Table of Contents

Advertisement

Trochoid Pump

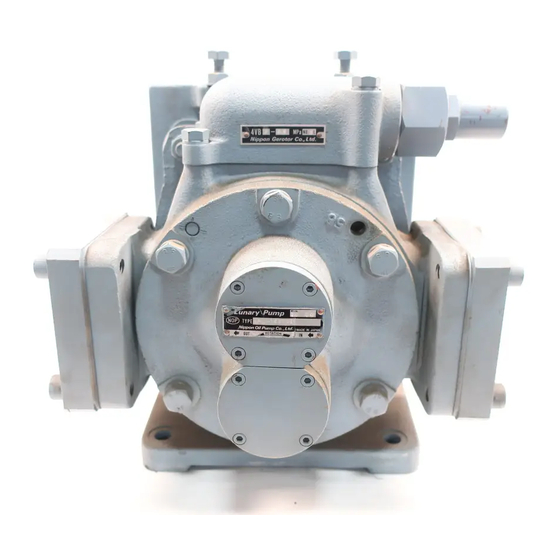

Lunary Pump

Instruction Manual

Read this manual thoroughly and carefully before installing or selecting a

pump.

Follow all instructions carefully to ensure the correct and efficient pump

installation and operation.

This manual contains suggestions and instructions on pump selection,

installation, operation, and troubleshooting.

Failure to observe this manual prior to operation may result in personal

injury and/or equipment damage.

Store this manual in a safe and readily accessible

location for future references

Important

T201806EN

Advertisement

Table of Contents

Summary of Contents for Nippon Oil Pump Trochoid Pump

- Page 1 Trochoid Pump Lunary Pump Instruction Manual Important Read this manual thoroughly and carefully before installing or selecting a pump. Follow all instructions carefully to ensure the correct and efficient pump installation and operation. This manual contains suggestions and instructions on pump selection, installation, operation, and troubleshooting.

-

Page 2: Table Of Contents

●Safety Measures .......................... 2 Pump Installation ●Installation ............................ 3 ●Installation Positions for the Trochoid Pump, Trochoid Pump with Motor, Trochoid Pump with Motor and Base Coupling, Lunary Pump with Motor and Base Coupling ..3 ●Installation Site ..........................3 Pipe Arrangement ●Pipe Connections ........................ -

Page 3: For Safe Pump Operation

For Safe Pump Operation Be sure to obtain a thorough understanding of all safety measures. Always conduct the indicated precautionary steps and safety measures. When you see the following symbols and titles in this manual, be alert to the potential for personal injury or equipment damage. -

Page 4: Pump Installation

・There are no particular restrictions on the mounting directions when installing only the pump itself. ・When installing a Trochoid pump with a motor, the pump cannot be installed in a position higher than the motor (as seen from the horizontal position). -

Page 5: Pipe Arrangement

Pipe Arrangement ・The maximum torque allowances when tightening the screws for the Trochoid pump's pipe connections are as shown in the table below. Diameter Rc 1-1/4 1-1/2 Torque N・m Caution: The pump bore may get damaged if these values are exceeded. The use of seal tape or liquid sealants may result in reduced Caution: frictional resistance and over tightening, which in turn could... - Page 6 ●Pipe Arrangement for Suction Side ・For the suction side, select pipes with diameter that will keep the fluid velocity in the pipe at 1.5m/s or less and suction resistance at -0.03MPa or less. ・Make sure that the total pressure resistance of devices installed on the suction side of pipes, filter and valves in the pump suction line is smaller than 0.03MPa.

-

Page 7: Discharge Pipework

0.03MPa. Excess pressure in suction line may cause oil seal Caution: damage, oil leakage. Special attention will be required particularly if you use forward and reverse type Trochoid pump. ●Discharge Pipework ・Select pipes which is wide enough to allow the fluids flowing through the discharge line at a speed of 3m/s or less. -

Page 8: Preparations

Preparations ●Before Operation ・Check the direction of the pump rotation, suction port and discharge port. ・The rotation direction for our NOP motors (which is specially customized to work with NOP pump), is indicated on the wiring plates on the motor frame or terminal box section. Make If using our NOP motor the necessary connections after first checking these directions. -

Page 9: Regular Inspections

・The coupling and oil seals used for the Trochoid pump and motor are consumable parts and so will need to be replaced on a regular basis (1 year or 8,000 hours of use). -

Page 10: Pump Selection

Pump Selection ●Necessary Flow Rate. ・Refer to the Trochoid Pump Catalog or the drawings. (Catalog values are just for reference only and not for guaranteeing the performance.) ・The discharge flow rate will vary depending on the type of oil you use, temperature and pressure. -

Page 11: Applicable Liquids

Trochoid pumps and Lunary pumps can handle a very wide range of applications, but be aware that these pumps were intended to use with oils. -2HT and GD series, the trochoid pump for low viscosity, is applicable to fuel oils (except high vapor pressure oils such as gasoline) -2HW series, the Trochoid pump for coolant, can be used with coolant fluid. -

Page 12: Oil Temperature Range

●Applicable Viscosity Ranges. ・The permissible viscosity range of oils for Trochoid pump is 10 ~ 500mm Refer to “Suction Capacities” on P.14 for your reference. -The permissible viscosity range of oils for 2HT series (for oils with low viscosity) and 2HW series (for coolant fluids) is 2 ~ 100mm ・The permissible viscosity range of oils for high-viscosity pumps (3V, Lunary... -

Page 13: Rotation Direction

●Rotation Direction. ・The rotation, suction and discharge directions of the Trochoid and Lunary pumps are fixed, except for some models that offer forward and reverse rotation. Set the rotation direction of the motor in accordance with the rotation direction displayed on the pump nameplate. ・The Trochoid and Lunary pumps have holes on the pump suction (negative pressure) which are provided to release pressure for protecting the oil seal. -

Page 14: Applicable Voltage And Frequency

●Driving Method. ・Pump driven by special-purpose motor: Trochoid pump with motor. ・Pump driven by general-purpose motor: Trochoid pump with motor and base coupling or Lunary pump with motor and base coupling. ・Power source other than electric motor: Trochoid pump, Lunary pump. -

Page 15: Suction Capacities

Suction Capacities ・Set the suction head for the Trochoid and Lunary pumps within 1m when running the motor at a speed of 1,000 ~ 2,500min or keep the suction pressure at the suction port within -0.03 ~ 0MPa when the port is fully filled with oil. ・Pressure on the suction side lower than -0.03MPa could result in cavitation, abnormal noise, heating, poor discharge and damage to the pump. -

Page 16: Troubleshooting Chart

Troubleshooting Chart ・If you experience no oil discharge, a high pitched sound, or such other abnormal phenomena soon after the installation, check the troubleshooting chart in the table that follows. If you cannot find out the cause of trouble, consult us or your dealer. - Page 17 Symptom Possible causes Check methods Possible remedies ・Blackout or voltage drop. ・Check the power supply No oil discharge. Motor doesn’t equipment. rotate. ・Solenoid valve or breaker trips. ・Reset the Solenoid valve, Breaker trips. breaker. ・Power supply is disconnected ・Replace or reconnect the cable. or has a poor connection.

- Page 18 T201806EN Revision number : Your dealer: For further information: HP:http://www.nopgroup.com Tel : +81-3-6402-4041 Fax : +81-3-3436-1777 Sumitomo Fudosan Higashi Shimbashi Building-6 3F, 1-2-4 Hamamatsucho, Minato-ku, Tokyo, Japan, 105-0013...

Need help?

Do you have a question about the Trochoid Pump and is the answer not in the manual?

Questions and answers