Summary of Contents for RFT CU2

- Page 1 Wide-ranging rectangular fire damper up to 120’ 0749 www.rft.be Rf-Technologies nv Lange Ambachtstraat 40 9860 Oosterzele Belgium Tel +32 9 362 31 71 Fax +32 9 362 33 07 info@rft.be...

-

Page 2: Table Of Contents

Variant CU2L Range and dimensions CU2L Variant CU2-L500 Range and dimensions CU2-L500 Variant CU2 ATEX Range and dimensions CU2 ATEX Variant CU2L ATEX Range and dimensions CU2L ATEX Evolution - kits Options - at the time of order Flange types - at the time of order... - Page 3 Explanation of the abbreviations and pictograms Explanation of the abbreviations and pictograms Wn = nominal width E.TELE = power supply magnet Sn = free air passage Hn = nominal height E.ALIM = power supply motor ζ [-] = pressure loss coefficient Dn = nominal diameter V = volt Q = air flow...

-

Page 4: Declaration Of Performance

Declaration of performance Harmonised standard EN 15650:2010... -

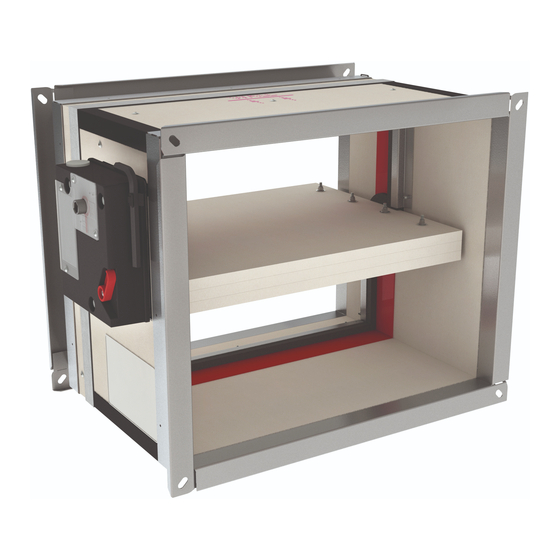

Page 5: Product Presentation Cu2

120 minutes. The refractory casing is made of asbestos-free panels, which are resistant to humidity. Its many options make the CU2 damper a universal reference on the market. Fire dampers are installed where air ducts penetrate fire-resistant compartment walls. Their role is to restore the fire resistance grade of the penetrated wall and to prevent smoke propagation. -

Page 6: Variant Cu2L

Variant CU2L Variant CU2L Damper with a tunnel casing extension at one or both sides so that the damper blade does not exceed the tunnel. This version allows to connect a grill or a bend directly on the damper flange or to use a circular connection. ∎... -

Page 7: Variant Cu2-L500

Variant CU2-L500 CU2 damper with a tunnel casing extension at the wall side to facilitate the connection to the duct when the supporting construction is thicker than 100 mm. This version also ensures that the damper blade doesn't exceed the casing at the wall side (up to a height of 500 mm), which allows to connect a grill or a bend directly on the damper flange or to use a circular connection. -

Page 8: Variant Cu2 Atex

ATEX certificate TÜV 14 ATEX 7540 X 1. explosion proof mechanism 2. equipotential connection Range and dimensions CU2 ATEX Wn/Hn per step of 50 mm; intermediate dimensions are subject to extra cost (heights between ≥ 275 and ≤ 299 mm are not possible). -

Page 9: Variant Cu2L Atex

Variant CU2L ATEX Variant CU2L ATEX Explosion protected fire damper for use in zone 1,2 (gas) and zone 21,22 (combustible dust) with a tunnel casing extension at one or both sides so that the damper blade does not exceed the tunnel. This extension makes it possible to use a circular connection (PR flange). -

Page 10: Evolution - Kits

Evolution - kits Evolution - kits Automatic unlocking mechanism CFTH with FCU and without FTH 72 KITS CFTH Spring return actuator BFL 24V KITS BFL24 Spring return actuator BFL 24V with plug (ST) KITS BFL24-ST Spring return actuator BFL 24V with thermo-electric fuse (T) KITS BFLT24 Spring return actuator BFL 24V with thermo-electric fuse (T) and plug (ST) KITS BFLT24-ST... - Page 11 Evolution - kits Spring return actuator BFN 24V with thermo-electric fuse (T) KITS BFNT24 Spring return actuator BFN 24V with thermo-electric fuse (T) and plug (ST) KITS BFNT24-ST Spring return actuator BFN 230V KITS BFN230 Spring return actuator BFN 230V with thermo-electric fuse (T) KITS BFNT230 Spring return actuator BF 24V (BF kits must be used instead of BFN kits for fire dampers KITS BF24...

-

Page 12: Options - At The Time Of Order

Kit equipotential connection (per set of 5 pieces) KITS EQ Options - at the time of order Inspection shutter (set of 2) Equipotential connection Air-tightness class C (note: for CU2 H>600 or W>800 / for CR2 Ø>315). EN1751_C EN 1751... -

Page 13: Flange Types - At The Time Of Order

Flange types - at the time of order Flange types - at the time of order Connection to ducts with 30 mm flanges (either by sliding profile, PG30 or with bolts, or with clamps). Elliptical holes Ø 8,5 x 16 mm. Connection to ducts with 40 mm flanges. -

Page 14: Storage And Handling

Storage and handling Storage and handling As this product is a safety element, it should be stored and handled with care. Avoid: • any kind of impact or damage • contact with water • deformation of the casing It is recommended: •... -

Page 15: Installation At A Minimal Distance From Another Damper Or From An Adjacent Supporting Construction

Installation Installation at a minimal distance from another damper or from an adjacent supporting construction ≥ 75 mm ≥ 75 mm ≥ 200 mm ≥ 200 mm ≥ 25 mm ≥ 50 mm ≥ 50 mm ≥ 200 mm 1. Principle 2. -

Page 16: Installation In Rigid Wall And Floor

Installation in rigid wall and floor The product was tested and approved in: Range Wall type Sealing Classification 200x200 mm ≤ CU2 ≤ 1500x1000 mm Rigid wall Aerated concrete ≥ 100 mm Gypsum EI 120 (v i n o) S - (500 Pa) 200x200 mm ≤... - Page 17 Installation ≥150 kg/m³ ≤60% ≥ 40 kg/m³ ≥150 kg/m³ ≥100 5. Make the necessary openings (Wn + 100 mm) x 6. Mount the dampers in the opening. (Hn + 100 mm) in the wall. Apply rigid stone wool panels (150 kg/m³) to a depth of 400 mm (150 mm on each side of the wall) to seal the opening at the side with minimal distances.

-

Page 18: Installation In Flexible Wall (Metal Stud Gypsum Plasterboard Wall)

Range Wall type Sealing Classification Metal studs gypsum plasterboard 200x200 mm ≤ CU2 ≤ 1200x800 mm Flexible wall Stone wool ≥ 40 kg/m³ + cover plates EI 90 (v i n o) S - (500 Pa) Type A (EN 520) ≥ 100 mm Metal studs gypsum plasterboard 200x200 mm ≤... - Page 19 Installation ≥150 kg/m³ ≤60% ≥ 40 kg/m³ ≥ 40 kg/m³ ≥150 kg/m³ 7. Mount the dampers in the opening. 8. Seal the rest of the opening with standard stone wool Apply rigid stone wool panels (150 kg/m³) to a depth of 40 kg/m³...

-

Page 20: Installation In Flexible Wall (Metal Stud Gypsum Plasterboard Wall), Sealing With Gypsum

Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm Gypsum EI 60 (v i n o) S - (300 Pa) 200x200 mm ≤ CU2 ≤ 1500x1000 mm Flexible wall Metal studs gypsum plasterboard Type F (EN 520) ≥ 100 mm Gypsum... - Page 21 Installation ≥150 kg/m³ ≤60% ≥ 40 kg/m³ ≥150 kg/m³ 2x12.5 / 1x25 mm 5. Build the drywall and foresee horizontal and vertical studs 6. Mount the dampers in the opening. around the opening. Apply rigid stone wool panels (150 kg/m³) to a depth of 400 mm (150 mm on each side of the wall) to seal the opening at the side with minimal distances.

-

Page 22: Installation In Gypsum Block Wall

Installation in gypsum block wall The product was tested and approved in: Range Wall type Sealing Classification 200x200 mm ≤ CU2 ≤ 1500x1000 mm Flexible wall Gypsum blocks ≥ 100 mm Block glue EI 120 (v i n o) S - (500 Pa) 200x200 mm ≤... - Page 23 Installation ≥150 kg/m³ ≤60% ≥ 40 kg/m³ ≥150 kg/m³ ≥70 5. Make the necessary openings (Wn + 100 mm) x 6. Mount the dampers in the opening. (Hn + 100 mm) in the wall. Apply rigid stone wool panels (150 kg/m³) to a depth of 400 mm (150 mm on each side of the wall) to seal the opening at the side with minimal distances.

-

Page 24: Installation In Flexible And Rigid Wall, Sealing With Rigid Rock Wool Boards With Coating

Range Wall type Sealing Classification 200x200 mm ≤ CU2 ≤ 1200x800 mm Rigid wall Aerated concrete ≥ 100 mm Stone wool + coating ≥ 140 kg/m³ EI 90 (v i n o) S - (300 Pa) Metal studs gypsum plasterboard Type A 200x200 mm ≤... - Page 25 Installation TEST! TEST! 2x50 mm 2x60 mm A (EN520) 60’ F (EN520) 90’ F (EN520) 120’ (BELGIUM) ≥ 25 ≤ Wn+600 ≤ 300 ≥ 50 ≤ 400 ≤ Hn+600 200-400 mm Promat : HxW ≤ 5 m² Hilti EI90 : HxW ≤ 3,2 m² Hilti EI120 : HxW≤...

- Page 26 Installation PROMASTOP-E / CC HILTI CFS-S ACR PROMASTOP-E / CC HILTI CFS-S ACR 140 kg/m³ PROMASTOP-CB 50 / CC HILTI CFS-CT B 11. Seal the rest of the opening with 2 layers of 50 mm-thick coated rigid mineral wool panels (see above).

-

Page 27: Installation In Rigid Floor, Sealing With Rigid Rock Wool Boards With Coating

The product was tested and approved in: Range Wall type Sealing Classification 200x200 mm ≤ CU2 ≤ 1200x800 mm Rigid floor Aerated concrete ≥ 150 mm Stone wool + coating ≥ 140 kg/m³ EI 90 (h i n o) S - (300 Pa) ≤... -

Page 28: Battery Assembly

The product was tested and approved in: Range Wall type Sealing Classification CU2/B ≤ 4 x CU2 (200x200 mm ≤ CU2 ≤ 1200x800 mm) Rigid wall Reinforced concrete ≥ 110 mm Mortar EI 120 (v i n o) S - (500 Pa) CU2/B ≤... -

Page 29: Installation In Shaft Wall

Sealing Classification Asymmetrical flexible Metal studs gypsum plasterboard 200x200 mm ≤ CU2 ≤ 1500x800 mm Stone wool ≥ 40 kg/m³ + cover plates EI 60 (v i n o) S - (300 Pa) wall (shaft wall) Type F (EN 520) ≥ 82.5 mm ≥... -

Page 30: Operation And Mechanisms

Operation and mechanisms Operation and mechanisms CFTH Mechanism with fusible link The unlocking mechanism CFTH automatically unlatches the damper blade when the temperature in the duct rises above 72°C. The damper can also be unlocked and reset manually. 1. unlocking button 2. - Page 31 The end of range switches need 1 second after operation to adopt a stable position. † prod. < 1/7/2015 prod. ≥ 1/7/2015 CR60(1s) CU-LT CR2≤400 CR2>400 CR60(1s) CU-LT CR2≤400 CR2>400 CR120 CU-LT-1s CU2≤1200 CU2>1200 CR120 CU-LT-1s CU2≤1200 CU2>1200 Kit ONE ...

- Page 32 Stop as soon as the motor is completely rearmed (end of range). † prod. < 1/7/2015 prod. ≥ 1/7/2015 CR60(1s) CU-LT CR2≤400 CR2>400 CR60(1s) CU-LT CR2≤400 CR2>400 CR120 CU-LT-1s CU2≤1200 CU2>1200 CR120 CU-LT-1s CU2≤1200 CU2>1200 Kit BFL Kit BFN ...

- Page 33 The spring return actuator BFN(T) is specially designed to remotely control fire dampers. The BFN(T) model is intended for fire dampers with large dimensions (ø > 400 mm (CR2) or W+H > 1200 mm (CU2, CA2, CU2-15, CU4)) or for dampers CU-LT(-1s), CR60, CR120 with a production date before 1 July 2015.

- Page 34 Operation and mechanisms Ex (ROTORK-SCHISCHEK) Explosion proof (ATEX) motor Explosion proof (ATEX) motor for different risk areas:• Zone 1/21: average risk of explosion >100h/year explosive environment• Zone 2/22: low risk of explosion <10h/year of explosive environment 1. access for manual resetting 2.

- Page 35 Operation and mechanisms Ex (ROTORK-SCHISCHEK) Explosion proof (ATEX) motor Explosion proof (ATEX) motor for different risk areas:• Zone 1/21: average risk of explosion >100h/year explosive environment• Zone 2/22: low risk of explosion <10h/year of explosive environment 1. access for manual resetting 2.

-

Page 36: Electrical Connection

Electrical connection Electrical connection CFTH 11 12 11 12 black DC : Switch open position re damper FC : Switch closed position re damper 24VDC 24VAC Ex (ROTORK-SCHISCHEK) 230VAC DC : Switch open position re damper 24...240 VAC/ DC FC : Switch closed position re damper −... - Page 37 Operation and mechanisms BFL(T) BFN(T) black black 24VDC 24VDC 24VAC 24VAC 230VAC 230VAC DC : Switch open position re damper DC : Switch open position re damper FC : Switch closed position re damper FC : Switch closed position re damper Resetting time Running Noise level...

-

Page 38: Weights

Weights Weights CU2 + CFTH Hn\Wn [mm] 200 kg 10,8 11,9 12,9 14,0 15,0 16,1 17,1 18,2 19,3 20,3 21,4 22,4 23,5 24,5 25,6 250 kg 11,8 12,9 14,0 15,2 16,3 17,4 18,5 19,7 20,8 21,9 23,0 24,2 25,3 26,4... - Page 39 Weights CU2 + ONE T Hn\Wn [mm] 200 kg 11,6 12,7 13,7 14,8 15,8 16,9 17,9 19,0 20,1 21,1 22,2 23,2 24,3 25,3 26,4 250 kg 12,6 13,7 14,8 16,0 17,1 18,2 19,3 20,5 21,6 22,7 23,8 25,0 26,1 27,2...

- Page 40 Weights CU2 + BFL Hn\Wn [mm] 1000 200 kg 10,8 11,9 13,0 14,0 15,1 16,1 17,2 18,2 19,3 20,4 21,4 22,5 23,5 24,6 25,7 26,7 27,8 250 kg 11,9 13,0 14,1 15,2 16,3 17,5 18,6 19,7 20,8 22,0 23,1 24,2...

- Page 41 Weights CU2 + BFN Hn\Wn [mm] 200 kg 250 kg 300 kg 350 kg 30,1 400 kg 30,7 32,0 450 kg 31,2 32,6 33,9 500 kg 31,5 33,0 34,4 35,9 550 kg 31,7 33,2 34,8 36,3 37,8 600 kg 31,8...

- Page 42 Weights CU2 + BFNT Hn\Wn [mm] 200 kg 250 kg 300 kg 350 kg 30,2 400 kg 30,8 32,1 450 kg 31,3 32,7 34,0 500 kg 31,6 33,1 34,5 36,0 550 kg 31,8 33,3 34,9 36,4 37,9 600 kg 31,9...

- Page 43 Weights CU2-L500 + CFTH Hn\Wn [mm] 200 kg 11,6 12,8 13,9 15,1 16,2 17,4 18,6 19,7 20,9 22,0 23,2 24,3 25,5 26,6 27,8 250 kg 12,7 14,0 15,2 16,4 17,6 18,9 20,1 21,3 22,5 23,8 25,0 26,2 27,4 28,7 29,9...

- Page 44 Weights CU2-L500 + ONE T Hn\Wn [mm] 200 kg 12,4 13,6 14,7 15,9 17,0 18,2 19,4 20,5 21,7 22,8 24,0 25,1 26,3 27,4 28,6 250 kg 13,5 14,8 16,0 17,2 18,4 19,7 20,9 22,1 23,3 24,6 25,8 27,0 28,2 29,5...

- Page 45 Weights CU2-L500 + BFL Hn\Wn [mm] 1000 200 kg 11,7 12,8 14,0 15,2 16,3 17,5 18,6 19,8 20,9 22,1 23,2 24,4 25,5 26,7 27,9 29,0 30,2 250 kg 12,8 14,0 15,2 16,5 17,7 18,9 20,1 21,4 22,6 23,8 25,0 26,3...

- Page 46 Weights CU2-L500 + BFN Hn\Wn [mm] 200 kg 250 kg 300 kg 350 kg 32,7 400 kg 33,3 34,8 450 kg 33,9 35,4 36,9 500 kg 34,2 35,8 37,4 39,0 550 kg 34,5 36,1 37,8 39,4 41,1 600 kg 34,5...

- Page 47 Weights CU2-L500 + BFNT Hn\Wn [mm] 200 kg 250 kg 300 kg 350 kg 32,8 400 kg 33,4 34,9 450 kg 34,0 35,5 37,0 500 kg 34,3 35,9 37,5 39,1 550 kg 34,6 36,2 37,9 39,5 41,2 600 kg 34,6...

- Page 48 Weights CU2 ATEX + RMEX / + EMEX Hn\Wn [mm] 200 kg 13,8 14,9 15,9 17,0 18,0 19,1 20,1 21,2 22,3 23,3 24,4 25,4 26,5 27,5 28,6 250 kg 14,8 15,9 17,0 18,2 19,3 20,4 21,5 22,7 23,8 24,9 26,0...

- Page 49 Weights CU2 ATEX + RMEXT / + EMEXT Hn\Wn [mm] 200 kg 13,9 15,0 16,0 17,1 18,1 19,2 20,2 21,3 22,4 23,4 24,5 25,5 26,6 27,6 28,7 250 kg 14,9 16,0 17,1 18,3 19,4 20,5 21,6 22,8 23,9 25,0 26,1...

-

Page 50: Selection Data

Selection data Selection data Δp [Pa] = ζ*v²*0,6 Hn\Wn [mm] 200 ζ [-] 3,42 2,92 2,64 2,46 2,34 2,25 2,18 2,12 2,07 2,04 2,01 1,98 1,96 1,94 1,92 250 ζ [-] 1,91 1,58 1,39 1,27 1,19 1,13 1,08 1,05 1,02 0,99 0,97 0,96... -

Page 51: Selection Data

Selection data CU2 - CU2L - CU2-L500 - CU2 ATEX - CU2L ATEX - A-weighted sound power level in the duct Hn\Wn [mm] Sn [m²] 0,0195 0,0255 0,0314 0,0374 0,0433 0,0493 0,0552 0,0612 0,0671 0,0731 0,0790 0,0850 0,0909 0,0969 Sn [%]... - Page 52 Selection data Hn\Wn [mm] Sn [m²] 0,0523 0,0683 0,0842 0,1002 0,1161 0,1321 0,1480 0,1640 0,1799 0,1959 0,2118 0,2278 0,2437 0,2597 Sn [%] 68,44 71,01 72,70 73,90 74,80 75,49 76,05 76,50 76,88 77,19 77,46 77,70 77,91 78,09 Q [m³/h] 1.700,00 2.090,00 2.470,00 2.850,00 3.240,00 3.620,00 4.000,00 4.380,00 4.770,00 5.150,00 5.530,00 5.910,00 6.290,00 6.670,00 45 Δp [Pa] 17,21 12,72...

- Page 53 Selection data Hn\Wn [mm] Sn [m²] 0,0851 0,1111 0,1370 0,1630 0,1889 0,2149 0,2408 0,2668 0,2927 0,3187 0,3446 0,3706 0,3965 0,4225 Sn [%] 73,86 76,63 78,46 79,75 80,72 81,47 82,07 82,56 82,96 83,30 83,60 83,85 84,07 84,27 Q [m³/h] 2.470,00 3.010,00 3.550,00 4.080,00 4.620,00 5.150,00 5.680,00 6.220,00 6.750,00 7.280,00 7.810,00 8.340,00 8.870,00 9.410,00 45 Δp [Pa] 10,03 6,84...

- Page 54 Selection data Hn\Wn [mm] Sn [m²] 0,1179 0,1539 0,1898 0,2258 0,2617 0,2977 0,3336 0,3696 0,4055 0,4415 0,4774 0,5134 0,5493 0,5853 Sn [%] 76,55 79,42 81,31 82,66 83,66 84,44 85,05 85,56 85,98 86,34 86,64 86,90 87,13 87,34 Q [m³/h] 3.230,00 3.920,00 4.610,00 5.300,00 5.980,00 6.660,00 7.340,00 8.020,00 8.700,00 9.380,00 10.050,00 10.730,00 11.400,00 12.070,00 45 Δp [Pa] 7,55 4,90...

- Page 55 Selection data Hn\Wn [mm] 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500 Sn [m²] 0,1028 0,1088 0,1147 0,1207 0,1266 0,1326 0,1385 0,1445 0,1504 0,1564 0,1623 0,1683 0,1742 Sn [%] 59,28 59,39 59,49 59,58 59,66 59,73 59,80 59,86 59,92 59,97 60,02...

- Page 56 Selection data Hn\Wn [mm] 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500 Sn [m²] 0,2756 0,2916 0,3075 0,3235 0,3394 0,3554 0,3713 0,3873 0,4032 0,4192 0,4351 0,4511 0,4670 Sn [%] 78,25 78,39 78,52 78,64 78,74 78,84 78,93 79,01 79,09 79,16 79,22...

- Page 57 Selection data Hn\Wn [mm] 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500 Sn [m²] 0,4484 0,4744 0,5003 0,5263 0,5522 0,5782 0,6041 0,6301 0,6560 0,6820 0,7079 0,7339 0,7598 Sn [%] 84,44 84,60 84,74 84,86 84,98 85,08 85,18 85,27 85,35 85,42 85,49...

- Page 58 Selection data Hn\Wn [mm] 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500 Sn [m²] 0,6212 0,6572 0,6931 0,7291 0,7650 0,8010 0,8369 0,8729 0,9088 0,9448 0,9807 1,0167 1,0526 Sn [%] 87,52 87,68 87,82 87,95 88,07 88,18 88,28 88,37 88,45 88,53 88,61...

-

Page 59: Correction Factor Δl

Correction factor ΔL Every air flow lower than the above mentioned maximum value, will meet the listed A-weighted sound power level for the respective dimension. Correction factor ΔL To obtain the sound power level for the octave midband: LW oct = ΔL + Lwa [Hz] 1000 2000... -

Page 60: Approvals And Certificates

Approvals and certificates Approvals and certificates All our dampers are submitted to a number of tests by official test institutes. Reports of these tests form the basis for the approvals of our dampers. BCCA-0749-CPR-BC1-606-0464-15650.03-0464; BCCA-0749-CPR- BC1-606-0464-15650.13-2517 0749 18.12 SC0652-15 26813 The NF-label guarantees: conformity with the standard NF S 61-937 Parts 1 and 5: “Systèmes de Sécurité...

Need help?

Do you have a question about the CU2 and is the answer not in the manual?

Questions and answers