully before using your machine. 1.SPECIFICATION Model HM-32B Drilling capacity 30mm Face mill capacity 76mm END mill capacity... - Page 3 2.FEATURES: (1)This machine has several uses,such as surface cutting,drilling,milling,and also can be equipped with and electric switch for tapping. (2)This machine is of fine quality,can be operated easily,and it is not limited to skilled operators. (3)The drilling and milling operation can be performed by two methods. 1)Handoperation,which makes quick drilling.

-

Page 4: Cleaning& Lubricating

4.CLEANING& LUBRICATING (1)Your machine has been coated with a heavy grease to protect it in shipping.This coating should be completely removed before operating the machine.Commercialdegreaser,kerosene or similar solvent may be used to remove the grease from the machine,but avoid getting solvent on belts or other rubber parts. -

Page 5: Precaution For Operation

6.PRECAUTION FOR OPERATION Check all parts for proper condition before operation,if normal safety precautions are notice carefully, this machine can provide you withstanding of accurate service. (1)Before operation (a)Fill the lubricant. (b)In order to keep the accurate precision.The table must be flee from dust and oil deposits. - Page 6 the left side head handle(3-50)to raise and lower the head on its rack and pinion mechanism.When the desired height is reached,tighten ten bolts to avoid vibration. (b)Head may be rotated 360 ° by loosening the same bolts mentioned above.Adjust he head to the desired angle,the fix the bolt according to 3- 52,Tighten three bolts and the sometime to fix the head if drilling &...

- Page 7 Fig.3 8.CLAMPING,TABLE BASE,AND MACHINE BASE (1)When milling left and right, it is advisable to lock the fore and aft table travel to insure the accuracy of your work. To do this, tighten the leaf screw(4- 13) located on the right side of the table base(Fig.4). (2)To tighten the left and right travel of the table for fore and aft milling.

-

Page 8: Speed Changing

9.SPEED CHANGING (1)Turn power off . (2)Remove belt cover. (3)Loosen motor mount leaf screw. (4)Push motor in order to loosen belts(right side of motor mount is fixed left side with motor screw to tighten or loosen belts. (5)Loosen two screws of base for speed change pulley that also adjust,the location of base speed change pulley. - Page 9 Fog.6 10.TO CHANGE TOOLS (1)Removing Face Mill or Drill Chuck Arbor. Loosen the draw bar bolt at the top of the spindle approximately 2 turns with a wrench, Rap the top of the spindle sharply with a mallet. After taper has been broken loose hold chuck arbor in one hand and unscrew spindle with the other hand.

-

Page 10: Ordering Replacement Parts

11.ORDERING REPLACEMENT PARTS Complete parts list is attached. If parts are needed, contact your local distributor. 12.TAPPING EQUIPMENT REQUIREMENT This machine can be equipped with an electric switch for tapping operation clockwise or counterclockwise, and the working depth also can be adjusted by the limit switch(Electric switch will be installed according to your requirement, and you must par the cost only). - Page 11 (a)Overload----Decrease the load of feed. (b)Lower voltage----Adjust to accurate Voltage. (c)Spoiled contact point of magnetic switch----Replace with new one. (d)Breakdown of overload relay----Connect it or replace with new one. (e)Motor is poor----Replace with new one. (f)Break down of fuse or poor contact with wire(it is easily spoil motor while short circuit)----Switch off power source at once and replacefuse with new one.

- Page 12 bearing; it is ok as long as nogap between them. (c)The gap of taper sliding plate too wide----Adjust the tension of bolt in proper. (d)Loosening of chuck----Fasten chuck. (e)Cutter is dull----Resharpen it. (f)Workpiece has not hold firmly----Be sure to tighten workpiece. (7)Micro feed does not work smoothly (a)Loosening of clutch----Be sure to tighten it.

- Page 13 (a)Clean and coat the cross leading screw with oil. (b)Check to see if sliding surface and turning parts of lack lubricant If the lubricant is insufficient, fill it. (3)Monthly maintenance (a)Adjust the accurate gap of slide both in right and left and forward and backward feed.

- Page 15 Spindle head parts list CODE NAME CODE NAME 0501 HEAD CASTING CAP SCREW M6X20 0518 0504 DRAW BAR WORM GEAR 0525.9 COMPRESSION SPRING SPINDLE LOCK NUT M42x1.5 0513 0525.8 SPINDLE PULLEY LEVER BASE 0530 0569 SPINDLE TAPER SLEEVE KNOB BOLT M10-1.5x45 0549.1 CAP SCREW M5x12 LEVER M12-1.75X145...

- Page 16 CODE NAME CODE NAME CAP SCREW M8X40 FLAT WASHER 8 HEX NUT M16 HEX BOLT M8X30 WASHER 16 MOTOR 2HP 220V 1-PH SPINDLE KEY 8X25 0516 IDLER PULLEY MOTOR PULLEY SET 0514 0515 ELEVATION CRANK BRACKET BALL BEARING 6204Z 0503 INT RETAINING RING 47 0541 WORM SHAFT BUSHING...

- Page 18 Base parts list Code Name Code Name Base 300102 300401.1 Coolant drain screen 300201 Column base Screw M3×25 300204 Column ring 300206 Way cover 300203 Elevation rack 300307 Way cover uppfr plate 300202 Column cap 300205 Way cover uppfr plate 300102 Cap screwM6×16 Y-Axis leadscrew...

- Page 19 Certificate of Inspection Geared Head Milling and Drilling Machine Model HM-32B Dispatch No.:...

- Page 20 The machine has been qualified and may be permitted to dispatch Head of Inspection Depart__________ Date___________ Director___________ Date___________...

- Page 21 ACCURACY TEST FOR Total 2 MILLING & DRILLING MACHINE Checking items Tolerance Error tested The flatness of worktable surface 0.025 for any tesred length 200 Max 0.08 Squareness of worktable longitudinal movement to 0.04/300 cross movement Parallelism of worktable longitudinal movement to 0.05 the base T-slot Ran-out of spindle hole center line...

- Page 22 ACCURACY TEST FOR Total 2 MILLING & DRILLING MACHINE Checking items Tolerance Error tested Parallelism of worktable a 0.02 for any 100 movement to worktable surface testing length b 0.0.3 for any 300 testing Max 0.06 Squarencess of spindle a 0.05/300 rotating line to worktable surface a≤90º...

- Page 23 PACKING LIST FOR GEARED HEAD DRILLING & MILLING MACHINE HM-32B Series No : Dimension : G/W : N/W : Name Spec Model Quantity Milling & drilling machine HM-32B Draw bar Adapter MT3/MT2 Taper shank for drilling MT3/B16 chunck Φ1~Φ13 Drilling chuck T slot bolt M12×55...

Need help?

Do you have a question about the HM-32B and is the answer not in the manual?

Questions and answers