Table of Contents

Advertisement

Quick Links

Adhesive control requires a

Features...

-

Two Independently

programmable Patterns

- Two separate

Outputs

- Selectable Stitch

option for each Pattern

- Automatic Latch-on

- 24 VDC Output

- Four Program storage

capacity in Non-Volatile Memory

- No battery back-up required

- 20 character by two line LCD Display Window

- On-screen Status Line

- Input and Output test routines simplify Installation and maintenance

- Program Security ("Access Code") to protect Programs

- Single Cycle, Repeat Cycle, and No Pattern Cycle Modes of Operation

- Optional cable assemblies and optional plug-in connector kits for Outputs

V a n S c o P r o d u c t s - T h e G l u i n g E q u i p m e n t I n n o v a t o r s

2652 Lashbrook Avenue • South El Monte, CA 91733 • 626-448-7611 • Fax 626-448-0221

E-mail: sales@vansco.com • URL: www.vansco.com

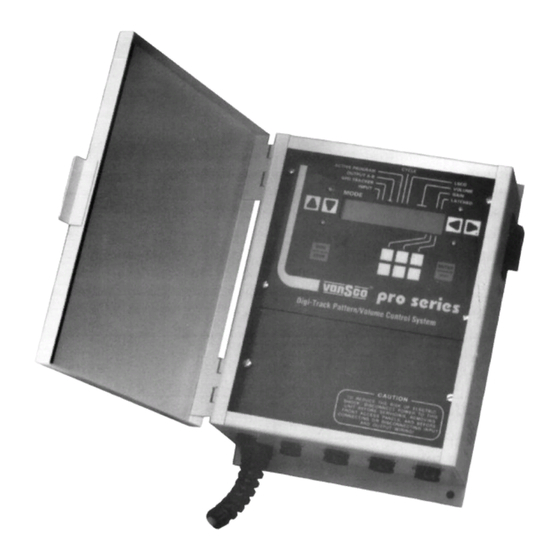

pro series

DIGI-TRACK

Speed Compensating, Distance Based

Electronic Adhesive Control System

VANSCO PRO...

Advertisement

Table of Contents

Summary of Contents for Vansco Pro Series

- Page 1 V a n S c o P r o d u c t s - T h e G l u i n g E q u i p m e n t I n n o v a t o r s 2652 Lashbrook Avenue • South El Monte, CA 91733 • 626-448-7611 • Fax 626-448-0221 E-mail: sales@vansco.com • URL: www.vansco.com...

- Page 2 PRO SERIES DIGI-TRACK From TRIGGER SIGNAL to start of PATTERN CYCLE: Less than 1 millisecond RESPONSE TIME: TOTAL RESPONSE TIME PRO SERIES DIGI-TRACK response time plus INPUT DEVICE response time OUTPUT RESOLUTION: +/- 0.1 inch from programmed START and STOP settings PATTERN RESOLUTION: 0.1 inch...

- Page 3 A and B. In Pressing the run/stop button on the control addition, either or both outputs A and B can be panel will put the PRO SERIES DIGI-TRACK in disabled from the control panel. run Mode, which allows a trigger signal to begin a pattern cycle.

- Page 4 applied to Pattern X and Pattern Y at the start signal. Increases and decreases in pressure of each Pattern Cycle in order to maintain the increase and decrease the flow (volume) of correct pattern length and position even if the fluid.

- Page 5 Examples of applications where the PRO SERIES DIGI-TRACK could be used include business forms, collating, labeling, cartooning, and bag making.

- Page 6 A functional PRO SERIES DIGI-TRACK Installation should include at least ne each of the following items: 45 -20-21 Pro Series Digi-Track PRO SERIES CONTROLLER 95-06-38 Driver Board, DC DRIVER BOARD(S) 95-02-19 Driver Board, H/S Actuator (One 95-06-38 DC Driver Board is included...

-

Page 7: Flow Chart

VANSCO PRO SERIES DIGI-TRACK Speed Compensating Control System FLOW CHART X: PATTERN X: STOP AT X: START AT 0 to 99.9“ X: OFFSET 0 to 99.9“ X: STITCH? 0 to 99.9“ X: ON DELAY YES or NO X: OFF DELAY... -

Page 8: Component Parts

T h e G l u i n g E q u i p m e n t I n n o v a t o r s 2652 Lashbrook Avenue • South El Monte, CA 91733 • 626-448-7611 • Fax 626-448-0221 E-mail: sales@vansco.com • URL: www.vansco.com... - Page 9 Installing the Speed Tracker on the Belt of a Folder/Gluer Speed Tracker Installation Install the Vansco Speed Tracker to a Folder/Gluer as shown in the example (Figure 1) above. Mount the Speed Tracker so that the wheel is on the center of the belt and positioned close to but not pressed against the opposing wheel for best traction.

-

Page 10: Photo Sensors

V a n S c o P r o d u c t s - T h e G l u i n g E q u i p m e n t I n n o v a t o r s 2652 Lashbrook Avenue • South El Monte, CA 91733 • 626-448-7611 • Fax 626-448-0221 URL: www.vansco.com • E-mail: sales@vansco.com... - Page 11 95-01-91 95-01-92 95-01-93 95-01-94 DIMENSIONS & COMPONENT PARTS ITEM No. PART No. DESCRIPTION ITEM No. PART No. DESCRIPTION 95-02-42 3-Wire Plug Kit 95-08-42 Fiber Optic 95-06-16 Circular Plug, 4-Pin 95-07-35 Swivel Mount 95-06-22 Barrel Socket, 20-24 Ga. 95-07-34 Bracket 95-06-18 Strain Relief 95-06-24 Barrel Socket, 14 Ga.

Need help?

Do you have a question about the Pro Series and is the answer not in the manual?

Questions and answers