Table of Contents

Advertisement

Quick Links

-Setup & instal -

lation

- Use

- Maintenance

- Accessories

ORIGINAL USER'S MANUAL

Carefully read these instructions before starting

to skid with your log winch!

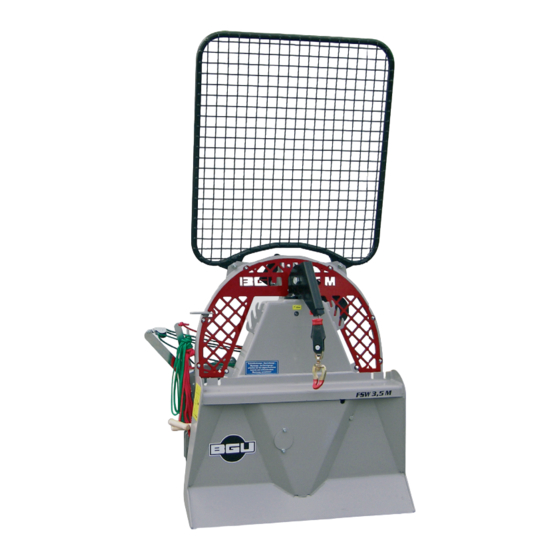

Logging winch

FSW 3.5 M

Mechanical version

Südharzer Maschinenbau GmbH

Helmestraße 94 ∙ 99734 Nordhausen/Harz

Zentrale: 03631/6297-0 ∙ 7-111

Internet: www.bgu-maschinen.de

e-mail: info@bgu-maschinen.de

Advertisement

Table of Contents

Summary of Contents for BGU FSW 3.5 M

- Page 1 ORIGINAL USER’S MANUAL Carefully read these instructions before starting to skid with your log winch! Logging winch -Setup & instal - lation FSW 3.5 M - Use - Maintenance Mechanical version - Accessories Südharzer Maschinenbau GmbH Helmestraße 94 ∙ 99734 Nordhausen/Harz Zentrale: 03631/6297-0 ∙...

-

Page 2: Table Of Contents

Other areas of possible hazard Mechanical dangers Ectrical dangers Legal warranty Extended warranty Operation tips for new winches 11.1 12. Exploded drawing, FSW 3.5 M part list 13. FSW 3.5 M - Spare 13.1 Part 1 13.2 Part 2 14. EC Statement of complianc... -

Page 3: General Information

Our timber winches are available in different versions of different pull force. FSW 3.5 M pull force 3.5 t, mechanical control system All versions are designed and conceived for farming and logging applications. - Page 4 Have the truck driver accept your claim by hand signing it. Should your shipper or the truck driver refuse to accept your claim and countersign the delivery bill, fully reject delivery and make sure to inform us (the manufacturer) immediately. No claims shall be taken into account by the shipper or by the insurance company, if a reserva- tion note is not made on the delivery bill.

-

Page 5: Safety Pictograms And Warning Signs

"Disconnect the winch, read and comply with manufacturer’s maintenance instructions.” 6. Identification label „Product identification“ This label shows the company details of the manufac- turer and the main machine technical data. 7. Identification label „BGU-Maschinen” manufacturer’s logo" 8. Operator’s safety label „Wear steel-toe safety shoes"... -

Page 6: Safety

SAFETY Strictly perform installation, set-up, maintenance, cleaning and transportation of the winch with the power switched off and all moving parts motionless against accidental operation. The user shall strictly comply with these operation, set-up, mainte- nance, repair and trouble-shooting instructions in order to assure safe operation and no damages to the equipment. -

Page 7: Mandatory Application Field

• Do not stand in the dangerous area. Assure that nobody stands in between winch and tractor, unless the tractor is safely braked and blocks have been put underneath the wheels to avoid accidental moving. • Do not remove nor start handling timber before the winch has come to a complete stop. -

Page 9: Pto-Powered Operation Mode

4. PTO-POWERED OPERATION • Use only and strictly CE approved drivelines duly connected and secured in compliance with the manufacturer’s instructions. • Never use a PTO driveline without safety shield or with a damaged guard. • Make sure that the shield is of the correct size and length for the drive shaft and is duly mounted on it. -

Page 10: Positioning The Drawbar To The Pto Shaft

In order to transfer torque from the tractor to the winch you must use a driveline with torque overload clutch coupler. Mount the winch to the tractor and then secure the stabilisers underneath the lower hitch points. Finally incline the winch by approximately 20° using the upper hitch bar. -

Page 11: Unwinding The Wire Rope

Fit the rope into the special groove and tighten the screw (Pos. 8). Now start spooling as described under pulling procedures. In order to avoid possible rope damages keep winding up for a while after complete spooling of the entire rope length, as described under section “Spooling of the wire rope”. 5.4.1 Unwinding the wire rope After you have correctly installed the winch, you can start spooling the rope off. -

Page 12: Skidding

Skidding Set the hydraulic cylinder of the tractor three-point hitch in its lo- west position. Firmly settle the winch down on the skid and engage the tractor manual brake. NEVER start pulling operations before ha- ving securely and firmly settled the winch in a stable position. Pull the green line (Pos. -

Page 13: Clutch

5.6.1 Clutch Before attempting any intervention, make sure to first switch the tractor engine off and remove the ignition key! Proper clutch settings will ensure optimum pull force. The clutch is set by the manufacturer during final testing of the product before ship- ment. -

Page 14: Stretching The Drive Chain

The brake is engaged by means of a nut (3) and a nut (4). When the brake is engaged the lever (1) shifts into its position EIN (Fig. 7). First adjust the nut (3) using an open-end spanner until the nut stands approx 5 mm away from the lever. -

Page 15: Lubrication

Lubrication Make sure that the motor is switched off and all moving parts are secured before peforming any maintenance/repair work on the machine. Improper lubrication may cause dangerous contamination of the sliding parts and consequent dama- ges for which the manufacturer holds no responsibility! The winch is equipped with self-lubricating bearings that require no further lubrication or maintenance. -

Page 16: Troubleshooting

Troubleshooting Type of malfunction Possible origins Remedies Winch is not skidding • Rope is too short • See technical specification enough • Wrong clutch setting • Reset the clutch • Oil on clutch discs • Clean the clutch lining or •... -

Page 17: Repairs And Maintenance

REPAIRS AND MAINTENANCE Make sure that the machine is fully disconnected and all mo- ving parts are secured before performing any maintenance/re- pair work on the machine. Periodic maintenance Before starting to work with your winch, make sure to perform the fol- lowing visual inspections: •... -

Page 18: Effects Of Overload And Misuse

What to do? When to do? How to do? • Spool the rope out until 3-4 winds • Only for new winches visually are left on the drum and strongly • Always when the rope is loose pull with load on •... -

Page 19: Dismounting And Discarding An Obsolete Loader

DISPOSING OF AN OBSOLETE WINCH When the winch is fully obsolete and cannot be of any longer use, it should be duly dismounted ahead of discarding. Certain components need deactivation and dismantling in order to assure that no further use is made by other parties and that no worn out parts are recycled for other applications. -

Page 20: Technical Specifications

TECHNICAL SPECIFICATIONS Technical data Unit of mea- FSW 3,5 M surement Max skidding capacity Cable winch speed at 300 RPM of the PTO shaft 0,90 Rope length Compacted steel rope Ø Rope tensile strength Max cable rewind length with compacted steel rope m/mm 75 / 8 Tractor power requirements... -

Page 21: Other Areas Of Possible Hazard

OTHER AREAS OF POSSIBLE DANGERS Mechanical dangers Possible dangers related to machine moving parts are minimized by means of suitable safeties and protections that cannot be dismounted unless special tools and equipment is used. WARNING: skidding without due safety devices might result into seri- ous injures to the operator or the other person around the workplace. -

Page 22: Legal Warranty

10. LEGAL WARRANTY All BGU machines are covered with warranty terms in accordance with the law. Customers should promptly notify the manufacturer eventual material or production claims on their detection. While asking for war- ranty service, customer should show copy of their purchase invoice or receipt. -

Page 23: Operation Tips For New Winches

11.1 OPERATION TIPS FOR NEW WINCHES Before putting your new winch to work make sure to read the user's manual and get familiar with all operation and safety instructions con- tained in the manual. •Spool the rope off making sure to leave 3 to 4 coils on the drum •... -

Page 24: Exploded Drawing, Fsw 3.5 M

12. EXPLODED DRAWING - FSW 3.5 M Part 1... - Page 25 Part 2...

-

Page 26: Fsw 3.5 M - Spare Part List

13. SPARE PART LIST, FSW 3.5 M 13.1 Part 1 Pos. Description Number Pos. Description Number of pieces of pieces Welded steel construction Cotter pin 3 Main shaft Pull grip Sprocket assembly with clutch Brake line (red) Rope drum Control roller... - Page 27 13.2 Part 2 Pos. Description Number Pos. Description Number of pieces of pieces Shaft w. chain sprocket Washer Ø 8,5 DIN 125 A Shaft guard Screws M12x40 to DIN 933 Grooved ball bearing 6306 2RS Washer Ø 13 to DIN 125 A Grooved ball bearing 6306 2RS Safety shield Nut M12 to DIN 985...

-

Page 28: Ec Statement Of Complianc

EN ISO 12100-2, EN ISO 4254-1, EN ISO 14492-1 Person in charge of the technical documents: René Pareis (Director) Südharzer Maschinenbau GmbH Helmestraße 94 ∙ 99734 Nordhausen/Harz Service-Tel. 03631/6297-104 ∙ Fax 03631/6297-111 Internet: www.bgu-maschinen.de e-mail: info@bgu-maschinen.de Nordhausen, 23.11.2016 Date René Pareis (Director) - Page 32 Subject to changes Südharzer Maschinenbau GmbH Helmestraße 94 ∙ 99734 Nordhausen/Harz Service-Tel. 03631/6297-104 ∙ Fax 03631/6297-111 Form: 2095.23.11.2016 - Rev. C Internet: www.bgu-maschinen.de e-mail: info@bgu-maschinen.de...

Need help?

Do you have a question about the FSW 3.5 M and is the answer not in the manual?

Questions and answers