Table of Contents

Advertisement

OWNER'S /

OPERATOR'S

MANUAL

MODEL NO's

FM 560

FM 572

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SINO LEEINGLES, PIDA AYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE THOROUGHLY UNDERSTOOD

1. Select an area for assembly that is clean and free of any

debris which might cause persons working on the

assembly to trip.

2. Do not lift heavy parts or assemblies. Use crane, jack,

tackle, fork trucks or other mechanical devices.

3. Preview the assembly instructions in your operator's

manual before proceeding further.

4. If the assembly instructions call for parts or assemblies to

be blocked up, use only blocking material that is in good

condition and is capable of handling the weight of the

assembly to be blocked. Also insure that the blocking

material is on a clean, dry surface.

5. Never put hands, or any part of body, under blocked up

assemblies if at all possible.

For Cat. I 3-Pt. Hitch Tractors up to 35 HP

Safety Instructions

Tractor Preparation

Operating Instructions

CAUTION

BEFORE ATTEMPTING TO BEGIN ASSEMBLING THIS MACHINE

3 PT. REAR

FINISHING MOWER

6. After completing assembly, thoroughly inspect the

machine to be sure that all nuts, bolts, hydraulic fittings

or any other fastened assemblies have been thoroughly

tightened.

7. Before operating the machine, thoroughly read the

operation section of your operator's manual.

8. Before operating, read the maintenance section of your

operator's manual to be sure that any parts requiring

lubrication, such as gearboxes, are full, to avoid any

possible damage.

9. Before operating equipment – If you have any

questions regarding the proper assembly or

operation, contact your dealer or representative.

Assembly & Mounting

Maintenance

Repair Parts

Advertisement

Chapters

Table of Contents

Summary of Contents for Worksaver FM 560, FM 572

-

Page 1: Operating Instructions

OWNER’S / OPERATOR’S MANUAL MODEL NO’s FM 560 FM 572 CAUTION For Safe Operation Read Rules And Instructions Carefully SINO LEEINGLES, PIDA AYUDA A AIGUIEN QUE SI LO LEA PARA QUE LE TRADUZCA LAS MEDIDAS DE SEGURIDAD. THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE THOROUGHLY UNDERSTOOD BEFORE ATTEMPTING TO BEGIN ASSEMBLING THIS MACHINE 1. -

Page 2: Table Of Contents

Like all mechanical products, it will require cleaning and upkeep. Lubricate the Mower as specified. Use only genuine Worksaver service parts. Substitute parts will void the warranty and may not meet standards required for safe and satisfactory operation. Record the model and serial number of your Mower here: Model:________________________________________ Serial Number:_______________________________ RETAIL CUSTOMER’S RESPONSIBILITY... -

Page 3: Delivery Checklist

DELIVERY CHECKLIST Inspect the mower thoroughly after assembly to be cer- tain it is set up properly. The following checklist is a reminder of points to inspect. Check off each item as it is found satisfactory or after proper adjustment is made. Check operator's manual and familiarize the opera- tor with all sections of it. -

Page 4: Safety Information

To the Owner/Operator/Dealer All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded opera- tor who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of accidents. Read the safety messages on the implement and shown in your manual. -

Page 5: Safety Instructions

SAFETY INSTRUCTIONS (continued) EQUIPMENT SAFETY GUIDELINES Safety of the operator is one of the main concerns in designing and developing a new piece of equipment. Designers and manufacturers build in as many safety features as possible. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. - Page 6 SAFETY INSTRUCTIONS SAFETY SIGNS Keep safety signs clean and legible at all times. Replace safety signs that are missing or have become illegible. Replaced parts that displayed a safety sign should also display the current sign. Safety signs are available from your Distributor or Dealer Parts Department or the factory. How to Install Safety Signs: Be sure that the installation area is clean and dry.

- Page 7 SAFETY INSTRUCTIONS SAFETY TRAINING Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to pro- vide safe equipment can be wiped out by a single careless act of an operator. In addition to the design and configuration of equipment, hazard control and accident prevention are depend- ent upon the awareness, concern, prudence and proper training of personnel involved in the operation, trans- port, maintenance and storage of equipment.

- Page 8 SAFETY INSTRUCTIONS (continued) PREPARATION Never operate the tractor and mower until you have read and completely understand this manual, the Tractor Operator’s Manual, and each of the Safety Messages found on the safety signs on the tractor and mower. Personal protection equipment including hard hat, safety glasses, safety shoes, and gloves are recommended during assembly, installation, operation, adjustment, maintaining, repairing, removal, or moving the implement.

- Page 9 SAFETY INSTRUCTIONS STARTING AND STOPPING SAFETY Mower operating power is supplied from tractor PTO. Refer to your tractor manual for PTO engagement and disengagement instructions. Always operate the tractor PTO in the 540 rpm speed selection. DO NOT OVER SPEED! Know how to stop tractor and mower quickly in case of an emergency. When engaging PTO, the engine RPM should always be low.

- Page 10 SAFETY INSTRUCTIONS (continued) OPERATIONAL SAFETY (continued) Take all possible precautions when leaving unit unattended: Disengage PTO, set parking brake, stop engine and remove key from ignition. Park in level area. Do not allow riders on the rotary mower or tractor at any time. There is no safe place for any riders. Disengage power takeoff (PTO) and place transmission into neutral before attempting to start engine.

- Page 11 SAFETY INSTRUCTIONS (continued) OPERATIONAL SAFETY (continued) The mower discharge deflectors, belt guards, driveline and gearbox shields should be used and maintained in good working condition. They should be inspected carefully at least daily. Missing, broken or worn items must be replaced at once and before operating mower to reduce the possibility of injury from thrown objects or entanglement.

- Page 12 SAFETY INSTRUCTIONS (continued) TRANSPORT SAFETY Comply with state and local laws governing highway safety and movement of farm machinery on public roads. The use of flashing amber lights is acceptable in most localities. However, some localities prohibit their use. Local laws should be checked for all highway lighting and marking requirements. When driving the tractor and equipment on the road or highway under 20 mph (32 kph) at night or during the day, use flashing amber warning lights and a slow moving vehicle (SMV) identification emblem.

- Page 13 SAFETY INSTRUCTIONS (continued) MAINTENANCE SAFETY Good maintenance is your responsibility. Poor maintenance is an invitation to trouble. Follow good shop practices. - Keep service area clean and dry. - Be sure electrical outlets and tools are properly grounded. - Use adequate light for the job at hand. Make sure there is plenty of ventilation.

- Page 14 SAFETY INSTRUCTIONS MAINTENANCE SAFETY (continued) After servicing, be sure all tools, parts and service equipment are removed. Check to ensure all safety signs are installed and in good condition. (See safety sign section for location drawing.) Do not allow grease or oil to build up on any deck or platform. Never replace hex bolts with less than grade five bolts unless otherwise specified, i.e.

-

Page 15: Safety Sign Location

SAFETY SIGN LOCATION... -

Page 16: Safety Signs

SAFETY SIGNS DANGER GUARD MISSING DO NOT OPERATE ITG 300 ITEM 1 – Part No. 101106 DANGER THROWN OBJECT HAZARD To prevent serious injury or death: • Do not operate unless all guards are installed and in good condition. • Stop blade rotation if bystanders come within several hundred feet. - Page 17 SAFETY SIGNS (continued) ITEM 10 – Part No. 101176...

- Page 18 SAFETY SIGNS WARNING To prevent serious injury or death: Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las medidas de seguridad. • Read and understand Operator’s Manual before using. Review annually. • Do not permit riders on the tractor or mower. Never carry children on tractor seat.

-

Page 19: Instructions

TRACTOR REQUIREMENTS AND PREPARATION The models FM 560 and FM 572 Finishing Mowers are designed for light duty cutting such as lawn maintenance with a Category I, 3 pt. hitch and with a 540 rpm PTO. These mowers are not designed for tractors over 40 horsepower. -

Page 20: Assembly Instructions

ASSEMBLY INSTRUCTIONS The mower will attach to most tractors with a Category I, 3 pt. hitch system and a 540 RPM PTO. Do not exceed horsepower recommendations. DANGER! Operating with PTO speed over 540 RPM can cause excessive vibration and mower failure, which can result in serious injury or even death. -

Page 21: Operation Instructions

OPERATION INSTRUCTIONS The safe operation of this mower is the responsibil- ity of the operator. Only qualified people familiar with this manual should operate this machine. The operator should be familiar with the machine, tractor and all safe- ty practices before starting operation. This mower is designed for lawn and grass mowing. -

Page 22: Detaching And Storing

OPERATION INSTRUCTIONS STARTING AND STOPPING MOWER The safe operation of this machine is the responsibility of the owner/operator. The operator should be familiar with the mower, tractor and all safety practices before starting operation. Read the safety rules on pages 3 thru 13. The power required for operating the mower is supplied via the tractor PTO. -

Page 23: Front Gauge Wheel Interference Check

OPERATION INSTRUCTIONS FRONT GAUGE WHEEL INTERFERENCE CHECK Do not operate the mower until this interference check has been performed. If you use the mower with a differ- ent tractor, you must perform the check for that particular mounting again. 1. Raise the mower with the tractor hydraulic system to the maximum height of lift. -

Page 24: Trouble-Shooting Guide

TROUBLE-SHOOTING GUIDE PROBLEM POSSIBLE CAUSE Streaking. 1. Slow blade tip speed. 2. Worn blade tips. 3. Dull blades. 4. Blades unable to cut that part of grass pressed down by tractor’s tire path or mower’s casters. 5. Mowing too fast. 6. - Page 25 TROUBLE-SHOOTING GUIDE PROBLEM POSSIBLE CAUSE Belt slippage. 1. Mower is overloading, grass is too tall or heavy. 2. Oil on belt from over lubrication. 3. Belt hung or rubbing. Belt rollover. 1. Sheave misalignment. 2. Damaged belt. 3. Foreign object in sheave groove. 4.

- Page 26 TROUBLE-SHOOTING GUIDE PROBLEM Blade wears too fast. Mower seems to require excessive power. Blade is scalping ground. Mower will not cut. Mower moves from side to side when cutting. PTO contacts mower front frame when raised. Blade bolts come loose. POSSIBLE CAUSE 1.

- Page 27 TROUBLE-SHOOTING GUIDE PROBLEM Gearbox noisy. Gearbox leaking. Gearbox overheating. PTO driveline failure. Tractor stalls. POSSIBLE CAUSE 1. Worn bearings. 2. Low oil in gearbox. 3. Improper gearbox lubricant. 1. Damaged oil seal. 2. Bolts loose. 3. Gasket damaged. 4. Oil seal installed wrong. 5.

-

Page 28: Maintenance Instructions

MAINTENANCE INSTRUCTIONS Before operating the mower, make sure that it is properly lubricated and thoroughly inspected. Only a minimum of time and effort is required to regularly lubricate and maintain it. Following a regular program will provide long life and trouble free operation. WARNING! Always disengage the tractor PTO before raising the mower for transport or making adjustments. -

Page 29: Blade Spindle Lubrication

MAINTENANCE INSTRUCTIONS DRIVELINE LUBRICATION Grease fittings are located on the cross and bearing kit assemblies of both U-joints. U-joints should be greased after every 8 hours of operation. See figure 10 for the location of the grease fittings. Do not force grease through the needle bearing cup assemblies. -

Page 30: Blade Installation

MAINTENANCE INSTRUCTIONS BLADE INSTALLATION Install washer and lock washer on blade bolt, insert bolt into blade and bolt into the spindle shaft. Note: Always wear heavy leather gloves while tightening blade bolts. Blade bolt has left hand threads and it should be tight- ened to 85 ft. - Page 31 MAINTENANCE INSTRUCTIONS STORAGE Your mower represents an investment from which you should get the greatest possible benefit and use. Therefore, when the cutting season is over, the mower should be thoroughly checked and prepared for storage so that a minimum amount of work will be required to put it back into operation for the next season.

-

Page 32: Replacement Parts

REPLACEMENT PARTS WARNING! For maximum safety and reliability, always use genuine replacement parts. The use of inferior replacement parts may cause premature or catastrophic failure which could result in serious injury or death. For questions regarding parts please contact your DEALER. The manufacturer reserves the right to substitute parts where applicable. -

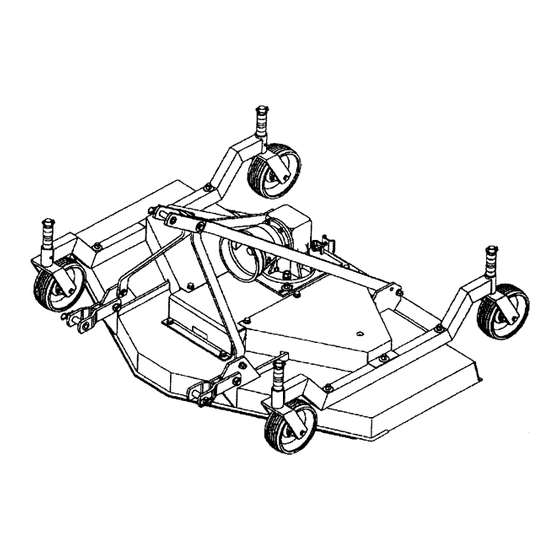

Page 33: General Mower Assembly

GENERAL MOWER ASSEMBLY ITEM PAGE NO. DESCRIPTION 3-Point lift assembly Gearbox assembly Shield assembly Belt assembly Blade and spindle assembly Spindle and housing assembly Wheel and axle assembly... -

Page 34: Driveline Assembly

DRIVELINE AND DRIVELINE SHIELD ASSEMBLY... -

Page 35: Three-Point Lift Assembly

3 POINT LIFT ASSEMBLY... - Page 36 GEARBOX ASSEMBLY 560 & 572...

-

Page 37: Shield Assembly

SHIELD ASSEMBLY... -

Page 38: Blade And Spindle Assembly

BLADE AND SPINDLE ASSEMBLY... -

Page 39: Pulley, Belt And Wheel Assembly

PULLEY, BELT WHEEL ASSEMBLY... -

Page 40: Safety Precautions

(6) months from date of purchase. Upon written approval, Worksaver will repair or exchange with- out charge any part, which upon examination by Worksaver or its authorized agent, shall disclose to be defective.

Need help?

Do you have a question about the FM 560, FM 572 and is the answer not in the manual?

Questions and answers