Advertisement

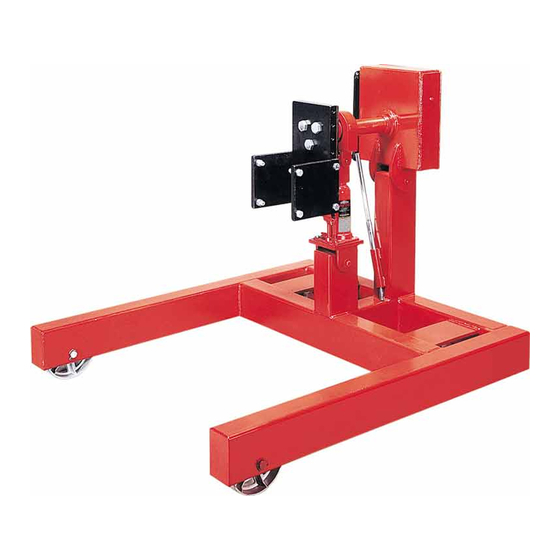

MODEL 78160 3 TON CAPACITY DIESEL ENGINE STAND

SETUP • OPERATING • MAINTENANCE INSTRUCTIONS

Note: Revision letters (A, B, C, D etc.) after model numbers have been omitted as they do not affect the setup,

operating and maintenance instructions of a particular jack unless otherwise noted.

IMPORTANT: READ THESE INSTRUCTIONS BEFORE OPERATING

BEFORE USING THIS DEVICE, READ THIS MANUAL

COMPLETELY

AND

THOROUGHLY,

OPERATING

PROCEDURES,

MAINTENANCE REQUIREMENTS. FAILURE TO DO SO COULD

CAUSE ACCIDENTS RESULTING IN SERIOUS OR FATAL

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

The use of portable automotive lifting and support devices is subject

to certain hazards that cannot be prevented by mechanical means,

but only by the exercise of intelligence, care, and common sense.

It is therefore essential to have owners and personnel involved in

the use and operation of equipment who are careful, competent,

trained, and qualified in the safe operation of the equipment and its

proper use. Examples of hazards are dropping, tipping, or slipping

of engines or their components caused primarily by improperly

securing loads, overloading, off-centered loads, use on other than

•

Inspect the engine stand before each use. Do not use the

engine stand if it is damaged, altered, modified, in poor

condition, leaking hydraulic fluid, or has loose or missing

hardware or components. Take corrective action before using

the engine stand.

•

Do not use the engine stand beyond its rated capacity. The

maximum capacity (6000 lbs.) is determined at a point where

the center of the engine is located no more than 13" from the

mounting hub surface. The engine stand is equipped with

a universal adapter that bolts to the mounting hub surface.

Center lines of engines weighing 5000 lbs. can be mounted no

more than 20" from the mounting hub surface and center lines

of engines weighing 4000 lbs. can be mounted no more than

25" from the mounting hub surface.

•

Use only on a hard level surface.

•

Wear approved eye protection.

•

Assure load is centered and secured to mounting adapters.

Consult the engine manufacturer for the proper engine

mounting hole locations.

•

Use only grade 8 bolts in all adapter and engine mounting

applications. Before handling and/or starting repairs, make sure

all hardware is tight and secure.

1.

This engine stand is equipped with a universal adapter which

can be configured to fit certain engines or certain optional engine

adapters. Determine the correct adapter for the engine you are

working on and tighten all hardware that attaches the adapter to

the engine stand's mounting hub.

2.

Sometimes air gets trapped in the hydraulic jack that controls

the angle of the mounting hub. An air bound hydraulic system feels

spongy when pumped and sometimes the jack will not pump in full

incremental strokes.

PROFESSIONAL LIFTING EQUIPMENT

UNDERSTAND

SAFETY

WARNINGS AND

WARNING

®

hard level surfaces, and using equipment for a purpose for which

ITS

it was not designed.

It is the responsibility of the owner to make sure all personnel read

this manual prior to using this device. It is also the responsibility of

the device owner to keep this manual intact and in a convenient

location for all to see and read. If the manual is lost or not legible,

contact Norco Industries, Inc. for a free replacement. If the operator

is not fluent in English, the product and safety instructions shall be

read to and discussed with the operator in the operator's native

language by the purchaser/ owner or his designee, making sure

that the operator comprehends its contents.

This product is covered by a Limited Lifetime Warranty. For details

see the back cover of Norco's product catalog.

•

Threaded holes in adapters and engine blocks must be clean

and not damaged to insure thread engagement. A bolt thread

engagement must be equal to 1-1/2 times the bolt thread

diameter in order to maintain strength requirements.

•

Lock the rotating gear drive by engaging the crank handle with

the locking fork before applying a load to the engine stand and

working on the engine.

•

Avoid unsafe, off-balance loads by aligning the engine's center

of balance (rotational axis of the engine) with the rotational axis

of the engine stand's gear drive shaft. The center of balance

is generally a few inches above the crankshaft. The alignment

should not be off more than two inches. Consult the engine

manufacturer to determine the exact center of balance.

•

Keep body from underneath engine when being lifted or

suspended.

•

The engine stand's hydraulic jack is only used to gain engine

clearance when rotating the engine. Keep the jack at its lowest

possible position when working on an engine in order to avoid

tipping. Always release the jack slowly and carefully when

lowering a load.

•

No alterations should be made to this product.

•

Only attachments and/or adapters supplied by Norco shall be

used.

SETUP

PURGING AIR FROM THE HYDRAULIC SYSTEM

a.

Open the release valve by turning the handle in a

counterclockwise direction two full turns.

b.

Pump the handle ten full strokes.

c.

Close the release valve by turning the handle in a clockwise

direction until tight.

d.

Pump the jack until the ram is extended to maximum height.

e.

If the condition remains, repeat steps "a" through "d" until all

air is purged from the system.

WARRANTY

Advertisement

Table of Contents

Summary of Contents for Norco 78160

- Page 1 If the manual is lost or not legible, The use of portable automotive lifting and support devices is subject contact Norco Industries, Inc. for a free replacement. If the operator is not fluent in English, the product and safety instructions shall be to certain hazards that cannot be prevented by mechanical means, but only by the exercise of intelligence, care, and common sense.

- Page 2 Take corrective action before using the stand again. REPAIR SERVICE If your Norco product requires service or repair, contact the Norco It will be necessary to provide the Norco Authorized Service Center Customer Service Department for the location of the nearest Norco with a copy of the bill of sale if requesting warranty repair.

Need help?

Do you have a question about the 78160 and is the answer not in the manual?

Questions and answers