Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for LEYBOLD ISO-KF Series

- Page 1 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

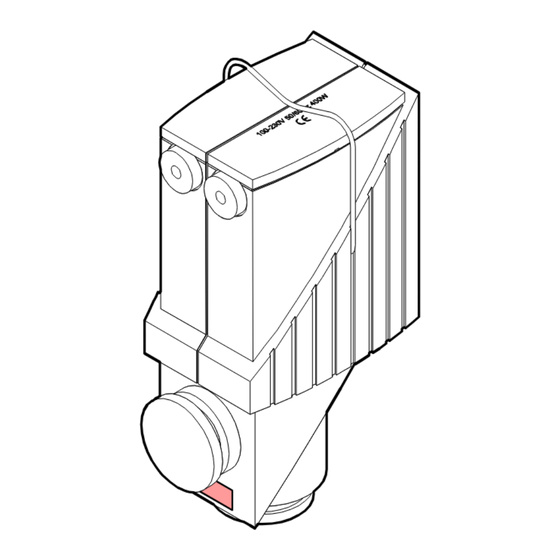

- Page 2 Application LEYBOLD VAKUUM Support Vacuum Solutions Service GA 06.422/2.02 Angle Valve electromagnetically actuated with automatic voltage adaptation 85 … 248 VAC DN 16 … 40 ISO-KF Catalog numbers 287 65 287 66 287 67 288 65 288 66 288 67...

-

Page 3: Product Identification

Product identification In all communications with Leybold Vakuum, please specify the information given on the product nameplate. For convenient reference copy that information into the nameplate replica below. Leybold Vakuum GmbH, D-50968 Köln Typ: F-No: Validity This document applies to products with the following catalog numbers:... -

Page 4: Table Of Contents

Contents Product identification Validity Intended Use Functional Principle Trade Marks 1 Description 1.1 Operating modes 1.2 Indication of Positions and Faults 1.3 Position Indicator (in REMOTE mode only) 2 Safety 2.1 Symbols Used 2.2 General Safety Instructions 2.3 Liability and Warranty 3 Technical Data 4 Installation 4.1 Vacuum Connection... -

Page 5: Description

1 Description 1.1 Operating modes The angle valve has two operating modes: · REMOTE mode Drive via control voltage 15 … 30 VDC. · LOCAL mode Drive via supply voltage 85 … 248 VAC. The operating mode is selected by setting a switch (® 2 12). REMOTE mode In the REMOTE mode, the supply voltage of 85 …... -

Page 6: Indication Of Positions And Faults

1.2 Indication of Positions and Faults Green LED lit = valve open Red LED lit = valve closed Red LED flashing = fault, for instance a temperature overload 1.3 Position Indicator The integrated position indicator allows for polling the valve positions. In the event of a fault, the signal "valve closed"... -

Page 7: Safety

Communicate the safety instructions to all other users. 2.3 Liability and Warranty Leybold Vakuum assumes no liability and the warranty becomes null and void if end-users or third parties · disregard the information in this document ·... - Page 8 Notes GA 06.422/2.02 (0209) DN 16–40 ISO-KF.om Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 9: Technical Data

3 Technical Data Connection flange DN 16 ISO-KF DN 25 ISO-KF DN 40 ISO-KF Actuation opening: electromagnetically closing: by pressure spring Supply voltage 85 … 248 VAC Frequency 50 / 60 Hz Power consumption 400 W (max. upon switching on) Pickup-/Holding power 405/8.1 W 416/8.3 W... - Page 10 Connection flange DN 16 ISO-KF DN 25 ISO-KF DN 40 ISO-KF Conductance 4 l/s 16 l/s 40 l/s Materials housing aluminum (3.2374) or stainless steel (1.4301) inside section 1.4301 and 1.4541 seals 287 65-67 288 65-67 288 68 EPDM shell PAGV 30 Weight aluminum housing...

-

Page 11: Installation

4 Installation 4.1 Vacuum Connection Skilled personnel The vacuum connection may only be established by persons who have suitable technical training and the necessary experience or who have been instructed by the end-user of the product. DANGER Caution: overpressure in the vacuum system >1 bar Injury caused by released parts and harm caused by escaping process gases can result if clamps are opened while the vacuum system is pressurized. -

Page 12: Electrical Connection

4.2 Electrical Connection Skilled personnel The electrical connection, in accordance with the VDE 0100 guidelines, may be made only by a licensed electrician, qualified as per VDE 0105. The line cables shall be isolated from the line supply during all electrical work. DANGER Caution: mains voltage Products that are not professionally connected to ground can be... -

Page 13: Setting The Operating Mode Selection Switch

4.2.2 Setting the Operating The operating mode must be selected before the electrical connection is estab- Mode Selection Switch lished. If a 15 … 30 VDC control voltage is available, choose REMOTE. Setting the operating mode switch Control voltage 15 ... 30 VDC available? REMOTE mode LOCAL mode... -

Page 14: Connecting The Feeder Line

4.2.3 Connecting the Feeder Œ Prepare the feeder line. Line Caution The cable must meet the following specifications: · flexible · conductor cross-section 1 mm · 3-pole with protective conductor (P+N+PE) · 5 … 7 mm diameter (for the cable feedthrough to meet the IP 54 specifications) ... -

Page 15: Connecting The Control Cable (For Remote Mode Only)

4.2.4 Connecting the Control Œ Prepare the control cable. Cable (for REMOTE Mode Only) Caution The cable must meet the following specifications: · flexible, 4 poles · conductor cross-section 0.75 mm · 5 … 7 mm diameter (for the cable feedthrough to meet the IP 54 specifications) ... -

Page 16: Mounting The Cover

Ž Connect the conductors. 4.2.5 Mounting the Cover Œ Mount the cover. Caution Be careful not to squeeze any cable leads. Mount the clamp again. GA 06.422/2.02 (0209) DN 16–40 ISO-KF.om Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 17: Operation

5 Operation The product is ready for operation as soon as it has been installed. DANGER Caution: bursting pressure Overpressures >3 bar (e.g. in the event of an explosion) can cause the inside section and housing to burst. This could result in injuries caused by catapulted parts and health damages due to leaking process gases. - Page 18 Pressure range 1×10 mbar … 1.3 bar (absolute) Pressure difference Dp in closing Caution direction Caution: pressure difference Dp bar p + D p At Dp >1.3 bar the valve may no longer be tight. Avoid pressure differences Dp >1.3 bar. Pressure difference Dp in Caution opening direction...

-

Page 19: Deinstallation

6 Deinstallation 6.1 Electrical Connection Skilled personnel The electrical connection, in accordance with the VDE 0100 guidelines, may be made only by a licensed electrician, qualified as per VDE 0105. The line cables shall be isolated from the line supply during all electrical work. -

Page 20: Vacuum Connection

6.2 Vacuum Connection Skilled personnel The vacuum connection may only be disassembled by persons who have suitable technical training and the necessary experience or who have been instructed by the end-user of the product. DANGER Caution: contaminated parts Contaminated parts can be detrimental to health and environment. Before beginning to work, find out whether any parts are contaminated. -

Page 21: Troubleshooting

7 Troubleshooting Troubleshooting Problem Valve does not Valve leaks Red LED flashing stay open Cause Position indicator Valve seat dirty or Temperature gasket defective overload dirty Valve actuator Ambient tempe- blocked rature too high Remedy Cool valve, keep ambient tem- perature <... -

Page 22: Maintenance

8 Maintenance ® 2 22 ® 2 23 ® 2 24 ® 2 25 ® 2 26 ® 2 27 Maintenance work: • Replacing the fuse and the fuse holder • Replacing the electronics • Replacing the gaskets • Replacing the hoisting magnet or the inside section •... - Page 23 Removing the cover Œ Remove the clamp. Remove the cover. Removing the fuse holder Ž together with the fuse Remove the fuse holder together with the fuse. GA 06.422/2.02 (0209) DN 16–40 ISO-KF.om Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 24 Removing the shell Remove the connectors. Pierce the stopper with a pointed tool and pull it out. ‘ Loosen and remove the shell screws. GA 06.422/2.02 (0209) DN 16–40 ISO-KF.om Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 25 ’ Remove the shell parts. Caution When reassembling the product: insert the electronics in the guide notch of the shell parts, be careful not to squeeze any cables. Disassembling the electronics “ Unscrew the position indicator. The photoelectric barrier must not be dirty. Cross-recess screw Washer Position indicator...

- Page 26 ” Detach the the protective conductor (PE). Hexagon socket screw Serrated lock washer Cable lug Serrated lock washer • Unsolder the red and the blue wire of the electronics. Do not inhale the vapors. Soldering iron blue Check the LED seal and replace it as required. Cemented LED seal GA 06.422/2.02 (0209)

- Page 27 Removing the hoisting magnet together with the inside section Remove the hoisting magnet together with the inside section. DANGER Caution: prestressed spring Spring forces: DN 16 =35 N DN 25 =60 N DN 40 =105 N Uncontrolled releasing of the spring can cause injuries. When loosening the Torx screws, counterhold the hoisting magnet.

- Page 28 Separate the hoisting magnet from the inside section Loosen the inside section. Caution Since the inside section is secured with Loctite 241, it is difficult to loosen it. Carefully retract Size 6 the bellow. Size 10 Hold stationary. Remove the inside section and the spring. Reassembly: secure with loctite.

-

Page 29: Spare Parts

9 Spare Parts When ordering spare parts, always indicate: · all information on the product nameplate · description and ordering number according to the spare parts list Mounting the spare parts ® 2 21. Fuses Ordering numbers DN 16 ISO-KF: 288 83 (ø5 × 20, 2 A, super slow) DN 25 ISO-KF: 288 83 (ø5 ×... - Page 30 Bellows assembly comprising bellows complete, (without spring), Loctite 241, 6 stoppers Ordering numbers DN 16 ISO-KF: 288 88 DN 25 ISO-KF: 288 89 DN 40 ISO-KF: 288 90 GA 06.422/2.02 (0209) DN 16–40 ISO-KF.om Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 31: Returning The Product

Contaminated products (e.g. radioactive, toxic, caustic or micro- biological hazard) can be detrimental to health and environment. Products returned to Leybold Vakuum should preferably be free of harmful substances. Adhere to the forwarding regulations of all involved countries and forwarding companies and enclose a duly completed declaration of contamination. -

Page 32: Declaration Of Contamination

Declaration of Contamination The service, repair, and/or disposal of vacuum equipment and components will only be carried out if a correctly completed declaration has been submitted. Non-completion will result in delay. This declaration may only be completed (in block letters) and signed by authorized and qualified staff. Description of product Reason for return Type... - Page 33 Bonner Strasse 498 (Bayenthal) D–50968 Köln Deutschland Tel. +49 (0) 221 347-0 Fax +49 (0) 221 347-1250 documentation@leyboldvac.de Original: German GA 06.422/2.01 (0201) www.leyboldvac.de ga06. 422/ 2. 02 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 34 Artisan Technology Group is your source for quality new and certified-used/pre-owned equipment SERVICE CENTER REPAIRS WE BUY USED EQUIPMENT • FAST SHIPPING AND DELIVERY Experienced engineers and technicians on staff Sell your excess, underutilized, and idle used equipment at our full-service, in-house repair center We also offer credit for buy-backs and trade-ins •...

Need help?

Do you have a question about the ISO-KF Series and is the answer not in the manual?

Questions and answers