Hupfer SGR Operating Instructions Manual

Belt conveyor system

Hide thumbs

Also See for SGR:

- Operating instructions manual (33 pages) ,

- Operating instructions manual (36 pages) ,

- Operating instructions manual (39 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hupfer SGR

- Page 1 Operating Instructions Belt Conveyor System SGR | SPV 4330053_A7...

-

Page 2: Introduction

Appliance name Belt Conveyor System Appliance type/s SGR | SPV Year of manufacture 2014 Manufacturer HUPFER® Metallwerke GmbH & Co KG Dieselstraße 20 48653 Coesfeld Germany Postfach 1463 48634 Coesfeld, Germany ' +49 2541 80 50 +49 2541 805 111 www.hupfer.de... -

Page 3: Table Of Contents

Transport, Installation, Initial Operation and Taking out of Service Transport Assembly 4.2.1 Assembly of segments 4.2.2 Pulling up the belt 4.2.3 Stretching the belt 4.2.4 Adjusting the belt Commissioning 4.3.1 Connecting the conveyor system Belt Conveyor System 4330053_A7 SGR | SPV... - Page 4 Notes on Care and Maintenance Measures 7.3.1 Table of care measures 7.3.2 Maintenance table Special Care Instructions Spare Parts and Accessories Introduction Spare Parts and Accessories List Annex Monthly Maintenance Checklist Safety Instruction Protocol EC Declaration of Conformity Belt Conveyor System SGR | SPV 4330053_A7...

-

Page 5: List Of Abbreviations

Light diode LMHV Regulation on the hygiene of foodstuffs Residual Current Device Residual current device (RCD) Safety temperature limiter Association of Electrical Engineering, Electronics and Information Technology (Verband der Elektrotechnik, Elektronik und Informationstechnik e.V.) Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 6: Definitions Of Terms

The basis for machine safety is directives and laws for protecting users of technical devices and systems valid nationally and across the EC. Passive layer A non-metallic protective layer on a metallic material that prevents or slows down material corrosion. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 7: Orientation Of The Appliance

"Right" refers to the right side of the conveyor system in relation to the conveying direction. The left "Left" refers to the left side of the conveyor system in relation to the conveying direction. Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 8: Notes On Using The Manual

Brief description of additional information Attention is pointed to special conditions or additional important information on the topic concerned. INFO Short title It contains additional information on work ease or recommendations on the topic concerned. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 9: Safety Instructions

Hazardous electrical voltage Risk of hand injuries caused by belt drive Risk of hand injuries Risk of crushing Hazard caused by hot surfaces Switching prohibited Wear hand protection Read and observe the operating instructions Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 10: Safety Instructions For Appliance Safety

Do not place the appliance on sloping floors. Before placing the appliance in position make sure that the floors are level and even and the conveyor system is level. § A maximum belt length of 7 m may not be exceeded. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 11: Position Of The Emergency Stop Button

Unimpeded access to the Emergency Stop buttons must be on hand at all times. § Make sure that nobody is exposed to a hazard as a result of the activation of the conveyor system before switching on the appliance. Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 12: Safety Instructions For Maintenance And Care

Tighten the loosened screw connections and fit the safety devices back to the appliance if dismantled, and test their proper functioning after completing the repair work. § Defective components may be replaced with original parts only. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 13: Notes On Specific Hazards

The appliances on which inspection, maintenance and fault repairs are performed must be disconnected from the power supply and secured against reactivation when power is not required for such work. This may only be carried out by a qualified electrician. Belt Conveyor System 4330053_A7 SGR | SPV... -

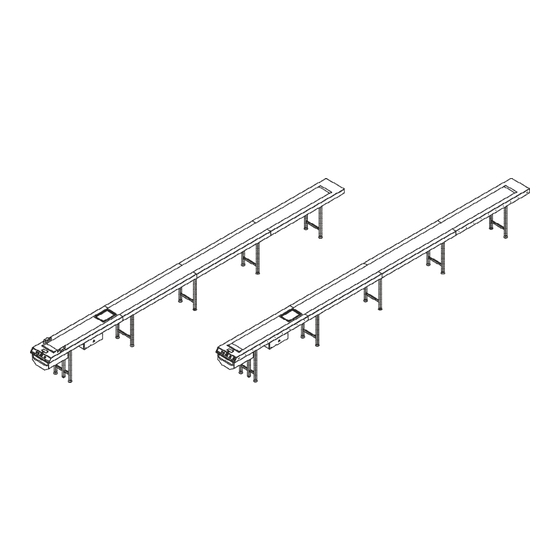

Page 14: Description And Technical Data

The conveyor system is mainly designed to hold up Gastronorm and Euronorm trays. Any other use is not permitted. The crockery return belt system (SGR) is used to hold up and to convey away trays with dirty crockery, cutlery, glasses and napkins. -

Page 15: Appliance Description

Section 3 Appliance Description Page 15 Appliance Description 3.4.1 View of the crockery return belt system Figure 2 View of the appliance SGR Beginning of the belt Connector with conveyor roller Belt Control Belt system leg Cleaning drawer with scraper... -

Page 16: View Of The Food Distribution Belt System

§ Plastic shelves in the base (SGR and SPV) The plastic shelves are designed as storage shelves in the base. The elements are placed on the long rails in the base of the conveyor system. The shelves are suitable for long-term use, even at maximum load (up to 10 kg/m) at temperatures between -30°C and +70°C. - Page 17 Page 17 § End segment with limit rocker switch (SGR and SPV) The limit rocker switch is fitted in the end segment of the frame surface at the end of the belt. In case of mechanical strain the limit rocker switch will be pressed down, thus generating an electric signal, and the belt will stop moving.

-

Page 18: Technical Data

Operating and ambient +41 to +131 °F conditions (+5 to +55) (°C) You can find the corresponding certification marks on our homepage at www.hupfer.de. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 19: Rating Plate

Disposal of old appliances Nominal current Certification mark Frequency Protection class Nominal voltage Refrigeration capacity Payload Refrigerant Tare weight Induction frequency Serial number/Order number Electrical serial number Item and brief description Electric power Manufacturer Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 20: Transport, Installation, Initial Operation And Taking Out Of Service

Wear protective goggles and safety gloves at all times when placing and joining the belt. INFO Conveyor systems longer than 6 m The following section only applies to conveyor systems longer than 6 m which need not be delivered and mounted as a unit. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 21: Assembly Of Segments

Preload both plates with a hammer and a punch, then fasten all nuts with a maximum torque of 20 Nm. § Continue with the assembly as described above until the last segment. § Check again the inclination and align the conveyor system horizontally with the spirit level until it is level. Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 22: Pulling Up The Belt

Trim any plastic strips protruding from the sides to the width of the belt using robust scissors after stretching the belt. § Finally, scorch and seal these both places with a small flame (e.g., with a lighter), so that the plastic strips cannot slip out any more. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 23: Adjusting The Belt

Switch off the conveyor system and secure it against unintended reactivation after the belt has been adjusted. Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 24: Commissioning

To connect the conveyor system, proceed as follows: § Connect the connecting cable with the distributor of the conveyor system. § Connect the three-phase motor in such a way that it rotates in a specified direction. Belt Conveyor System SGR | SPV 4330053_A7... -

Page 25: Measures For Putting The Appliance Into Operation

Transport, Installation, Initial Operation and Taking out of Service Section 4 Decommissioning, Storage and Recycling Page 25 Electrical connections SPV/SGR Control system and SPV cold SPV-I SPV-II SPV-III power distribution Number of 230 V sockets Electrical supply 230V~, N/PE 230V~, N/PE... - Page 26 NOTE Disposal of electrical equipment Electrical equipment is not a part of household refuse. Please return the machine to the manufacturer for disposal purposes: HUPFER® Metallwerke GmbH & Co. KG Dieselstrasse 20 48653 Coesfeld ' +49 2541 805-0 +49 2541 805-111 www.hupfer.de...

-

Page 27: Operation

Never reach into the hazardous area of the conveyor system during operation. Before switching on the conveyor system, make sure there is no risk of reactivation of the belt. Arrangement and Function of the Controls Figure 6 Controls Main switch (SGR only) Stop button Emergency Stop button Start button Potentiometer Position... -

Page 28: Operation

Press the red stop button (2) or the foot switch (option) to stop the conveyor system, if required. § Set the main switch (1) on the SGR from the switch position 1 to the switch position 0. As a result, the conveyor system will switch off. -

Page 29: Troubleshooting And Repair

In the event of after-sales service and when ordering spare parts specify always the data given in the rating plate. Regular inspections and maintenance of the appliance prevent disruptions to operation and ensure safety. Fault and Action Table Only a specialist staff authorised by HUPFER® may perform troubleshooting work. Fault Cause Measures... - Page 30 Impurities between the belt and Clean and readjust the driving roller driving roller and/or deflection pulley and/or deflection pulley The belt runs obliquely The tension is too low Check and adjust the tension Belt Conveyor System SGR | SPV 4330053_A7...

-

Page 31: Care And Maintenance

Let the belt dry well after cleaning. The use of degreasing, chlorine-free agents (e.g. soapy water used normally in kitchens) and cleaning cloth is sufficient for cleaning. PVC surfaces are never to be cleaned with solvents and aggressive substances. Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 32: Table Of Care Measures

Belt tension check Bearing of the drive and deflection side check Function of the limit switch check Function of the conveyor rollers check Chain tension check Chain Lubricate = every 6 months Belt Conveyor System SGR | SPV 4330053_A7... -

Page 33: Special Care Instructions

Therefore, only use refined steel wool or brushes with natural, plastics or refined steel bristles only for physical cleaning. Steel wool or brushes with unalloyed steel cause extraneous rust due to abrasion. Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 34: Spare Parts And Accessories

21.89 (015223024) Double link cropped 3/8" C-06B-1 (Package contents: 1 unit 5223024) 21.89 (015223023) Connecting link 3/8" x 7/32" (Package contents: 1 unit 5223023) 21.89 (0116300554) Lower belt roller 431/50/28 0116301248 Belt Variable length Belt Conveyor System SGR | SPV 4330053_A7... -

Page 35: Annex

Check the belt tension Check the bearing of the drive and deflection side Check the function of the limit switch Check the function of the conveyor rollers Check the chain tension Lubricate the chain Belt Conveyor System 4330053_A7 SGR | SPV... -

Page 36: Safety Instruction Protocol

Annex Section 9 Page 36 Safety Instruction Protocol Safety Instruction Protocol The following staff members have received instruction on safety procedures. They have read and understood the operating instructions. Name Signature / date Belt Conveyor System SGR | SPV 4330053_A7... -

Page 37: Ec Declaration Of Conformity

Annex Section 9 EC Declaration of Conformity Page 37 EC Declaration of Conformity Belt Conveyor System 4330053_A7 SGR | SPV... - Page 38 Annex Section 9 Page 38 EC Declaration of Conformity Belt Conveyor System SGR | SPV 4330053_A7...

Need help?

Do you have a question about the SGR and is the answer not in the manual?

Questions and answers