Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for CECOR SA5-DT

- Page 1 OPERATION MANUAL & PARTS LIST SA5-DT...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SECTION 1 – SAFETY INFORMATION ......................3 1.1 – CAUTION ............................3 1.2 – PRECAUTIONS ..........................4 SECTION 2 – THE SUMP CLEANER ......................... 5 2.1 – UNIT IDENTIFICATION ........................5 2.2 – MODEL & SERIAL NUMBER ......................6 2.3 –... -

Page 3: Section 1 - Safety Information

SECTION 1 – SAFETY INFORMATION 1.1 – CAUTION CAUTION FLAMMABLE THIS EQUIPMENT IS INTENDED FOR USE WITH STANDARD METALWORKING FLUIDS (WATER-BASE & CUTTING OILS) INFLAMMABLE ONLY. IT SHOULD NOT BE USED WITH FLAMMABLE FLUIDS, (FUELS, PAINT, SOLVENTS, ETC.) CORROSIVE, TOXIC OR REACTIVE MATERIALS. -

Page 4: Precautions

1.2 – PRECAUTIONS READ THROUGH THE "OPERATIONS MANUAL" COMPLETELY BEFORE ATTEMPTING TO OPERATE THE MACHINE. RELIEF VALVES ARE SET BEFORE SHIPMENT AND SHOULD NOT BE CHANGED AS THE USE OF EXCESSIVE PRESSURE COULD CAUSE SERIOUS INJURY OR DAMAGE. ... -

Page 5: Section 2 - The Sump Cleaner

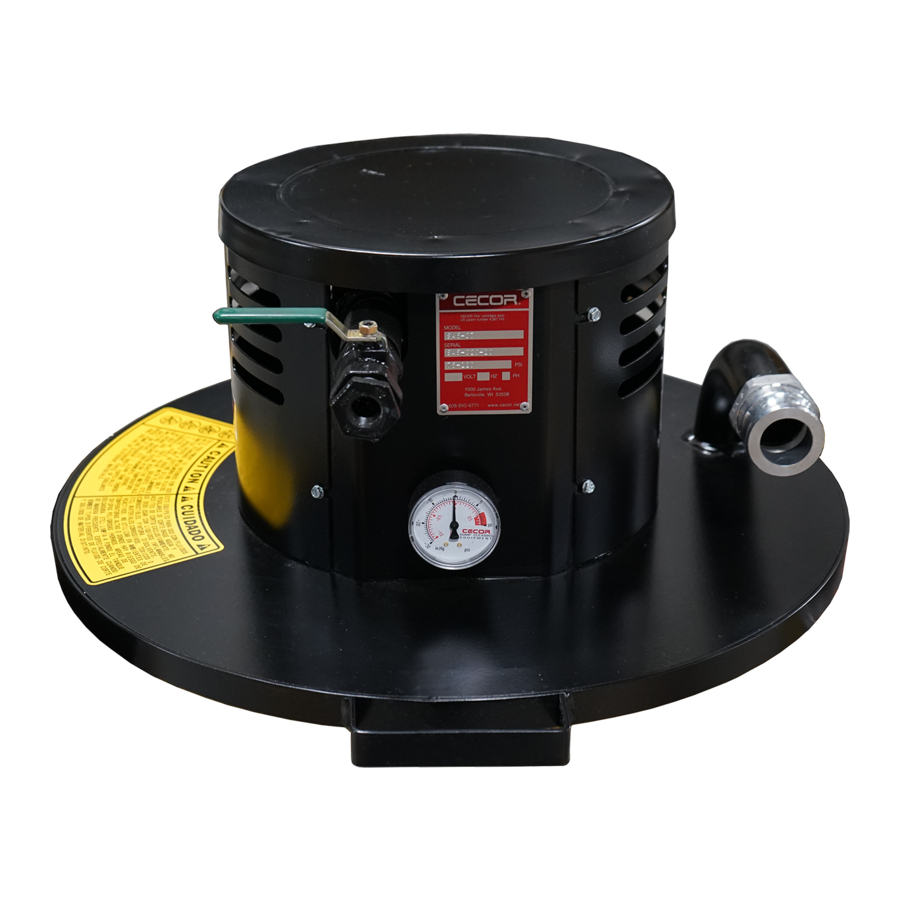

SECTION 2 – THE SUMP CLEANER 2.1 – UNIT IDENTIFICATION WHEN ORDERING PARTS OR ASKING QUESTIONS REGARDING YOUR SUMP SHARK, IT IS IMPORTANT TO HAVE THE MODEL AND SERIAL NUMBER OF THE UNIT. THE MODEL AND SERIAL NUMBER CAN BE FOUND ON THE SUMP CLEANER’S NAMEPLATE LOCATED ON THE FRONT PANEL. -

Page 6: Model & Serial Number

2.2 – MODEL & SERIAL NUMBER THE MODEL NUMBER IDENTIFIES YOUR SUMP CLEANER AND INDICATES STANDARD FEATURES ON YOUR MACHINE. THE SERIAL NUMBER IDENTIFIES YOUR SPECIFIC SUMP CLEANER AND WILL HELP IDENTIFY ANY SPECIAL FEATURES THAT MAY BE UNIQUE TO YOUR SUMP CLEANER. THE SERIAL NUMBER IS LOCATED ON THE NAMEPLATE. -

Page 7: Drum Top Features

2.3 – DRUM TOP FEATURES SUCTION PORT VACUUM/ FLOAT PRESSURE CONTROL GAUGE SA5 OPERATIONS MANUAL & PARTS LIST (Rev. 8/2020) - Page 8 VACUUM IS TOO GREAT FOR THE 55-GALLON DRUMS USED, THE VACUUM RELIEF MAY BE ADJUSTED DOWN TO DECREASE THE VACUUM. IF THE SUMP CLEANER IS USED IN CONJUCTION WITH CECOR’S TX-55PL, VACUUMS UP TO 29 inHg MAY BE REACHED. SA5 OPERATIONS MANUAL & PARTS LIST...

-

Page 9: Section 3 - Installation

SECTION 3 – INSTALLATION 3.1 – ASSEMBLE FLOAT CONTROL FOR SHIPPING PURPOSE, SOME MODELS MAY REQUIRE THE INSTALL OF THE DISCHARGE VALVE AND QUICK DISCONNECT ADAPTER. USE PIPE SEALANT ON ALL JOINTS AND TIGHTEN SECURELY. 3.2 – LOOSE ITEMS SOME ITEMS MAY BE PACKAGED IN A BOX LOCATED ON THE SHIPPING PALLET. - Page 10 FLOAT CONTROL HOSE PLUG FLARE NOZZLE FLEX QUICK NOZZLE DISCONNECT COUPLER STRAIGHT NOZZLE SUMP CLEANER HOSE AIR HOSE 1/2” x 20’ SA5 OPERATIONS MANUAL & PARTS LIST (Rev. 8/2020)

- Page 11 3.3 – AIR SUPPLY CONNECTION YOU ARE REQUIRED TO SUPPLY AIR CONNECTIONS THAT FIT YOUR AIR SYSTEM. THE SHARKS AIR-LINE TERMINATES IN ½” NPT PIPE THREAD. THE SHARK REQUIRES A MINIMUM 3/8” DISCONNECT; (½” FOR OPTIMAL PERFORMANCE). ¼” BLOW-OFF CONNECTIONS ARE TOO LIMITING ON THE AIR SUPPLY REDUCING PERFORMANCE.

-

Page 12: Section 4 - Operation

1. SCREW FLOAT CONTROL ONTO PIPE PROTRUDING THROUGH LID UNDERSIDE. (SEE 3.1 – ASSEMBLY FLOAT CONTROL) 2. PLACE UNIT ON AN OPTIONAL CECOR TX-55PL DRUM TANK OR AN EMPTY OPEN-ENDED 55 GALLON DRUM. 3. ATTACH THE SUMP CLEANER HOSE TO THE SUCTION PORT, AND INSERT SUCTION TOOL INTO HOSE END. - Page 13 4. CONNECT AIR HOSE TO SHOP SUPPLY. SHOP AIR SUPPLY MUST BE BETWEEN 75-120 PSI FOR BEST RESULTS. AIR HOSE SUMP CLEANER 1/2” x 20’ HOSE 5. OPEN AIR SUPPLY VALVE. 6. SUMP CLEANER IS READY FOR USE. SA5 OPERATIONS MANUAL & PARTS LIST (Rev.

-

Page 14: Section 5 - Maintenance

THAT WILL KEEP YOUR SUMP CLEANER IN TOP-NOTCH, DEPENDABLE CONDITION. ANY WORN OR DAMAGED PART SHOULD BE REPLACED IMMEDIATELY. CECOR STOCKS SUMP CLEANER PARTS AND MOST CAN BE SHIPPED THE SAME OR THE NEXT DAY. CALL 1-800-356-9042 TO ORDER PARTS. -

Page 15: Section 6 - Troubleshooting

SECTION 6 – TROUBLESHOOTING PROBLEM POSSIBLE CAUSE: SOLUTION: WILL NOT START AIR SUPPLY. MAKE SURE THE UNIT IS CONNECTED TO AN ADEQUATE AIR SUPPLY. HOSE RESRICTIONS. CHECK AIR LINES FOR KINKS OR OTHER RESTRICTIONS. BLOCKAGE OF AIR FLOW. CHECK FOR DEBRIS THAT MAY HAVE COME THROUGH THE AIR LINE. -

Page 16: Section 7 - Repair Parts List

SECTION 7 – REPAIR PARTS LIST Part No. Description HOOD ASSEMBLY A220-868 VAVUUM GAUGE SP-195 SP-405 DISCONNECT ADAPTER 1-1/2" DRUM GASKET A210-106 SA5 OPERATIONS MANUAL & PARTS LIST (Rev. 8/2020) - Page 17 Part No. Description AIR SUPPLY VALVE SP-463 SP-506 VACUUM RELIEF VALVE SP-318-B AIR EXHAUSTER MUFFLER SP-559 SA5 OPERATIONS MANUAL & PARTS LIST (Rev. 8/2020)

- Page 18 14,15 Part No. Description 1-1/2” HOSE PLUG ASSEMBLY A220-775 FLOAT CONTROL A220-863 A220-149 FLEX NOZZLE A220-150 FLARED NOZZLE STRAIGHT NOZZLE A210-474 QUICK DISCONNECT COUPLER 1-1/2” SP-404 SP-370 COUPLER GASKET 1-1/2” 1-1/2” SUMP CLEANER HOSE A220-142 AIR HOSE ½” x 20’ SP-173 SA5 OPERATIONS MANUAL &...

-

Page 19: Section 8 - Accessories

SECTION 8 – ACCESSORIES TX-55PL CECOR’S HEAVY DUTY 55-GALLON DRUM TANK, MADE OF HEAVY GAUGE STEEL, IS STRONGER THAN A STANDARD 55-GALLON DRUM. THE TANK IS MOUNTED ON FOUR CASTERS FOR EASY ROLLING AND MANEUVERABILITY. FORK POCKETS BUILT INTO THE BASE PROVIDE EASY HANDLING BY FORK TRUCK. -

Page 20: Section 9 - Warranty

SECTION 9 – WARRANTY WARRANTY STATEMENT PLEASE PRINT OUR WARRANTY AT HTTPS://CECOR.NET/CECOR-WARRANTY/ SA5 OPERATIONS MANUAL & PARTS LIST (Rev. 8/2020) -

Page 21: Section 10 - Record Model & Serial Number

SECTION 10 – RECORD MODEL & SERIAL NUMBER WHEN YOU RECEIVE YOUR CECOR SUMP SHARK, RECORD THE MODEL NUMBER, SERIAL NUMBER AND DATE DELIVERED FOR YOUR RECORDS. MODEL #: ________________________________________ SERIAL #: ________________________________________ DELIVERED: ____________ / ____________ / ____________ SA5 OPERATIONS MANUAL & PARTS LIST... - Page 22 SA5 OPERATIONS MANUAL & PARTS LIST (Rev. 8/2020)