Endress+Hauser SpectraSensors SS2100i-1 Safety Manual

Hide thumbs

Also See for SpectraSensors SS2100i-1:

- Hardware installation and maintenance manual (122 pages) ,

- Operating instructions manual (64 pages) ,

- Overview manual (47 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Endress+Hauser SpectraSensors SS2100i-1

- Page 1 SS2100i-1 Analyzer Safety Manual P/N 4900002260 rev B...

- Page 3 SS2100i-1 Analyzer Safety Manual Products of 4333 W Sam Houston Pkwy N, Suite 100 Houston, TX 77043-1223 Tel: 800.619.2861 Fax: 713.856.6623 www.spectrasensors.com Copyright © 2017 SpectraSensors, Inc. No part of this manual may be reproduced in whole or in part without the express written permission of SpectraSensors, Inc. SpectraSensors reserves the right to change product design and specifications at any time without prior notice.

- Page 4 Revision History Revision Engineering Order Date EO17016 Mar. 10, 2017 ECR17354 Dec. 20, 2017...

-

Page 5: Table Of Contents

ABLE OF ONTENTS List of Figures/Tables ........iii 1: Introduction How to Use This Manual. - Page 6 SS2100i-1 Analyzer THIS PAGE INTENTIONALLY LEFT BLANK 4900002260 rev. B 12-20-17...

- Page 7 IST OF IGURES ABLES Figures Figure 5–1. Analyzer component overview ......5-1 Figure 5–2. Components on electronics panel assembly (Upper level) ..5-2 Figure 5–3.

- Page 8 SS2100i-1 Analyzer THIS PAGE INTENTIONALLY LEFT BLANK 4900002260 rev. B 12-20-17...

-

Page 9: How To Use This Manual

1 - I NTRODUCTION SpectraSensors’ SS2100i-1 products are high-speed, diode-laser based extractive analyzers designed for extremely reliable monitoring of very low (trace) to standard concentrations of specific components in various background gases. In order to operate the analyzer safely, it is important to closely review all information contained in the manuals related to system installation, operation and maintenance, as referenced in Documents Provided with the SS2100i- 1 Analyzer. -

Page 10: Spectrasensors Overview

SS2100i-1 Analyzer • System Drawings • Calibration Certificate SpectraSensors Overview SpectraSensors, Inc. is a leading manufacturer of technologically advanced electro-optic gas analyzers for the industrial process, gas distribution and environmental monitoring markets. Headquartered in Houston, Texas, Spec- traSensors was incorporated in 1999 as a spin-off of the NASA/Caltech Jet Propulsion Laboratory (JPL) for the purpose of commercializing space-proven measurement technologies initially developed at JPL. -

Page 11: Intended Equipment Use

2 - G ENERAL AFETY NFORMATION Each analyzer shipped from the factory includes documentation for the purpose of relaying installing, operating and safety instructions to the responsible party and/or operator of the equipment. This chapter reviews the general safety instruction for every SS2100i-1 analyzer. Intended Equipment Use The SS2100i-1 analyzer is intended for use as instructed in the documentation package provided with the equipment. -

Page 12: Instructional Symbols

SS2100i-1 Analyzer Maximum voltage and current specifications for fuses. PROTECTIVE EARTH GROUND - Symbol indicates the connection point of the ground wire from the main power source. Instructional Symbols General notes and important information concerning the installation and operation of the analyzer. Failure to follow all directions may result in damage or malfunction of the analyzer. -

Page 13: Equipment Rating

General Safety Information Equipment Rating The following equipment rating information is provided for the SS2100i-1 Table 4-1. This information includes, but is not limited to, the following: • Supply voltage, power and current rating • Description of all input connections •... -

Page 14: Mitigating Risks

SS2100i-1 Analyzer Technicians are expected to follow all safety protocols established by the customer that are necessary for servicing the analyzer. This may include, but is not limited to, lockout/tagout procedures, toxic gas monitoring protocols, PPE requirements, hot work permits and other precautions that address safety concerns related to performing service on process equipment located in hazardous areas. -

Page 15: Lifting/Carrying The Analyzer

3 - E QUIPMENT NSTALLATION The information in this chapter is related to safety during the equipment installation. When an “X” is included after the certificate number, it indicates that the product is subject to the Special Conditions of Use specified in the Table 4-1 on page 4–3 schedule to this certificate. -

Page 16: Protective Chassis Ground Connections

SS2100i-1 Analyzer It is critical to mount the analyzer so that the supply and return lines reach the supply and return connections on the chassis, while still maintaining flexibility, so that the sample lines are not under excessive stress. The SS2100i-1 is intended to be mounted to a wall or secured upright frame. Secure the analyzer frame in position using bolts or screws of the size indicated in the system drawings. -

Page 17: External Circuit Breaker Requirements

Equipment Installation External Circuit Breaker Requirements Because the breaker in the customer-provided power distribution panel or switch will be the primary means of disconnecting the power from the analyzer, the power distribution panel should be located in close proximity to the equipment and within easy reach of the operator, or within 10 feet of the analyzer. -

Page 18: Cable Glands

SS2100i-1 Analyzer of cable lugs, core-end sleeves or by the type of terminal, but not by soldering alone. The creepage distances and clearances shall not be reduced by the method in which the conductors are connected to the terminals. Cable Glands Certified compound barrier seal type glands and cables shall be used where appropriate in compliance with local regulations. -

Page 19: Ventilation Requirements

Equipment Installation Ventilation Requirements Instruction for connecting ventilation to the SS2100i-1 analyzer is provided in the system drawings that accompany the equipment. Inspecting the Analyzer There are three grades of inspection; visual, close and detailed. Visual and close inspections can be performed with the analyzer energized. Detailed inspections generally require the equipment to be isolated. -

Page 20: Table 3-1 Inspection Schedule For Ex "D", Ex "E", Ex "N

SS2100i-1 Analyzer smeared with a suitable grease (e.g., Silicon Grease GS9) to prevent corrosion and to assist weather-proofing. Only non-metallic scrapers and non-corrosive cleaning fluids may be used to clean flanges. Bolts, screws and similar parts, depending on the type of protection required, shall only be replaced by similar parts in accordance with the manufacturer’s design. - Page 21 Equipment Installation Table 3-1 Inspection Schedule for Ex “d”, Ex “e”, Ex “n” (Continued) Items to Description Ex “d” Ex “e” Ex “n” Check General (All Equipment) Grade of Inspection Unused terminals are tightened Enclosed-break and hermetically sealed devices are undamaged Encapsulated components are undamaged Breathing and draining devices are satisfactory There is no obvious damage to cables...

- Page 22 SS2100i-1 Analyzer THIS PAGE INTENTIONALLY LEFT BLANK – 4900002260 rev. B 12-20-17...

-

Page 23: 4: Equipment Operation

4 - E QUIPMENT PERATION This chapter provides an overview of safety operational instructions for the SS2100i-1. Firmware Version Each SpectraSensors analyzer operates based on its own version of firmware. The firmware version for each analyzer is listed in the system calibration report, and displays upon start-up of the analyzer. - Page 24 SS2100i-1 Analyzer 6. Turn off the purge supply. 7. Allow all residual gas to dissipate from the lines. 8. Close any valves controlling the sample flow effluent to the low pressure flare or atmospheric vent. 9. Disconnect power to the system. 10.

-

Page 25: System Specifications

Equipment Operation System Specifications Table 4-1 SS2100i-1 analyzer specifications Performance Concentration See analyzer calibration report Repeatability See analyzer calibration report Measurement Time Typically less than 20 seconds Application Data Environmental Temperature –20C to 50C (–4F to 122F) - Standard Range –10C to 60C (14F to 140F) - Optional 50... -

Page 26: Exd Accessory Conditions Of Use

SS2100i-1 Analyzer Table 4-1 SS2100i-1 Analyzer Specifications (Continued) Physical Specifications IP66 copper-free aluminum with weather-resistant poly- Electronics Enclosure urethane powder coating, 80-120 micron thickness 670 mm H 489 mm W 377 mm D Size (26.38” H 44.17” W 9.76” D) Weight Approximately 86 Kg (190 lbs) Sample Cell Construction... - Page 27 Equipment Operation Table 4-2 Exd accessory conditions of use (Continued) Accessory Rating Notes Type Breather/Drainer Exd, Zone 1 1. The breather/drainer shall be suitable for bottom entry application only. 2. It is the user’s responsibility to ensure that the ingress protection level of an associated enclo- sure is maintained at the interface, IP66.

- Page 28 SS2100i-1 Analyzer THIS PAGE INTENTIONALLY LEFT BLANK – 4900002260 rev. B 12-20-17...

-

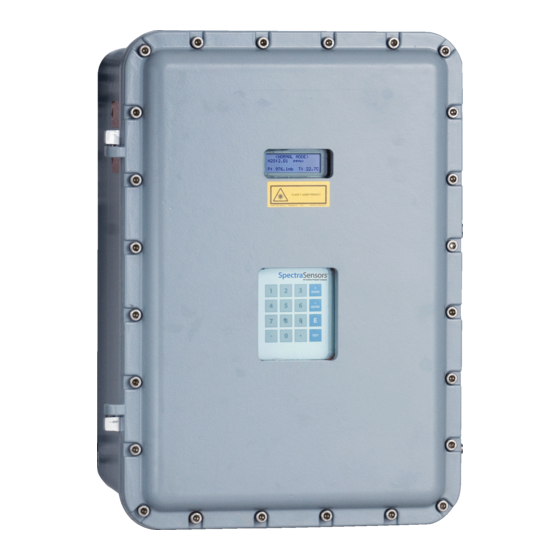

Page 29: 5: Maintenance And Service

5 - M AINTENANCE AND ERVICE This chapter provides safety information related to maintenance and service of the SS2100i-1 analyzer. Refer to Figure 5–1 for a view of the SS2100i-1 analyzer configuration. ELECTRONICS PANEL ASSEMBLY SAMPLE CELL PANEL ASSEMBLY ANALYZER ENCLOSURE Figure 5–1 Analyzer component overview The SS2100i-1 analyzer supports two levels inside the analyzer enclosure. - Page 30 SS2100i-1 analyzer 4-20mA AI 4-20mA AO TEMPERATURE BOARD BOARD CONTROL BOARD FUSE (F3) ARM9 CONTROL ELECTRONICS HIGH TEMP. LIMIT THERMOSTAT SET @ 70C ANALYZER POWER SUPPLY RS-232 TO RS-485 CONVERTER RELAYS AC LINE FILTER AUXILIARY POWER SUPPLY GROUND TERMINAL FUSES (F4-F10) BLOCKS TERMINAL GROUND...

- Page 31 Maintenance and Service TRANSITION PLATE THERMISTOR HEATER THERMISTOR ASSEMBLY MEASUREMENT CELL TEMPERATURE CONTROLLER PRESSURE SENSOR AC TERMINAL BLOCK FOR HEATER SOLID-STATE RELAY Figure 5–3 Components on sample cell panel assembly (8/28-m sample cell) (Lower level) – Safety Manual...

-

Page 32: Accessing The Measurement Cell

SS2100i-1 analyzer Accessing the Measurement Cell To access the measurement cell for mirror cleaning or to replace the pressure sensor, for example, the electronics assembly (top level) panel must first be removed. Refer to the Hardware Installation and Maintenance Manual for instruction on maintaining the components on the sample cell (lower level) panel. - Page 33 Maintenance and Service KEYPAD/ DISPLAY CABLE CLIPS KEYPAD/ DISPLAY CABLE OPTICAL HEAD CABLE TEMPERATURE/ PRESSURE CABLES WATLOW CONTROLLER QUICK CONNECT WIRE DUCT COVER HEATER POWER TERMINAL PROTECTIVE GROUND Figure 5–4 Electronics assembly panel 6. Disconnect the optical head cable. 7. Disconnect the temperature/pressure cables by removing the green connector block.

-

Page 34: Potentially Hazardous Substances

SS2100i-1 analyzer Figure 5–5 Accessing the measurement cell Potentially Hazardous Substances SS2100i-1 analyzers may be provided with a scrubber and scrubber indicator. See below for proper disposal of these items. Disposal of Hazardous Substances For analyzer equipped with H S scrubbers, use the following instruction for safe disposal of old components. -

Page 35: Fuse Ratings And Characteristics

Maintenance and Service 1. Discard used scrubber and scrubber indicator in an appropriate leak- proof receptacle. Fuse Ratings and Characteristics Hazardous voltage and risk of electric shock. Turn off and lock out system power before opening the electronics enclosure and making any connections. -

Page 36: Service Contact

SS2100i-1 analyzer Service Contact Technical and Customer Service and can be reached as follows: Customer Service 4333 W Sam Houston Pkwy N, Ste. 100 Houston, TX 77043-1223 United States of America Fax: (713) 856-6623 For SpectraSensors Tech Support inside the USA: Phone: 888-Endress E-mail: techsupport@us.endress.com Hours: Service engineers are on duty Monday-Friday, 8:00 a.m.

Need help?

Do you have a question about the SpectraSensors SS2100i-1 and is the answer not in the manual?

Questions and answers