Table of Contents

Advertisement

Quick Links

Manufacturer:

Optimal-Vertrieb Opitz GmbH

Eysoelden M 41

91177 Thalmaessing

Germany

Phone: ++ 49 - 9173 - 79 18 0

Fax:

++ 49 - 9173 - 79 18 49

eMail: info@opitz-optimal.com

web:

www.opitz-optimal.com

M A N U A L

O N

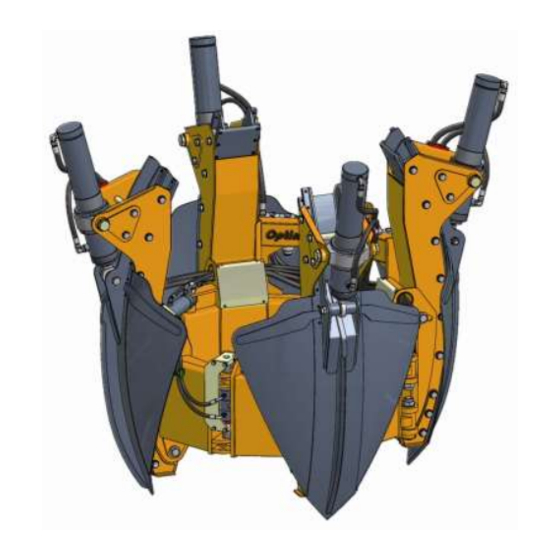

TREE SPADE OPTIMAL 1400

Distributor:

Fieldworks Nursery Equipment

5191 Dawes Rd

Grand Bay AL 36541

U.S.A.

Phone: (251) 490-9871

Email: Fieldgrown@gmail.com

Email: Sales@optimaltreespades.com

Web:

www.OptimalTreeSpades.com

Advertisement

Chapters

Table of Contents

Summary of Contents for Optimal 1400

- Page 1 M A N U A L TREE SPADE OPTIMAL 1400 Manufacturer: Distributor: Optimal-Vertrieb Opitz GmbH Fieldworks Nursery Equipment Eysoelden M 41 5191 Dawes Rd 91177 Thalmaessing Grand Bay AL 36541 Germany U.S.A. Phone: ++ 49 - 9173 - 79 18 0...

-

Page 2: Table Of Contents

- 2 - C O N T E N T S Page Safety Warnings Operating Specifications Assembly Putting into Service 8 – 10 Operating Instructions 11 – 14 Care and Maintenance Appendix Attachment Points Wiring diagram for Control Box Wiring diagram for Control System Hydraulic systems Lubrication chart Trouble Shooting... - Page 3 - 3 - WARNING Operator must have read and understood instructions before running the tree spade. Untrained operators can cause injury or death. Safety Alert Symbol: This symbol is used for important safety messages. When you see this symbol, follow the message to avoid personal injury or death.

- Page 4 - 4 - 1. Tower: 4. Tower: 7. Frame: Part N° 7118000001 Part N° 7118000004 Part N° 7118000001 Part N° 7118000006 8. Frame Part N° 7118000008 Part N° 7118000009 Part N° 7118000010 Part N° 7118000015 Part N° 7118000016 5. Gate Cylinder: 5.

-

Page 5: Operating Specifications

- 5 - Operating Specifications Description Tree Spade OPTIMAL 1400 serial number capacity upper root ball diameter 140 cm (55") root ball depth 90 cm (35") dimensions of height 180 cm (71") basic machine width, frame closed 165 cm (65") width, frame open 260 cm (102") -

Page 6: Assembly

- 6 - Assembly IMPORTANT: When doing assembly work, heed relevant instructions of manufacturers of power unit! Back Plate The tree spade is attached to the power unit by means of a back plate. The back plate is procured from the manufacturer of the power unit, or it might be fabricated according to the drawings and instructions of the manufacturer of the power unit. -

Page 7: Putting Into Service

- 7 - Putting into Service The tree spade with the back plate is attached and secured to the power unit. Both the hydraulic connecting hoses of the tree spade are to be connected to the hydraulic disconnect of the auxiliary hydraulic circuit of the power unit. The plug of the electric control cable is to be plugged into the socket on the power unit (see section 2.2.2). -

Page 8: Operating Instructions

- 8 - Operating Instructions IMPORTANT: The Operator must be a reliable person. Before commencing production work, he or she must study these operating instructions thoroughly. The following safety instructions must be observed: It is the operator's prime duty to ensure that any persons must stay clear off the danger area. - Page 9 But in case stabilizers have been installed with the tree spade and they are controlled by Optimal control box, extend rear stabilizers by setting pre-selector: function 4 (optional), rear stabilizers...

- Page 10 - 10 - 4.2.9 Once all blades have been completely pressed into the soil, the tree spade with the planting material is lifted out of the ground by means of the lift arms of the power unit. 4.2.10 The root ball is lowered by means of the lift arms of the power unit. Then the gate is unlocked: pre-selector: function 1, gate lock...

-

Page 11: Care And Maintenance

- 11 - Care and Maintenance IMPORTANT: Tree spade must be lowered to the ground and switched off when doing cleaning, maintenance or repair work ! Use original spare parts only ! The tree Spade must be inspected by an expert on operational safety once per year ! Do not alter the design of the tree spade without having consulted the manufacturer ! - Page 12 - 12 - Adjusting Blades Illustration 1 Illustration 2 Overall view of spade tower guard adjustment screw locking screw Loosen screws of guard A and remove guard. Loosen locking screw C. Use adjustment screw B to incline spade tower forward or backward until it is in the required position.

- Page 13 - 13 - Replacing Plastic Bushings at Blade Cylinder Illustration 4 Illustration 5 Loosen adjustment pin D, replace plastic bushings E. Then tighten adjustment pin D with a torque of 420 Nm.

- Page 14 - 14 - Replacing Plastic Bushings at Gate Cylinder Illustration 6 Illustration 7 Illustration 8 Illustration 6: Overall view of gate cylinder in position. Illustration 7: Loosen hex screw G (M10x20) and remove pin F. If necessary, remove hydraulic hoses, too. Illustration 8: Remove plastic bushings H and J with suitable object and insert new bushings.

-

Page 15: Attachment Points

- 15 - Attachment points... -

Page 16: Wiring Diagram For Control Box

- 16 - Wiring Diagram for Control Box... -

Page 17: Wiring Diagram For Control System

- 17 - Wiring Diagram for Control System... -

Page 18: Hydraulic Systems

- 18 - Hydraulic system... -

Page 19: Lubrication Chart

- 19 - lubriction chart lubricate once per week... -

Page 20: Trouble Shooting

- 20 - Trouble Shooting 1. Nothing moves. (none of the hydraulic functions works) Electricity supply to control box is interrupted. Check fuses at power unit. Hydraulic disconnect is not properly attached. Check attachment. Two hydraulic functions (e.g. gate lock and spades) work at the same time. On one of the valves the plunger does not move. - Page 21 - 21 - 5. Although the gate has been closed and locked properly, the blades do not move down. The safety switch at the lock needs readjustment. The electricity supply is interrupted. Check fuses at power unit. 6. The blades do not close properly although the spade cylinders are fully extended. Guides are worn and must be replaced.

-

Page 22: Warranty

LIMITED WARRANTY Optimal-Vertrieb Opitz GmbH ("Opitz") warrants that this product will be free from defects in material and workmanship for a period of 6 months from the date of purchase (the "Warranty Period"). If, during the Warranty Period, this product proves to be defective, Opitz will remedy the defect by either repairing or replacing the product or any of its defective parts, at Opitz’s option. - Page 23 S P A R E P A R T S TREE SPADE OPTIMAL 1400 Manufacturer: Distributor: Optimal-Vertrieb Opitz GmbH Fieldworks Nursery Equipment Eysoelden M 41 5191 Dawes Rd 91177 Thalmaessing Grand Bay AL 36541 Germany U.S.A. Phone: ++ 49 - 9173 - 79 18 0...

- Page 25 Table 1 OPTIMAL 1400 - SPARE PARTS LIST basic machine Item Quantity Description Part Number main frame spade tower 3181410011 guide 3061400010 hex head screw M 20 x 35 50120035933 hex head screw M 20 x 45 50120045933 washer 506203 pivot pin ø...

- Page 26 Table 1 OPTIMAL 1400 - SPARE PARTS LIST basic machine Item Quantity Description Part Number bush 544455040 washer 33 506933 lock nut M 33 x 1,5 50233150985 spade cylinder 3010114010 union 515070511621 adjustment pin 3071410050 union 515070511221 bush 3111410090 bolt M 24 x 190...

- Page 27 Table 1 OPTIMAL 1400 - SPARE PARTS LIST basic machine Item Quantity Description Part Number lock pin, top 3071400011 lock pin, bottom 3071400021 transvers plate, top 3181410190 transvers plate, bottom 3181410195 socket head screw M 10 x 70 50110070912 butt plate...

- Page 28 Table 1 OPTIMAL 1400 - SPARE PARTS LIST basic machine Item Quantity Description Part Number socket head screw M6 x 40 DIN 912 50106040912 socket head screw M8 x 80 DIN 912 50108080912 control block 5471410010 pressure relief valve 547VSPC150...

- Page 29 Table 1 OPTIMAL 1400 - SPARE PARTS LIST basic machine Item Quantity Description Part Number lock nut M 24 502240985 pipe clamp 510RAPR-112 socket head screw M 6 x 20 DIN 912 50106020912...

- Page 31 Table 2 OPTIMAL 1400 - SPARE PARTS LIST spade Item Quantity Description Part Number spade, complete plastic guide, short 30614024000 plastic guide, long 30614024002 lock nut M 6 502060985 countersunk socket screw M 6 x 25 501060257991 countersunk socket screw M 6 x 20...

- Page 33 Table 3 OPTIMAL 1400 - SPARE PARTS LIST telescopic spade cylinder 3010114010 Item Quantity Description Part Number cyinder body 302020012 guide bush 31102300 cyinder body 302020031 guide bush 31180453751 bottom plate 30402401 locking ring 599029030 cyinder body 303020041 piston 312022011...

- Page 34 Table 3 OPTIMAL 1400 - SPARE PARTS LIST telescopic spade cylinder Item Quantity Description Part Number o-ring 517045030 piston seal 516048066 rod seal S16/2016 51602016206 o-ring 27 x 2.5 5170270025 piston seal 51604110096 o-ring 78 x 2.5 517078025 seal kit complete...

- Page 36 Table 4 OPTIMAL 1400 - SPARE PARTS LIST gate cylinder Item Quantity Description Part Number cylinder body 3020600120 piston rod ø 36 x 231 3030360160 piston, HZ 60/36 3126036240 guide bush HZ 60/36 3116036365 sleeve 3111410100 union 515021000813 union 515070510813...

-

Page 38: Socket Head Screw M 8 X 20

Table 5 OPTIMAL 1400 - SPARE PARTS LIST gate lock cylinder Item Quantity Description Part Number cylinder body, HZ 50/30 3020500160 piston rod ø 30 x 175 3030300150 piston, HZ 50/30 3125030250 guide bush, HZ 50/30 3115030020 socket head screw M 8 x 20... - Page 40 Table 6 OPTIMAL 1400 - SPARE PARTS LIST Hydraulic System Item Quantity Description Part Number spade cylinder 3010114010 gate cylinder 3010200100 gate lock cylinder 3010300120 control block 5471410010 control valve NG06 547001 socket head screw M 5 x 50 DIN 912...

- Page 41 Table 6 OPTIMAL 1400 - SPARE PARTS LIST Hydraulic System Item Quantity Description Part Number elbow, male 515070511221 elbow, male 515070511621 union 3991410010 union 515020230813 union 515021000813 union 515070510813 union 515070391626 union 7/8-14UNF 5150300216 plug 5150103316 hydraulic hose NW16, length 11,4“...

-

Page 42: Pipe Clamp

Table 6 OPTIMAL 1400 - SPARE PARTS LIST Hydraulic System Item Quantity Description Part Number hydraulic hose NW6, length 36,2“ 513062092011 hydraulic hose NW6, length 87,4“ 513062222013 hydraulic hose NW6, length 88“ 513062224013 pipe clamp 510RAPR-320 pipe clamp 510RAPR-325 socket head screw M 6 x 35... - Page 44 Table 7 OPTIMAL 1400 - SPARE PARTS LIST Electrical System Item Quantity Description Part Number casing 3981110010 toggle switch 5470700728 name plate 5470700168 indicator lamp, 12V 5997149845 rotary switch 0,1,2,3,4 5470A242600E straight cable fitting M20x1,5 5997527727 straight cable fitting M12x1,5 5997527701 cable 12x1,5 –...

- Page 45 Table 7 OPTIMAL 1400 - SPARE PARTS LIST Electrical System Item Quantity Description Part Number cable 2x1,5 – 57cm (22,5“) – gate 5122015 cable 2x1,5 – 198cm (78“) – blade 2 5122015 cable 2x1,5 – 55cm (22“) – blade 4...

Need help?

Do you have a question about the 1400 and is the answer not in the manual?

Questions and answers