Tractel GRIPHOIST blocstop BSO 500 Series Assembly And Operating Instructions Manual

Fall arrest device for suspended man-riding installations

Hide thumbs

Also See for GRIPHOIST blocstop BSO 500 Series:

- Original operation and installation manual (96 pages) ,

- Original operation and installation manual (60 pages)

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tractel GRIPHOIST blocstop BSO 500 Series

- Page 1 ® BSO 500 and BSO 1000 series Fall arrest device for suspended man-riding installations Assembly and Operating Instructions STOP STOP ® G671_BA_BSO5_10_US.pm6 © GREIFZUG GmbH 03/2007 ® Griphoist Division www.tractel.com...

-

Page 2: Table Of Contents

Contents General Page Information for this manual ........................Explanation of symbols used ....................... Safety advice ............................ Machine description ............................ Assembly Evidence of carrying capacity ......................Anchoring 2.1 Position of anchor components ....................® 2.2 Installing the BLOCSTOP ......................Wire rope installation 3.1 Preparing the wire rope ........................ -

Page 3: Explanation Of Symbols Used

They must have read and understood these as- by GREIFZUG Hebezeugbau GmbH, other com- sembly and operating instructions pany of the TRACTEL Group or a hoist work- shop. This instruction manual as well as the appli- cable safety regulations must be available... -

Page 4: Machine Description

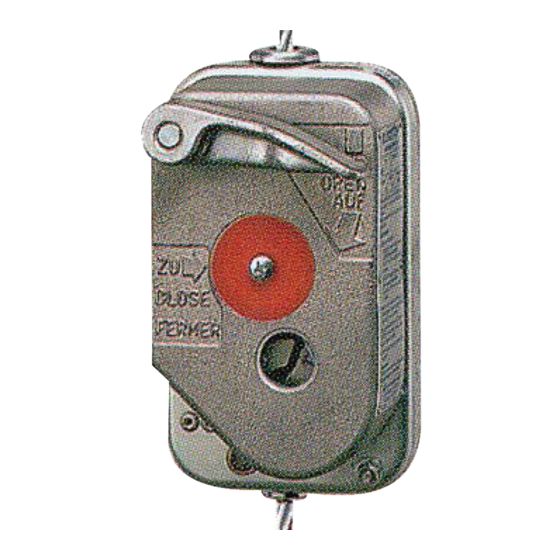

D. Machine description D.1 Purpose D.2 Working principle ® The blocstop BSO 500 and BSO 1000 series with The BSO secondary brake operates automatic- automatic overspeed device – hereafter also called ally. A centrifugal detector continuously monitors BSO secondary brake – is a fall arrest device the speed of the wire rope running through it. -

Page 5: Assembly

1. Evidence of carrying capacity Capacity of suspension and min. 4•Capacity Fig. 3 anchor component The structure from which the safety wire rope is suspended and the component to which the BSO secondary brake is anchored should have at least four times the carrying capacity of the blocstop ®... -

Page 6: Installing The Blocstop

2.2 Installing the blocstop ® Fig. 5a (Principle sketch) 2.2.1 Installing principles Connect the equipment to its anchor point by a bolt (b) with the anchor component (a) of the work- ing platform. Bolt diameter: 12 mm STOP Minimum quality: ... -

Page 7: Wire Rope Installation

3.2 Wire rope anchoring Fasten the safety wire rope to a suspension struc- ture (see section 1) which has sufficient load- carrying capacity. 3.3 Wire rope installation Fig. 10 Fig. 9 a) The safety wire rope must be freely suspended. b) To open the BSO secondary brake depress the lever until it locks into po- Closed... -

Page 8: Operation

3. Wire rope installation Fig. 6a Fig. 6b Indication on the ferrule: CAUTION! example for 9 mm dia. Wear gloves when handling wire ropes. 2 x d 3.1 Preparing the wire rope a) Only use an original wire rope with the correct diameter. -

Page 9: Operation

– Secure the platform by appropriate measures 5.2 Checks during operation so that the defective blocstop ® on the suspended platform may be replaced. During operation check the rotation of the cen- trifugal governor regularly through the inspec- b) If the safety wire rope is locked when the tion window. -

Page 10: Troubleshooting

Release the BSO. b) Mechanical defect b) Replace the BSO secondary brake and return unit to TRACTEL. 3. Hoist does not lift a) Limit switch connection to hoist a) Check the plug connection or (on device with control system interrupted. -

Page 11: Inspections

8.2 Inspection 8.2.1 Routine inspection 8.2.2 Safety inspection a) General Annual inspection Before use A safety inspection is due once a year. during operation We recommend inspection on site by the manufac- turer or an approved representative. make sure that the blocstop ®... -

Page 12: Spare Parts

9. Spare part orders Fig. 14 ® BLOCSTOP fall arrest device Model Serial number ® 9.1 blocstop device Rated load Wire rope Ø Year of manuf. As well as the part number and the name of the spare part always quote lbs.

Need help?

Do you have a question about the GRIPHOIST blocstop BSO 500 Series and is the answer not in the manual?

Questions and answers