Table of Contents

Summary of Contents for Dynisco LMI5000 Series

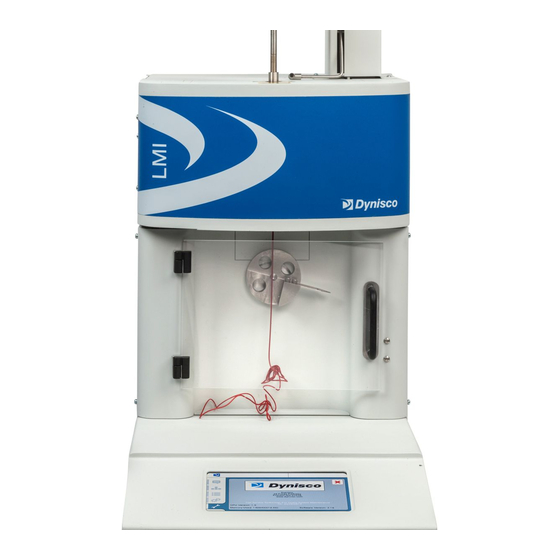

- Page 1 From lab to production, providing a window into the process Dynisco LMI5000 Series Melt Indexer Setting the Standard for Evaluating Polymer Melt Flow Characteristics Operating Manual P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com...

- Page 2 From lab to production, providing a window into the process SUPPORT CONTACT INFORMATION Dynisco Polymer Test can be contacted for questions and support at: By Phone and Fax: Phone +1 508 541 9400 Fax +1 508 541 6206 To help us handle your questions as quickly as possible, have the following items ready before you call: 1.

- Page 3 The information provided herein is believed to be true and correct but no warranty is given as to its completeness, accuracy or fitness for use for any particular purpose. Dynisco shall not be liable for any loss or damage arising from the failure to achieve a particular result by the application of any route, method or process that is recommended herein.

-

Page 4: Table Of Contents

Cleaning Up ..............................37 TROUBLESHOOTING ......................... 38 Actions ............................38 Generic Run Check List ......................38 Prior to loading Sample ......................38 Long term items: .......................... 39 Support Vendors .......................... 39 P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com... - Page 5 From lab to production, providing a window into the process APPENDIX A—DIGITAL ENCODER OPTION ................40 APPENDIX B—PNEUMATIC LIFT ....................43 APPENDIX C—PNEUMATIC PACKER .................... 49 APPENDIX D—AUTO CUTTER……………………………………………………………………..51 P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com...

-

Page 6: Safety Instructions

General safety instructions concerning the activities are given at the beginning of the relevant chapter. Special safety instructions concerning the individual steps of action will be given together with the corresponding step of action. The following pictographs are used in the present operating instructions P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com... -

Page 7: Safety Summary

The following are recommended safety precautions unrelated to any specific procedures in this manual and therefore do not appear elsewhere. Personnel must understand and apply them as appropriate during all phases of operation and maintenance. IN ALL CASES, BE PRUDENT. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com... -

Page 8: Use Gloves--It's Very Hot

Your Dynisco Lab Melt Flow Indexer contains high voltage inside the housing. DO NOT remove the housing or any part of its outer covers; there are no user serviceable parts inside. Service should only be done by a qualified DYNISCO Service Technician. Be sure the outlet used to power the indexer is properly grounded. -

Page 9: Pinch Points

3. No modifications will be made to the component except by a Dynisco service person. 4. The necessary personal protective equipment for the operation, maintenance, and service will be available and used by any personnel performing these functions. - Page 10 8. Additional instructions, in accordance with facility, local, state and federal industrial safety regulations and their corresponding, related ordinances for the use of work materials, will have to be made available as a supplement to the operating instructions. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -10-...

-

Page 11: Introduction

Dynisco Polymer Test Systems has found that charging a consistent mass of material into the barrel (±0.1 grams) is the most critical factor in getting precise data. -

Page 12: Specifications

Packer Option (PSI/Bar): MIN: 20/1.4 MAX: 50/3.5 Instrument with weight system could have up to 70lbs/31.6Kg weights installed (shipped uninstalled with unit). OTHER: Complies with ISO ASTM D1238 and ISO 1133-1, ISO 1133-2. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -12-... -

Page 13: Instrument Maintenance Recommendations

Pneumatic Lift maintenance: The guide rod and the pneumatic cylinder rod can be lubricated. Dynisco Polymer Test suggests that WD-40 or machining oil be used as a lubricant. You can also spray a small amount of WD-40 into the air manifold through the manifold’s air intake to lubricate all internal parts. -

Page 14: Equipment Setup

As a minimum, the lab bench should easily be able to support the indexer and operator (total approx. 300lbs/136.36Kg). DYNISCO POLYMER TEST recommends placing from left to right, if using these options, the melt indexer; sample scale and computer. Shake test the melt indexer for stability. The bench top should also be able to withstand hot dies and tools being dropped on them. -

Page 15: Level The Melt Indexer

Be sure to remove the level before turning on the machine. The level will be damaged if it gets hot. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -15-... -

Page 16: Instrument Overview

Figure 1: LMFI with lift, encoder and packer. (Cutter Location Shown) Figure2: LMFI base unit (Encoder and Cutter Location Shown) Rear View Power Switch Power Cord Figure 3: LMFI rear view Power connections P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -16-... - Page 17 USB cable. The product sticker on the back of the LMFI will show the model, power requirements and the instrument serial number. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -17-...

-

Page 18: Instrument Operation/Log-In

Tester, and Manager levels will have to be added by the Admin level user if desired. Logging-in at power-up can be turned off if not desired. Simply log-in at the Admin level. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -18-... -

Page 19: Instrument Operation/Icons

From lab to production, providing a window into the process Instrument Operation/Icons Icons –An icon will be displayed when a device has been connected to either the master or host USB connections. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -19-... -

Page 20: Instrument Operation/Menus

From lab to production, providing a window into the process Instrument Operation/Menus P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -20-... -

Page 21: Instrument Operation/Buttons

There are three states to a button: released, pressed, and disabled along with the option of a press and hold which will repeat the desired action as long as the button is pressed P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -21-... - Page 22 Prints a test page to a connected printer. Displays the import test conditions window. Displays the export test conditions Displays the test results export Saves the current information. Selects all Deselects all P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -22-...

- Page 23 Select/ OK button that will accept the current condition. Displays the tool tip Logs the user in or displays the Edit user window. Displays the RTD calibration Displays the LCD/ Display Calibration P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -23-...

-

Page 24: Instrument Operation/Miscellaneous Touch Areas

Miscellaneous Touch Areas—The following items are touch areas that will perform the specified operation after the button has been released. There are three states to a button: released, pressed, and disabled. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -25-... -

Page 25: Test Calculations

Method B flow rate must equal Method A. This apparent melt density definition forces the two test methods to agree. DYNISCO POLYMER TEST recommends taking an average of apparent melt densities from at least five separate A/B tests on representative samples of polymer. -

Page 26: Calculations: Method B

The encoder senses distance travelled by following the bottom of the test weight(s) which are at the top of the piston. With all Dynisco Polymer Test Systems flags, Method A and B start in the same place. Flags may be any length desired and a test can have any number as long as the total distance of flags is not longer than the distance from the start point and where the piston would land on the top of the die (≈25.4mm). -

Page 27: Calculating Pet Intrinsic Viscosity (I.v.) From The Melt Indexer

Melt Index values. This is described in greater detail in the applications brief, "Correlating Melt Rheology of PET to Solution Intrinsic Viscosity" by J. Reilly and P. Limbach, available from DYNISCO POLYMER TEST on request P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com... - Page 28 Method A Pull Plug (cm) Time (seconds) (seconds) 1.081 1.27 0.975 2.54 0.950 1.27 0.749 2.54 0.705 2.54 0.662 2.54 0.660 2.54 0.626 2.54 0.556 2.54 0.554 2.54 0.389 180+ 2.54 P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -29-...

-

Page 29: The Amount Of Sample

“PLUG” appears indicates you cannot put enough material into the barrel such that after 6 minutes there would be enough left to test, the barrel must have a flow plug inserted at the base of the die to keep the material from escaping. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -30-... - Page 30 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -31-...

- Page 31 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -32-...

- Page 32 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -33-...

- Page 33 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -34-...

- Page 34 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -35-...

- Page 35 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -36-...

-

Page 36: System Configuration

The lift option can be used to lower weight onto the piston. The lift must be enabled, through the System Configuration screen. On the test setup screen, Auto raise, Auto lower and Auto Hold can be enabled and used for weight sequencing . P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -37-... - Page 37 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -38-...

-

Page 38: Cleaning Up

(use safety glasses when looking down the barrel and beware of noxious fumes that may come from heated material inside!). Ensure the inside surface of the barrel is smooth and shiny when completely clean. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -39-... -

Page 39: Troubleshooting

Machine on for 20 minutes to allow temperature to stabilize? Correct Die in machine? Correct program being run? Hand tools in position for run (packing funnel and tool, cleaning drill bit etc.)? Encoder Arm in place? P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -40-... -

Page 40: Long Term Items

Delta, B.C. Canada V4G 1C9 Tech Assistance (800)926-8999 (604) 940-0975 or call Fisher Scientific 3. PRINCO Instruments Inc. (Accepts Standards Hg for Recycle) 1020 Industrial Highway Southampton, PA 18966 (215) 355-1500 P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -41-... -

Page 41: Appendix A-Digital Encoder Option

Encoder Option Tests, using from one digital flag up to fifteen digital flags, can be performed. The Dynisco Encoder for Method B tests employs an encoder coupled to a precisely calibrated arm. The tip of this arm employs a hardened & ground tip for extra long life. Accuracy of the measurement range ±0.025mm over 25.4 mm. - Page 42 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -43-...

- Page 43 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -44-...

-

Page 44: Appendix B-Pneumatic Lift

The lift will be used during test if set to “ON” in the configuration screen above. The screen will prompt the user during test steps when the lift is going to be moved and where to key or place the weight fork during the test procedure. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -45-... - Page 45 Enter any delay time as required in the box next to “Rise Time”. The “Rise Time” delay will expire before the lift is raised. A raise delay can be used to “Purge” the barrel of remaining material after a test P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -46-...

- Page 46 Enter any delay time as required in the box next to “Rise Time”. The “Rise Time” delay will expire before the lift is raised. A raise delay can be used to “Purge” the barrel of remaining material after a test. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -47-...

- Page 47 The hold keeps the weights from extruding the melted sample before the melt time has expired. After setting lift options, press to get to button and save in test procedures or recipes. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -48-...

- Page 48 It is useful if one wanted to check movement or positions of the lift for accuracy or workability. Lift safety measures such as safety shield and weight fork must be employed for “Lift Bypass” to function. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -49-...

- Page 49 When setup correctly, the system will alert the operator where to place the weight fork depending on the test procedures’ defined test weight. An installation guide accompanies all weight system shipments showing how to install the physical weights in the LMFI. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -50-...

- Page 50 From lab to production, providing a window into the process P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -51-...

-

Page 51: Appendix C-Pneumatic Packer

Option is only visible when the control cable for the packer is assembled onto the main board. If the packer is used with the lift option, the lift will not lower unless the packer is back in its starting position, outside of the unit’s working area. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -52-... -

Page 52: Appendix D-Auto Cutter

60 second interval between tests without affecting the Auto Cutter operation during a test. At anytime during a test, the sample extrudate can be cut by the operator by simply pressing the cut button. P/N: M0726(3) | Rev: 012020 | ECO: 51182 www.dynisco.com -53-... - Page 53 From lab to production, providing a window into the process P/N: M0726 | Rev: 012020 | ECO: 51182 www.dynisco.com -54-...

Need help?

Do you have a question about the LMI5000 Series and is the answer not in the manual?

Questions and answers