Table of Contents

Advertisement

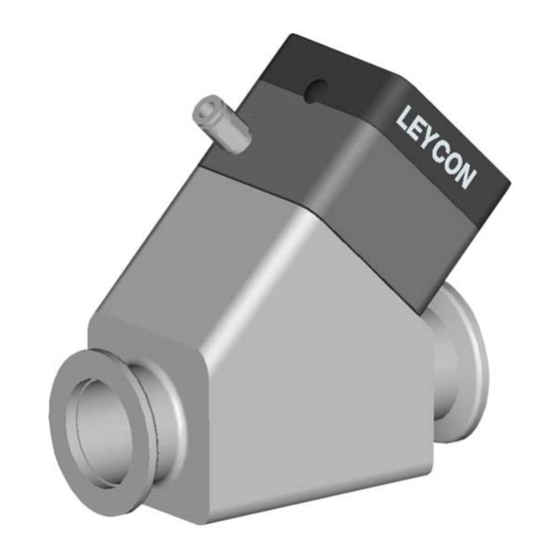

LEYCON

User manual 17200295_002_C0/2016

High Vacuum Angle Valve BAV

DN 16–50 ISO-KF

with pneumatic actuator P

single acting with closing spring (NC)

with electropneumatic actuator EP

single acting with closing spring (NC)

with electropneumatic actuator EP

single acting with opening spring (NO)

(DN 16 - 40 ISO-KF, version AL)

aluminum version AL

stainless steel version VA

Part numbers

215130

215339 – 215345

215314 – 215337

215347 – 215357

High Vacuum Inline Valve BIV

DN 16–50 ISO-KF

with pneumatic actuator P

single acting with closing spring (NC)

with electropneumatic actuator EP

single acting with closing spring (NC)

aluminum version AL

stainless steel version VA

215359 – 215361

215367 – 215369

215363 – 215365

215371 – 215373

215391 – 215393

215394V01 – 215395V01

Advertisement

Table of Contents

Summary of Contents for LEYBOLD LEYCON BAV P AL Series

- Page 1 LEYCON User manual 17200295_002_C0/2016 High Vacuum Angle Valve BAV High Vacuum Inline Valve BIV DN 16–50 ISO-KF DN 16–50 ISO-KF with pneumatic actuator P with pneumatic actuator P single acting with closing spring (NC) single acting with closing spring (NC) ...

- Page 2 Leybold. Offenders are liable to pay damages. The use of trade names, brand names, trademarks, etc. in this user manual does not entitle third parties to consider these names to be unprotected and to use them freely.

-

Page 3: Table Of Contents

Maintenance ..................25 Exchange of vacuum seals ................26 6.1.1 Dismount actuator / plate assembly ............27 6.1.2 Replacement of plate seal ..............27 6.1.3 Mount actuator / plate assembly ............27 Repairs ....................28 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 3/40... - Page 4 Transport ......................31 Disposal ..................... 32 Spare parts and accessories ............33 Appendix ................... 35 12.1 Safety information on contamination ..............35 12.2 Declaration of chemical contamination ............36 12.3 Declaration of incorporation ................37 4/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX...

-

Page 5: Description Of Product

..Build ..Leybold GmbH Bonner Str. 498, D-50968 Köln, Germany Figure 1-1 In all communications with Leybold, please specify the information on the product nameplate. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 5/40... -

Page 6: Validity Of The User Manual

215345 ISO KF 50 215334 ISO KF 50 BAV . . EP AL 24 VDC ISO KF 16 215395V01 ISO KF 25 215394V01 ISO KF 40 215130 ISO KF 50 currentless open (NO model) 6/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... - Page 7 Descriptions and illustrations within this user manual refer to the currentless closed valves (NC). In large parts this is valid for the currentless open valves (NO) as well. Differences are identified and highlighted, if existing. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 7/40...

-

Page 8: Technical Data

1 · 10 to 5000 [mbar], absolute Differential pressure on the plate [bar] In opening direction ≤ 2 In closing direction ≤ 5 Differential pressure at ≤ 2 in either direction opening [bar] see «Figure 3-1» 8/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... - Page 9 Cover of position indicator 0 to 80 Pilot valve 0 to 80 10 millions (except wearing parts such as sealing elements and Cycles until first service position indicators) under clean, static conditions and at max. 80°C 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 9/40...

- Page 10 All valves with position indicator Pilot valve Voltage see specification on pilot valve (range ±10%) Power DC [W] ≤ 2.5 AC [VA] ≤ 4.8 starting / 3.6 holding current Protection class IP50 Table 1-3 10/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX...

- Page 11 29.6 36.1 37.6 129.6 184.6 120.2 168.7 – aluminum version L1/M1 = stainless steel version Valve seat side Required for dismantling Mechanical position indication Leak detection slot Electrical connection Compressed air connection Figure 1-3 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 11/40...

- Page 12 Angle valve: aluminum, NO model Pos. 78.9 79.1 110.2 73.5 59.4 49.3 48.3 74.4 aluminum version Valve seat side Required for dismantling Mechanical position indication Leak detection slot Electrical connection Compressed air connection Figure 1-4 12/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX...

-

Page 13: Components Delivered With The Valve

Improperly accomplished maintenance work may reduce the safety, lifetime and performance of the product and lead to refusal of warranty claims. Maintenance work not described in this user manual may only be carried out by the Leybold service staff or by specialists trained and authorized by Leybold. 270727EI.DOCX 17200295_002_C0/2016 - ©... -

Page 14: Safety

CAUTION Low risk Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury. NOTICE Command Indicates a hazardous situation which, if not avoided, may result in property damage. 14/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 15: Purpose Of Use

• Either use, not explicitly mentioned as permitted use, applies as adverse use. Obligations / area of responsibility 2.4.1 Manufacturer Leybold GmbH as manufacturer is responsible for supplying the product, with its user manual and original accessories, in a completely safe condition. 2.4.2 Operator The operator is the person in charge of the product. -

Page 16: Personnel Qualifications

Adhere to the relevant regulations and take the necessary precautions when handling contaminated parts. Safety labels Label Part No. Location on valve T-9001-155 On protective covers of flanges 253198 On valve body or actuators Table 2-1 16/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 17: Design And Function

Bellows Pilot valve Bonnet seal Actuator complete Screws Pneumatic connection Function Valve is closed by a spring (NC) and opened pneumatically. NO model: Valve is closed pneumatically and opened by a spring (NO). 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 17/40... -

Page 18: Installation

• Store the original packaging material. It may be useful if products must be returned. Remove the protective covers from the valve only at the moment when the valve is being installed into the system. Keep unprotected sealing surfaces clean and do not damage them. 18/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 19: Installation Into The System

Overpressure in the vacuum system >2.5 bar KF flange connections with elastomer seals (e.g. O-rings) cannot withstand such pressures. Process media can thus leak and possibly damage your health. Use O-rings provided with an outer centering ring. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 19/40... - Page 20 «F » Inch lbf · ft 1½ A combination of both forces «F » and «M» is not allowed. Please contact Leybold. Inline valve Angle valve Table 4-1 Keep the protective lids. Check that the vacuum connections are leak tight.

-

Page 21: Compressed Air Connection

With the help of chapter «1.3 Validity of the user manual» check whether it is a valve with or without pilot valve. Connect electrical power. • Valve without pilot valve; see «Figure 4-1» on page 22. • Valve with pilot valve; see «Figure 4-2» on page 22. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 21/40... -

Page 22: Valve With Position Indicator

Figure 4-1 Wiring diagram 4.4.2 Valve with pilot valve and position indicator 7-pole connector < 50V 7-pole connector > 50V Figure 4-2 Wiring diagram The polarity of the 24 VDC connection need not to be considered. 22/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 23: Operation

Behavior in case of air pressure drop Valve closed: Valve remains closed and leaktight. Valve open: Valve will be closed leaktight by a spring. Behavior in case of power failure Valve will be closed leaktight by a spring. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 23/40... -

Page 24: Operation Of The No Model

Valve is closed pneumatically and opened by a spring (NO). • Behavior in case of air pressure drop: Valve closed: Valve will be opened. Valve open: Valve remains opened. • Behavior in case of power failure: Valve will be opened by a spring. 24/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 25: Maintenance

Risk of burning when touching hot surfaces. Touch hot surfaces only if the valve has cooled down. NOTICE Discoloration of the plastic cover The plastic cover may discolor during cleaning with aggressive detergent (e. g. Acetone). Use mild detergent only. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 25/40... -

Page 26: Exchange Of Vacuum Seals

Inappropriate tools Sealing surfaces may get damaged. Do not use sharp-edged tools. Leybold assumes no liability and the warranty becomes null and void if maintenance works are performed, which are not covered by this user manual. Exchange of vacuum seals... -

Page 27: Dismount Actuator / Plate Assembly

Check sealing surfaces of bonnet flange / valve seat and clean it with a cleanroom wiper. Put bonnet seal (62) into body. Insert actuator / plate assembly carefully. Fasten screws (60) uniformly and in crosswise order in 2 to 3 rounds. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 27/40... -

Page 28: Repairs

You will find the addresses of the service centers on the backside of the document. When contacting us, please always specify the fabrication number of the valve; see chapter «1.2 Identification of product». 28/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 29: Dismounting And Storage

Valve must be stored at: – relative humidity between 10% and 70% – temperature between 10 °C and +50 °C – non-condensing environment Clean / decontaminate valve. Cover all valve openings with protective covers or foils. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 29/40... -

Page 30: Packaging And Transport

Harmful substances Risk of injury in case of contact with harmful substances. Remove harmful substances (e. g. toxic, caustic or microbiological ones) from product before you return the product to Leybold. NOTICE Wrong handling during transport Valve and attached parts may get damaged. -

Page 31: Packaging

Valve mechanism may get damaged if valve gate is in open position. Make sure that the valve is closed. Cover all valve openings with protective covers or foils. Pack valve appropriately, by using the original packaging material. Leybold disclaims any liability for damages resulting from inappropriate packaging. Transport NOTICE Inappropriate packaging Product may get damaged if inappropriate packaging material is used. -

Page 32: Disposal

Contaminated components (radioactive, toxic, caustic, microbiological hazard etc.) must be decontaminated in accordance with the relevant national regulations, separated according to their materials, and disposed of. • Other components Such components must be separated according to their materials and recycled. 32/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 33: Spare Parts And Accessories

Non-original spare parts Non-original spare parts may cause damage to the product. Use original spare parts from Leybold only. When you place an order for spare parts, please specify the fabrication number of the valve; see chapter «1.2 Identification of product». This is to ensure that the appropriate spare parts are supplied. - Page 34 (for 4 mm tube) Quick connector EN-7607- EN-7607- EN-7607- EN-7607- (for 6 mm tube) 7-pole connector enclosed, 599998003 loose Table 11-1 Pilot valves with voltage >50 V have an integrated protective conductor in the plug additionally. 34/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX...

-

Page 35: Appendix

• Drain all service fluids • Remove filter elements, where applicable • Close all openings airtight • Pack products appropriately • Dispatch products in suitable transport containers Attach declaration on contamination to the outside of the transport container. 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 35/40... -

Page 36: Declaration Of Chemical Contamination

APPENDIX 12.2 Declaration of chemical contamination 36/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX... -

Page 37: Declaration Of Incorporation

APPENDIX 12.3 Declaration of incorporation 270727EI.DOCX 17200295_002_C0/2016 - © Leybold 37/40... - Page 38 APPENDIX Notes 38/40 17200295_002_C0/2016 - © Leybold 270727EI.DOCX...

- Page 39 (EU), póngase en contacto con su representante de Leybold. Français Le mode d‘emploi fourni avec ce produit est rédigé en anglais et en allemand. N‘hésitez pas à contacter votre agence Leybold si (003) vous avez besoin du mode d‘emploi traduit dans la langue de votre pays (union européenne).

- Page 40 Sales and Service Germany Great Britain America Leybold Japan Co., Ltd. Tsukuba Technical Service Center Leybold UK LTD. 1959, Kami-yokoba Leybold GmbH Unit 9 Tsukuba-shi, Ibaraki-shi 305-0854 Sales, Service, Support Center (3SC) Silverglade Business Park Leybold USA Inc. Japan Bonner Straße 498...

Need help?

Do you have a question about the LEYCON BAV P AL Series and is the answer not in the manual?

Questions and answers