Summary of Contents for Scantool RS 100

- Page 1 Industrivej 3-9 DK-9460 Brovst Tlf.: +45 98 23 60 88 Fax: +45 98 23 61 44 27.09.07 Manual SCANTOOL RS 100/RSX 100 Pipe Notcher...

- Page 2 Fax.: +45 98 23 61 44 hereby declares that SCANTOOL Pipe Notcher 100 RS/RSX is manufactured in accordance with the provisions of the COUNCIL DIRECTIVE of 17. May 2006 (2006/42/EC) – The Machinery Directive (order no. 561 of 25 June 1994 with subsequent amendments)

-

Page 3: Table Of Contents

3.2 Spare Parts List for Pipe Notcher with Exhaust Unit (RSX 100) ........12 3.3 Drawing of Pipe Notcher without Exhaust System (RS 100) ..........13 3.4 Spare Parts List for Pipe Notcher without Exhaust System (RS 100) ........ 14 Technical Data ....................... 15 4.1 Technical Specifications .................... -

Page 4: Transport & Handling

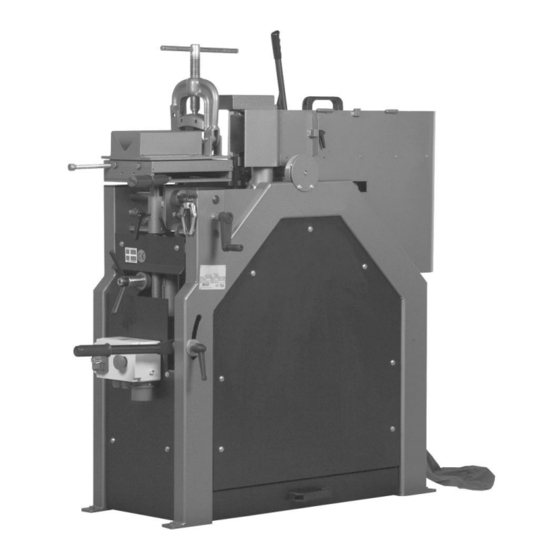

Transport & Handling 1.1 Transport SCANTOOL RS 100/RSX 100 Pipe Notcher is delivered mounted on a pallet with the following dimensions: 120 x 80 x 154 cm The Pipe Notcher is packed in a protective container. 1.2 Handling The SCANTOOL Pipe Notcher can easily be transported on the pallet. - Page 5 Fig.: 1.1...

-

Page 6: Directions For Use

The lifetime of the grinding belt is increased when beginning with a slight pressure. 2.2 Examples of Pipe Joints The SCANTOOL Pipe Notcher is constructed to process pipes of various dimensions for joining with another pipe. Please see examples below. Normally it will be necessary to remove burrs after grinding. -

Page 7: Security

2.3 Security Follow them to achieve best results and full benefit from your new machine The very good craftsman respects the tools with which he works. He knows they represent years of constantly improved design. He also knows that they are dangerous if misused. This is the theme of a new safe-use program for stationary power tools. - Page 8 9. Don’t force tool. It will do the job better and be safer at the rate for which it was designed. 10. Use right tool. Don’t force tool or attachment to do a job it was not designed for. 11. Wear proper apparel. Wear no loose clothing, 12.

-

Page 9: Maintenance

2.4 Maintenance It is recommended occasionally to check if the spark arrester and the suction channels need cleaning. The dust bag has to be emptied after use and drawer (P) if necessary. The contact wheel must be replaced if it is loose. Replace the grinding belt when needed. Replacing the grinding belt (fig. - Page 10 Fig.: 2.3 Replacing the contact roller (fig. 2.3) When replacing the contact roller first dismount the grinding belt as described earlier. Tilt the contact roller forwards and unscrew the nuts (U) (see fig.: 2.3) – now dismount the distance bushing. Fit the bearing puller (Å) on the bearing bracket (W) and turn the spindle clockwise until the bearing bracket is loose enough to take off the shaft (Y).

-

Page 11: Spare Parts List

Spare Parts List 3.1 Drawing of Pipe Notcher with Exhaust Unit (RSX 100) -

Page 12: Spare Parts List For Pipe Notcher With Exhaust Unit (Rsx 100)

3.2 Spare Parts List for Pipe Notcher with Exhaust Unit (RSX 100) When ordering spare parts please state production number and serial number together with item number and description of the part according to this list. Pos. no. Description Item no. Pos. -

Page 13: Drawing Of Pipe Notcher Without Exhaust System (Rs 100)

3.3 Drawing of Pipe Notcher without Exhaust System (RS 100) -

Page 14: Spare Parts List For Pipe Notcher Without Exhaust System (Rs 100)

3.4 Spare Parts List for Pipe Notcher without Exhaust System (RS 100) When ordering spare parts please state production number and serial number together with item number and description of the part according to this list. Pos. Description Part no. -

Page 15: Technical Data

Technical Data 4.1 Technical Specifications Model RS 100 RSX 100 Grinding belt 100x1600 100x1600 Motor 3x230/460V 60 Hz 4,1 HP 4,1 HP Class IEC 34-1 IEC 34-1 IP class Rpm. 1410 (1692) 1410 (1692) 8,8/5,1 8,8/5,1 Cos 0,82 0,82... -

Page 16: Accessories

Cyclone complete 740681300 4.4 Wiring Diagram SCANTOOL Pipe Notcher can be connected to 3x380-440V (50/60 Hz) and to 3x230 V (60 Hz). Below please find a wiring diagram showing how to connect the machines to the wiring supply. 3x400-440V, 50/60 Hz... -

Page 17: Warranty

Warranty Guarantee If within 2 year of purchase this machine supplied by SCANTOOL A/S becomes defective due to faulty materials or workmanship we guarantee to repair or replace the machine or defective part or parts free of charge provided that: The product is returned complete to one of our Service Branches or Official Service Agents.

Need help?

Do you have a question about the RS 100 and is the answer not in the manual?

Questions and answers