Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Showa Denki MAA1050-Y005E

- Page 1 MAA1050-Y005E Blower Operating Instructions Axial Flow/Mixed Flow Type Blower...

- Page 2 Blower Operating Instructions Introduction Thank you for purchasing Showa Denki’s blower. These Operating Instructions provide explanations on items for operation, maintenance, etc., of the blower. To ensure this blower exhibits its full performance and can be used safely without failures for a long period of time, read these Operating Instructions carefully.

-

Page 3: Table Of Contents

Contents Page Safety Precautions ........................- 3 - Overview of the Product ......................- 6 - Types and meanings of model symbols ................- 6 - Structure of the product and names of parts ............... - 7 - Reception of the Product ......................- 8 - Unloading and checking the product at the time of reception .......... -

Page 4: Safety Precautions

1. Safety Precautions Warning Intake of hazardous gas and installation in a hazardous location are strictly prohibited. This blower does not have an explosion-proof structure. Intake of flammable gas or operating the blower in a location with an explosive atmosphere may lead to explosion due to a spark caused by static electricity or contact with an electric device, metal, etc. - Page 5 Caution When installing piping, minimize the resistance to ducts, pipes, etc., for air to flow smoothly. If the blower is operated with the duct closed, it may enter stall operation status, which may cause the impeller blade to generate abnormal vibration, leading to an impeller damage accident.

- Page 6 The blower cannot take in solid material, dust or liquid. Intake of them may cause an accident resulting in damage. In the case of deceleration by an inverter, etc., a resonance between the main body and a duct around it may cause an increase in vibration or generation of sound at a specific frequency (rotation speed).

-

Page 7: Overview Of The Product

2. Overview of the Product 2.1 Types and meanings of model symbols Types and meanings of model symbols used for standard specifications are as shown in the table below. The model is indicated on the product nameplate (nameplate) affixed to the side face of the blower main body (casing). -

Page 8: Structure Of The Product And Names Of Parts

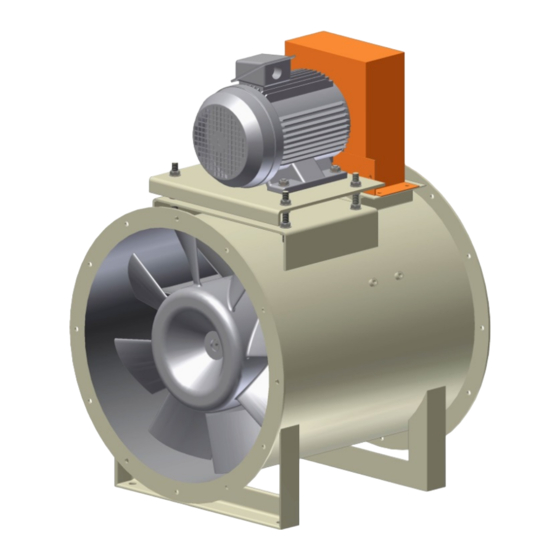

2.2 Structure of the product and names of parts 2.2.1 Disassembling parts drawing V-belt Pulley on the motor side Motor Motor base Casing Belt guard Axis Bearing Holder Axial flow impeller Pulley on the fan Holder side Mixed flow impeller V-belt drive Mixed flow intake cone... -

Page 9: Reception Of The Product

3. Reception of the Product 3.1 Unloading and checking the product at the time of reception Although we test and inspect carefully in order to ship an accepted product, please check the following points upon reception of the delivered product. •... -

Page 10: Duct Connection

4.2 Duct connection • Install a removable duct for maintenance and inspection and an inspection hole in front of and behind the fan. (Secure a space for inspection with the duct removed.) • Attach a metal wire net to each of the openings of the intake duct and discharge duct as a safety measure. -

Page 11: Installation Of The Motor (When The Blower Adopts The Specification Of V-Belt Drive Main Body Only)

4.3 Installation of the motor (when the blower adopts the specification of V-belt drive main body only) Pulley on the 4.3.1 Assembly motor side For the names of parts, refer to the disassembling structure drawing in page 6. • Prepare the motor, pulley on the motor side, and V-belt that are required. - Page 12 Step 4. Tension adjustment Adjust the tension of the belt in such a manner that the read value of the deflection load matches that shown in the following table. Table of deflection load Range of small Deflection load P (N/belt) Types of pulley diameter When a new belt...

-

Page 13: Test Operation

4.3.2 Electric wiring • The electric wiring of the blower must be installed by a qualified electrical engineer, as per the “electrical equipment technical standards” and the “extension rules.” • Confirm the power supply specified on the product nameplate affixed to the side surface of the main body and then use the power supply for this blower. -

Page 14: Operation

5. Operation 5.1 Operation, Maintenance and Inspection After starting to operate the blower, perform the maintenance and inspection regularly. If daily inspection is performed on the following items from the beginning of the operation and the results are recorded, abnormalities can be detected early to prevent problems. During the maintenance and inspection, an experienced worker or trained worker should secure the safety. -

Page 15: Replenishment Of Lubricating Oil (Grease) (V-Belt Drive Only)

Vibration allowance value with antivibration Vibration allowance value equipment 5.1.2 Vibration If vibration exceeds the allowable value, stop the operation and perform the inspection. Possible causes of vibration are as follows: • Unbalance of the impeller due to adhesion of dust to it •... -

Page 16: Cleaning Of A Blower And The Impeller

Rough indication of interval for replenishment of grease Environmental conditions Temperature of Large volume of dust, high handled gas Quite clean Much refuse (flour humidity, or much spray or (normal mill, sawmill, dust water (refuse disposal ºC environment) collector, etc.) facility, processed marine product factory, etc.) 50 or less... -

Page 17: Management Of Belts

5.4 Management of belts For the belt, perform the tension management and visual inspection regularly according to the description in section 4.3.1. If the blower has a belt driving system, powder dust is generated from the belt. In particular, the amount of powder dust may be a little larger for approx. 2 months after the start of operation. -

Page 18: Warranty

7. Warranty Scope of warranty Repair service is provided free of charge for a failure during the warranty period, as long as the blower has been used in compliance with these Operating Instructions, labels attached to the body, and other instructions. In the case that this product is incorporated into other equipment used by the customer, the warranty does not cover costs for removal from such equipment, reattachment to such equipment, costs of other incidental work, costs of transportation etc., resulting opportunity loss... -

Page 19: Malfunction Causes And Measures

8. Malfunction Causes and Measures Fan malfunction causes and measures Malfunction status Measures Malfunction cause Defective installation ○ ○ ○ ○ ○ Re-installation Poor foundation ○ ○ ○ Renovation Processing of contact part, Contact with the rotator? ○ ○ ○ ○... - Page 20 Note on your purchased blower Fan identification information that you may need when making an inquiry of us. TYPE SERIAL NO. Date of Date of start Year/Month/Day Year/Month/Day Purchase of operation Supplier TEL: Person in charge:...

Need help?

Do you have a question about the MAA1050-Y005E and is the answer not in the manual?

Questions and answers