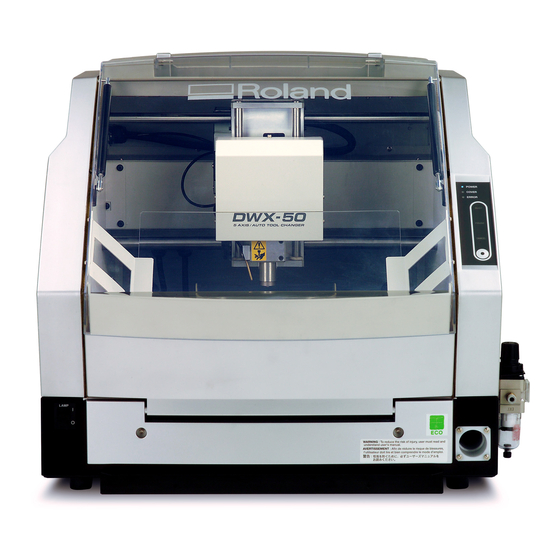

Roland DWX-50 How To Use Manual

Manual correction in vpanel

Hide thumbs

Also See for DWX-50:

- Setup & maintenance manual (77 pages) ,

- Operation manual (10 pages) ,

- How to install (2 pages)

Advertisement

Quick Links

Advertisement

Summary of Contents for Roland DWX-50

- Page 1 How to use manual correction in VPanel DWX‐50 Ver.1.0 Jan 28th, 2013 ...

- Page 2 Contents 1. Manual correction 1‐1. Introduction 1‐2. How to find a displacement in Z‐axis 2. Manual correction using a test block Appendix. Calculation sheet...

-

Page 3: Manual Correction

1. Manual correction 1‐1. Introduction In VPanel, you can make corrections of the machine. Perform corrections if you want to precisely adjust the accuracy. Refer to VPanel Guide for more information. NOTE : Corrections in VPanel does not guarantee any cutting accuracy. Coordinates and origin of DWX‐50 Direction of each axis is as follows with DWX‐50. XYZ origin will be set at the center of the clamp. A and B origins are the point where the clamp is leveled. Manual correction A correction window comes up when you click [Manual correction]. You can make three corrections in VPanel. NOTE : If you tick [Clear these values when executing rotary axis correction], all the correction values will be cleared when you execute [Correct rotary axis] in VPanel. All the manual correction values will be ignored when you execute [Correct rotary axis]. - Page 4 1. Distance (correction of distance in the XYZ direction) It would be ideal for the modeling machine if its moving distance is exactly the same as you expected but it does not always fit without any error. Correction of distance in the XYZ direction works for compensating the error between the value you expected and actual value. Each DWX‐50 has its internal correction value at the factory (Factory auto correction) for error compensation so that moving distance will fit as you expected. In VPanel, you can make correction of distance manually. You can find the two correction values on the system report as "LENGTH CORRECTION". Factory auto correction Manual correction Function This is used when an object is bigger / smaller in certain direction. Available offset range : 99.500 % to 100.500 %, in increments of 0.001 % Default : 100 % bigger than 100% If a offset value is the size becomes bigger. smaller than 100% If a offset value is the size becomes smaller. If you input 100.1% in Y‐axis, the length in Y‐axis will be longer in 100.1%. In case the original length is 10.00mm, it will be 10.01mm. 2. A axis back side (inversion correction of A axis) In two‐surafe cutting, it is important that the A axis turns (A=0 / A=180) without any error. Inversion correction of A axis works for compensating the error. Function This is used when the thickness in Z direction is different between the left and the right. Available offset range : ‐1.00 degree to 1.00 degree, in increments of 0.01 degree Default : 0.00 degree...

- Page 5 If you input a positive offset value, thinner, the thickness at the right will be thicker the left will be If you input (+) 0.01 degree, the rightmost thickness will be thinner by 0.008 mm, the leftmost thickness will be thicker by 0.008 mm. 98mm +0.008mm ‐0.008mm 3. Origin point (correction of the origin) When DWX‐50 performs cutting displacement could occur in the cutting result, because the machine performs two‐surface cutting using the rotary axis (A axis). Correction of origin compensates the error by shifting the origin position. Material Object 1. Cut the first surface 2. Turn A‐axis 3. Cut the second surface in 180 degrees Function This is used when there is a displacement in Y direction, or the thickness in Z direction is thicker / thinner than you expected. The function varies depending on the direction. Available offset range : ‐1.00 mm to 1.00 mm, in increments of 0.01 mm Default : 0 mm...

- Page 6 Correction of X origin It is not necessary to make a correction for X origin basically. Cutting location does not change in two‐surface (A=0 / A=180) cuttting, therefore the displacement may not occur. Object Object Top View Material A : 0 A : 180 Correction of Y origin In Y axis direction, cutting location is inverted in two surface cutting, therefore the displacement could occur. Correction of Y origin can minimize the displacement between the first surface and the second surface. Top View Object Object A : 0 A : 180 First surface Displacement in Y‐direction Second surface...

- Page 7 If you input a positive offset value, the first surface will move to the right, the second surface will move to the left. If you input (+) 0.01 mm, the first surface will move 0.01 mm to the right, the second surface will move 0.01 mm to the left. The step will be 0.02 mm. Example : If the displcement is 0.02 mm, you will enter 0.01 mm in VPanel. displacement : 0.02mm 0.01mm Positive value Negative value 0.01mm Correction of Z origin If Z origin is different between the one the software calculates and the one actually set, it makes the thickness of the object thicker / thinner. Correction of Z origin compensates the error in thickness. 1. Z origin matches with the point you expected. Z origin C ORRECT No difference between the one you expected and actual result. ‐ 2. Z origin is higher than you expected. Z origin INCORRECT The cutting result will be thicker. ‐ ...

- Page 8 3. Z origin is lower than you expected. Z origin INCORRECT The cutting result will be thinner. ‐ If you input a positive offset value, the thickness will be thicker. If you input (+) 0.01 mm, the thickness will be 0.02 mm thicker. +0.01mm +0.02mm (increased amount) +0.01mm...

- Page 9 1‐2. How to find a displacement in Z‐axis It is important to make an appropriate correction depending on the situation of the error. Make sure the situation shown below to make a correction in an appropriate way. Actual size Expected size (error) Case 1 : Correction of distance in the Z direction is required The amount of error increases in proportion to the thickness. Case 2 : Inversion correction of the A axis is required The error reverses across the A axis. Case 3 : Correction of the Z origin is required The amount of error is always the same regardless of the position.

- Page 10 2. Manual correction using a test data You can make correction manually using a test data. A test data is prepared for calculating each correction value by measuring the test block. Necessary items Have the following items ready for manual correction using a test data. digital caliper wax disc with levels R1 ball end mill or dial caliper required accuracy : 0.01mm 14mm effective length : 10mm or more (e.g. ZCB‐100D) 2‐1. Outputting the test data Workflow 1. Set a wax disc on the clamp. 2. Set a R1 ball end mill on the stocker #1. 3. Set the air pressure as 0.05MPa. 4. Output the test data (DWX‐50_correctiontest.prn) from VPanel. Cutting area is as follows. You can cut three pieces of test block in one disc. Required time : 30 min. R1 ball end mill wax disc with levels (14mm) cutting area...

- Page 11 2‐2. Measuring the test block 1. Measure each part using a caliper. NOTE : Measure the shadow area (upper part) for X1, X2, Y1 Do not measure at curved part for Z1. and Y2. Measure the upper part above the center for Y3. Measure the lower part below the center for Y4.

- Page 12 2. Enter each measurement value in the calculation sheet. 2‐3. Entering the current correction value Check each correction value in VPanel. Enter the current correction value in the calculation sheet.

- Page 13 2‐4. Entering the calculated correction value Calculated value will be shown in the calculation sheet. Enter each correction value in VPanel. Output the test data again in reference to the step 2‐1. Measure the test block in reference to the step 2‐2. Manual correction is finished if the cutting result comes out as you expected.

Need help?

Do you have a question about the DWX-50 and is the answer not in the manual?

Questions and answers