Summary of Contents for Technische Alternative FRISTAR3-WP

- Page 1 FRISTAR3-WP FRESH WATER STATION FOR HEAT PUMPS Operating manual Manual Version 1.01 English...

-

Page 3: Table Of Contents

Connection of a circulation line ..........11 Activating the DHW circulation pump using the FRISTAR3-WP controller ......11 Hydraulic circuit diagram with circulation line . -

Page 4: Safety Instructions

If you are connecting the FRISTAR3-WP to an electrical system via a residual current device (RCD), use an RCD of type A which will detect pulsating direct currents and bears the following marking: Checking using a high voltage insulation tester may cause damage to the pump and the control elec- tronics. -

Page 5: Mode Of Operation

Mode of operation Through use of the instantaneous heating concept, drinking water is heated both hygienically and with low energy consumption in the FRISTAR freshwater station. If water is drawn from the mains, the primary circuit pump transports tank water from a buffer tank through the plate heat exchanger. -

Page 6: Components

Components Ventilation primary circuit Cold water Sec- Hot water Sec- ondary circuit ondary circuit Ball valve Ball valve Volumen- stromsensor Plate heat ex- changer Volume flow sensor + DHW temperature Valve Cold water sensor Primary sensor Controller Pump Ball valve Ball valve Return pri- Flow primary... -

Page 7: Installation

Installation Preparation • A safety valve (max. 6 bar) must be installed in the cold water supply corresponding to stand- ards DIN 1988 and 4753, part 1 and TRD 721. • If the cold water pressure > 6 bar, fit a diaphragm pressure reducer max. 6 bar. •... -

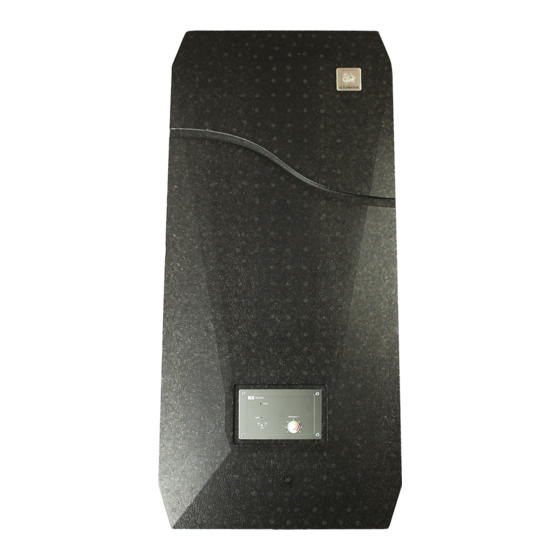

Page 8: Dimensions

Dimensions Housing dimensions (thermal insulation cover) W x H x D = 366 x 811 x 158 mm... -

Page 9: Interchanging Connections

Interchanging connections For optimum matching of the pipelines to the freshwater station it is possible to interchange the con- nections (right/left). This does not change venting of the primary circuit, however. Version Version „Pump right“ „Pump left“ Pump connection-plug Procedure: 1. -

Page 10: Installation

Installation • Mounting position: Only vertical • Installation with the heat exchanger at the top/above the controller (acc. to diagrams) is recom- mended. • Pull off the cowling in a forwards direction. • If necessary: Interchange the right/left connections (see chapter "Interchanging connections"). •... -

Page 11: Connection Of A Circulation Line

Primary pump Circulation pump (optional) If an external DHW circulation pump is connected directly to the FRISTAR3-WP controller, it will op- erate in pulse mode. While water is being tapped, the circulation pump runs provided the temperature set at sensor T lies below the set temperature by the difference set with the potentiometer. -

Page 12: Cascade Switching

Cascade switching The FRISTAR3-WP is designed for a maximum water draw-off of 30 l/min. For a greater draw-off of domestic hot water, multiple freshwater stations can be used in a cascade. The first module is fed directly, all others stations are added with stop valves, if necessary. These valves must open or close in at least 30 seconds. -

Page 13: Control With Uvr67

Control with UVR67 Step-by-step instructions Level/menu Technician menu password 32, expert menu PW 64 Adoption of the flow rate at sensor FTS9-150DL as Expert EXT input 1. When using an FTS5-85DL, the DL bus Ext. sensors index is specified as 7. ... -

Page 14: Control Of Cascade Switching With Freely Programmable Controllers

Cascade switching with circulation line Schematic diagram for activating the DHW circulation pump with the FRI- STAR3-WP controller Figure with fresh water stations version, version "Pump on the right" Circulation pump The circulation pump is connected only to the always ready FRISTAR3-WP. -

Page 15: Schematic Diagram For Activating The Dhw Circulation Pump With A Different Switching Device

If the DHW circulation pump is also to be switched on and off according to temperature, the maxi- mum possible number of FRISTAR3-WP modules is three. This is done using the program 480 for switching modules 2 and 3 on and off via outputs A1 and A2. The DHW circulation pump can be switched at output A3 via the differential S5 –... -

Page 16: Data Transfer With Dl Bus

FRISTAR3-WP controller. The FRISTAR3-WP controller returns the corresponding value when requested by the control system. The request is made up of the DL address of the FRISTAR3-WP controller and the index of the read- ing. -

Page 17: Status (Index 13)

Status (Index 13) A status code is assigned to each status. The sum of all active status codes is output under index 13 ("Status"). Circulation pump running Zirkomat, enable Sensor T.DHW circ: short circuit Sensor T.DHW circ: open circuit Sensor T.DHW: short circuit Sensor T.DHW: open circuit Sensor T.cold water: short circuit Sensor T.cold water: open circuit... -

Page 18: For Uvr67

In the expert level under "Ext. sensors", DL bus is specified as the source for one of the inputs and the DL address of the FRISTAR3-WP controller is spec- ified. The required index according to the table on the previous page should... -

Page 19: Electrical Connection

The polarity of the DL bus connections (DL and "Earth") is not interchangeable and must be observed. Safety instructions If you are connecting the FRISTAR3-WP to an electrical system via a residual current device (RCD), use an RCD of type A which will detect pulsating direct currents and bears the following marking: Checking using a high voltage insulation tester may cause damage to the pump and the control elec- tronics. -

Page 20: Operation Of The Controller And Led Indicators

Operation of the controller and LED indicators Operation of the controller has been kept as simple as possible, so that it can also be operated by inexperienced users. Status-LED Pumpen-LED Temperaturwahl Hand/Automatik-Umschalter The temperature can only be selected on the FRISTAR controller if no set value has been issued by a freely programmable controller via the DL bus. -

Page 21: Technical Data

Technical data Rated power 70 kW Min. flow 2 l/min Max. flow for 65 °C tank and 45 °C outlet temperature 30 l/min Max. permissible flow 30 l/min Volume of plate heat exchanger primary/secondary side 2,2 l each Max. operating pressure primary side (tank water) 4 bar Max. -

Page 22: Pressure Loss Characteristic Curve Plate Heat Exchanger

Pressure loss characteristic curve plate heat exchanger Pump curve (1 kPa = 10 mbar) The pump operates in heating mode, meaning that at a 5 % PWM value, the pump will run at full speed. A break in the PWM lead therefore results in full pump speed. The eight curves shown correspond to the following PWM values: 5 % (max.), 20 %, 31 %, 41 %, 52 %, 62 %, 73 %, 88 % (min.). -

Page 23: Information On The Eco-Design Directive 2009/125/Ec

Information on the Eco-design Directive 2009/125/EC Product Class Energy efficiency Standby Power consump- Max. power con- max. [W] tion typ. [W] sumption [W] FWR33 0,88 / 0,90 1,0 / 3,0 Definitions according to Official Journal of the European Union C 207 dated 03/07/2014 The classification applied is based on optimum utilisation and correct application of the products. -

Page 24: Tips On Troubleshooting

Tips on troubleshooting The following troubleshooting approaches may help in the event of faulty operation, but before work- ing on the freshwater module, it is always important to ensure that it is at zero volt and that no hot pipe temperatures can occur. Not illuminated Status LED illuminated? Check power supply,... - Page 25 EU Declaration of conformity Document-No. / Date: TA21001 / 19/02/2021 Company / Manufacturer: Technische Alternative RT GmbH Address: A-3872 Amaliendorf, Langestraße 124 This declaration of conformity is issued under the sole responsibility of the manufacturer. Product name: FRISTAR3 / FRISTAR3-WP...

- Page 28 Note: The following warranty conditions do not in any way limit the legal right to warranty, but rather expand your rights as a consumer. 1. The company Technische Alternative RT GmbH provides a one-year warranty from the date of purchase for all the devices and parts which it sells. Defects must be reported immediately upon detection and within the guarantee period.

Need help?

Do you have a question about the FRISTAR3-WP and is the answer not in the manual?

Questions and answers