Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Meech CyClean

- Page 1 Operating Manual CyClean™ Non-Contact Web Cleaning...

-

Page 3: Table Of Contents

CYCLEAN SYSTEM OVERVIEW OPERATING THE SYSTEM Model and Function Before Use Double Sided Cleaning System Setup Correct Use of a CyClean System How CyClean Works MAINTENANCE AND INSPECTION Inspection Maintenance – Ionisation Equipment UNPACKING THE SYSTEM Fault Finding – Ionisation Equipment SUGGESTED ORDER OF INSTALLATION Maintenance –... -

Page 5: Cyclean System Overview

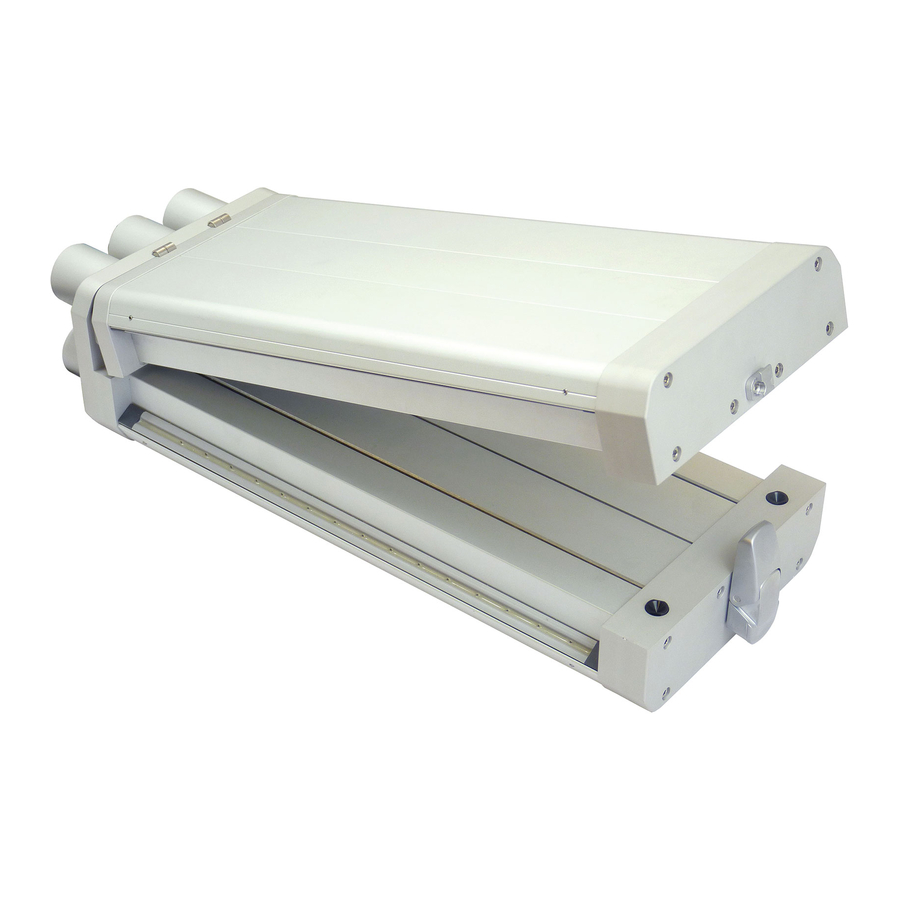

CyClean™ System Overview Models and Function The Meech CyClean has been designed in response to increased demand for a compact, high performance, non-contact web cleaning system. Through the application of advanced computational fluid dynamics, Meech has optimised the cleaning efficiency of CyClean to remove and extract contamination as small as 0.5 micron. -

Page 6: Correct Use Of A Cyclean System

Meech CyClean web cleaning systems should only be used in installations for which they are designed. If the CyClean is used in any other way than instructed in this manual, it will be considered as improper use. How CyClean Works The excellent cleaning performance of CyClean is achieved from the combination of the following processes. -

Page 7: Suggested Order Of Installation

The CyClean system should be installed in the position that was recommended by your Meech contact. The exact installation location will vary depending on the machine and application requirements. In general, the CyClean system should be installed as close to the critical process as possible to minimise the potential of re-contaminating the web via airborne contamination. -

Page 8: Web Direction And Tension

Web Direction and Tension The CyClean must be mounted with the web passing through the unit so that it reaches the aerodynamic flap before the blowing air slot. Direction Direction IMPORTANT The web must be kept under tension whilst the unit is running. -

Page 9: Standard Web Gap And Adjustment

Standard Web Gap and Adjustment The web gap is the total distance between the two halves of the CyClean head that the web passes through. Manual Opening The web gap is fixed at 8mm and is not adjustable. Pneumatic Opening The web gap is 8mm as standard. -

Page 10: Connecting The Active Ionisation Equipment

Qty 4 x Meech Model A914 Ionising Bars that are installed in the CyClean head unit. „ Qty 1 x Meech Model A905 Ionising Power Supply for systems to suit web widths up to 1,000mm, or, qty 2 for systems to suit „... - Page 11 Push the connector through a port in the power supply adjacent to the high voltage terminal. Then refit both the lock washer and nut to the ionising bar. Ensure that the nut is fully tightened. Connect the cable eyelet of the ionising bar to the high voltage stud of the 905 using the screw provided. Ensure that the nut of the ionising bar connector is fully tightened.

-

Page 12: Connecting The Remote On/Off Signal From The Line

Connecting the Remote On/Off Signal From the Line The following applies if your system has pneumatic opening and closing. Connect a normally open (NO) signal from the line in the CyClean control box as shown in the image below and consult the wiring diagram in this manual. -

Page 13: System Installation - Pneumatic

„ Compressed Air Connections - Control Box The main incoming compressed air supply should be connected to the 4mm compressed air push fit fitting on the CyClean control box labelled Air In 1. The compressed air hoses (blue and black) should be connected from the CyClean unit to the 4mm compressed air push fittings labelled Port 2 and Port 3. -

Page 14: Setting The Required Air Pressure

Setting the Required Air Pressure There is a pressure relief regulator valve inside the CyClean control box. Adjusting this valve will change the air pressure that will be fed to the cylinders mounted as part of the CyClean head. This valve will have been set at Meech before your system was supplied. -

Page 15: Compressed Air Circuit

System Installation – Ducting Meech offers 3 standard ducting kits that are detailed below. Each kit allows the CyClean head to be 5mtrs from the AHU. There is a drawing of each kit in the drawings section at the end of this manual. -

Page 16: Operating The System

The airflows of the CyClean non-contact web cleaning system should be adjusted to achieve optimum cleaning results. The best cleaning results will be achieved, when the system is set to have a positive airflow into the CyClean head, on both the web entry and exit sides (minimising the risk of any recontamination). -

Page 17: Maintenance And Inspection

Maintenance and Inspection IMPORTANT Always make safe the electrical and compressed air supplies before undertaking any maintenance work on the CyClean system. IMPORTANT Maintenance should only be completed on the CyClean system by those with suitable qualifications. Inspection The system will perform without serious deterioration, giving many years of service, providing the following visual inspection is made weekly. -

Page 18: Maintenance - Ionisation Equipment

Meech distributor. Fault Finding – Ionisation Equipment Fault finding guides for the Meech Model A905 ionising power supply and A914 AC ionising bars can be downloaded directly from the Meech website at www.meech.com For further fault finding guidance please contact Meech International directly or your local Meech distributor. -

Page 19: Spare Parts

Spare Parts It is recommended that only Meech spare parts are used in your CyClean system. The use of non Meech parts may invalidate your warranty. For details of spare parts, please contact Meech or your nearest Meech distributor. Please quote the serial number of your CyClean system when ordering spare parts. -

Page 20: Troubleshooting

A914 AC ionising bars, which can be downloaded directly from the Meech website at www.meech.com If the problem being experienced is not listed above, or the remedy is unclear please contact Meech International directly or your local Meech distributor. -

Page 21: Drawing Pack

Technical Drawings Ducting Configuration - Manual Opening... - Page 22 Ducting Configuration - Pneumatic Opening Single End Feed...

- Page 23 Ducting Configuration - Pneumatic Opening Double End Feed...

-

Page 42: Declaration Of Conformity

…………………. Ian Walker, Engineering Manager. Meech Static Eliminators Ltd Offices in: Registered in England No. 1525004 VAT No. GB236 1298 65 • UK • USA • Belgium • Hungary • China... - Page 44 Fax: +44 (0)1993 776977 email: info@meech.com email: sales@meech.com email: mesa@meech.com Meech Shavotech Meech CE Meech Static Eliminators (Shanghai) Co. Ltd 7G, 7F, LP Tower Shavo House, Survey No.21A / 10 B, Plot No.394 2151 Fót Széchenyi út. 46 #25 Xiangfeng Road...

Need help?

Do you have a question about the CyClean and is the answer not in the manual?

Questions and answers