Summary of Contents for Torishima Pump ETA-N

- Page 1 Operation and Maintenance Manual ETA-N End Suction Volute Pump PT TORISHIMA GUNA INDONESIA 1/13...

-

Page 2: Table Of Contents

Operation and Maintenance Manual CONTENTS Description Page General Before starting initial operation Quality control Name plate Handling Pump Installation Installation of common baseplate Direct coupling Piping Operation Starting Shutdown Operation and Maintenance 2.3.1 General 2.3.2 Shaft seal Gland packing without lantern ring Gland packing with lantern ring 2.3.3 Gauges 2.3.4 Bearing... -

Page 3: General

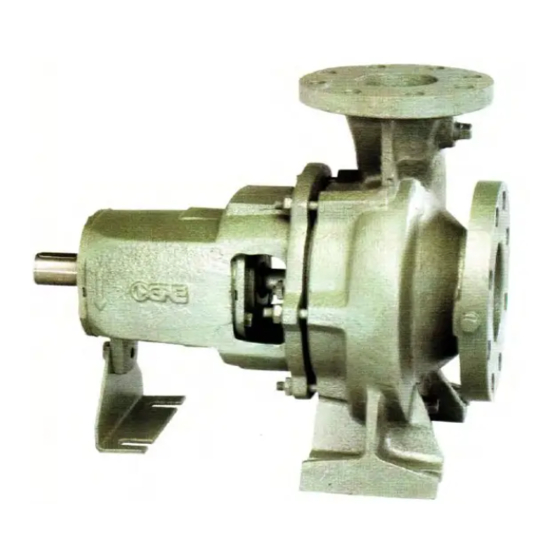

Operation and Maintenance Manual 0. General 0.1. Before starting initial operation CEN type pump is the general purpose single-stage single suction centrifugal pump conforming to JIS B8313-81 "End Suction Centrifugal Pumps". Each pump model fully satisfies the specified requirements of the said JIS Standard. -

Page 4: Pump Installation

Operation and Maintenance Manual 1. Installation 1.1. Installation of common baseplate Installation and centering of the pump should be performed by skilled workers. Improper installation and centering would cause various troubles during the pump running. When the pump and its driver are shipped as directly coupled on the common baseplate, they have already been leveled and centered completely at our fabrication shop before shipment. -

Page 5: Piping

Operation and Maintenance Manual (2) In this case, measure the concentricity and parallelism of the coupling halves (the both shafts) respectively at 4 points spaced at 90°. The specified accuracy shall be within 0.1 mm respectively. (3) Check the driver’s rotating direction without fail, before connecting one coupling half (pump side) and other coupling half (driver side) together. -

Page 6: Operation

Operation and Maintenance Manual 2. Operation 2.1. Starting (1) Before starting the initial operation after installation, observed the following check items and, if anything abnormal is found, take necessary corrective action in accordance with this manual. (1) Are the pump and the suction pipe filled up with pumping liquid ? (2) Is the driver's rotating direction correct ? (Pump rotates clockwise viewing from the driver's side) (3) No abnormal in the direct coupling ? (4) No abnormal load to the pump by piping ? -

Page 7: Shaft Seal

Operation and Maintenance Manual (7) Is the pump running with no abnormal noise and no vibration ? 2.3.2. Shaft seal The shaft seal is available in two different types of gland packing and mechanical seal. The descriptions here under covers the gland packing seal type. Refer to Chapter IV for the detailed instructions of the mechanical seal. The gland packing insertion space in the casing cover is designed to be equivalent the either five packing rings (4610) or three packing rings plus one lantern ring (4580). - Page 8 Operation and Maintenance Manual 8/13 - 6 -...

-

Page 9: Gauges

Operation and Maintenance Manual 2.3.3. Gauges For the operation control, it is recommended to provide a compound gauge on the suction pipe line and a pressure gauge at the pump casing or close to the casing on the discharge pipe line. These gauges shall be able to indicate the pressure equivalent to about 150% of the maximum operating pressure. - Page 10 Operation and Maintenance Manual Clean adequately each pump component / parts. Prevent adhesion of dust on the connections and joint portions. When replacing the ball bearings, use the designated bearing No. (63 series, LLU-C3) without fail and fit them in the pump shaft by shrinkage-fit after warming them in heated oil of 110 °C ~ 120 °C. Take good care not to damage each gasket and the sealed contact surface of each parts.

-

Page 11: Mechanical Seal

Operation and Maintenance Manual - 8 - 4. Mechanical Seal 4.1. General Cautions (1) The mechanical seal service life is significantly shortened by impurities if include therein. Therefore, clean the mechanical seal and the pump internals when reassembling and prevent invasion of such impurities into the mechanical seal from the flushing line during pump running. - Page 12 Operation and Maintenance Manual Possible Trouble Cause Emergency remedy and correction action Final remedy and correction action suction from gland Increase the sealing water to gland. Replace packing rings. packing. Retighten gland. Air suction from discharge Try to throttle discharge valve. Check seat surface.

- Page 13 Operation and Maintenance Manual Reverse rotating direction. Check each impeller and other parts for loose and retighten it if loosened. Abnormal wear of pump Overhaul and repair the pump. component. Too high rotational speed. Adjust governor. Pump running significantly deviated from rated Adjust discharge valve opening degree.

Need help?

Do you have a question about the ETA-N and is the answer not in the manual?

Questions and answers