Table of Contents

Advertisement

Quick Links

Features

•

Redundant Solenoid Valve Release

•

Externally Resetable Clapper

•

One Main Drain

Product Description

Reliable Single Interlock Preaction Systems are designed for

water-sensitive areas that require protection from inadvertent

water flow into the sprinkler system piping. A single event, the

activation of the electrical detection system, causes the valve to

operate and flow water into the piping network.

Sprinkler piping in single interlock systems can effectively

be supervised by means of the Reliable Model A Pressure

Maintenance Device (provided) and a tank-mounted air

compressor. Loss of supervising pneumatic pressure, due to

a damaged sprinkler or sprinkler pipe will not cause water to

flow through the Model EX Valve and into the system piping. A

significant loss of pneumatic pressure will activate a trouble-

annunciating device when the system pressure falls below a

predetermined pressure level.

The system incorporates two normally closed solenoid valves on

the releasing trim. These solenoid valves, when closed, retain

sufficient AIR pressure on the pneumatic actuator, which in turn

preserves sufficient WATER pressure in the push rod chamber

of the Model EX Valve in order to maintain it closed. When the

electrical detection system senses the presence of fire, the

electrical releasing control panel activates fire alarm devices and

energizes the two redundant, normally-closed solenoid valves into

the open position.

Energizing the solenoid valves relieves the air pressure on the

pneumatic actuator, thereby releasing the water pressure that it

was retaining. This in turn relieves the pressure in the push rod

chamber of the Model EX Valve. Venting the push rod chamber

will open the Model EX Valve and allow water to flow into the

sprinkler system.

Water flowing into the sprinkler system piping will simultaneously

produce water pressure that causes the transfer of contacts in

the pressure switch mounted in the trim. This pressure switch can

Valve Size

2" (50mm), 2-1/2" (65mm), 76mm &

3" (80mm)

4" (100mm)

6" (150mm) & 165mm

8" (200mm)

Availability: UK

electrically initiate the shutdown or startup of equipment, such as

computers or other second alarm devices. The flow of water into

the sprinkler system piping effectively converts the dry system

into a wet pipe system. In the event that the fire subsequently

produces sufficient heat to operate a fire sprinkler, water will flow

from that sprinkler, controlling or suppressing the fire.

The major benefits of a single interlock preaction system, when

compared with a wet pipe (deluge) system are as follows:

1.

A fire alarm sounds prior to the operation of a sprinkler,

which may enable extinguishing the fire by handheld means

before the actual operation of any sprinklers and subsequent

water damage.

2.

A trouble annunciator signals whenever the integrity of the

piping or sprinklers is accidentally or intentionally disturbed;

however, no water flow or water damage will occur at that

time.

3.

Speedy detection and an early fire alarm are provided by

fire detectors, without the delay associated with water flow

detection in the event of a fire. Note: with a wet pipe system,

the fire alarm is delayed until after water has begun flowing

from an operated sprinkler.

End Connection

Groove/ Groove

Groove/ Groove

Flange/ Groove

Flange/ Flange

Groove/ Groove

Flange/ Groove

Flange/ Flange

Groove/Groove

Flange/Flange

www.reliablesprinkler.com

Bulletin 739 January 2021

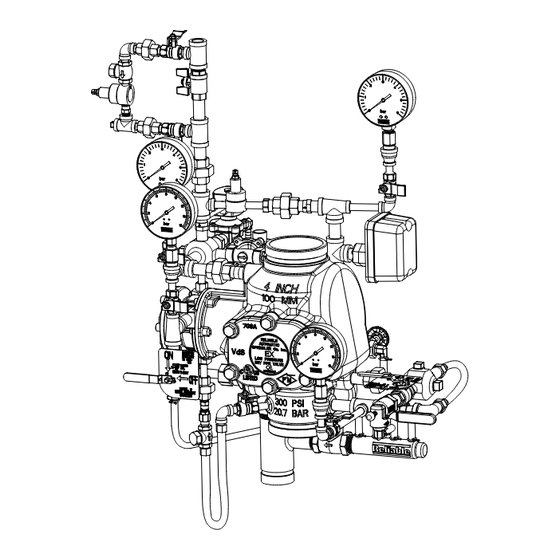

Model EX Single Interlock

Preaction Type A (LPCB)

2", 2-1/2", 76mm, 3", 4", 6", 165mm, & 8"

Approx. Shipping Weight

44lbs (20kg)

74lbs (34kg)

105lbs (48kg)

158lbs (72kg)

Table A

Advertisement

Table of Contents

Summary of Contents for Reliable EX Series

- Page 1 Sprinkler piping in single interlock systems can effectively be supervised by means of the Reliable Model A Pressure Maintenance Device (provided) and a tank-mounted air compressor. Loss of supervising pneumatic pressure, due to a damaged sprinkler or sprinkler pipe will not cause water to flow through the Model EX Valve and into the system piping.

- Page 2 Model EX Single Interlock Preaction System Type A Technical Data Listings and Approvals Technical Specifications LPCB Pressure Rating: 175 psi (12,1 bar) End Connections Minimum Water Supply Pressure: See Table A 20psi (1,4 bar) Minimum Water Supply Temperature: Specifications 40°F (4°C) Groove: ANSI/AWWA C606 Maximum Water Supply Temperature: Flange: ASME B 16.5 or ISO 7005-2 PN16...

-

Page 3: System Operation

The nylon cable piping. The Reliable Model EX Valve is shown in both closed and tie is designed to allow, in case of an emergency, forceful turning of open positions in Fig.2. -

Page 4: System Design Considerations

Note: During the initial system set-up, a higher pneumatic pressure may be required in order to properly seat the internal diaphragm of the pneumatic actuator. Refer to Reliable Bulletin 251 for instructions on how to modify these pressure settings. Friction Loss... - Page 5 Single Interlock Preaction System Air Pressure Settings Figure 3 Bulletin 739 Page 5 of 9 January 2021 www.reliablesprinkler.com...

- Page 6 Model EX Type A Components Figure 4 Resetting the Model EX Single Interlock 11. Open the main drain approximately two turns. 12. Open the pushrod chamber supply valve. System (Ref. Fig. 5) 13. Slightly open the main control valve until water can just be heard running out the main drain.

-

Page 7: Inspection And Testing

O-rings, proceed to step 8. in proper operating condition. Any system maintenance or testing Using Reliable P/N 6881603000 Seat Wrench for 2” (50mm), that involves placing a control valve or detection/control system out 2½” (65mm), 76mm and 3” (80mm) valve sizes, Reliable of service may eliminate the fire protection that is provided by the fire P/N 6881604000 for 4”... -

Page 8: Troubleshooting

Solenoid Valve Clapper Gasket and Seat Replacement Procedure (cont.) WARNING: The owner is responsible for maintaining the 8 (cont). Reach into the valve and grasp the seat and remove fire protection system in proper operating condition. Any it from the valve. Then remove the clapper-mounting ring system maintenance or testing that involves placing a control subassembly from the valve. -

Page 9: Listing & Approvals

Ordering Information CONDITION TWO (System Air coming out of the bleed hole): Specify: System air coming out of the bleed hole is caused by a worn O-ring Model EX Single Interlock Preaction System Type A assembled to the pushrod guide. Remove the piston-pushrod •...

Need help?

Do you have a question about the EX Series and is the answer not in the manual?

Questions and answers