Summary of Contents for Donaldson PowerCore CPC Series

- Page 1 INSTALLATION, OPERATION AND MAINTENANCE MANUAL PowerCore Mist Collectors ® Series CPC Publication 1A65198039 - 3023J 1019 MASTER LANGUAGE - ENGLISH...

-

Page 2: Table Of Contents

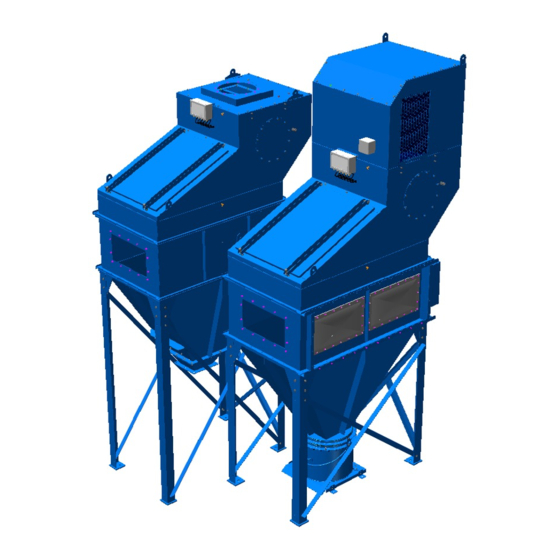

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® TABLE OF CONTENT SAFETY RECOMMENDATIONS ....................4 INSTALLATION ..........................7 Product information ......................8 General guidance to lifting ....................8 CPC-3 and CPC-4 assembly ....................9 CPC-6, CPC-8 and CPC-12 assembly .................. 11 Compressed air requirements ....................12 Controller ..........................13 Collectors with integral fan ....................14... - Page 3 Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® LIST OF FIGURES Figure 1: PowerCore dust collector (model CPC-6F illustrated) ............7 Figure 2: Four-point lifting arrangement (CPC-6R and CPV-6FR illustrated) ........9 Figure 3: PowerCore dust collector (model CPV-6F illustrated) ............10 Figure 4: Support assembly ......................11 Figure 5: Earthing connection between collector side panel and hopper (CPC-6 illustrated) ..13 Figure 6: Attaching Power Box to collector (CPC-6 illustrated) ............14...

-

Page 4: Safety Recommendations

Delivery is an integral part of the manual. Other items of equipment, not supplied under the Scope of Delivery from Donaldson, should be installed, operated and maintained according to the documentation supplied with the respective equipment. Any modification carried out on the ‘as supplied’ equipment may reduce reliability and safety, and will nullify warranty;... - Page 5 Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® The access door requires tools to open. To avoid danger from rotating fan impellor, ensure fan is isolated and allow sufficient time for fan to become stationary. Compressed air is recommended for collectors that operate using reverse jet cleaning.

- Page 6 Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® The explosion relief assembly, where fitted to the dust collector, is not suitable for use with dusts that are classified as poisonous, corrosive, irritant, carcinogenic, teratogenic or multigenic unless the dust released during the explosion venting process can be contained to a safe level.

-

Page 7: Installation

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® INSTALLATION Fan terminal box Compressed air inlet Controller Filter pack retainer Hinged access door Filter pack Lifting bracket Explosion relief Contaminated air inlet Discharge hopper Fan motor Support Diaphragm valve Dust container Compressed air distribution manifold... -

Page 8: Product Information

This can be achieved by applying a continuous 5 mm bead of sealing compound to the mounting surface, along each side of the hole pattern. For non-Donaldson equipment please also check supplier’s IOM manual for any specific requirements. General guidance to lifting Refer also to figure 2. -

Page 9: Cpc-3 And Cpc-4 Assembly

3. Drill through base holes and insert suitable foundation bolts (if required, details of foundation fixing positions are provided in Publication 3021). Foundation bolts are not supplied by Donaldson. 4. Tighten foundation bolts, legs and cross bracing. 5. Stand hopper on the discharge end and apply sealant to top flange, each side of hole pattern. -

Page 10: Figure 3: Powercore Dust Collector (Model Cpv-6F Illustrated)

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® 8. For collectors with dust container, locate position for dust container base panel, drill through fixing brackets and secure with bolts. Adjust height to provide an effective seal between dust container and sealer gear. When the collector is fitted with an earthing post, an earthing connection must be made between the base panel and the dust container, using the earthing cable provided. -

Page 11: Cpc-6, Cpc-8 And Cpc-12 Assembly

3. Drill through base holes and insert suitable foundation bolts (if required, details of foundation fixing positions are provided in Publication 3021). Foundation bolts are not supplied by Donaldson. 4. Tighten foundation bolts, legs and cross bracing. 5. Apply sealant to top flange of dirty air plenum, each side of hole pattern. -

Page 12: Compressed Air Requirements

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® 6. Following the general guidance to lifting, lift the collector onto dirty air plenum. Align bolt holes in flanges with drift pins, install bolts, washers and nuts and tighten all round to form an airtight seal. -

Page 13: Controller

It is a requirement that adequate precaution is taken to avoid exceeding this pressure. Where a relief valve is supplied by Donaldson this device has a relief rating of 17 dm³/s at 6.9 bar. Extra system relief will be required if the connected supply can exceed this. -

Page 14: Collectors With Integral Fan

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Figure 6: Attaching Power Box to collector (CPC-6 illustrated) Collectors with integral fan When the collector is fitted with an Controller, the fan will be wired to the terminal box located on the front of the collector. -

Page 15: Eex Controls

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® of a rotary valve fitted to the collector cease to function, the collector housing will gradually fill with dust until completely choked. Failure of the compressor could also cause a similar blockage. -

Page 16: Explosion Relief

This protection should ensure that pressures developed during an explosion are lower than the collector strength. Consult Donaldson for specific collector design pressures. Refer to Table 1 for predicted flame lengths during an explosion. -

Page 17: Installation Check List

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Installation check list Ensure the dust collector is securely bolted to the support structure. Ensure the support structure is securely bolted to the floor. Ensure compressed air supply is installed correctly and free from leaks. ... -

Page 18: Commissioning

It is a requirement of the Supply of Machinery (Safety) Regulations 1992 to provide adequate isolation and emergency stop facilities. Due to the varied nature of site installations this cannot be provided by Donaldson but instead is the responsibility of the customer. -

Page 19: Shut-Down Sequence

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Shut-down sequence At the end of any period of operation it is most important that all residual deposits are cleared from the PowerCore filter packs, casing, discharge hopper and equipment being served. -

Page 20: Figure 8: Section Through Collector Showing Principle Of Operation (Cpc-6F Illustrated)

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® a Filtering operation (continuous) b Cleaning operation (intermittent) (each filter pack is cleaned separately, in turn) Cleaned air outlet Contaminated air inlet Diaphragm valve Filter pack Compressed air manifold Figure 8: Section through collector showing principle of operation (CPC-6F illustrated) -

Page 21: Dust Disposal

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Dust disposal For safe handling of the dust container an assessment must be made to satisfy the requirements of the European Directive 90/269/EEC on manual handling. Dust containers may require regular emptying. If the dust being handled is explosive, then care should be taken to ensure that dust spillage is kept to a minimum to avoid the creation of potentially explosive atmospheres and secondary hazards. -

Page 22: Maintenenace

Ensure the pneumatic system is fully isolated and depressurised before any work is carried out. For ancillary equipment not manufactured by Donaldson, refer to manufacturer’s instructions. If it is unavoidable to work on the equipment while a potentially explosive atmosphere is present, care should be taken to avoid introducing ignition sources not present during expected operation. -

Page 23: Routine Inspection

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Routine inspection To maintain the optimum performance of any dust collector, a routine inspection should be made to minimise down-time in the event of equipment malfunction, particularly on continuous performance applications and to ensure the equipment is maintained to its original supply condition. -

Page 24: Figure 10: Valve Diaphragm Replacement

If it is found necessary to replace a diaphragm, use the following procedure (see figure 11): Use service kit available from Donaldson. Remove nylon tube (A) by pulling out from valve. 2. Remove the hexagon head set screws and shakeproof washers securing the valve bonnet (B). - Page 25 Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Six-monthly The fan impellor has been dynamically balanced and the fan assembly vibration level should be in line with category BV-3, ISO 14694. An assessment of vibration should be made every six months, or after a significant emission, or after any misuse and a record kept of measured values.

-

Page 26: Filter Pack Replacement

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Filter pack replacement Use safety and protective equipment when removing contaminants and filter packs. Dirty filter packs may be heavier than they appear. Take care when removing filter packs for inspection. Damaged filter packs must be replaced. -

Page 27: Fan Assembly Removal/Replacement

Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Fan assembly removal/replacement Isolate electric power supply. Refer also to figure 12. Disconnect electrical cables from terminal box. 2. Remove fan section top panel. 3. Remove side access cover. 4. - Page 28 Make a note of the distance from either impeller back plate to fan case (preferred) or inlet eye to impeller front plate, as this will assist with replacement. If required, refer to Donaldson for exact dimensions. 2. From front of fan assembly (non motor end) remove impeller inlet eye from fan casing by removing outer circle of bolts and pulling away the plate.

- Page 29 Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Replacing fan assembly: If changing fan assembly for a different type, e.g. K5 to K7, ensure the associated fan mounting plate and fan support channels are used. If required, any necessary electrical items should be resized.

- Page 30 *To run filter packs clear, allow the controller to perform several complete cleaning cycles before switching off compressor etc. This procedure is not recommended where explosion panels are fitted, as damage could result to the membrane. In such cases consult with Donaldson.

-

Page 31: Specification

1/2" NB (12) Normal operating pressure. Recommended initial settings; these may be varied with experience. Sizes suitable for runs of pipe up to 30 m (100ft) in length; for longer runs consult with Donaldson. *Estimated data 1 bar = 10... - Page 32 Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® TABLE 6 – STANDARD FAN MOTOR SUPPLY VOLTAGE DETAILS To comply with European standards the motor nameplate will display the following: 3 Phase / 50 Hz (IEC 60034-30) Nameplate details Range 230/3/50 D...

-

Page 33: Spare Parts

1A 3321 9390 † ART 562 fan assembly (including motor 1A 6521 9002 † For other types/specifications/motors for hazardous areas consult Donaldson † Impellor, K5 fan – item not illustrated 1A 3321 9138 Impellor, K7 fan – item not illustrated 1A 3321 9464 Impellor, SF40 fan –... - Page 34 Installation, Operation and Maintenance manual PowerCore Dust Collectors - Series CPC ® Donaldson Item Description Part number Silicone seal, access door CPC-3 1A 6519 3036 CPC-4 1A 6519 3038 CPC-6 1A 6519 3040 CPC-8 1A 6519 3042 ...

Need help?

Do you have a question about the PowerCore CPC Series and is the answer not in the manual?

Questions and answers