Table of Contents

Advertisement

Quick Links

MECHAN CONTROLS

Installation Guide : F-SERIES Safety system

Keep this guide for future reference

This information is designed to help suitably qualified

personnel install and operate Mechan Safety equipment.

Before using this product, read this guide thoroughly along

with any relevant European and/or National standards e.g.

Machinery Directive 2006/42/EC and it's amendments,

Provision and Use of Work Equipment Regulations.

Further information can be obtained from Mechan Controls

Tel +44 (0)1695 722264

Description

The F-Series safety system is a complete electronic safety

switch and emergency stop button monitoring system for

machine guarding applications.

The control unit can monitor up to 30 inputs (F-Series

safety switches and emergency stop buttons), maintaining

CAT 4 SIL 3 and PL e.

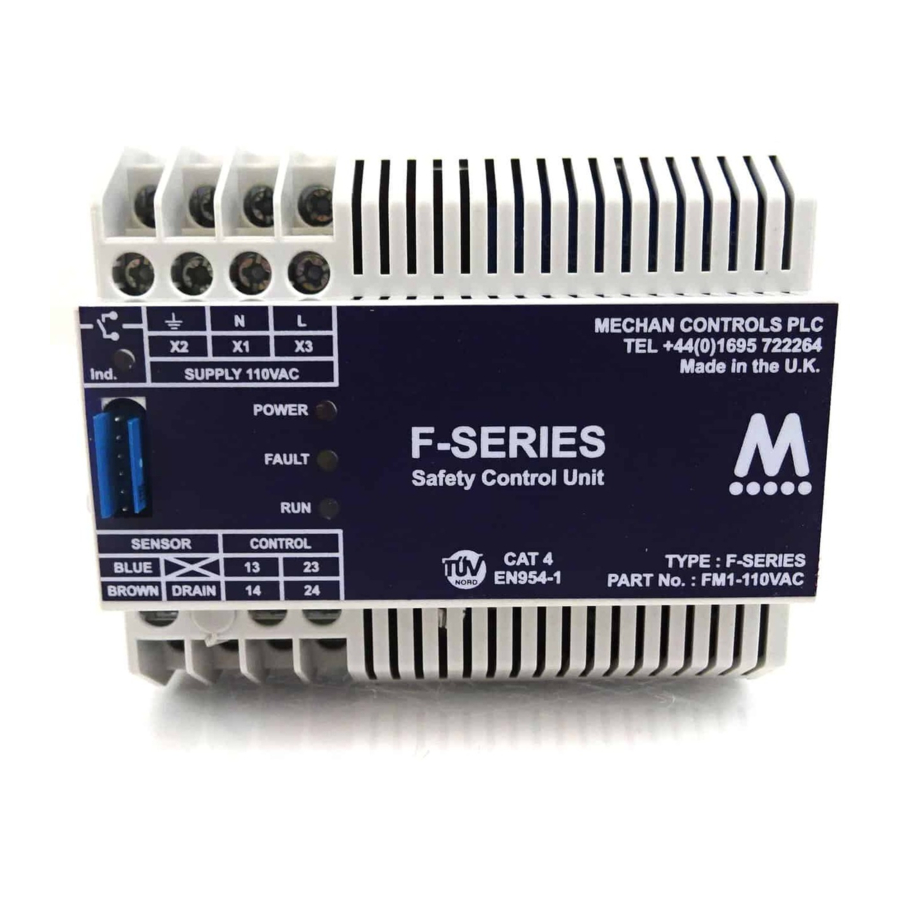

FM1 Safety Control Module contains the power supply

regulation, dual safety contact outputs, external reset/moni-

toring circuit, system & gate indication, and the input for

one safety switch sensor and it's volt free indicator output.

The FM1 and a safety switch sensor are all that is required

for a system that is monitoring one guard.

FX1/FX2 Safety Extender Modules connect to the FM1

to build systems monitoring more than 1 guard. By simply

connecting the required number of FX1's (one guard switch

input) or FX2's (two guard switch inputs) to the FM1 sys-

tems can be built to monitor up to 30 guards. The extender

modules provide connections for the safety switches along

with LED and volt free indicator outputs for each safety

switch input.

ESM Emergency Stop Monitor allows the connection of

dual channel Emergency stop buttons or other dual chan-

nel safety devices with volt free contact outputs. Giving

indication for each input channel and overall output indica-

tion.

F-Series Safety Switches are solid state electronic

devices with no contacts or moving parts. This provides a

tamper proof safety system that can only be activated by

the Mechan actuator. When energized the safety switches

are continuously monitored whether the guard is opened or

not.

The Safety switches are resin encapsulated into an ABS

case, to provide a fully sealed, IP67 & IP69K, sensor which

can withstand the most arduous of conditions. Water, dust,

oil, machine vibration and even steam cleaning have little

or no effect on their performance, and with a 7-10 mm

switching distance they are easy to install and provide a

long and reliable working life span.

Applications

Interlocked guards where additional security required.

Door locking is not required. Harsh environments where

vibration, water or dust are problems.

Food and Beverage packing/filling systems Dairy Pharma-

ceutical Paper Industry, Can Forming and Filling, (Alumini-

um, Steel, Plastic) Semi conductor Manufacture/Assembly.

APPROVALS

CE

Complies with all relevant sections of the

CE marking directive

TUV

CAT 4 SIL 3 PLe

INTERNATIONAL DIRECTIVES

Machinery Directive 2006/42/EC

Low Voltage Directive 2014/35/EU

Electromagnetic Compatibility Directive 2014/30/EU

INTERNATIONAL STANDARDS

EN ISO

Safety of Machinery

13849-1

Safety related parts of control systems

EN ISO

Safety of Machinery - Functional safety

62061

of safety related electrical, electronic and

programmable electronic control systems

EN 60204

Safety of Machinery

Electrical equipment for machines

EN

Low voltage switchgear and controlgear

60947-5-1

EN 14119

Interlocking devices associated with

guards

EN

Safety of Machinery

60947-5-3

Specification for low voltage switchgear

and controlgear

Declaration of Conformity

Please contact Mechan Controls.

CAT 4

SIL 3 PLe

Advertisement

Table of Contents

Summary of Contents for Mechan F Series

- Page 1 European and/or National standards e.g. Machinery Directive 2006/42/EC and it’s amendments, Provision and Use of Work Equipment Regulations. Further information can be obtained from Mechan Controls Tel +44 (0)1695 722264 Description The F-Series safety system is a complete electronic safety switch and emergency stop button monitoring system for machine guarding applications.

-

Page 2: System Assembly

SAFETY CONTROL UNIT Mounting on 35mm DIN Rail Removal from 35mm DIN Rail The control modules are designed to be To remove the modules, gently lever mounted in an IP55 (minimum) control out the DIN clip with a small screw- cabinet. -

Page 3: Safety Switches

Operation All Mechan electronic safety switches can only be operated by the mechan actuator. They can approach each other from most angles, but when in place the targets shown in the diagrams below must be aligned and facing each other. - Page 4 CONNECTIONS The Mechan fixed safety switch is supplied pre-wired with 5, 10 or 15 metres of cable encapsulated into it when manufactured. This ensures a completely water-tight seal to the electronics within the switch. Longer cables can be supplied up to maximum of 100 me- tres and this will not significantly affect performance.

- Page 5 CONNECTION FOR MULTI-GATE SYSTEM AND E’STOP SEE ‘RESET CIRCUIT OPTION’ TABLE Note : 1) When the unit is powered, safety switches closed, e’stop’s released and the re-set circuit is made the N/O safety out- puts will close and the N/C indicator output will be open. 2) When a safety switch is opened, ( the actuator moved away from the switch) or one of the e’stops actuated, the N/O safety outputs will open and the N/C indicator output will be close.

- Page 6 DIMENSIONS FX1 / FX2 [4.12] 17.5 17.5 [0.69] [0.69] [3.53] [3.53] [3.53] DNK1 DNK2 14 [0.55] 3[ 0.11] [0.86] [0.86] [2.05] [1.06] [0.75] [1.1] SIDE VIEW [1.06] [2.05] [1.42] 52 [2.04] 52 [2.04] 4.2 [0.16] dia. [1.1] [1.42] [0.75] 8.1 [0.32] dia. [1.77] 6.4 [0.25] [1.42]...

-

Page 7: Technical Specifications

TECHNICAL SPECIFICATIONS SAFETY CONTROL UNIT FX1/FX2 Supply nominal voltage 24Vdc 24Vac 110Vac 230Vac Nominal power consumption Safety contacts 2 x N/O Output contact rating (max) 4A/230Vac; 2A/24Vdc(Res.)@Cos=1 Output contact rating (min) 10V/10mA Output contact fuse rating AC=5A; DC=2.5A; Quick blow Drop out time Deactivation by sensor, 13ms Internal fuse... -

Page 8: Atex - Declaration Of Conformity

Category 3D/Zone 22 DESCRIPTION 2.1 GENERAL The safety switch, Type FMA from the “F” series, manufactured by Mechan Controls Ltd. It is a type of Machine Guard safety switch and Actuator used for machine interlocking. The switch consisted of the sen- sor head and the Actuator target block both consist of solid-state electronic circuits, encapsulated into an ABS polymer casing with approximate dimensions 74mm x 33mm x 30mm to provide a fully sealed, IP67 &...

Need help?

Do you have a question about the F Series and is the answer not in the manual?

Questions and answers