Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Data Translation DT300 Series

- Page 1 Title Page UM-16501-T DT300 Series User’s Manual...

- Page 2 Information furnished by Data Translation, Inc. is believed to be accurate and reliable; however, no responsibility is assumed by Data Translation, Inc. for its use; nor for any infringements of patents or other rights of third parties which may result from its use.

- Page 3 Changes or modifications to this equipment not expressly approved by Data Translation could void your authority to operate the equipment under Part 15 of the FCC Rules.

-

Page 5: Table Of Contents

Table of Contents Table of Contents About this Manual ........... . . 11 Intended Audience. - Page 6 Connecting Pulse Output Signals ......... . . 56 Chapter 5: Verifying the Operation of a DT300 Series Board ....59 Running the Quick DataAcq Application.

- Page 7 Contents Internal A/D Sample Clock ..........76 External A/D Sample Clock .

- Page 8 Contents Chapter 7: Supported Device Driver Capabilities......107 Data Flow and Operation Options..........109 Buffering .

- Page 9 Connector J1 on the DT300 Series Board........

- Page 10 Contents...

-

Page 11: About This Manual

It describes how to wire signals to the board and how to verify the board’s operation using the Quick DataAcq application. This manual also describes the features of the DT300 Series boards, the capabilities of the DT300 Series Device Driver, and how to program the DT300 Series boards using the DT-Open Layers for .NET Class Library™... -

Page 12: Conventions Used In This Manual

• Items that you select or type are shown in bold. Related Information Refer to the following documents for more information on using the DT300 Series board: • Measure Foundry Manual (UM-19298) and online help. These documents describe how to use Measure Foundry™... -

Page 13: Where To Get Help

(Revision 2.1, June 1, 1995). • Windows XP, Windows Vista, or Windows 7 documentation. Where To Get Help Should you run into problems installing or using a DT300 Series board, our Technical Support Department is available to provide technical assistance. Refer to Chapter 9... - Page 14 About this Manual...

-

Page 15: Chapter 1: Overview

Overview Features ..............Supported Software . -

Page 16: Features

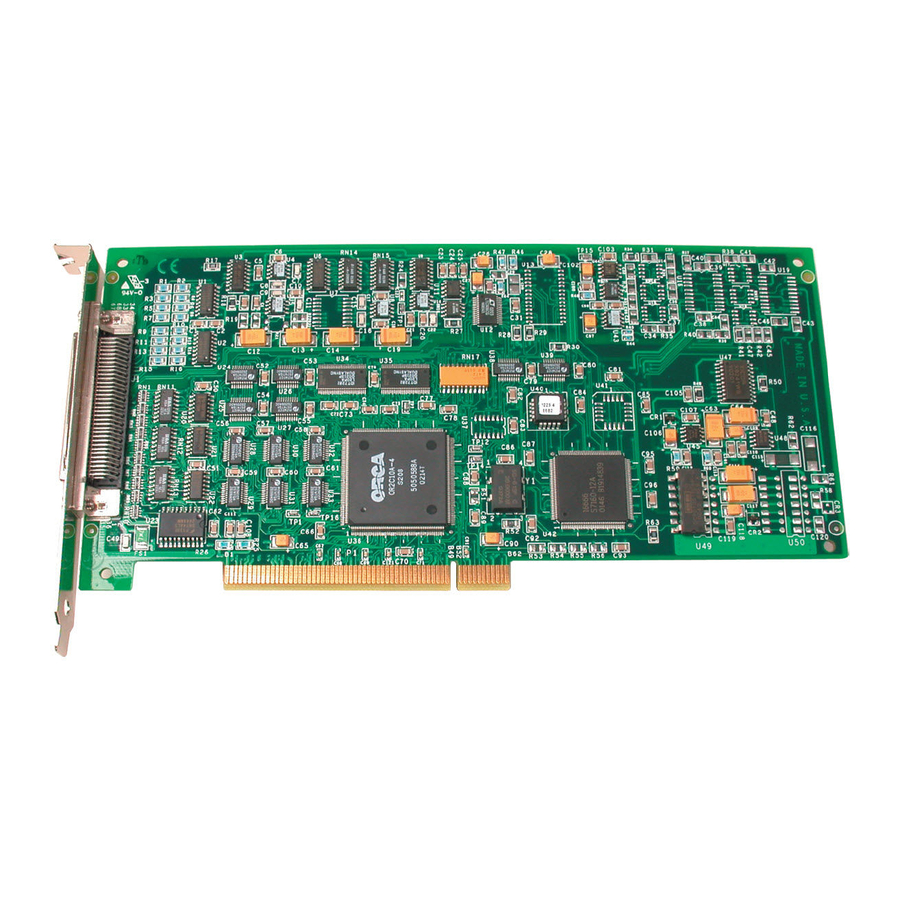

Chapter 1 Features The DT300 Series is a family of low-cost, multifunction data acquisition boards for the PCI bus. The DT300 Series consists of the following boards: DT301, DT302, DT303, DT304, DT321, and DT322. The different features of these boards are shown in... - Page 17 Overview • Four user counter/timers programmable for event counting, frequency measurement, rate generation (continuous pulse output), one-shot pulse output, and repetitive one-shot pulse output • Programmable gate types • Programmable pulse output polarities (output types) and duty cycles For a discussion of these features in detail, refer to Chapter 6 starting on page...

-

Page 18: Supported Software

Chapter 1 Supported Software The following software is available for use with the DT300 Series board and is shipped on the Data Acquisition OMNI CD: • DT300 Series Device Driver – The device driver is installed automatically when you install the software from the Data Acquisition OMNI CD. You need the device driver to use the DT300 Series board with any of the supported software packages or utilities. -

Page 19: Accessories

• STP300 screw terminal panel – Screw terminal panel with two connectors. Connector J1 accommodates the analog and digital I/O signals from the DT300 Series board, and connector J2 allows you to connect 5B and 7B Series signal conditioning backplanes. -

Page 20: Getting Started Procedure

Chapter 1 Getting Started Procedure The flow diagram shown in Figure 1 illustrates the steps needed to get started using a DT300 Series board. This diagram is repeated in each getting started chapter; the shaded area in the diagram shows you where you are in the getting started procedure. Install the Board and Load the Device Driver (see Chapter 2 starting on page... -

Page 21: Part 1: Getting Started

Part 1: Getting Started... -

Page 23: Chapter 2: Installing The Board And Loading The Device Driver

Installing the Board and Loading the Device Driver Unpacking ..............Setting up the Computer . - Page 24 Chapter 5 starting on page Note: All DT300 Series boards are factory-calibrated and require no further adjustment prior to installation. If you are using the DT300 Series board and decide later to recalibrate it, refer to Chapter 8 starting on page 117...

-

Page 25: Unpacking

• DT300 Series data acquisition board • Data Acquisition OMNI CD If an item is missing or damaged, contact Data Translation. If you are in the United States, call the Customer Service Department at (508) 481-3700, ext 1323. An application engineer will guide you through the appropriate steps for replacing missing or damaged items. -

Page 26: Setting Up The Computer

To set up the computer, do the following: 1. Install the software from the Data Acquisition OMNI CD or Data Translation web site. Note: If you are using Windows 7, you must install the device driver before installing the board in the computer. -

Page 27: Setting Up An Expansion Slot

Installing the Board and Loading the Device Driver Setting up an Expansion Slot Once you have set up the computer, set up an expansion slot by doing the following: 1. Select a 32-bit or 64-bit PCI expansion slot. PCI slots are shorter than ISA or EISA slots and are usually white or ivory. Commonly, three PCI slots (one of which may be a shared ISA/PCI slot) are available. - Page 28 Chapter 2 Inserting the DT300 Series Board into the Computer Once you have set up an expansion slot, do the following to insert the DT300 Series board into the computer: 1. Discharge any static electricity by holding the wrapped board in one hand while placing your other hand firmly on a metal portion of the computer chassis.

-

Page 29: Loading The Device Driver

8. Open the Control Panel. 9. Double-click the Open Layers Control Panel icon. 10. Select the DT300 Series board to configure, and then click Advanced. By default, the prompt “Handles Overloaded Bus?” is checked. 11. If you are using an Optiplex computer or experience timing problems with your DT300 Series board, uncheck this box. -

Page 30: Windows 7

4. Open the Control Panel. 5. Double-click the Open Layers Control Panel icon. 6. Select the DT300 Series board to configure, and then click Advanced. By default, the prompt “Handles Overloaded Bus?” is checked. 7. If you are using an Optiplex computer or experience timing problems with your DT300 Series board, uncheck this box. -

Page 31: Chapter 3: Attaching And Configuring A Screw Terminal Panel/ Backplane

Attaching and Configuring a Screw Terminal Panel/ Backplane Using an STP300 Screw Terminal Panel ......... . Using an STP68 or STP68-DIN Screw Terminal Panel . - Page 32 Chapter 3 Install the Board and Load the Device Driver (see page Attach and Configure a Screw Terminal Panel and Signal Conditioning Backplane (this chapter) Wire Signals (see page Verify the Operation of the Board (see page...

-

Page 33: Using An Stp300 Screw Terminal Panel

STP300 screw terminal panel for use with a DT300 Series board. Attaching an STP300 Screw Terminal Panel To attach an STP300 screw terminal panel to the DT300 Series board, you need the EP305 or equivalent cable. The STP300 screw terminal panel and the EP305 cable are offered by Data Translation as accessories to the DT300 Series boards. -

Page 34: Configuring Jumpers On The Stp300

Chapter 3 J1, 68-Pin Connector Counter/Timers R8 to R1 Spare Jumpers R16 to R8 Counter/Timers Clk & Trig Pwr Gnd +5 V Analog Inputs Digital I/O Analog Outputs Gnd Amp Low Digital I/O J2, 26-Pin Connector Figure 4: Layout of the STP300 Screw Terminal Panel Note: The STP300 panel is designed to fit inside a standard 4-inch by 8-inch plastic enclosure. -

Page 35: Configuring Jumper W1 - Common Ground Sense

5B01 or 7BP16-1 signal conditioning backplane. Install jumpers W4 and W5 to connect DAC0 from the DT300 Series board to channel 14 on the 5B01 or 7BP16-1 backplane. Jumper W4 connects DAC0 to channel 14; jumper W5 connects DAC0’s return. -

Page 36: Configuring Resistors On The Stp300

Chapter 3 Configuring Resistors on the STP300 Locations are provided on the STP300 screw terminal panel for installing bias return and current shunt resistors. The following subsections describe how to configure these resistors. Configuring Resistors R1 to R8 - Bias Return Resistor locations R1 to R8 connect the low side of analog input channels to analog ground. -

Page 37: Using An Stp68 Or Stp68-Din Screw Terminal Panel

Attaching and Configuring a Screw Terminal Panel/ Backplane Using an STP68 or STP68-DIN Screw Terminal Panel To attach the STP68 or STP68-DIN screw terminal panel to the DT300 Series board, you need the EP305 or equivalent cable. The STP68, STP68-DIN, and the EP305 are offered by Data Translation as accessories to the DT300 Series boards. -

Page 38: Using 5B And 7B Series Signal Conditioning Backplanes

5B Series signal conditioning modules, AC1315 cable, and the PWR-977 power supply are offered by Data Translation as accessories to the DT300 Series boards. To attach a 5B01 or 5B08 backplane to the STP300 screw terminal panel, do the following: 1. -

Page 39: Considerations When Using 5B Or 7B Series Accessories

Ensure that you select an input range that matches the output of the 5B or 7B modules that you are using. For example, if you are using 5B modules that have an output of ±5 V, use a bipolar input range and a gain of 2 on the DT300 Series board. - Page 40 Chapter 3 • Connect all unused inputs to analog common. Reading an open channel can cause settling problems on the next valid channel. • Refer to the user’s manuals and data sheets for the 5B and 7B Series for more information.

-

Page 41: Chapter 4: Wiring Signals

Wiring Signals Before Wiring ..............Connecting Analog Input Signals . - Page 42 Chapter 4 Install the Board and Load the Device Driver (see Chapter 2 starting on page Attach and Configure a Screw Terminal Panel and Signal Conditioning Backplane (see Chapter 3 starting on page Wire Signals (this chapter) Verify the Operation of the Board (see Chapter 5 starting on page This chapter describes how to wire signals to the STP300 screw terminal panel.

-

Page 43: Before Wiring

With the connector held up, the screw terminals on the right side of the STP300 match pins 23 to 34 and pins 57 to 68 of the standard 68-pin connector on the DT300 Series boards; these screw terminals represent the analog I/O signal connections. The remaining screw terminals are located on the left side of the STP300 screw terminal panel and are provided for the digital I/O, counter/timer, and +5 V power signals. -

Page 44: Analog Input Screw Terminals

Chapter 4 Analog Input Screw Terminals Table 2 lists the screw terminal (TB) assignments for analog input connections on the STP300 screw terminal panel. The corresponding resistors and their use are also listed. Table 2: Analog Input Screw Terminal Assignments on the STP300 Resistor Use Bias Return Current Shunt... -

Page 45: Analog Output And Power Screw Terminals

Wiring Signals Analog Output and Power Screw Terminals Table 3 lists the screw terminal (TB) assignments for analog output and power connections on the STP300 screw terminal panel. Table 3: Analog Output and Power Screw Terminal Assignments on the STP300 J1 Pin Description DAC0 Output... - Page 46 Chapter 4 Table 4: Counter/Timer and Digital I/O Screw Terminal Assignments on the STP300 (cont.) J1 Pin Description J1 Pin Description Digital Ground Digital I/O Port B, Line 5 User Clock Input 3 Digital I/O Port B, Line 6 User Counter Output 3 Digital I/O Port B, Line 7 External Gate 3 Digital I/O Port C, Line 0...

-

Page 47: Connecting Analog Input Signals

Wiring Signals Connecting Analog Input Signals The STP300 screw terminal panel supports both voltage and current loop inputs. You can connect analog input voltage signals to the STP300 in the following configurations: • Single-ended – Choose this configuration when you want to measure high-level signals, when noise is not significant, when the source of the input is close to the STP300 screw terminal panel, and when all the input signals are referred to the same common ground. -

Page 48: Connecting Pseudo-Differential Voltage Inputs

Chapter 4 STP300 Panel Jumper W1 Signal Installed Source TB17 (Amp Low) TB18 Analog In 0 source Analog In 8 Analog In 1 source source Analog Ground Figure 8: Connecting Single-Ended Voltage Inputs (Shown for Channels 0, 1, and 8) Connecting Pseudo-Differential Voltage Inputs Figure 9 shows how to connect pseudo-differential voltage inputs (channels 0, 1, and 8, in this... -

Page 49: Connecting Differential Voltage Inputs

Wiring Signals Connecting Differential Voltage Inputs Figure 10A illustrates how to connect a floating signal source to the STP300 screw terminal panel using differential inputs. (A floating signal source is a voltage source that has no connection with earth ground.) You need to provide a bias return path by adding resistors R1 to R8 for channels 0 to 7, respectively, for floating signal sources. -

Page 50: Connecting Current Loop Inputs

Chapter 4 Note that since they measure the difference between the signals at the high (+) and low (− ) inputs, differential connections usually cancel any common-mode voltages, leaving only the signal. However, if you are using a grounded signal source and ground loop problems arise, connect the differential signals to the STP300 screw terminal panel as shown in Figure 11. -

Page 51: Connecting Analog Output Signals

(Shown for Channel 0) If you do not connect the Analog Output Reference to TB21, the board provides an internal +10 V reference, as shown in Figure DT300 Series Board STP300 Panel Analog Output 0 TB19 Analog Output 0 Return... -

Page 52: Connecting Digital I/O Signals

Chapter 4 Connecting Digital I/O Signals Figure 15 shows how to connect digital input signals (lines 0 and 1 of digital Port A, in this case) to the STP300 screw terminal panel. STP300 Panel Digital I/O Port A, Line 0 TB49 TB50 TTL Inputs... -

Page 53: Connecting Counter/Timer Signals

Wiring Signals Connecting Counter/Timer Signals The DT300 Series board and STP300 screw terminal panel provide counter/timer channels that you can use to perform the following operations: • Event counting • Frequency measurement • Pulse output (rate generation, one-shot, and repetitive one-shot) This section describes how to connect counter/timer signals to perform these operations. - Page 54 Chapter 4 STP300 Panel Digital Ground TB25 TB26 Signal Source User Clock Input 0 Figure 18: Connecting Event Counting Signals without an External Gate Input (Shown for Clock Input 0) Figure 19 shows an example of how to cascade two counters externally to perform an event counting operation using user counters 0 and 1.

-

Page 55: Connecting Frequency Measurement Signals

Wiring Signals Connecting Frequency Measurement Signals This section describes two examples of how to connect frequency measurement signals to the STP300 screw terminal panel. The first configuration uses the same wiring as an event counting application that does not use an external gate signal (see Figure 18 page 54);... -

Page 56: Connecting Pulse Output Signals

Chapter 4 Connecting Pulse Output Signals Figure 21 shows one example of connecting pulse output signals to the STP300 screw terminal panel using user counter 0. STP300 Panel Digital Ground TB25 TB27 TB28 Heater TB29 Controller User Counter Output 0 External Gate 0 Gating... - Page 57 Wiring Signals STP300 Panel User Digital Ground TB25 Counter TB26 Output 0 TB27 TB28 Signal Source TB29 User Clock Input 0 TB30 User Clock Input 1 External Gating Switch Gate 0 Digital Ground Figure 22: Cascading Counters (Shown for Rate Generation Using Counters 0 and 1 and External Gate 0) Figure 23 shows an example of how to cascade two counters externally to perform a one-shot...

- Page 58 Chapter 4...

-

Page 59: Chapter 5: Verifying The Operation Of A Dt300 Series Board

Verifying the Operation of a DT300 Series Board Running the Quick DataAcq Application......... - Page 60 Verify the Operation of the Board (this chapter) You can verify the operation of a DT300 Series board using the Quick DataAcq application. Quick DataAcq allows you to do the following: • Acquire data from a single analog input channel or digital input port •...

-

Page 61: Running The Quick Dataacq Application

For information on each of the features provided, use the online help for the Quick DataAcq application by pressing F1 from any view or selecting the Help menu. If the system has trouble finding the help file, navigate to C:\Program Files\Data Translation\Win32\ dtdataacq.hlp, where C: is the letter of your hard disk drive. -

Page 62: Testing Single-Value Analog Input

2. In the Quick DataAcq application, choose Single Analog Input from the Acquisition menu. 3. Select the appropriate DT300 Series board from the Board list box. 4. In the Channel list box, select analog input channel 0. 5. In the Range list box, select the range for the channel. -

Page 63: Testing Single-Value Analog Output

2. In the Quick DataAcq application, choose Single Analog Output from the Control menu. 3. Select the appropriate DT300 Series board from the Board list box. 4. In the Channel list box, select analog output channel 0. -

Page 64: Testing Continuous Analog Input

To verify that the board can perform a continuous analog input operation, do the following: 1. Connect known voltage sources, such as the outputs of a function generator, to analog input channels 0 and 1 on the DT300 Series board (using the differential configuration). Refer to page 49 for an example of how to connect a differential analog input. -

Page 65: Testing Single-Value Digital Input

Testing Single-Value Digital Input To verify that the board can read a single digital input value, do the following: 1. Connect a digital input to digital input line 0 of port A on the DT300 Series board. Refer to page 52 for an example of how to connect a digital input. -

Page 66: Testing Single-Value Digital Output

Testing Single-Value Digital Output To verify that the board can output a single digital output value, do the following: 1. Connect a digital output to digital output line 0 of port B on the DT300 Series board. Refer page 52 for an example of how to connect a digital output. -

Page 67: Testing Frequency Measurement

Testing Frequency Measurement To verify that the board can perform a frequency measurement operation, do the following: 1. Wire an external clock source to counter/timer 0 on the DT300 Series board. Refer to page for an example of how to connect a an external clock for a frequency measurement operation. -

Page 68: Testing Pulse Output

Chapter 5 Testing Pulse Output To verify that the board can perform a pulse output operation, do the following: 1. Connect a scope to counter/timer 0 on the DT300 Series board. Refer to page 56 for an example of how to connect a scope (a pulse output) to counter/timer 0. -

Page 69: Part 2: Using Your Board

Part 2: Using Your Board... -

Page 71: Chapter 6: Principles Of Operation

Principles of Operation Analog Input Features ............Analog Output Features . - Page 72 Chapter 6 This chapter describes the analog input, analog output, digital I/O, and counter/timer features of the DT300 Series board. To frame the discussions, refer to the block diagram shown Figure 24. Note that bold entries indicate signals you can access.

-

Page 73: Analog Input Features

• Error conditions Input Resolution Table 5 lists the input resolutions supported by the DT300 Series boards. The resolution is fixed for each board type; therefore, it cannot be programmed in software. Table 5: Supported Analog Input Resolutions Board Type... -

Page 74: Specifying A Single Channel

Chapter 6 The DT300 Series board can acquire data from a single analog input channel or from a group of analog input channels. Onboard channels are numbered 0 to 15 for single-ended and pseudo-differential inputs or 0 to 7 for differential inputs. The following subsections describe how to specify the channels. -

Page 75: Input Ranges And Gains

Through software, specify the range for the subsystem as 0 to 10 V for unipolar signals or − 10 V to +10 V for bipolar signals. DT300 Series boards provide gains of 1, 2, 4, and 8, which are programmable per channel. Table 6 lists the effective ranges supported by the DT300 Series board using these gains. -

Page 76: Specifying The Gain For One Or More Channels

Chapter 6 Specifying the Gain for One or More Channels For DT300 Series boards, you can use software to specify the gain for each analog input channel entry in the analog input channel list. Note: For analog input channel 16 (the 16 digital I/O lines) in the channel list, specify a gain of 1 for the channel entry. -

Page 77: External A/D Sample Clock

Single-value operations stop automatically when finished; you cannot stop a single-value operation. • Scan mode takes full advantage of the capabilities of the DT300 Series boards. In a scan, you can specify a channel list, clock source, trigger source, trigger acquisition mode, scan mode, and buffer using software. -

Page 78: Continuously-Paced Scan Mode

(256 times per trigger x 1024-location channel list). When it detects an initial trigger, the DT300 Series board scans the channel list a specified number of times (up to 256), then waits for an software retrigger to occur. When it detects the software retrigger, the board scans the channel list the specified number of times, then waits for another software retrigger to occur. - Page 79 Using software, specify the frequency of the software retrigger. The minimum retrigger frequency is 1.2 Hz (1.2 Samples/s). Table 8 lists the maximum retrigger frequency supported by the DT300 Series boards. Table 8: Maximum Retrigger Frequency Maximum Board Retrigger Frequency...

-

Page 80: Externally-Retriggered Scan Mode

• The number of times to scan per trigger or retrigger (also called the multiscan count). Triggers A trigger is an event that occurs based on a specified set of conditions. The DT300 Series boards support a number of trigger sources and trigger acquisition modes, described in the following subsections. -

Page 81: Trigger Acquisition Modes

Principles of Operation An external digital trigger event occurs when the DT300 Series board detects either a rising (positive) or falling (negative) edge on the External TTL Trigger input signal connected to screw terminal TB46 on the STP300 screw terminal panel (pin 56 of connector J1). The trigger signal is TTL-compatible. -

Page 82: Pre-Trigger Acquisition

Chapter 6 Figure 26 illustrates the same example using triggered scan mode (either internally or externally retriggered). The multiscan count is 2, indicating that the channel list will be scanned twice per trigger or retrigger. In this example, post-trigger analog input data is acquired on each clock pulse of the A/D sample clock until the channel list has been scanned twice;... - Page 83 Principles of Operation If you are using software-retriggered scan mode and the post-trigger event has not occurred, the board continues to acquire pre-trigger data using the software retrigger clock to clock the operation. When the post-trigger event occurs, acquisition stops. Refer to page 78 for more information on software-retriggered scan mode.

-

Page 84: About-Trigger Acquisition

Chapter 6 About-Trigger Acquisition Use about-trigger acquisition mode when you want to acquire data both before and after a specific external event occurs. This operation is equivalent to doing both a pre-trigger and a post-trigger acquisition. Using software, specify • The dataflow as ContinuousPrePostTrigger. •... - Page 85 Principles of Operation Chan 0 Chan 0 Chan 0 Chan 0 Chan 0 Chan 0 Chan 1 Chan 1 Chan 1 Chan 1 Chan 1 Chan 1 . . . Sample Clock Pre-trigger data acquired Post-trigger data acquired Pre-trigger event occurs Post-trigger event Figure 29: Continuous About-Trigger Mode Figure 30...

-

Page 86: Data Format

• LSB is the least significant bit. • FSR is the full-scale range. For the DT300 Series, the full-scale range is 10 for the unipolar range or 20 for the bipolar range. Note: DT321 and DT322 boards support bipolar signals only. -

Page 87: Data Transfer

The host software ignores the extra sample. The DT300 Series Device Driver accesses the hardware circular buffer to fill user buffers that you allocate in software. It is recommended that you allocate a minimum of two buffers for analog input operations and add them to the subsystem queue using software. - Page 88 Chapter 6 • Input FIFO Overflow – Indicates that the analog input data is not being transferred fast enough from the Input FIFO across the PCI bus to the host computer. This error is reported when the Input FIFO becomes full; the board cannot get access to the PCI bus fast enough.

-

Page 89: Analog Output Features

Both DACs power up to a value of 0 V ±10 mV. Resetting the board does not clear the values in the DACs. The DT300 Series board can output data from a single analog output channel only. Specify the channel for a single-value analog output operation using software; refer to “Conversion... -

Page 90: Conversion Modes

• LSB is the least significant bit. • FSR is the full-scale range. For the DT300 Series, the full-scale analog output range is 5 for the unipolar range of 0 to 5 V; 10 for the unipolar range of 0 to 10 V or the bipolar output range of ±5 V;... - Page 91 Principles of Operation Similarly, assume that you are using a DT322 board with a bipolar output range of ±10 V. The minus full-scale value is − 10 V. If you want to output a voltage of 4.7 V, determine the code value as follows: LSB = = 0.000305 V...

-

Page 92: Digital I/O Features

• Digital I/O operation modes Digital I/O Lines DT300 Series boards support 23 digital I/O lines through the digital input (DIN) and output (DOUT) subsystems; DIN and DOUT subsystems use the same digital I/O lines. These lines are divided into the following ports: •... -

Page 93: Digital I/O Operation Modes

Single-value operations stop automatically when finished; you cannot stop a single-value operation. • Continuous digital input takes full advantage of the capabilities of the DT300 Series board. In this mode, enter all 16 digital input lines of Ports A and B as channel 16 of the analog input channel list;... -

Page 94: Counter/Timer Features

• Counter/timer operation modes Counter/Timer Channels The DT300 Series board supports four user 16-bit counter/timer channels (called counters); counters are numbered 0, 1, 2, and 3. Each counter accepts a clock input signal and gate input signal and outputs a clock output... -

Page 95: C/T Clock Sources

Principles of Operation C/T Clock Sources The following clock sources are available for the user counters: • Internal C/T clock • External C/T clock • Internally cascaded clock Refer to the following subsections for more information on these clock sources. Internal C/T Clock The internal C/T clock uses a 20 MHz time base. -

Page 96: Internally Cascaded Clock

Chapter 6 Internally Cascaded Clock The DT300 Series board supports internal cascading on counters 0 and 1, 1 and 2, and 2 and 3. Cascading counters internally is an effective way to create a 32-bit counter without externally connecting two counters together. -

Page 97: Pulse Outputs

• For Counter 3, the external C/T output signal is screw terminal TB39 (pin 3 of connector The DT300 Series board supports the following pulse output types on the clock output signal: • High-to-low transitions – The low portion of the total pulse output period is the active portion of the counter/timer clock output signal. -

Page 98: Event Counting

Chapter 6 Refer to the following subsections for more information on these operation modes. Event Counting Use event counting mode to count events from the counter’s associated clock input source. If you are using one counter, the board can count a maximum of 65,536 events before the counter rolls over to 0 and starts counting again. -

Page 99: Frequency Measurement

Principles of Operation Figure 34 shows an example of performing an event counting operation. In this example, the gate type is low level. high level disables operation Gate Input low level Signal 0 enables operation External C/T Clock 0 Input Signal 3 events are counted while the operation is enabled event counting... - Page 100 Chapter 6 In this configuration, use software to specify the counter/timer mode as frequency measurement or event counting, and the duration of the Windows timer over which to measure the frequency. (The Windows timer uses a resolution of 1 ms.) In this configuration, frequency is determined using the following equation: Frequency Measurement = Number of Events...

-

Page 101: Rate Generation

Principles of Operation Figure 37 shows an example of performing a frequency measurement operation. In this example, three events are counted during a duration of 300 ms. The frequency, then, is 10 Hz, since 10 Hz = 3/(.3 s). 3 Events Counted External C/T Clock Input Signal... - Page 102 Chapter 6 Digital Ground TB25 TB26 TB27 Signal Source TB29 User Counter Input 0 STP300 Panel User Counter Output 0 Heater Controller Digital Ground Figure 38: Connecting Rate Generation SIgnals (Shown for Counter 0; a Software Gate Is Used) Figure 39 shows an example of performing an enabled rate generation operation using an external C/T clock source with an input frequency of 4 kHz, a clock divider of 4, a low-to-high pulse type, and a duty cycle of 75%.

-

Page 103: One-Shot

Principles of Operation Continuous Pulse Output Operation Starts External C/T Clock Input Signal (4 kHz) Pulse Output 25% duty cycle Signal Figure 40: Example of Rate Generation Mode with a 25% Duty Cycle One-Shot Use one-shot mode to generate a single pulse output signal from the counter when the operation is triggered (determined by the gate input signal). - Page 104 Chapter 6 Digital Ground TB25 TB27 TB28 Heater TB29 Controller User Counter Output 0 STP300 Panel External Gate 0 Gating Switch Digital Ground Figure 41: Connecting One-Shot Signals (Shown for Counter Output 0 and Gate 0) Figure 42 shows an example of performing a one-shot operation using an external gate input (rising edge), a clock output frequency of 1 kHz (pulse period of 1 ms), and a low-to-high pulse type.

-

Page 105: Repetitive One-Shot

Principles of Operation Repetitive One-Shot Use repetitive one-shot mode to generate a pulse output signal each time the board detects a trigger (determined by the gate input signal). You can use this mode to clean up a poor clock input signal by changing its pulse width, then outputting it. When the one-shot operation is triggered (determined by the gate input signal), a pulse is output. - Page 106 Chapter 6...

-

Page 107: Chapter 7: Supported Device Driver Capabilities

Supported Device Driver Capabilities Data Flow and Operation Options..........Buffering . - Page 108 The tables in this chapter summarize the features available for use with the DT-Open Layers for .NET Class Library and the DT300 Series boards. The DT-Open Layers for .NET Class Library provides properties that return support information for specified subsystem capabilities.

-

Page 109: Data Flow And Operation Options

Supported Device Driver Capabilities Data Flow and Operation Options Table 11: DT300 Series Data Flow and Operation Options DT300 Series DOUT QUAD Single-Value Operation Support SupportsSingleValue Simultaneous Single-Value Output Operations SupportsSetSingleValues Continuous Operation Support SupportsContinuous Continuous Operation until Trigger SupportsContinuousPreTrigger Continuous Operation before &... -

Page 110: Buffering

Buffer Support SupportsBuffering Single Buffer Wrap Mode Support SupportsWrapSingle Inprocess Buffer Flush Support SupportsInProcessFlush Triggered Scan Mode Table 13: DT300 Series Triggered Scan Mode Options DT300 Series DOUT QUAD Triggered Scan Support SupportsTriggeredScan Maximum Number of CGL Scans per Trigger... -

Page 111: Channels

Supported Device Driver Capabilities Channels Table 15: DT300 Series Channel Options DT300 Series DOUT QUAD Number of Channels NumberOfChannels SE Support SupportsSingleEnded SE Channels MaxSingleEndedChannels DI Support SupportsDifferential DI Channels MaxDifferentialChannels Maximum Channel-Gain List Depth CGLDepth 1024 Simultaneous Sample-and-Hold Support... -

Page 112: Ranges

Chapter 7 Ranges Table 17: DT300 Series Range Options DT300 Series DOUT QUAD Number of Voltage Ranges NumberOfRanges 1 or 2 4 or 1 Available Ranges ±10 V, 0 to 10 V, SupportedVoltageRanges ±10 V, 0 to 10 V ±5 V, or 0 to 5 V... -

Page 113: Thermocouple And Rtd Support

Supported Device Driver Capabilities Thermocouple and RTD Support Table 19: DT300 Series Thermocouple and RTD Support Options DT300 Series DIN DOUT C/T QUAD Thermocouple Support SupportsThermocouple RTD Support SupportsRTD Resistance Support ReturnsOhms Voltage Converted to Temperature in Hardware SupportsTemperatureDataInStream Supported Thermocouple Types... -

Page 114: Triggers

Chapter 7 Triggers Table 21: DT300 Series Trigger Options DT300 Series DOUT QUAD Software Trigger Support SupportsSoftwareTrigger External Positive TTL Trigger Support SupportsPosExternalTTLTrigger External Negative TTL Trigger Support SupportsNegExternalTTLTrigger External Positive TTL Trigger Support for Single-Value Operations SupportsSvPosExternalTTLTrigger External Negative TTL Trigger Support... -

Page 115: Clocks

Supported Device Driver Capabilities Clocks Table 22: DT300 Series Clock Options DT300 Series DOUT QUAD Internal Clock Support SupportsInternalClock External Clock Support SupportsExternalClock Simultaneous Input/Output on a Single Clock Signal SupportsSimultaneousClocking Base Clock Frequency BaseClockFrequency 20 MHz 0 20 MHz... -

Page 116: Counter/Timers

Chapter 7 Counter/Timers Table 23: DT300 Series Counter/Timer Options DT300 Series DOUT QUAD Cascading Support SupportsCascading Event Count Mode Support SupportsCount Generate Rate Mode Support SupportsRateGenerate One-Shot Mode Support SupportsOneShot Repetitive One-Shot Mode Support SupportsOneShotRepeat Up/Down Counting Mode Support SupportsUpDown... -

Page 117: Chapter 8: Calibration

Calibration Running the Calibration Utility ..........Calibrating the Analog Input Subsystem . - Page 118 We recommend that you check and, if necessary, readjust the calibration of the analog I/O circuitry on the DT300 Series boards every six months. Note: Ensure that you installed the DT300 Series Device Driver and prior to using the DT300 Series Calibration Utility.

-

Page 119: Running The Calibration Utility

1. Click Start from the Task Bar. 2. Browse to Programs|Data Translation, Inc| Calibration|DT300 Calibration Utility. The main menu appears. Once the DT300 Series Calibration Utility is running, you can calibrate the analog I/O circuitry, as described in the following sections. -

Page 120: Calibrating The Analog Input Subsystem

1. From the main menu of the DT300 Series Calibration Utility, click Configure, and then Board. 2. Select the name of the DT300 Series board to configure from the combo box, and then click 3. From the main menu of the DT300 Series Calibration Utility, click Calibrate, and then A/D. -

Page 121: Using The Manual Calibration Procedure

1. From the main menu of the DT300 Series Calibration Utility, click Configure, and then Board. 2. Select the name of the DT300 Series board to configure from the combo box, and then click 3. From the main menu of the DT300 Series Calibration Utility, click Calibrate. - Page 122 Chapter 8 Note: Calibrating the PGH Zero setting in software is no longer required; the hardware calibrates this setting automatically. If you are not satisfied with the analog input calibration, you can load the factory default settings stored in the EEPROM by clicking Restore in the Factory Settings box.

-

Page 123: Calibrating The Analog Output Subsystem

1. From the main menu of the DT300 Series Calibration Utility, click Configure, and then Board. 2. Select the name of the DT300 Series board to configure from the combo box, and then click 3. From the main menu of the DT300 Series Calibration Utility, click Calibrate. - Page 124 Chapter 8...

-

Page 125: Chapter 9: Troubleshooting

Troubleshooting General Checklist ............Technical Support . -

Page 126: General Checklist

5. Check that you have loaded the device driver properly using the instructions in Chapter 6. Search the DT Knowledgebase in the Support section of the Data Translation web site (at www.datatranslation.com) for an answer to your problem. If you still experience problems, try using the information in Table... - Page 127 Possible Solution Computer does Board is not seated properly. Check that the slot in which your DT300 Series board not boot. is located is a PCI slot, that the board is correctly seated in the slot, and that the board is secured in the slot with a screw.

-

Page 128: Technical Support

Chapter 9 Technical Support If you have difficulty using a DT300 Series board, Data Translation’s Technical Support Department is available to provide technical assistance. To request technical support, go to our web site at http://www.datatranslation.com and click on the Support link. -

Page 129: If Your Board Needs Factory Service

Troubleshooting If Your Board Needs Factory Service If your board must be returned to Data Translation, do the following: 1. Record the board’s serial number, and then contact the Customer Service Department at (508) 481-3700, ext. 1323 (if you are in the USA) and obtain a Return Material Authorization (RMA). - Page 130 Chapter 9...

-

Page 131: Appendix A: Specifications

Specifications Analog Input Specifications ........... Analog Output Specifications. -

Page 132: Analog Input Specifications

Appendix A Analog Input Specifications Table 25 lists the specifications for the A/D subsystem. Table 25: A/D Subsystem Specifications DT301/302 DT303/304 DT321/322 Feature Specifications Specifications Specifications Number of analog inputs Single-ended/ pseudo-differential: Differential: Number of gains 4 (1, 2, 4, 8) Resolution 12 bits 12 bits... - Page 133 Specifications Table 25: A/D Subsystem Specifications (cont.) DT301/302 DT303/304 DT321/322 Feature Specifications Specifications Specifications ±40.0 μV Channel-to-channel offset 3 μs 1 μs 1 μs Channel acquisition time 4.4 μs 2.5 μs 4 μs A/D conversion time Effective number of bits 11.5 bits 11.5 bits 13.5 bits...

-

Page 134: Analog Output Specifications

Appendix A Analog Output Specifications Table 26 lists the specifications for the D/A subsystem. Table 26: D/A Subsystem Specifications Feature Specifications Number of analog output channels (DT302, DT304, and DT322 only) Resolution DT302, DT304: 12 bits DT322: 16 bits Data encoding (input) Offset binary Nonlinearity (integral) DT302, DT304:... -

Page 135: Digital I/O Specifications

Specifications Digital I/O Specifications Table 27 lists the specifications for the DIN/DOUT subsystems. Table 27: DIN/DOUT Subsystem Specifications Port A Port B Port C Feature Specifications Specifications Specifications Number of lines 8 (bidirectional) 8 (bidirectional) 7 (bidirectional) 47 kΩ resistor pullup to +3.3 V; 33 Ω series resistor Termination Inputs Input type:... -

Page 136: Counter/Timer Specifications

Appendix A Counter/Timer Specifications Table 28 lists the specifications for the C/T subsystems. Table 28: C/T Subsystem Specifications Feature Specifications Number of counter/timer channels Clock Inputs Input type: Schmitt trigger, rising-edge sensitive Input load: 1 HCT14 (TTL) High-level input voltage: 2.0 V minimum Low-level input voltage: 0.8 V maximum... -

Page 137: Power, Physical, And Environmental Specifications

Specifications Power, Physical, and Environmental Specifications Table 29 lists the power, physical, and environmental specifications for the DT300 Series board. Table 29: Power, Physical, and Environmental Specifications Feature Specifications Power +5 V (±0.25 V): 1.2 A nominal − 5 V:... -

Page 138: Connector Specifications

Appendix A Connector Specifications Table 30 lists the connector specifications for the DT300 Series board. Table 30: Connector Specifications Feature Specifications Connector part number AMP, 68-pin, 0.05 Subminiature D, #749621-7 Shielded enclosure with jack screws AMP #750752-1 Recommended shielded cable... -

Page 139: Screw Terminal Panel Specifications

Specifications Screw Terminal Panel Specifications Table 31 lists the specifications for the STP300 screw terminal panel. Table 31: STP300 Specifications Feature Specifications Mechanical 68-pin connector, SCSI II (AMP/ Tyco 5787170-7) 26-pin connector (3M N2526-50K2RB) Terminal block insulator: Polyamide 6.6 GV Screw type: M 2.5 x 5, Chrome-plated steel Wire size:... -

Page 140: Cable Specifications

Appendix A Cable Specifications Table 32 lists the specifications for the cable EP305. Table 32: EP305 Cable Specifications Feature Specifications Length 2 meters Conductors 34 twisted pairs, shielded, #28 AWG on 50 mil centers Connectors (1) 68-pin, self-locking receptacle (AMP/Tyco 5749621-7) -

Page 141: Appendix B: Connector Pin Assignments

Connector Pin Assignments Connector J1 on the DT300 Series Board......... -

Page 142: Connector J1 On The Dt300 Series Board

Appendix B Connector J1 on the DT300 Series Board Table 33 lists the pin assignments of connector J1 on the DT300 Series board. Table 33: Pin Assignments for Connector J1 on the DT300 Series Boards Number Signal Description Number Signal Description... - Page 143 Connector Pin Assignments Table 33: Pin Assignments for Connector J1 on the DT300 Series Boards (cont.) Number Signal Description Number Signal Description Analog Output 0 Return Analog Output 0 DAC1 Reference DAC0 Reference Analog Input 14/6 Return Analog Input 6...

-

Page 144: Screw Terminal Assignments For Connector J1 On The Stp300

Appendix B Screw Terminal Assignments for Connector J1 on the STP300 Table 34 lists the screw terminal assignments for connector J1 on the STP300 screw terminal panel. Table 34: Pin Assignments for Connector J1 on the STP300 J1 Pin Description J1 Pin Description Analog Input 0... - Page 145 Connector Pin Assignments Table 34: Pin Assignments for Connector J1 on the STP300 (cont.) J1 Pin Description J1 Pin Description Digital I/O Port A, Line 6 Digital I/O Port A, Line 7 Digital I/O Port B, Line 0 Digital I/O Port B, Line 1 Digital I/O Port B, Line 2 Digital I/O Port B, Line 3 Digital I/O Port B, Line 4...

-

Page 146: Screw Terminal Assignments For Connector J2 On The Stp300

Appendix B Screw Terminal Assignments for Connector J2 on the STP300 Table 35 lists the screw terminal assignments for connector J2 on the STP300 screw terminal panel. Table 35: Pin Assignments for Connector J2 on the STP300 Description Description Analog Input 0 Analog Input 8 Analog Ground Analog Input 9... -

Page 147: Screw Terminal Assignments For The Stp68 And Stp68-Din

Connector Pin Assignments Screw Terminal Assignments for the STP68 and STP68-DIN Table 36 lists the screw terminal assignments for the STP68 and STP68-DIN screw terminal panel. Table 36: Screw Terminal Assignments for the STP68 and STP68-DIN Screw Terminal Panel Signal Description Signal Description +5 V Output @ 1 A User Clock Input 3... - Page 148 Appendix B Table 36: Screw Terminal Assignments for the STP68 and STP68-DIN Screw Terminal Panel (cont.) Signal Description Signal Description Digital I/O Port C, Line 2 Digital I/O Port C, Line 0 Digital Ground External A/D Trigger Analog Output 0 Return Analog Output 0 DAC1 Reference DAC0 Reference...

-

Page 149: Appendix C: Using Your Own Screw Terminal Panel

Using Your Own Screw Terminal Panel Analog Inputs ............. . . Analog Outputs . - Page 150 This appendix describes additional considerations to keep in mind when designing your own screw terminal panel for use with a DT300 Series board. Refer to Appendix B for connector and cable specifications.

-

Page 151: Analog Inputs

Using Your Own Screw Terminal Panel Analog Inputs DT300 Series boards have three different types of analog input configurations that you can use: • Single-ended • Pseudo-differential • Differential Single-Ended Inputs With single-ended inputs, you have the maximum number of inputs but have the worst-case noise immunity without external signal conditioning. -

Page 152: Differential Inputs

Appendix C Differential Inputs Differential inputs offer the maximum noise rejection at the expense of half your total channel count. For the best results, shielded twisted pairs are a must. The shield must connect at one end so that ground currents do not travel over the shield. In low-level voltage applications, differential inputs reduce problems not only due to electrostatic and magnetic noise, but due to cross-talk and thermal errors. -

Page 153: Analog Outputs

Using Your Own Screw Terminal Panel Analog Outputs The analog output channels on DT300 Series boards have a resolution of 12 or 16 bits (even though the accuracy may be less). Data Translation ensures that the analog outputs do not break into a high frequency oscillation with high capacitance loads that may be experienced with long cables. -

Page 154: Digital Inputs And Counter/Timer Inputs

Digital Inputs and Counter/Timer Inputs TTL-type inputs must have current limiting so that circuitry is not damaged when power is removed. On all Data Translation PCI boards, current limiting is used to prevent damage in this fault condition. On high-speed clock inputs, a ground that is located in the connector next to the clock must be... -

Page 155: Digital Outputs

Using Your Own Screw Terminal Panel Digital Outputs If you are using the high drive capability of any of the PCI boards, ensure that the load is returned to the digital ground provided in the connector next to the outputs. If just eight of the digital outputs are switching 16 mA per output, then 128 mA of current flows. - Page 156 Appendix C...

-

Page 157: Index

Index Index Numerics differential configuration error conditions 5B01 backplane gain attaching input ranges configuring for analog outputs pseudo-differential configuration considerations when using resolution 5B08 backplane screw terminal assignments attaching single-ended configuration considerations when using specifications 7BP04-1 backplane trigger acquisition modes attaching trigger sources considerations when using... - Page 158 AC1315 pulse output applications AC1393 single-ended analog inputs AC1393 adapter connector J1 pin assignments EP305 DT300 Series board calibration STP300 screw terminal panel analog input subsystem connector J2 pin assignments, STP300 screw analog output subsystem terminal panel running the utility...

- Page 159 DIN subsystem rate generation mode specifications repetitive one-shot mode DOUT subsystem screw terminal assignments specifications specifications DT300 Series Device Driver subsystem DT-Open Layers for .NET Class Library variable pulse width DTx-EZ when not using the STP300 duty cycle counting events...

- Page 160 A/D sample clock internal gate type internal C/T clock internal retrigger clock internal retrigger clock frequency measurement J1 connector pin assignments DT300 Series board gain STP300 screw terminal panel actual available STP68 panel analog input J2 connector pin assignments...

- Page 161 R9 to R16 resolution PCI bus master analog input physical specifications analog output pin assignments availalble DT300 Series J1 connector digital I/O STP300 screw terminal panel J1 connector number of STP300 screw terminal panel J2 connector programmable STP68 panel J1 connector retrigger...

- Page 162 Index retrigger clock frequency software packages retrigger frequency software supported retriggered scan mode software trigger externally software-retriggered scan mode software specifications returning boards to the factory analog input rising-edge gate type analog output counter/timer running the Quick DataAcq application digital I/O environmental physical power...

- Page 163 Index SupportsOneShotRepeat Visual C++ programs SupportsPosExternalTTLTrigger voltage ranges SupportsProgrammableGain number of SupportsRateGenerate SupportsSingleEnded SupportsSingleValue W1 jumper SupportsSoftwareResolution W4 to W7 jumpers SupportsSoftwareTrigger Windows 7, loading the device driver SupportsTriggeredScan Windows Vista, loading the device driver SupportsVariablePulseWidth Windows XP, loading the device driver SupportsWrapSingle wiring recommendations when using your own screw terminal panel...

- Page 164 Index...

Need help?

Do you have a question about the DT300 Series and is the answer not in the manual?

Questions and answers