Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Uchida Yoko AeroCut X

- Page 1 OPERATION MANUAL UCHIDA YOKO CO., LTD. 78-708 V1.00...

- Page 2 AeroCut X OPERATION MANUAL ・ Use machine only after reading the "Safety Instructions" given below carefully. ・ These safety instructions are given to ensure that the machine will be used safely and properly and to prevent operators from sustaining harm and injuries.

- Page 3 AeroCut X OPERATION MANUAL Caution ① Don't put a hand into the cover or a clearance between parts. There is a danger of receiving an injury. ② Don't bring a hand, face, hair, sleeves of clothes and the like close to the rotating parts of the machine.

-

Page 4: Table Of Contents

AeroCut X OPERATION MANUAL Contents Introduction ........................5 Names of parts ......................5 Accessories .......................7 Touch panel .......................8 Paper weight / quality ....................9 Layout terminology ....................10 Operating instructions ....................11 Lock a caster brake、Adjuster settings ..............11 Turning the power on ....................11 Initial position ...................... - Page 5 AeroCut X OPERATION MANUAL How to use options ......................31 Y-perforator ......................31 How to adjust the Y-perforation location ..............31 How to adjust the depth of Y-perforation ............... 33 Barcode reader ...................... 34 Belt conveyor tray ....................35 Adjustment ........................36 Adjustments on the paper feed section ..............

-

Page 6: Introduction

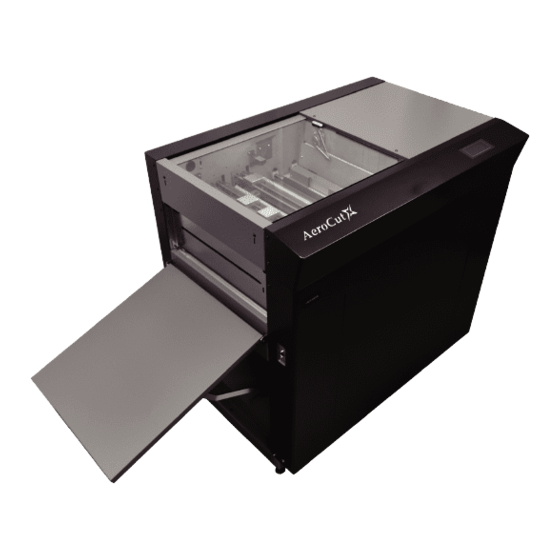

AeroCut X OPERATION MANUAL 1 Introduction 1.1 Names of parts Name Name Safety cover Touch panel Skew adjustment dial Stacker table Feed table Delivery guide Power switch Margin slitter unit Inlet Gutter slitter unit Caster Guillotine Adjuster Creaser Waste box... - Page 7 AeroCut X OPERATION MANUAL Warning Don’t put hands inside work area. May result in severe injury. Don't touch any rotating part. There is a danger of receiving an injury. Don't open the cover of the equipment. There is a danger of receiving an injury or electric shock.

-

Page 8: Accessories

AeroCut X OPERATION MANUAL 1.2 Accessories Operation manual Template Electric power cord Waste box ×1 ×1 ×1 ×1 Business card Stacker end Card stacker partition ×1 ×2 ×1 Paper guide Paper guide Feed paper Stacker paper (Small) (Large) long guide long guide ×2... -

Page 9: Touch Panel

AeroCut X OPERATION MANUAL 1.3 Touch panel ・ Home screen Home screen ① PRESET Page.21 MANU SET Page.23 ② FLEX MODE Page.25 ③ Setting Page.45 ④ Counter Page.18 ⑤ Initial position Page.12 ⑥ Pause Page.16 ⑦ Stop Page.18 ⑧ Compensation Page.40... -

Page 10: Paper Weight / Quality

AeroCut X OPERATION MANUAL ・ Settings screen Settings screen ⑯ Inching Page.45 Cutter Page.45 ⑰ (Guillotine) Table Page.45 ⑱ ⑲ Vacuum Page.36 Blower Page.37 ⑳ Speed Page.39 ㉑ Calibration Page.43 ㉒ Paper feed ㉓ Page. 38 work time ㉔ Double feed Page.38... -

Page 11: Layout Terminology

AeroCut X OPERATION MANUAL 1.5 Layout terminology... -

Page 12: Operating Instructions

AeroCut X OPERATION MANUAL 2 Operating instructions 2.1 Lock a caster brake、Adjuster settings 2.2 Turning the power on Power switch Electric power cord AC 200-240V 50/60Hz Unlock Lock nut Turn the Adjuster clockwise with a Lock wrench until the casters slightly float, and tighten the Lock nut. -

Page 13: Initial Position

AeroCut X OPERATION MANUAL 2.3 Initial position ① When the power turned on, the touch screen shows INITIAL POSITION button. Press INITIAL POSITION button. ② The slitters will move to their initial position automatically. Then the button changes to SET. -

Page 14: Set

AeroCut X OPERATION MANUAL ・ When the number of sheets is 1 or more, the machine will process the number of the sheets entered, which becomes one set. ・ The machine stops running when the number of sets processed reaches the number of sets entered. -

Page 15: Paper Setting

AeroCut X OPERATION MANUAL 2.6 Paper setting ① Press the START button on the home screen. If the feed table is in upper position. The feed table moves down. Press STOP button to stop the table moving. ② Flip through the sheets well before you put Paper them on the feed table. -

Page 16: Waste Box Setting

AeroCut X OPERATION MANUAL ④ When finishing long papers, use the long paper feed guide. ・ Remove the screws for fall prevention, slide the guide into the slot of the feed tray, and tighten the screws. 2.7 Waste box setting ・... - Page 17 AeroCut X OPERATION MANUAL ・ Change the settings of the stacker according to the cut pattern. When cutting papers into Post cards Card stacker Stacker end When cutting papers into Business cards ① Press the PAUSE button before starting to process.

-

Page 18: Stacker Paper Long Guide

AeroCut X OPERATION MANUAL ③ Place the business card partitions according to the positions of the paused cards. Business card partition 2.8.2 Stacker paper long guide When finishing long papers, use the Stacker paper long guide. ·... -

Page 19: Start

AeroCut X OPERATION MANUAL 2.9 Start ・ Press START to start an automatic operation. The display will change to RUNNING. ・ After processing the entered number of sheets in quantity, the machine stops automatically. ・ Do not open the Safety cover while the machine is running. Machine will stop immediately. -

Page 20: Waste Disposal

AeroCut X OPERATION MANUAL Sheet counter Set counter Total counter ・ The sheet counter indicates the number of finished sheet when the machine is stopped with STOP or END button. Press to reset the counter to 0. ・ The set counter indicates the number of finished sets when the machine is stopped with STOP or END button. -

Page 21: Power Off

AeroCut X OPERATION MANUAL 2.12 Power off Home screen ・ Make sure that the machine is stopped. ・ Return to the Home screen. ・ Turn off the Power switch. -

Page 22: Cut Pattern Input

AeroCut X OPERATION MANUAL 3 Cut pattern input 3.1 Outline PRESET is a series of cut patterns that are already stored in the machine. In MANUSET mode, user programs can be created and stored into the machine. In FLEX MODE, you can generate user data with a lot of flexibility in layout. - Page 23 AeroCut X OPERATION MANUAL ③ Select the cutting pattern. Cutting Pattern Selection Screen Cutting Pattern Confirmation Screen Cut pattern can be checked in detail and the measurements can be changed. Refer to MANUSET for measurement setting procedures. Copy the selected cutting pattern to FLEX MODE, then move to FLEX MODE screen.

-

Page 24: Manuset

AeroCut X OPERATION MANUAL 3.3 MANUSET ① Press MANUSET. ② The screen displays the current cut pattern. Move to User Program Selection Screen. Copy the selected cutting pattern to FLEX MODE, then move to FLEX MODE screen. Save Cut pattern as inputted into User Program memory. - Page 25 AeroCut X OPERATION MANUAL ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ④ There are some limitations in value as shown on below table. [inch] A: Paper size 8.25 –...

-

Page 26: Flex Mode

AeroCut X OPERATION MANUAL 3.4 FLEX MODE ① Press FLEX MODE. ② FLEX mode is an operation mode where you can input up to 20 actions (cross cut, crease or perforate) per page. This allows the machine to finish jobs which MANU SET cannot finish, such as multiple sizes of cards from a page and pass through pages without any actions. - Page 27 AeroCut X OPERATION MANUAL ③ The picture below is an example which will explain how to input values. :Cut :Crease ④ Press the number to change the value. ⑤ When data input is completed, press NEXT to the next screen.

- Page 28 AeroCut X OPERATION MANUAL ⑥ This screen allows you to input each pitch from No. 1 to No. 20. ・ The adjacent switches are used for selecting no operation, guillotine, creaser, or X- perforator. ・ Every time the switch is pressed, the selected operation changes.

-

Page 29: Save / Read

AeroCut X OPERATION MANUAL 3.5 Save / Read ・ 100 of MANUSET user data can be stored. ・ 50 of FLEX MODE user data can be stored. ・ SAVE/READ procedures are same in each mode. 3.5.1 Save ① Can store the contents of the MANUSET or FLEX MODE, Press the SAVE. -

Page 30: Read

AeroCut X OPERATION MANUAL ④ This message will be shown if SAVE was pressed. Then press OK and save data. ⑤ Saved user data can be deleted with a press of CLEAR. 3.5.2 Read ① Can store the contents of the MANUSET or FLEX MODE, Press the READ. -

Page 31: Copy And Paste Job Name

AeroCut X OPERATION MANUAL ② Press the button of the name you wish to retrieve. ③ Confirm the details of the program for retrieval. Data can be accessed with a press OK. 3.5.3 Copy and Paste Job name After pressing NAME COPY, select the job name you want to copy, and it will be copied ·... -

Page 32: How To Use Options

AeroCut X OPERATION MANUAL 4 How to use options 4.1 Y-perforator ① Remove the delivery guide. Note. In case Perforator unit is not set in the machine, please attach the delivery guide instead in order to avoid paper jam. ② Attach Y-Perforator unit. - Page 33 AeroCut X OPERATION MANUAL ② If the upper blades are positioned to come Clamp lever into contact with the lower blades, the Unlock upper blade position can be adjusted with the perforator attached to the main body. ③ Loosen the clamp levers, move the...

-

Page 34: How To Adjust The Depth Of Y-Perforation

AeroCut X OPERATION MANUAL 4.3 How to adjust the depth of Y-perforation ① Change in the paper thickness, recommend you adjust the depth of Perforation. ② The height of the upper blades can be individually adjusted. ③ Shift the perforator lock lever to the right and raise the upper blades. -

Page 35: Barcode Reader

AeroCut X OPERATION MANUAL 4.4 Barcode reader ・ With the barcode reader, the machine is capable to read barcodes (job number) printed on papers, recall jobs and process papers automatically. ① To activate the Barcode reader, press BARCODE button. ② Press the BARCODE MODE button to switch barcode reading modes according to the purpose. -

Page 36: Belt Conveyor Tray

AeroCut X OPERATION MANUAL 4.5 Belt conveyor tray ・ The conveyor control appears on the home screen by turning on the machine power with the belt conveyor tray connected. ① Adjust the belt speed. In case cut measurement is short, slow down the speed. If it is long, speed up. -

Page 37: Adjustment

AeroCut X OPERATION MANUAL 5 Adjustment 5.1 Adjustments on the paper feed section ・ Adjustments are required when the machine is likely to feed double or skew. Home screen Settings screen 5.1.1 Upper suction adjustment Default Reduce double feed Easier to feed ・... -

Page 38: Lower Suction Adjustment

AeroCut X OPERATION MANUAL 5.1.2 Lower suction adjustment Default Reduce skew Reduce double feed ・ BLOW will be turned off when the value is 0. ・ Empty feed may occur when paper is heavy. In such cases, turn up the blower. -

Page 39: Air Blow Adjustment

AeroCut X OPERATION MANUAL 5.1.4 Air blow adjustment Default Reduce double feed Reduce skew 5.1.5 PAPER FEED WORK TIME adjustment Default Reduce skew Reduce double feed ・ 0.5 sec. is the default setting. ・ Paper fed work time can be adjusted with a fraction of 0.1s. -

Page 40: Change Speed

AeroCut X OPERATION MANUAL 5.2 Change speed ・ There are eight feeding speed levels. 5.3 Skew adjustment ・ If print is skew on the sheet, the angle of the side guide can be adjusted. Skew ① The angle of the side guide changes as adjustment dial the skew adjustment dial is turned. -

Page 41: Fine Adjustments On Processing Positions

AeroCut X OPERATION MANUAL 5.5 Fine adjustments on processing positions ・ Make sure the original sheets are printed correctly and consistently. 5.5.1 In cases cutting positions don’t match to image positions. ○ ① Image shift compensation tab will pop up by pressing i ▼... - Page 42 AeroCut X OPERATION MANUAL ① Compensate the image shift by following procedure. When the leading edge and top margin are different from the artwork file. ・ If the leading edge was printed larger than as it should be, the images on cards seem moved to right.

- Page 43 AeroCut X OPERATION MANUAL When the print is shrunk or stretched. ・ Input ratio into D if the printing is stretching to the feed direction. ・ Input ratio into E if the printing is stretching to the width direction. ・ Ensure that when these ratios are changed, all parameters such as card size and gutter size will be changed as well.

-

Page 44: If The Cut Measurement Does Not Match The Input Value

AeroCut X OPERATION MANUAL 5.5.2 If the cut measurement does not match the input value ・ If the actual size and measurements of output differs from input values, calibrate the machine via ADJUST screen. Reset the machine to the factory setting, all the adjusted values will be 0. - Page 45 AeroCut X OPERATION MANUAL ② In case the length of leading edge is wrong. ・ With cut mark Input the difference between inputted value and actual measurement into E. In case input value is 0.400” and cut measurement is 0.450”, input -0.050 to E.

-

Page 46: Manual Control

AeroCut X OPERATION MANUAL 6 Manual control 6.1 Settings screen Feed roller will rotate. Inching. Feed roller will rotate in reverse. Inching. Guillotine will move once. Crease will move. Feed table will move. -

Page 47: Slitter

AeroCut X OPERATION MANUAL 6.2 Slitter After turning on the machine power and press “Initial position”, SLITTER button will · appear. Slitter will move. Inching. Return to the previous page. 6.3 Paper jam ① Enter settings screen, press << , >... -

Page 48: Error Messages

AeroCut X OPERATION MANUAL 7 Error messages Code Screen What to do Cover Open error Safety cover might be open. Make sure to close the Safety cover closed. Cut Paper Jammed error 1 Paper remains inside the machine. Remove the paper. - Page 49 AeroCut X OPERATION MANUAL Overload error 1 Cutting or creasing did not complete within a set time period. Remove the paper remaining inside the machine. Trailing edge error Correct the trailing edge to fit in the value specified below. Cut-mark error Cut-mark was unable to be detected.

- Page 50 AeroCut X OPERATION MANUAL Cut piece number error Correct the number of cut pieces to be in the value range below. The maximum number of pieces is subject to change depending on the operation. Guillotine error The cutter blade has moved and is staying at lower position.

- Page 51 AeroCut X OPERATION MANUAL Cutting measurement error Correct the cutting measurement to fit in the value range below. The maximum value is subject to change depending on the entered paper size. Communication error Communication with the touch panel is not possible.

- Page 52 AeroCut X OPERATION MANUAL FLEX MODE input error 4 Back margin error. Correct the back margin to fit in the value specified below. Barcode error1 Barcode was unable to be detected. Check the barcode. Barcode error2 A wrong barcode was detected.

- Page 53 AeroCut X OPERATION MANUAL Wrong job data error This job data cannot be processed. Check the job data. Back margin warning When the trailing edge is 1.000” or longer, it may cause troubles. ― Perforation location warning Correct the perforation location to fit in the value range below.

-

Page 54: Troubleshooting

AeroCut X OPERATION MANUAL 8 Troubleshooting ① Papers are not fed well. ・ Turn up Upper suction. ・ Shorten the PAPER FEED WORK TIME. i.e. less than 1.0 ・ Check if the paper guides on the feed table hold sheets too tight. -

Page 55: Product Specifications

AeroCut X OPERATION MANUAL 9 Product specifications Specifications Slitter 4 sets (6 slitter blades) Guillotine 1 set Creser 1 set Y perforator 2 set(Depends on configuration) Maximum paper size 14.60” x 29.53” Minimum paper size 8.25” x 8.25” Minimum work size 2.165”... - Page 56 If this “Operation Manual” is stained or lost, make contact with the distributor or our salesman or customer service section to ask for a new operation manual after making sure of its contents. When ordering consumables or parts, be sure to specify the machine model. UCHIDA YOKO CO., LTD., TOKYO, JAPAN...

Need help?

Do you have a question about the AeroCut X and is the answer not in the manual?

Questions and answers