Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Melec ADB-5F40

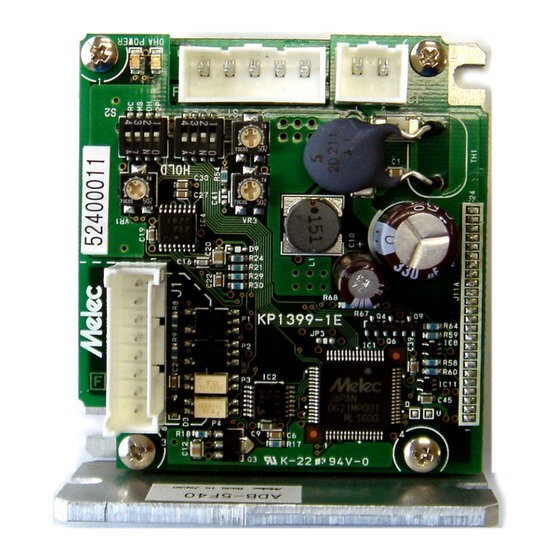

- Page 1 5-phase Stepping Motor Driver ADB-5F40 ADB-5F40A Instructions Manual (For designers' use) Please ensure to read and understand this Instructions Manual before using the product. Please keep this Instructions Manual at hand so that it is always available for reference. MN0090-2...

- Page 2 Instructions Manual Introduction This Instructions Manual describes the safe and proper method of handing "5-phase Stepping Motor Driver ADB-5F40" with emphasis on the specifications, assuming that our readers are engaged in designing of control devices incorporating stepping motors. Please ensure to read and understand this Instructions Manual before using the product.

- Page 3 Instructions Manual Descriptions in this manual on safety matters: This product must be operated and used properly. Otherwise , or when it is operated and used erroneously, unforeseen accidents may occur, causing physical injuries or property damages. Majority of these accidents can be avoided if you are well informed of hazardous circumstances in advance.

-

Page 4: Table Of Contents

Instructions Manual Introduction Descriptions in this manual on safety matters: CONTENTS PAGE 1. Safety 1-1. Safety Precautions 1-2. Safety Information for Handling 2. Overview 2-1. Characteristics 2-2. Product Configuration 2-3. Appearance 3. Name and Function of Each Section 3-1. Signal I/O Connector (J1) 3-2. - Page 5 Instructions Manual PAGE 8. Maintenance and Check-up 8-1. Maintenance and Check-up 8-2. Troubleshooting 9. Storing and Disposal 9-1. Storing 9-2. Disposal 10. Specifications 10-1. General Specifications 10-2. I/O Signal Example Circuit Connection Drive pulse input (CW,CCW) Motor excitation stop input (M.F) Phase signal output (P.O)

-

Page 6: 1.Safety

Instructions Manual 1.Safety 1-1.Safety Precautions WARNING (1) This product is not designed or manufactured for application for equipment requiring high level of reliability such as equipment related to nuclear energy, aeronautics-related equipment, automobiles, ships, medical appliances directly handling the human body and equipment that might seriously affect properties. -

Page 7: Safety Information For Handling

Instructions Manual 1-2.Safety Information for Handling ●Overall: Do not touch the driver during operation or immediately after stopping. it may cause burn on the skin due to overheating of the driver. ●When setting up the MOTOR SELECT switch: Erroneous setting may cause burn on the skin due to overheating of the motor. - Page 8 Instructions Manual ●When setting up the DRIVE CURRENT SELECT switch: A high setting value may cause burn on the skin due to overheating of the motor. Do not select a high value beyond the required. ●When setting up the PULSE INPUT TYPE SELECT switch: ...

- Page 9 Instructions Manual ●When inputting the motor excitation stop (M.F) signal: Deterioration of the holding power with the motor may cause breakage of the machine or injury. Check safety before inputting. ●When the overheat alarm (O.H.A) LED comes on: WARNING Overheating may cause fire.

-

Page 10: 2.Overview

Instructions Manual 2.Overview 2-1.Characteristics ADB-5F40 and ADB-5F40A is a driver for a 5-phase stepping motor with DC +24V input. It can drive a 5-phase stepping motor with 0.75A/phase and 1.4A/phase. Step angles can be selected from six step angles ranging from 1 division to 40 division of the basic angle. -

Page 11: 3.Name And Function Of Each Section

Instructions Manual 3.Name and Function of Each Section 3-1.Signal I/O Connector(J1) ADB-5F40 CW drive pulse signal input terminal ●Directs the motor to operate CW. CCW drive pulse signal input terminal CCW+ ●Directs the motor to operate CCW. CCW- Motor excitation stop signal input terminal M.F+... -

Page 12: Dc Input/Motor Output Connector (J2, J3)

Instructions Manual 3-2.DC Input/Motor Output Connector(J2,J3) ADB-5F40 BLK 1 GRN 2 ORN 3 Motor output terminal ●Outputs current to drive the motor. BLU 5 DC+24V DC+ 1 DC input terminal 0V DC- 2 ●Power input terminal. DC power supply is connected. -

Page 13: Operating Section

Instructions Manual 3-5.Operating Section Factory Name of Operating Section Function Setting ROTATE CHARACTRISTIC Select a charactristic of motor rotation. [OFF] SELECT switch MOTOR SELECT switch Use it with OFF. [OFF] HOLD SWITCHING TIME DRIVE/HOLD CURRENT automatic switching [OFF(DH1)] SELECT switch time is selected. -

Page 14: 4.Setting

Instructions Manual 4.Setting 4-1.Setting MOTOR SELECT switch Erroneous setting may cause burn on the skin due to overheating of the motor. Ensure correct setting. Set this switch with power OFF. The switch is factory-set to [OFF]. Use it with [OFF]. 4-2.Setting STEP ANGLE SELECT switch ... -

Page 15: Setting Hold Current Adjustment Trimmer

Instructions Manual 4-3.Setting HOLD CURRENT ADJUSTMENT trimmer A high setting value may cause burn on the skin due to overheating of the motor. Do not select a high value beyond the required. HOLD CURRENT is set up with the HOLD I.ADJ trimmer. The ratio of HOLD CURRENT to DRIVE CURRENT can be selected. -

Page 16: Setting Drive Current Select Switch

Instructions Manual 4-4.Setting DRIVE CURRENT SELECT switch A high setting value may cause burn on the skin due to overheating of the motor. Do not select a high value beyond the required. DRIVE CURRENT is set up with the DRIVE I.SEL switch. The switch is factory-set to [IH]. -

Page 17: Setting Pulse Input Type Select Switch

Instructions Manual 4-5.Setting PULSE INPUT TYPE SELECT switch Erroneous setting may cause breakage of the machine or injury due to unexpected rotation of motor. Ensure correct setting. Pulse input method is set up with the SPI SEL switch. Set this switch with power OFF. The switch is factory-set to 2-pulse input method[2P]. -

Page 18: Setting Hold Switching Time Select Switch

Instructions Manual 4-6.Setting HOLD SWITCHING TIME SELECT switch DRIVE/HOLD CURRENT automatic switching time is set up with the DHT SEL switch. The switch is factory-set to [DH1]. (1) Set the DHT SEL [DH1/DH2] switch. Hold Switching DHT SEL Time DH2(15ms) DH1(150ms) 4-7.Setting ROTATE CHARACTRISTIC SELECT switch The switch is factory-set to [OFF]. -

Page 19: 5.Installation

●Where it is not exposed to splashes of water, oil or chemicals. (2) Install the driver at least 15mm away from other equipment. 15mm or more 15mm or more ADB-5F40 ADB-5F40 15mm or more 15mm or more (3) Considering heat release, control the ambient temperature around the driver within the specified value. -

Page 20: Mounting Method

Instructions Manual 5-2.Mounting Method The round holes on the main body are used. The following items are required: ●M-3 screw (8mm or more in length): ●M-3 spring washer: ●M-3 flat washer: (1) Fix the product at the two round holes on the main body. ●Mounting example -20-... -

Page 21: 6.Connection

Instructions Manual 6.Connection 6-1.Overview of Connection Configuration Motor DC Power Supply DC+24V 0V(GND) User ADB-5F40 Controller Twisted J3 1 2 3 4 5 J2 1 2 pair wire CCWP CCW+ CCWP CCW- +COM M.F+ M.F- R.GND R.GND ●Connect only one motor to one driver. -

Page 22: Connecting Signal I/O Connector (J1

(Surface on which the contacts are inserted) Housing for J1 〈Crimping〉 〈Wiring〉 〈Insertion〉 〈Connection〉 Housing User Contact ADB-5F40 for J1 Controller (0.15mm or more) Drive pulse input CCWP CCW+ Drive pulse input... -

Page 23: Connecting Dc Input/Motor Output Connector (J2, J3

Also, check if the contacts are not displaced from the housing. (Surface on which the contacts are inserted) Housing for J2 Housing for J3 〔DC input Connector〕 〈Crimping〉 〈Connection〉 〈Insertion〉〈Wiring〉 ADB-5F40 Housing Contact for J2 Power Supply (0.3mm or more) DC+24V DC+24V (0.3mm... -

Page 24: Inputting Power

Instructions Manual 〔Motor output Connector〕 〈Connection〉 〈Crimping〉 〈Insertion〉〈Wiring〉 ADB-5F40 Housing Contact (0.3mm or more, for J3 Leads of the motor 5m Max.) BLK 1 Violet/Blue GRN 2 Red/Gray ORN 3 Motor Black/Yellow RED 4 White/Orange BLU 5 Green/Brown 〈Connection〉 〈Crimping〉... -

Page 25: 7.Confirmation Of Setting And Connection

Instructions Manual 7.Confirmation of Setting and Connection 7-1.Check Points This product requires different switch setting and motor wiring depending on the motor used. Check if the switch setting and the motor wiring are correctly performed. Check Points Check Remarks MOTOR SEL Setting of MOTOR SELECT switch (OFF) SPI SEL... -

Page 26: Maintenance And Check-Up

Instructions Manual 8.Maintenance and Check-up 8-1.Maintenance and Check-up WARNING Injury or fire is apprehended due to unexpected behavior. Do not replace fuse. Do not disassemble, repair or modify. (1) As for maintenance inspections the engineer of the specialty shall do it. (2) We recommend that the following check-ups should be performed periodically: ●Checking for any loosened contact on the connectors. -

Page 27: Troubleshooting

Instructions Manual 8-2.Troubleshooting Trouble Check Item Assumed Cause 1. POWER LED does not ・Connection of power supply. ・Wiring error with power come on. supply. ・Value of power voltage. ・Power voltage failure. ・Driver failure. 2. The motor is not excited. ・Connection of the motor to ・Wiring error with the motor (It can be easily the driver. -

Page 28: Storing

Instructions Manual 9.Storing and Disposal 9-1.Storing (1) Keep the product in the following environment: ●Indoors (where it is not exposed to direct sun). ●Where ambient temperature and humidity are controlled within the range set out in the specifications. ●Where there is no explosive, corrosive or inflammable gas. ●Where it can be protected from dust, salt or iron powder. -

Page 29: 10.Specifications

No abnormality should be found after a vibration test Vibration at 10~55Hz, 0.15mm P-P DC connector - signal connector - Frame Insulation resistance DC500V 100MΩ or more (Each other) H W D ●ADB-5F40 65 × 57 × 29 (mm) Exterior Dimensions H W D ●ADB-5F40A 65 ×... - Page 30 Instructions Manual 10-2.I/O Signal (1) Example Circuit Connection -30-...

-

Page 31: (2) Drive Pulse Input(Cw, Ccw

Instructions Manual (2) Drive pulse input(CW, CCW) ① Operating current range : 9mA~27mA The photo-coupler turns on with inter-terminal voltage of 3.1 V~5.5 V. (Photo-coupler diode V ≒ 1.6 V) ② Timing chart CCWP [To the line driver 26LS31] CW + (CCW +) t1≧1.45μs,t2≧1.45μs,tf,tr≦2μs 26LS31... -

Page 32: Motor Excitation Stop Input (M.f)

Instructions Manual (3) Motor excitation stop input(M.F) Deterioration of the holding power with the motor may cause breakage of the machine or injury. Check safety before inputting. ① Operating current range : 2.6mA~19.5mA The photo-coupler turns on with inter-terminal voltage of 4.5 V~26.4 V. (Photo-coupler diode V ≒... -

Page 33: Phase Signal Output (P.o)

Instructions Manual (4) Phase signal output(P.O) ① Output current a. I ≦6mA, V <5V CE(sat) b. I ≦2mA, V ≦0.6V CE(sat) ≦30V ● In case of the excitation home position, the signal is output. (photo-coupler ON) ② Timing chart ● P.O output timing (for 1/1 STEP) CCWP 7.2°... -

Page 34: Overheat Alarm(O.h.a)Led

Instructions Manual 10-3.Overheat alarm LED (O.H.A) WARNING Overheating may cause fire. Stop operation when this LED comes on. ● In case of internal temperature of the driver reaches approx. 70℃ or more, O.H.A LED comes on. At this time the motor output current is not blocked. ●... -

Page 35: Dimensions

Instructions Manual 10-4.Dimensions (Unit:mm) -35-... -

Page 36: Applicable Motors

Instructions Manual 10-5.Applicable Motors ●ADB-5F40 can drive a 5-phase stepping motor with 0.75A/phase and 1.4A/phase. Basic Current Setting Setting Torque Data ORIENTAL MOTOR Co., Ltd. Angle (A/phase DRIVE I.SEL MOTOR SEL Fig. No. (°) switch No. switch No. 0.72 0.75 OFF (IL) Fig.1... -

Page 37: Torque Characteristics

Instructions Manual 10-6.Torque Characteristics (1) Representations in the torque characteristics table are made in terms of the -1 motor rotation (s ) vs. torque (N・m). -1 Motor rotation (s ) and drive pulse frequency (Hz) are converted as follows: 360° -1... - Page 38 Instructions Manual -38-...

- Page 39 Instructions Manual -39-...

- Page 40 Instructions Manual -40-...

- Page 41 Instructions Manual -41-...

- Page 42 Instructions Manual -42-...

-

Page 43: Conforming To Europe Standards

Instructions Manual 10-7.Conforming to Europe standards (1) Low voltage directive This product is not subject to the EC’s Low Voltage Directive by the following. ・ This product should be installed within an enclosure. ・ For the driver’s power supply, use a DC power supply with reinforced insulation on its primary and secondary sides. -

Page 44: The Main Parts Which Revised By This Manual

Instructions Manual The main parts which revised by this manual Parts Content 【R1】 P10,P29,P35 Addition of [ADB-5F40A]. 【R2】 Deletion of the directive number. -44-... - Page 45 Technical Service TEL.(042)664-5382 FAX.(042)666-5664 E-mail s-support@melec-inc.com Sales and Service TEL.(042)664-5384 FAX.(042)666-2031 URL:http://www.melec-inc.com Melec Inc. Control equipment marketing department 516-10,Higashiasakawa-cho,Hachioji-shi,Tokyo 193-0834,Japan This Operating Manual is subject to change without prior notice 1610 for the purpose of product improvement.

Need help?

Do you have a question about the ADB-5F40 and is the answer not in the manual?

Questions and answers