Table of Contents

Advertisement

Quick Links

INSTRUCTION

MANUAL

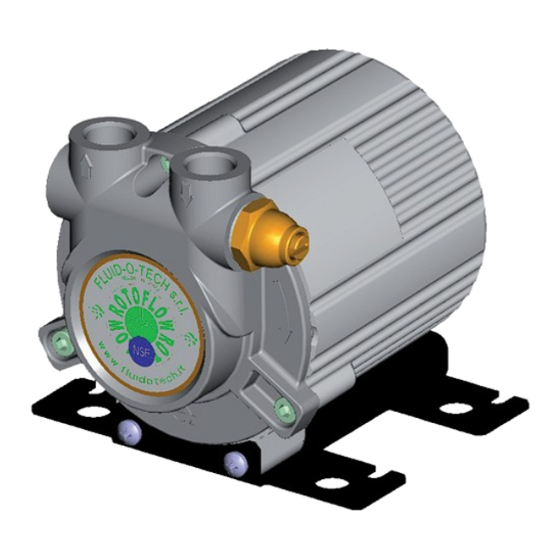

DRIVER TMFE2 FOR TMFR-TSFR PUMP

AND MOTOR UNIT

LEGEND

Puts in evidence the presence Indicates a warning of

a dangerous voltage. Concerning a generic danger

this symbol indicates a high or important operative

notes. Voltage condition which may cause a serious

accident or death.

FOREWORD

REPAIRS NOTE

Repairs may be performed only by workshops authorized by

Fluid-o-Tech who must use genuine spare parts.

Unauthorized repairs and the use of other spare parts can result

in personal injuries and property damage as well as loss of UL

approvals and safety functions, such as Safety Integrated.

Warning TMFR/TSFR units are used in high voltage

installations and are operated at voltages that when

touched can cause serious injuries or death!

PROPER USE

Note the following:

Warning This device may only be used as described

in the catalog and in the technical description and

only in connection with third–party devices and

components recommended or approved by Fluid-o-Tech.

To ensure trouble–free and safe operation of the product, it must

be transported, stored and installed as intended and maintained

and operated with care.

SAFETY INFORMATION

This documentation contains information that must be observed

to ensure your personal safety and to prevent material damage.

The instructions for your personal safety are marked by a warning

triangle. Instructions relating solely to material damage are not

marked by a warning triangle. The warnings appear in decreasing

order of risk as given below.

Danger Indicates that death or serious injury will result

if proper precautions are not taken.

Warning Indicates that death or serious injury may

result if proper precautions are not taken.

Caution With a safety alert signal indicates that minor

personal injury can result if proper precautions are not

taken.

Without a safety alert symbol, indicates that property damage can

result if proper precautions are not taken.

Notice Indicates that an undesirable result or state may arise if the

relevant note is not observed.

Warning: leakage current as a result of the high

switching frequencies, capacitances (parasitic and

integrated) with respect to ground may cause leakage

currents. This is the reason that a permanent

PE connection is required.The presence of the filter implies

an unavoidable increase of leakage current to the ground; it is

therefore suggested the use of a proper differential switches with

intervention for current ≥ 30 mA.

Warning: the TMFR/TSFR board control is not

insulated from power network. The components

of the inverter are under voltage when the unit

is connected to main supply. Contact with this voltage

can cause serious damage. The power supply of the

inverter must be protected by a fuse or with an automatic

cutout. Make sure that cables, especially ground wire,

are fixed properly. Keep separate the power cables

from the signal cables. Connect a spark quenching unit

in parallel to relays coils, solenoid valves and remote control

switches closely to the electronic, as in the following table:

www.fluidotech.com

Advertisement

Table of Contents

Summary of Contents for fluid-o-tech TMFR

- Page 1 Safety Integrated. of the inverter are under voltage when the unit Warning TMFR/TSFR units are used in high voltage is connected to main supply. Contact with this voltage installations and are operated at voltages that when can cause serious damage.

- Page 2 REMOTE CONTROL SWITCH SPARK QUENCHING UNIT • Further, all of the relevant national, local land plant/system- OR SOLENOID VALVE CHARACTERISTICS specific regulations and specifications must be taken into account. 220Vac, 240Vac >30A 0.5 μF + 100 Ω 0.5W 250V • All work should be undertaken with the system in a no–voltage 220Vac, 240Vac <30A 0.1 μF + 100 Ω...

-

Page 3: System Configuration

[Kg] current FEXXEXXX 230V (±10%) 0.25 Safety 50/60 Hz sing/ph CEI EN 60335-1 EMC: TMFR/TSFR 110V per ph 1.26 0.25 CEI EN 61000-6-1 30/120 Hz CEI EN 61000-6-3 CEI EN 61000-6-4 FEXXDXXX 230V (±10%) 0.25 UL 60730-1a... -

Page 4: Electrical Connections

NTC component rated 2.5 Ohm GUIDE TO SELECTION Warning The safety requirements of the TMFR/TSFR device in operation CONTROLLER MOTOR TYPE PUMPS COMPLIANCE require the installation and the startup to be made by technicians... -

Page 5: Motor Cables

OR EQUIVALENT PE W V U Power supply connections L PE N SUPPLY CONNECTOR PHOENIX 1700008 X3 + 1700024 X 1 OR EQUIVALENT 1700008 x 3 Phoenix connector information L PE N Mechanical data: Pin dimensions 0.8 x 0.8 mm Tightening torque, min 0.4 Nm SUPPLY CONNECTOR PHOENIX 1700008 X3 + 1700024 X 1... -

Page 6: Operation

OPERATION There are 6 different functionality modes to operate the TMFR/TSFR. Please choose one convenient to your application. Please note that the controller is required at all times whether or not variable speed control is utilized. Speed from 500 to 3500 rpm are possible. - Page 7 OPTO DIGITAL on EXTERNAL DIP SWITCH SETTINGS. MODE ANALOG IN VOLTAGE COMMAND (0-5 V) MODE OPTO DIGITAL (EXTERNAL DIP) ON BOARD CONNECTOR PIN 3 PIN 5 DIP STATUS DIP STATUS FUNCTION (SERVICE Connector) (SERVICE Connector) 0 Vs 0 Vs MODE ANALOG IN VOLTAGE COMMAND (0-5 V) 1100 rpm 0V (0) A/I 0-5 V...

- Page 8 5 - Rotor blocked; FAULT SIGNAL 6 – Module Fault (hardware) The TMFR/TSFR driver has a fault signal in OR function which 7 - Over-load power; includes the alarms (Autoresettable and Permanent): 8 - Over-current limit (50% more than the over-load power) 1 - Over-voltage;...

-

Page 9: Electric Installation

Electric/Manual valves in pump inlet/outlet circuit have to be : During restart no alarm is active. The alert LED is temporary opened before TMFR/TSFR start-up. If the pump is equipped with OFF. a relief valve (by-pass), the valve will work, in case of accidental... - Page 11 32-30-02 Mod.: TMFE P/N FEE2AWR1 Data code: 27/10 99260905.02 V in: 115Vac± 10 % I in: 5.4 A rms W in: 375 W Frequency: 50/60Hz OUTPUT RATING Vn: 180 Vac 3phase In: 1.89A rms DIN RAIL CLIP 333302 109.5 4.3110 in 3.3858 in 4.7243 in 82.5 (3.25 in)

-

Page 12: Standard Maintenance

In this case the internal parts get hot, scale parts were defective at the time of sale. develops and the hydraulic performances degrades. Fluid-o-Tech reserves the right to alter the specifications indicated in this catalogue at any time and without prior notice. Fluid-o-Tech srl Fluid-o-Tech Int’l Inc.

Need help?

Do you have a question about the TMFR and is the answer not in the manual?

Questions and answers