Advertisement

Quick Links

• In order to avoid any accidental ingress of

solid matter which might damage the internal

components of the pump, it is recommended

removing the two protection caps placed on the

inlet and outlet ports of the pump only immediately

before mounting the fittings and the pipework.

• Particular care must be taken when connecting the

pump with fittings in order to avoid leaks.

• If a sealing fluid or Teflon

tape is used, do not

®

allow any to enter the pump. It is advisable to use

stainless steel or plastic fittings.

• To prevent damage to the pump, do not run it dry.

• Disconnect the power supply before removing the

pump.

• Shut down the power supply of the unit when

connecting to external control equipment.

• Do not let liquid enter this pump drive.

Warranty

Every new unit manufactured by Fluid-o-Tech is

guaranteed to be free of defects in workmanship

and material when leaving the factory for a period

of 18 months from the production date stamped on

the pumps's housing, plus a period of 6 months to

cover the warehouse and transit time, or for a period

of maximum 24 months form the purchasing date

to the first product use. In no event shall this period

exceed 24 months from date of original invoice.

Fluid-o-Tech will repair or replace at its judgement

part or all of the product not conforming to this

warranty.

Fluid-o-Tech reserves the right to alter the specifications indicated in this catalogue at any time and without prior notice.

Fluid-o-Tech srl

Fluid-o-Tech Int'l Inc.

Via Leonardo da Vinci, 40

161 Atwater St.,

20094 Corsico, Milano, Italy

Plantsville CT (USA) 06479

Tel. +39 02 9995 01

Tel. +1 (860) 276 9270

Fax +39 02 9995 0999

Fax +1 (860) 620 0193

info@fluidotech.it

info@fluid-o-tech.com

Fluid-o-Tech's responsibility under this warranty is

limited to the repair or replacement of defective

equipment returned to us on a D.A.P. basis,

providing that our analysis discloses that such part or

parts were defective at the time of sale.

The warranty is not recognized if:

• The directions on how to handle, install or operate

the pump are disregarded.

• The unit has been disassembled or modified by

anyone other than a Fluid-o-Tech (or authorized by

Fluid-o-Tech) engineer or repaired with non original

components.

• The pump operated dry or in cavitation.

• Solid extraneous particles are found in the pump.

• Evident signs of over pressure are observed.

• The pump has been utilized for an application for

which it was not intended to be used where the

operating conditions and/or the pumped liquid

were incompatible with the pump itself and such

application has not been specifically approved by

Fluid-o-Tech.

• In case of pumps equipped with relief valve, the

operating pressure results to be less than 1 bar

(14.5 psi) below the relief valve setting. Normal

wear and tear is not covered by the present

warranty.

The adjustment or replacement of defective parts

made under this warranty will not extend the original

warranty period.

Fluid-o-Tech Int'l Inc. Japan

Fluid-o-Tech Asia (Shanghai) Co., Ltd.

2nd Floor, 4-3-8, Espoir Todoroki,

2/F, Factory building 6 (1), No. 258, Zhijiang Road,

Todoroki, Setagaya, Tokyo 158-0082

Fengxian District, Shanghai City, Z.P.: 201499 China

Tel. +81 (0) (3) 6432 1812

Tel. +86 (021) 67100 838

Fax +81 (0) (3) 6432 1813

Fax +86 (021) 67100 605

erkkato@fluidotech.jp

info@fluidotech-asia.com

INSTRUCTION

MANUAL

PUMP-MOTOR UNIT FG SERIES

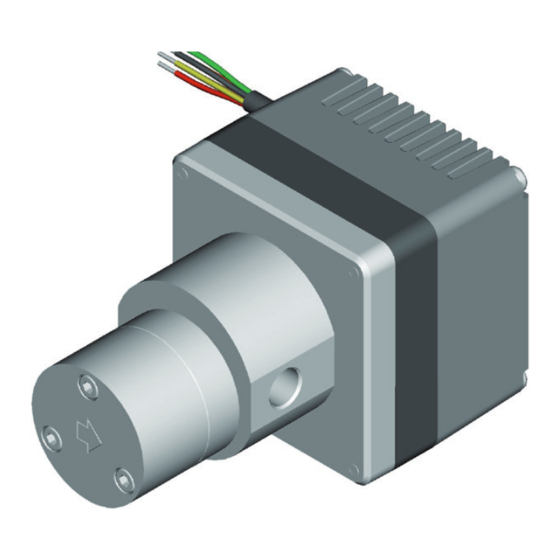

This integrated pump-motor unit is composed by a

Fluid-o-Tech mag drive gear pump and a BLDC 24V

motor. The units are available in 2 different versions: with

or without the integrated electronic driver.

Concerning the technical features of the version without

OPERATING WORKING CONDITIONS

Nominal torque

100 mNm @ 3500 rpm

Speed range

from 300 to 5000 rpm

Direction of rotation

clockwise / counterclockwise*

Min ambient temperature

5° C/41 F

Max ambient temperature

40° C/104 F at the maximum torque (70° C/158 F at 70 mNm torque)

Max fluid temperature

55° C/131 F at the maximum torque (95° C/203 F at the lower torque)

Unit protection level

IP52 only for the version with electronic driver

Insulation Class

Motor: B, Coils wire: H

Max relative humidity

90% without condense

Storage temperature

- 20° C + 85° C/- 4 F + 185 F

* counterclockwise available only for the version without electronic driver

THE TWO VERSIONS

With integrated elctronic driver

the integrated electronic diriver, please refer only to

the relevant paragraph "PIN FUNCTION: VERSION

WITHOUT ELECTRONIC DRIVER".

This version needs that the customer builds a dedicated

controller that manages the rotating magnetic field.

Without integrated elctronic driver

www.fluidotech.com

Advertisement

Summary of Contents for fluid-o-tech FG Series

- Page 1 * counterclockwise available only for the version without electronic driver THE TWO VERSIONS With integrated elctronic driver Without integrated elctronic driver Fluid-o-Tech reserves the right to alter the specifications indicated in this catalogue at any time and without prior notice. Fluid-o-Tech srl Fluid-o-Tech Int’l Inc. Fluid-o-Tech Int’l Inc. Japan Fluid-o-Tech Asia (Shanghai) Co., Ltd.

- Page 2 Version with electronic POSSIBLE ALTERNATIVE CONNECTION NOT connect the 0V speed command (brown) (in this case the speed linearity vs command can be > 5%) PIN FUNCTION WIRE COLOR SYMBOL DESCRIPTION PWR_VCC Power supply (+24V) 82 040 001 Black PWR_GND Power ground (0V) Red (PWR_VCC) Analog input speed command 0-5V...

- Page 3 Version without electronic Thermal protection motor is automatically stopped. To restart the system the The motor has an internal thermal protection built in the drive power supply voltage must be under 29V and the speed PIN FUNCTION board. The thermal upper limit is 120 °C/248 F and when input must be set to 0.

- Page 4 2) Separate motor and pumphead flange switch the motor off when that happens. It is also the pumped fluid. Fluid-o-Tech pumps are designed to 3) Replace the pump or the motor as needed 6) Assemble pumphead and motor inserting the 2 pins recommended to protect the system from accidental handle clean water at ambient temperature.

-

Page 5: "Foot" Mounting

• Directive 2014/35/ EU of the European Parliament and electronic equipment – RoHS. of the Council, of 26th February 2014, related to the A Fluid-o-Tech Declaration of Conformity can be electric material intended to be used within specified requested to state compliance with the above Directives.

Need help?

Do you have a question about the FG Series and is the answer not in the manual?

Questions and answers