Table of Contents

Advertisement

Quick Links

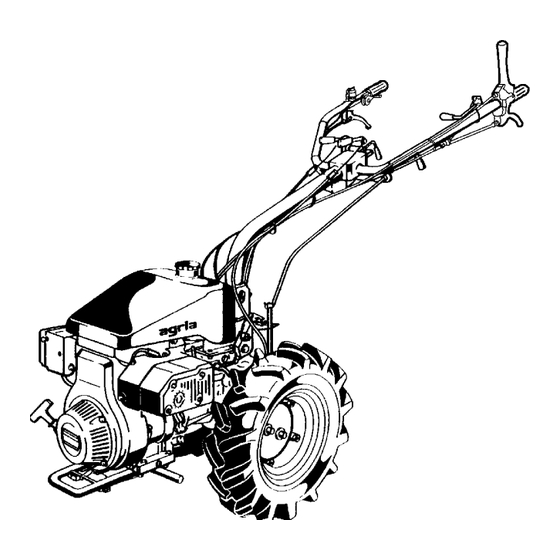

Power Machines for Soil Cultivation,

Grass and Property Maintenance

Operating Instructions

for agria

Petrol Engine EH 25 D

Diesel Engine 6LD 400

3658

Before commissioning the engine, read operating instructions

and observe warnings and safety instructions.

Operating instructions No. 998 733

®

Two-Wheel Tractor 3900

with Automatic Reversing Lock

04.97

Advertisement

Table of Contents

Summary of Contents for Agria 3900

- Page 1 Power Machines for Soil Cultivation, Grass and Property Maintenance Operating Instructions ® for agria Two-Wheel Tractor 3900 Petrol Engine EH 25 D with Automatic Reversing Lock Diesel Engine 6LD 400 3658 Before commissioning the engine, read operating instructions and observe warnings and safety instructions.

-

Page 2: Table Of Contents

Fig. D + E, Petrol ......62 Support leg ........30 Coupling and Decoupling Fig. F + G, Diesel, recoil starter .. 66 Attachments ........31 Electric Starter Version ....37 Fig. H + J, Diesel, electric starter 70 Two-wheel tractor 3900 Edition 04.97... -

Page 3: Amount Of Delivery

Fast Please state these data when ordering spare parts to avoid wrong deliveries. Slow Only use original agria spare parts! Specifications, figures and dimensions stated in these instructions are not bind- Differential Lock ing. No claims can be derived from them. -

Page 4: Recommendations

Recommendations Lubricants and Maintenance and Anti-Corrosive Agents: Repair: Use the lubricants specified for en- The trained mechanics of your AGRIA gine and gearbox (see “Specifica- workshop expertly carry out any main- tions”). tenance and repair work. We recommend using Bio-lubricat-... -

Page 5: Designation Of Parts

Designation of Parts: Petrol Engine Edition 04.97 Two-wheel tractor 3900... - Page 6 7 Gear shifter (with steering handle swivelled [front attachment] = PTO shifter) 8 Speed adjustment lever 9 Handle lever 10 Hand lever for steering brake, on the left 11 Hand lever for steering brake, on the right Two-wheel tractor 3900 Edition 04.97...

-

Page 7: Fuel

-20°C ca. - 9°C As a last resort, you can add up to 30% of regular petrol to avoid paraffine depositing in the machine. However, this has negative effects on fuel economy and driving. Edition 04.97 Two-wheel tractor 3900... -

Page 8: Assembly Instructions

W-clip (13). Check Bowden cables to ensure they are not bent and squeezed. Fit drive wheels (accessory) (see page 29). Electric starter version: Fill battery with accumulator battery acid and charge the battery (see page 35). Two-wheel tractor 3900 Edition 04.97... - Page 9 Designation of Parts: Diesel Engine Edition 04.97 Two-wheel tractor 3900...

- Page 10 6 Locking lever for steering handle side adjustment 7 Gear shifter (with steering handle swivelled [front attachment] = PTO shifter) 8 Speed adjustment lever 9 Handle lever 10 Hand lever for steering brake, left 11 Hand lever for steering brake, right Two-wheel tractor 3900 Edition 04.97...

-

Page 11: Safety Instructions

When transporting the tractor on vehi- cles or trailers outside the area to be cultivated, ensure that the engine is turned off. Careful with rotating tools – keep at a safe distance! Edition 04.97 Two-wheel tractor 3900... - Page 12 Never leave the operator’s position at that a safety distance is kept to enclo- the steering handle while tractor is at sures to prevent damage to tools. work. Never adjust the handles during work - danger! Two-wheel tractor 3900 Edition 04.97...

- Page 13 Then close fuel taps. Secure the two-wheel tractor against unauthorized use. If tractor is equipped with an ignition key, remove the key. For all other versions, remove the spark plug connector to secure the tractor. Edition 04.97 Two-wheel tractor 3900...

- Page 14 When coupling the drawbar, make sure manoeuvrability at coupling point is suf- ficient. Do not exceed gross axle weight rating, towing capacity and gross weights. Before driving, check brake function and rear lighting for proper operation. Two-wheel tractor 3900 Edition 04.97...

- Page 15 Make sure fuel is of specified quality. Only use original agria spare parts. All other conventional spare parts must Store fuel in approved cans only. correspond to quality and technical re- quirements specified by agria.

- Page 16 Any repairs are to be carried out by Persons having a pacemaker may not trained mechanics only and with the touch live parts of the ignition system appropriate tools. when the engine is running. Two-wheel tractor 3900 Edition 04.97...

- Page 17 Do not work without protective covers mounted. Before starting the engine, bring covers in proper position. With the engine running, keep at a safe distance from knife. Edition 04.97 Two-wheel tractor 3900...

-

Page 18: Specifications

Air pressure: ......1.2 bar 3990 011 5.0 -10 field tyre To fit the drive wheel, see page 29 Track Width Plan: [mm] Tyre: 5.0-10 AS 490 350 210 510 370 230 530 390 250 590 450 310 Two-wheel tractor 3900 Edition 04.97... -

Page 19: Machine

Accessory ......3940 011 gear independent at 3600 engine rpm direction of rotation: right clockwise, looking on PTO constant in forward and reverse Steering handle: ..height adjustable side adjustable without tools, swivels 180° for front attachments. Edition 04.97 Two-wheel tractor 3900... -

Page 20: Noise Levels

EC 84/538/EEC at 85% of engine speed Operability on Slopes: Engine is suited for use on slopes (with oil level at “max” = upper level mark) Continuous operation possible up to ....45° inclination (100%) Two-wheel tractor 3900 Edition 04.97... - Page 21 85% of engine speed Operability on Slopes: Engine is suited for use on slopes (oil level at “max” = upper mark) Continuous operation possible up to ....30° inclination (55%) Slalom operation up to ....35° inclination (78%) Edition 04.97 Two-wheel tractor 3900...

-

Page 22: Devices And Operating Elements

3. Devices and Operating Elements The two-wheel tractor agria 3900 is a During the first 20 operating hours powered basic machine and is always (break-in period) do not use engine to operated with an attachment mounted. maximum power. Therefore, the machine is suited for hor-... -

Page 23: Safety Circuit

The safety lever also serves to switch off in an emergency. Release the safety lever for fast engine switch-off. The lever automati- cally goes to STOP position. Edition 04.97 Two-wheel tractor 3900... -

Page 24: Gearbox

(see fig. S, p33). When turning on banks, always turn the machine towards the slope. When driving with a trailer mounted, do not use the trac- tor’s single-wheel brake but the operating brake of the trailer. Two-wheel tractor 3900 Edition 04.97... -

Page 25: Central Brake

The eccentric lever automatically comes to a stop – both drive-wheels are locked. To release the hand brake, swivel the eccentric lever back to original position – the brake is released. Edition 04.97 Two-wheel tractor 3900... -

Page 26: Pto

It also prevents the re- Front attachments: verse gear from being engaged while Pto engagement is unlocked for all the PTO is at work. speeds Two-wheel tractor 3900 Edition 04.97... -

Page 27: Steering Handle

Adjust handlebar to desired height ing handle. (fig. K). Release locking lever and fit handle- bar into proper notch, in such a way that the locking lever swivels back into its original position. Edition 04.97 Two-wheel tractor 3900... - Page 28 Release handle lever and lock it into an appropriate notch on the steering Swivel Steering Handle Back to handle. Original Position To swivel steering handle back to its original position, proceed in the same order, but swivel counter-clockwise. Two-wheel tractor 3900 Edition 04.97...

-

Page 29: Drive-Wheels

For full tractive power, mount wheels with pointed parts of lugs showing in driving direction (wheels seen from above). This applies also when steer- ing handle is swivelled 180° for front at- tachments. Edition 04.97 Two-wheel tractor 3900... -

Page 30: Front Weight

For working, push it back up. support kit (agria No. 719 66). front weight Two-wheel tractor 3900 Edition 04.97... -

Page 31: Coupling And Decoupling Attachments

The locking bolt locks automatically. If not, twist and turn the attachment slightly to the left and right. Decoupling attachments Turn locking lever (P/1) to position open “ ” (fig. P). Decouple attachment. Refit cap onto attachment coupling pin. Edition 04.97 Two-wheel tractor 3900... - Page 32 For but swivel anti-clockwise. this purpose, remove wheels and fit the right wheel onto the left side and the left wheel onto the right side. Two-wheel tractor 3900 Edition 04.97...

- Page 33 Push attachment in to the stop shoul- der and turn the locking lever (T/1) to position closed “ ”. Now the bolt locks into place automati- cally. If not, twist attachment slightly to the left or right. Edition 04.97 Two-wheel tractor 3900...

- Page 34 3. Devices and Operating Elements Adapter for coupling AGRIA Attach attachment bolts (1, 4 and 5) and tighten them. attachments – type ranges 3400 and 5500 On PTO-driven attachments move lever (6) on the attachment to position Coupling the Adapter ”I”.

-

Page 35: Electric Starter Version

I = Operation engine is running. This can START = Start position, ignition key damage the charging regulator. automatically goes into op- erating position Dashboard 1 Battery charge indicator 2 Ignition start switch 3 Socket for trailer Edition 04.97 Two-wheel tractor 3900... -

Page 36: Commissioning And Operation

Oil level Check fuel tank for sufficient fuel. To avoid problems when starting the engine first time or after longer periods of no operation, make sure fuel tank is filled to maximum. Two-wheel tractor 3900 Edition 04.97... -

Page 37: Before You Operate The Machine

(A/3 and C/3) shows an adequate level of transmission oil in the drive gear (to check, bring engine in horizontal position). The lower notch marks minimum, the upper notch maxi- mum oil level. Edition 04.97 Two-wheel tractor 3900... -

Page 38: Starting The Petrol Engine

After the start, carefully let the rope glide back. Do not let it snap. Once the engine has started, let it warm up for some time. Slowly push choke back into operating position, if necessary. Two-wheel tractor 3900 Edition 04.97... -

Page 39: Switching Off The Petrol Engine

This ensures the carburetor to be empty and no resin resi- due to deposit. Secure the two-wheel tractor against unauthorized use – disconnect spark-plug con- nector. Edition 04.97 Two-wheel tractor 3900... -

Page 40: Starting The Diesel Engine

Once the engine has started, slowly move the speed conrol lever to 1/3 throt- tle and let the engine warm up for some time. In case the engine does not start, re- peat the starting procedure as described above. Two-wheel tractor 3900 Edition 04.97... - Page 41 If the engine does not start and re-start is necessary, turn key back to position “0” to repeat start (re-start lock). Once the engine has started, slowly move speed control lever to 1/3 throttle and let engine warm up for some time. Edition 04.97 Two-wheel tractor 3900...

-

Page 42: Switching Off The Diesel Engine

On the electric-starter version, turn the ignition key back to position “0” – battery charge indicator goes off. Secure two-wheel tractor against unauthorized use – remove ignition key (electric- starter version). Two-wheel tractor 3900 Edition 04.97... -

Page 43: Operations

Never readjust steering handle dur- ing operation – danger! During all operation with the two- wheel tractor, especially when turn- ing, the operator must keep at a safe distance as defined by the steering handle. Edition 04.97 Two-wheel tractor 3900... -

Page 44: Driving With Mounted Trailer

Notes Two-wheel tractor 3900 Edition 04.97... - Page 45 (do not screw in), take out dip-stick and read oil level. In case oil level is below lower mark, refill engine oil (refer to “Specifications”) until oil level reaches rim of oil filler neck. Edition 04.97 Two-wheel tractor 3900...

- Page 46 Check the exhaust system each time tap out dust) and replace it after every before you take the two-wheel tractor 50 operating hours or at least once a into operation. year. Foamed pre- liminary filter Paper filter element Air filter Two-wheel tractor 3900 Edition 04.97...

- Page 47 0.6–0.7 mm aged. Then screw it back on correctly, to avoid fuel leakage. Edition 04.97 Two-wheel tractor 3900...

- Page 48 (For idling speeds refer to “Specifications”). We recommend to have the necessary Keep governor spring, lever and link- adjustments done by your agria work- ages free from dirt and plant trash at all shop. times. Two-wheel tractor 3900...

- Page 49 Changing Engine Oil The first oil change is after 25 oper- ating hours. Following oil changes are after 50 operating hours. Change the oil while the engine is still warm, but not hot – danger of burns! Edition 04.97 Two-wheel tractor 3900...

- Page 50 (ensure correct position). Install plug with new o-ring (3) and tighten. 1 Foamed ring 2 O-ring 3 Seal 4 Filter cartridge 5 Oil pot 1 Oil filter 2 Pressure spring 3 O-ring 4 Plug Oil level Two-wheel tractor 3900 Edition 04.97...

- Page 51 Crank the engine several times with recoil starter or electric starter and start the engine. Let the engine run for approx. 1 minute. Edition 04.97 Two-wheel tractor 3900...

- Page 52 (F/10 or H/10) and free from dirt and After every 400 operating hours, clean plant trash taken in. and check injection jet. For this pur- pose, contact your professional agria After every 100 operating hours or at workshop. least once a year before season starts...

-

Page 53: Machine

Install drain plug with o-ring and tighten. Fill in fresh transmission oil up to level mark “max.”. For proper oil quantity and quality, refer to chaper “Specifications”. Close filling opening with plug/dip-stick. Edition 04.97 Two-wheel tractor 3900... -

Page 54: Adjustments On Hand Levers

Check clutch play or clutch adjustment change, if necessary. each time you operate the machine. If For this purpose, contact your agria necessary, re-adjust (especially after workshop. commissioning the machine, during break-in period, and after exchanging Diesel Engine: If necessary, correct clutch linings). -

Page 55: Battery

– Clean the engine only with a cloth. Avoid danger of fire! spraying with air-compressed water jets, as water might leak into ignition and fuel system and cause malfunctions. Edition 04.97 Two-wheel tractor 3900... -

Page 56: Storage

Petrol Engine hand clutch lever pulled (pawl locked – Drain fuel or add fuel stabilizer in place). Otherwise clutch problems (AGRIA No. 673 50). may result due to corrosion. Method: Fill fuel tank, add anti-corro- sive and stabilizing liquid (amount “ON”... -

Page 57: Troubleshooting

6. Troubleshooting Observe safety instructions! Have all serious malfunctions on the machine or engine repaired by your agria workshop. They have the proper tools. Improper repairs can only add to the damage. Problem Possible cause Remedy Page Petrol engine - Spark plug connector not connected... - Page 58 - Wrong injection pressure Re-adjust injection pressure at high speeds Diesel Engine - Air filter clogged Clean air-filter frequently stalls in idle Diesel Engine - Improper adjustment Re-adjust engine-off-cable does not stop of engine-off-cable when set to “STOP” Two-wheel tractor 3900 Edition 04.97...

- Page 59 Clutch slips - Hand clutch lever misadjusted Adjust clutch free play - Worn out clutch Exchange clutch disc Excessive - Loosened fastening screws Tighten fastening screws vibration = For this purpose contact your agria workshop. Edition 04.97 Two-wheel tractor 3900...

- Page 60 Notes Two-wheel tractor 3900 Edition 04.97...

- Page 61 4 Engine oil plug with dip stick 5 Engine type plate 6 Engine drain plug 7 Support leg 8 Weight support 9 Cooling air screen 10 Starter handle 11 Spark plug and spark plug connector Edition 04.97 Two-wheel tractor 3900...

- Page 62 Designation of Parts: Petrol Engine Two-wheel tractor 3900 Edition 04.97...

-

Page 63: Lubricants, Varnishes, Wear Parts

559 95 Glue (strong) LOCTITE 270 bottle 50ml 559 96 Glue (ultra strong) LOCTITE 638 bottle 50ml 509 85 Surface sealing (liquid) LOCTITE 573 tube 50ml 509 68 Surface sealing (liquid) LOCTITE 573 tube 250ml Edition 04.97 Two-wheel tractor 3900... - Page 64 Foamed ring (Fig. W/1) 606 76 O-ring, Engine oil-filler plug 718 96 Plastic guard for attachment pin Ø 70 Lists of Spare Parts 997 091 Basic machine 3900 997 092 Attachments for 3900 997 077 Robin Engines 997 055 Lombardini Engines...

- Page 65 10 Cooling air screen Figure G 4 Engine oil dip-stick 5 Fuel tank 6 Fuel tank cap 7 Recoil starter 8 Recoil starter handle 9 Engine hoob guard 10 Oil bath filter 11 Engine number 12 Engine-off-lever Edition 04.97 Two-wheel tractor 3900...

- Page 66 Designation of Parts: Diesel Engine Recoil Starter Version Two-wheel tractor 3900 Edition 04.97...

-

Page 67: Electrical Wiring Diagrams

Electrical Wiring: Petrol Engine 1 Engine 2 Magnet ignition system 3 Switch with safety lever bl = blue Edition 04.97 Two-wheel tractor 3900... - Page 68 1 Battery charge indicator = yellow 2 Socket = red 3 Regulator rogn = red-green 4 Central socket for regulator = black 5 Generator = purple 6 Ignition switch wero = white-red 7 Electric starter 8 Battery Two-wheel tractor 3900 Edition 04.97...

- Page 69 1 Hood 2 Ball cup 3 Oil-dip stick for engine oil 4 Fuel tank 5 Fuel tank cap 6 Battery 7 Ball button 8 Engine hoob guard 9 Oil bath filter 10 Engine number 11 Engine-off-lever Edition 04.97 Two-wheel tractor 3900...

- Page 70 Designation of Parts: Diesel Engine Electric Starter Version Two-wheel tractor 3900 Edition 04.97...

- Page 71 Notes Edition 04.97 Two-wheel tractor 3900...

-

Page 72: Inspection And Maintenance Chart

B = After each cleaning K = Checks and maintenance to be executed by operator W = Maintenance to be executed by professional workshop F = Maintenance should be carried out by your agria workshop * = after 2 years Two-wheel tractor 3900... -

Page 73: Conformity Declaration

EC directive agria-Werke GmbH D-74215 Möckmühl/Württ. herewith declare in sole responsibility that the product Two-Wheel Tractor, Type 3900 to which this declaration refers, corresponds to the standard fundamental safety and health requirements as stipulated in the EC directive 89/392/EEC and the EMV directive 89/336/EEC. - Page 74 Two-wheel tractor power hoe Self-propelled ride-on Verticutter Lawn mower lawn mover Quality, to be proud of Contact your authorised agria dealer for service and prompt delivery of spare parts agria-Werke GmbH, D-74215 Möckmühl, Phone 0049 62 98/39-0, Fax 0049 6298/39-111...

Need help?

Do you have a question about the 3900 and is the answer not in the manual?

Questions and answers