Table of Contents

Advertisement

Quick Links

DIgITal EPIC-2 TEChnICal Manual

InstallatIon and operatIng InstructIons

To be used in conjunction with the relevant VCIOM-04592 for the D510/520 or VCIOM-04979

for the D530/540/550 short form installation and operating manuals

TablE Of CONTENTs

1. Introduction ................................................... 2

1.1

Product overview ................................ 2

1.2

Principles of operation ....................... 2

2. Definitions ...................................................... 3

2.1

acronyms ............................................ 3

2.2

Terms .................................................. 3

2.2.1 Safety .................................................. 3

2.2.2 Functional safety ................................ 3

2.2.3 Basic safety ........................................ 3

2.2.4 Safety assessment ............................. 3

2.2.5 Fail-safe state .................................... 3

2.2.6 Full-stroke test .................................. 3

2.2.7 Partial-stroke test .............................. 4

2.2.9 Signatures .......................................... 4

2.2.10 On-line proof test ............................... 4

3. Installation ..................................................... 4

3.1

Rotary direct mount ........................... 4

3.2

Rotary remote mount......................... 6

3.3

linear direct mount ........................... 7

3.4

linear remote mount ......................... 8

3.5

profiling enabled. ............................... 9

4. Field wiring .................................................. 10

4.1

D510/520 models ............................. 10

4.1.1 Direct mount..................................... 10

4.1.2 Remote mount .................................. 11

4.2

D530/540/550 models ...................... 12

4.2.1 Direct mount..................................... 12

4.2.2 Remote mount .................................. 13

5. Safety instrumented functions ................... 14

5.1

References and standards .............. 14

5.2

DEPIC-2 ESD description ................ 14

5.3

DEPIC-2 ESD .................................... 14

5.3.1 Safety function .................................. 14

5.3.2 Environmental limits ........................ 14

5.3.3 application limits.............................. 14

5.3.4 Design verification ............................ 15

5.3.5 SIl Capability .................................... 15

to the SIS logic solver ...................... 15

5.3.7 general requirements ..................... 16

www.westlockcontrols.com

Copyright © Crane Co. All rights reserved.

5.4

Diagnostics ....................................... 16

5.4.1 FST .................................................... 16

5.4.2 PST .................................................... 16

5.4.3 SOVT .................................................. 16

5.4.4 Signatures ........................................ 16

5.4.5 Proof test .......................................... 16

5.5

DEPIC-2 ESD product safety ........... 17

or replacement ................................. 17

6. Operation ..................................................... 18

6.1

Valve position transmitter ............... 18

6.2

6.3

pressure profiling ............................. 19

7. user interfaces ............................................ 21

7.1

local keypad/lCD ............................ 21

7.1.1 Boot-up lCD screen ........................ 21

7.1.2 Idle/main lCD screen ...................... 22

7.1.3 Quick setup screen .......................... 24

7.2

haRT communications .................... 27

7.2.1 Field device manager (FDM) ........... 27

7.2.2 Device type manager (DTM) ............ 27

communicator .................................. 27

7.3

user interface menu system ........... 28

7.3.1 login/logout menu ........................... 29

7.3.2 Configuration menus ....................... 29

7.3.3 Calibration menus ............................ 42

7.3.4 Diagnostics menus .......................... 48

7.3.5 Device information menus .............. 64

7.3.6 Device status menus ........................ 65

8. additional documentation ........................... 72

9. appendix....................................................... 73

9.1

schematic ......................................... 73

9.2

Cover lock operation ........................ 74

9.3

non-intrusive feature ...................... 74

VCIOM-05044-EN 17/03

Page 1 of 75

Advertisement

Table of Contents

Summary of Contents for Crane WESTLOCK CONTROLS DIGITAL EPIC-2

-

Page 1: Table Of Contents

5.3.4 Design verification ......15 5.3.5 SIl Capability ........15 5.3.6 Connecting the DEPIC-2 ESD to the SIS logic solver ...... 15 5.3.7 general requirements ..... 16 www.westlockcontrols.com VCIOM-05044-EN 17/03 Page 1 of 75 Copyright © Crane Co. All rights reserved. -

Page 2: Introduction

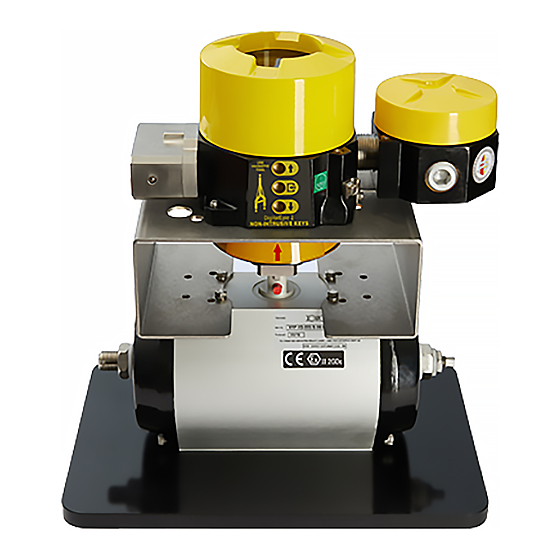

1.2 PrINCIPlEs Of OPEraTION 1.1 PrOduCT OVErVIEw as explained in the product overview section, the DEPIC-2 is a 4-20 ma position transmitter. Westlock Controls Digital EPIC-2 is a second The primary function of the device is to ® generation aRM... -

Page 3: Definitions

DIgITal EPIC-2 TEChnICal Manual InstallatIon and operatIng InstructIons 2 DEFInITIOnS 2.2 TErMs 2.1 aCrONyMs The following terms and abbreviations are related to the DEPIC-2 device and safety The following acronyms are related to the functions used throughout this document. DEPIC-2 and safety functions used throughout this document. -

Page 4: Partial-Stroke Test

Signature option enabled from beacon. Factory and by the user. FIguRE 1 Bracket / coupler mounting Bracket Inner beacon Flat head screw coupler actuator accessory mounting shaft Set screw VCIOM-05044 Page 4 of 75 Copyright © Crane Co. All rights reserved. - Page 5 6:00 placed at 3:00 D510/20 MODElS D530/40/50 MODElS Condition 2: actuator fails in a counter clockwise direction. placed at 9:00 placed at 6:00 D510/20 MODElS D530/40/50 MODElS Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 5 of 75...

-

Page 6: Rotary Remote Mount

(in fall position) Condition 2: actuator fails in a counter clockwise direction. Position sensor Conduit entry placed at 9:00 placed at 6:00 Inner beacon actuator (in fall position) VCIOM-05044 Page 6 of 75 Copyright © Crane Co. All rights reserved. -

Page 7: Linear Direct Mount

Centerline of magnetic pick-up unit Digital EPIC-2 (position sensor) housing assembly ½ stroke actuator split block actuator split block (at lower limit of travel) (at upper limit of travel) VCIOM-05044 Page 7 of 75 Copyright © Crane Co. All rights reserved. -

Page 8: Linear Remote Mount

Digital EPIC-2 housing assembly Mounting Midpoint of bracket travel mark Position sensor lower limit of travel mark Magnet assembly at lower limit of travel Conduit entry VCIOM-05044 Page 8 of 75 Copyright © Crane Co. All rights reserved. -

Page 9: Pneumatic Connections For Units Supplied With Esd And Pressure Profiling Enabled

¼” nPT or BSP. FIguRE 7 Figure pneumatic connections Single acting cylinder P1 port D510/20 MODElS D530/40/50 MODElS 3 way valve Pneumatic supply P2 port VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 9 of 75... -

Page 10: Field Wiring

Field wiring direct mount EXd enclosure Test point for haRT communicator Solenoid input Solenoid output (external solenoid) 4-20 mA(-) analog 4-20 mA(+) input Test point for haRT communicator VCIOM-05044 Page 10 of 75 Copyright © Crane Co. All rights reserved. -

Page 11: Remote Mount

Terminal board mounting screw Junction enclosure top view (no cover) FIguRE 10 Field wiring remote Mount-2 Terminal board Junction enclosure ISO view Yellow green Black White Connector orientation mark VCIOM-05044 Page 11 of 75 Copyright © Crane Co. All rights reserved. -

Page 12: D530/540/550 Models

FIguRE 11 Direct mount wiring (D540 /D550 shown) confirmation (output) Push button (PST initation input) Solenoid input Solenoid output (external solenoid) 4-20 ma position Product measured output Earth/ground connections VCIOM-05044 Page 12 of 75 Copyright © Crane Co. All rights reserved. -

Page 13: Remote Mount

5 - Yellow Wiring schematic 4 - green 3 - Red Shield Black hall green effect sensor 2 - Black White 1 - White Remote mount enclosure VCIOM-05044 Page 13 of 75 Copyright © Crane Co. All rights reserved. -

Page 14: Safety Instrumented Functions

SOVT) reduces the PFD by detecting dangerous failures or potential dangerous failures before they become failures thereby preventing the device from performing its safety functions on demand. VCIOM-05044 Page 14 of 75 Copyright © Crane Co. All rights reserved. -

Page 15: Design Verification

SFF > 90%, when the DEPIC-2 DEPIC-2 ESD Quick Start guide. ESD is used as the sole component in a final element subassembly, a design can meet SIl 3 at hFT=0. Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 15 of 75... -

Page 16: General Requirements

• Signatures on FST and PST if enabled. 5.4.1 fsT You can configure and run FST manually at any. For more information on FST refer to “Full-Stroke Testing” section in this document. VCIOM-05044 Page 16 of 75 Copyright © Crane Co. All rights reserved. -

Page 17: Depic-2 Esd Product Safety

• under normal operation, compressed air is vented to the surrounding area, and may require additional precautions or specialized installations if used in areas with potentially explosive atmospheres. VCIOM-05044 Page 17 of 75 Copyright © Crane Co. All rights reserved. -

Page 18: Operation

The device doesn’t monitor the ESD signal in this mode and doesn’t generate an ESD alarm if there is a safety demand and the valve moves to fail safe position. VCIOM-05044 Page 18 of 75 Copyright © Crane Co. All rights reserved. -

Page 19: Advanced Diagnostics With Pressure Profiling

PST fails. however more advanced PST and other tests like SOVT and FST are not available in this mode of operation. FIguRE 15 FIguRE 16 Closing full stroke signature Opening full-stroke signature Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 19 of 75... - Page 20 Figure 17 shows an example of a PST signature plot as they might appear displayed on a haRT host using the haRT DD: FIguRE 17 PST signature VCIOM-05044 Page 20 of 75 Copyright © Crane Co. All rights reserved.

-

Page 21: User Interfaces

The 3 membrane buttons/keys on the DEPIC-2 board are as shown in Figure 18. FIguRE 18 local user interface Select or enter key next or Previous down key or up key VCIOM-05044 Page 21 of 75 Copyright © Crane Co. All rights reserved. -

Page 22: Idle/Main Lcd Screen

FIguRE 19 lCD screen during power-up FIguRE 20 lCD main screen layout VCIOM-05044 Page 22 of 75 Copyright © Crane Co. All rights reserved. - Page 23 The maintenance PST is not performed yet MPST-FaIl The last maintenance PST was failed SOVT-FaIl The last SOVT failed with an error There is no error, device has been configured and running properly VCIOM-05044 Page 23 of 75 Copyright © Crane Co. All rights reserved.

-

Page 24: Quick Setup Screen

Device control configuration rotary position. linear: For linear actuators, it should be selected as linear as the DEPIC-2 will compensate non- linearity for linear magnets VCIOM-05044 Page 24 of 75 Copyright © Crane Co. All rights reserved. - Page 25 It will hide all pressure-1 related hysteresis and alarm settings in the full menu later on. VCIOM-05044 Page 25 of 75 Copyright © Crane Co. All rights reserved.

- Page 26 The user must have purchased a DEPIC-2 model that has the pressure sensor-2. VCIOM-05044 Page 26 of 75 Copyright © Crane Co. All rights reserved.

-

Page 27: Hart Communications

Quaternary variable - displays the pressure sensor 2 reading (if enabled and device has signature option enabled) as a percent of Supply Pressure during calibration, which can be the other actuator chamber (double-acting) or potentially a supply pressure (spring-return). VCIOM-05044 Page 27 of 75 Copyright © Crane Co. All rights reserved. -

Page 28: User Interface Menu System

6 categories: not be saved in this case. 1. login/logout menus 2. Configuration 3. Calibration 4. Diagnostics 5. Device information 6. Device status VCIOM-05044 Page 28 of 75 Copyright © Crane Co. All rights reserved. -

Page 29: Login/Logout Menu

Once logged in, it is user’s responsibility to log-out to prevent unauthorized access using the Keypad/lCD. VCIOM-05044 Page 29 of 75 Copyright © Crane Co. All rights reserved. - Page 30 Display timeouts Temperature display (°F/°C) Position display (%open/%close) Rotate lCD (normal/rotate) lCD contrast (27-63) (+/-1) Keypad timeout (1-60 min) (+/-1) Continued on next page Calibration timeout (1-60 min) (+/-1) VCIOM-05044 Page 30 of 75 Copyright © Crane Co. All rights reserved.

- Page 31 ESD alert (enable/disable) PST alerts (enable/disable) PsT alerts menu Invalid position(enable/disable) Solenoid fail (enable/disable) Exceed STTl (enable/disable) Exceed FTTl (enable/disable) Exceed lBPl (enable/disable) Exceed hBPl (enable/disable) Exceed TTl (enable/disable) Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 31 of 75...

- Page 32 EnTER to save it. FIguRE 34 navigating to configuration menu FIguRE 35 navigating to loop current mode menu VCIOM-05044 Page 32 of 75 Copyright © Crane Co. All rights reserved.

- Page 33 FIguRE 36 FIguRE 37 FIguRE 38 navigating factory options menu Viewing ESD factory option accessing factory defaults sub-menu FIguRE 39 FIguRE 40 Performing factory defaults Date/time configuration Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 33 of 75...

- Page 34 Keypad/lCD, the seconds default to 0 and so are not set. FIguRE 41 Viewing last clock set FIguRE 42 FIguRE 43 Configuring clock - month setup Configuring clock - date setup VCIOM-05044 Page 34 of 75 Copyright © Crane Co. All rights reserved.

- Page 35 The Partial-Stroke (PST) function will still be available even if the device control setting is disabled. FIguRE 44 accessing basic configuration menu VCIOM-05044 Page 35 of 75 Copyright © Crane Co. All rights reserved.

- Page 36 - Disabled: the DEPIC-2 hides the menus to configure the PST/SOVT related parameters FIguRE 45 and hides the menu item to perform these accessing disp/touts menu tests under the diagnostics menu. VCIOM-05044 Page 36 of 75 Copyright © Crane Co. All rights reserved.

- Page 37 This setting can be enabled or disabled for this functionality. Please read the DEPIC-2 IOM for wiring and signal description. FIguRE 46 accessing PST configuration menu VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 37 of 75...

- Page 38 SOVT Sub-menu as shown in Figure 49. FIguRE 47 FIguRE 48 accessing SOVT configuration menu Enabling auto SOVT FIguRE 49 Configuring auto SOVT day interval FIguRE 50 Configuring auto SOVT hours VCIOM-05044 Page 38 of 75 Copyright © Crane Co. All rights reserved.

- Page 39 FIguRE 51 accessing signature menu VCIOM-05044 Page 39 of 75 Copyright © Crane Co. All rights reserved.

- Page 40 It is used to determine the valve movement during PST and FST. FIguRE 52 FIguRE 53 alert hysteresis menu accessing service configuration menu VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 40 of 75...

- Page 41 - Cycle limit: indicates the limit to generate a cycle alarm (if enabled) when the Cycle Count reaches this value FIguRE 54 accessing alarm configuration menu VCIOM-05044 Page 41 of 75 Copyright © Crane Co. All rights reserved.

-

Page 42: Calibration Menus

3. Calibration < - linear calibration ma reverse 4. Diagnostics PV ranging Custom ma calibration 5. Device info 6. Device stats FIguRE 56 accessing calibration menu Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 42 of 75... - Page 43 FIguRE 57 FIguRE 58 Viewing last full calibration Full manual calibration FIguRE 59 FIguRE 60 Performing manual calibration - close position Performing manual calibration - open position VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 43 of 75...

- Page 44 The user has the option of selecting “no” or “Yes” by using the Down arrow key to switch. FIguRE 62 FIguRE 61 accessing full auto calibration Performing auto calibration FIguRE 63 accessing low calibration Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 44 of 75...

- Page 45 The valve must be in appropriate position before starting this calibration. FIguRE 64 Performing low calibration FIguRE 65 FIguRE 66 accessing high calibration Performing high calibration Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 45 of 75...

- Page 46 If “Yes”, the factory default settings are set to approximate a 4-20 ma current range. FIguRE 67 accessing ma calibration FIguRE 68 FIguRE 69 Performing default ma calibration Performing reverse ma calibration VCIOM-05044 Page 46 of 75 Copyright © Crane Co. All rights reserved.

- Page 47 (Prev+next) keys. FIguRE 70 accessing custom ma calibration FIguRE 71 FIguRE 72 Performing custom ma calibration Finishing custom ma calibration VCIOM-05044 Page 47 of 75 Copyright © Crane Co. All rights reserved.

-

Page 48: Diagnostics Menus

View closing run-time data menu Compare PST timing parameters Start SVOT Baseline closing run-time data View SOVT latest closing run-time data Compare closing time functions Compare closing pressure functions VCIOM-05044 Page 48 of 75 Copyright © Crane Co. All rights reserved. - Page 49 Press EnTER again to return to the Fix ma Test sub-menu. FIguRE 74 accessing diagnostics menu FIguRE 75 Fixed ma test VCIOM-05044 Page 49 of 75 Copyright © Crane Co. All rights reserved.

- Page 50 The following section describes each function available under this menu in detail. FIguRE 76 Device reboot function FIguRE 77 accessing Full Stroke Test (FST) menu VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 50 of 75...

- Page 51 FIguRE 78 FIguRE 79 View signature menu Viewing integrator signature data FIguRE 80 Viewing integrator signature data - page 2 Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 51 of 75...

- Page 52 SElECT to go back to the View Sign Menu. FIguRE 81 Viewing installer signature data FIguRE 82 Viewing baseline signature data VCIOM-05044 Page 52 of 75 Copyright © Crane Co. All rights reserved.

- Page 53 SElECT to lock it. FIguRE 83 FIguRE 84 accessing view maintenance signature menu Viewing maintenance signature data FIguRE 85 FIguRE 86 locking/unlocking maintenance signatures menu lock/unlock status VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 53 of 75...

- Page 54 The screen above will show the progress of the signature by showing x% complete. Once 100% is reached, it will be complete and the next screen should appear. VCIOM-05044 Page 54 of 75 Copyright © Crane Co. All rights reserved.

- Page 55 “Yes” and then press SElECT. If “no” is selected, it will return to the previous screen without performing the signature. If “Yes” is selected, the signature generation will start with the next screen below. VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 55 of 75...

- Page 56 From the FST Sign Menu, scroll down to is reached, it will be complete and the next “Runtime Data” to view critical signature data screen should appear. stored on the device, then press SElECT. VCIOM-05044 Page 56 of 75 Copyright © Crane Co. All rights reserved.

- Page 57 SElECT. next from the Open Runtime Data Sub-menu, scroll down to “latest Open” to view critical latest Maintenance Opening signature data stored on the device, then press SElECT. VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 57 of 75...

- Page 58 SElECT. next from the Close Runtime Data Sub-menu, scroll down to “latest Close” to view critical latest Maintenance Closing signature data stored on the device, then press SElECT. VCIOM-05044 Page 58 of 75 Copyright © Crane Co. All rights reserved.

- Page 59 100%. The user has the option of aborting by simultaneously pressing the up and Down arrow keys. From gen new PST sub-menu, scroll to “Start BPST” to generate a new Baseline PST, then press EnTER. VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 59 of 75...

- Page 60 PST will not be done and will return to the previous sub-menu. If Yes is selected the Baseline PST will start. From PST Sign Sub-menu, scroll down to “View all PST” then press SElECT. VCIOM-05044 Page 60 of 75 Copyright © Crane Co. All rights reserved.

- Page 61 View PST sub-menu. to “View BPST” then press SElECT. This is the Page 1 of 3 of the Baseline PST Data. Press the down arrow to go to Page 2. VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 61 of 75...

- Page 62 From Diagnostics Sub-menu, scroll down to “SOV Test” then press SElECT. This is the Page 2 of 3 of the Maintenance PST Data. Press the down arrow to go to Page 3. VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 62 of 75...

- Page 63 Press the Down arrow to go to progress with x% Done. In general this will page 2. proceed quickly since it’s not a long test. VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 63 of 75...

-

Page 64: Device Information Menus

SElECT/EnTER. This will display the required number of Preambles that the haRT host should send with all commands to the device which is usually 5. FIguRE 88 navigating to device info menu VCIOM-05044 Page 64 of 75 Copyright © Crane Co. All rights reserved. -

Page 65: Device Status Menus

Factory in that an additional sub-menu becomes available. line 5 will become “Error File” and alert File will move to line 6. FIguRE 90 navigating to device status menu Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 65 of 75... - Page 66 Figure out which variable is out of range and try to bring the variable in its normal operating range. FIguRE 91 accessing field device status sub-menu FIguRE 92 Viewing status bits in field device status VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 66 of 75...

- Page 67 4. ESD alarm, if On indicates an Emergency Shut-Down has occurred, indicated by a loss of SIS voltage to the solenoid. FIguRE 93 FIguRE 94 accessing general alarm status menu Viewing calibration errors VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 67 of 75...

- Page 68 If not, calibration will fail with the ma Out Span Error. In this case, the span should be increased during the ma output calibration and perform the ma calibration again. VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 68 of 75...

- Page 69 Keypad/lCD, it is not possible right now to show all alerts (active or Inactive). FIguRE 95 accessing PST alarms menu FIguRE 96 FIguRE 97 accessing alert file menu Viewing active alert VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 69 of 75...

- Page 70 Refer to Figure 98 from this sub-menu is primarily for Westlock/ From Device Specific Status Menu, scroll to Crane CPE personnel and would not be “5. Error File” alarms and press SElECT. note, meaningful to the user. Also note that some of...

- Page 71 EnTER/ SElECT key to exit sub-menu. FIguRE 101 FIguRE 102 Viewing haRT Dll statistics Viewing calibration data sub-menu Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 71 of 75...

-

Page 72: Additional Documentation

Operating device using 475 or other DD based hosts VCIOM-04615 DTM user guide Operating device using PaCTWare or other DTM based hosts VCTDS-03243 Product brochure Product features and specifications, ordering guide Copyright © Crane Co. All rights reserved. VCIOM-05044 Page 72 of 75... -

Page 73: Appendix

DIgITal EPIC-2 TEChnICal Manual InstallatIon and operatIng InstructIons 9 aPPEnDIX 9.1 fIEld wIrINg aNd grOuNdINg sCHEMaTIC FIElD WIRIng anD gROunDIng SChEMaTIC VCIOM-05044 Page 73 of 75 Copyright © Crane Co. All rights reserved. -

Page 74: Cover Lock Operation

See Figure 104. FIguRE 103 FIguRE 104 Cover lock non-intrusive calibration Dual pin side Single pin side VCIOM-05044 Copyright © Crane Co. All rights reserved. Page 74 of 75... - Page 75 This symbol draws attention to information that is essential for understanding the operation and/or features of the equipment. www.westlockcontrols.com Crane Co. We reserve the right to change designs and specifications without notice. VCIOM-05044 Page 75 of 75 Copyright © Crane Co. All rights reserved.

Need help?

Do you have a question about the WESTLOCK CONTROLS DIGITAL EPIC-2 and is the answer not in the manual?

Questions and answers