Table of Contents

Advertisement

Quick Links

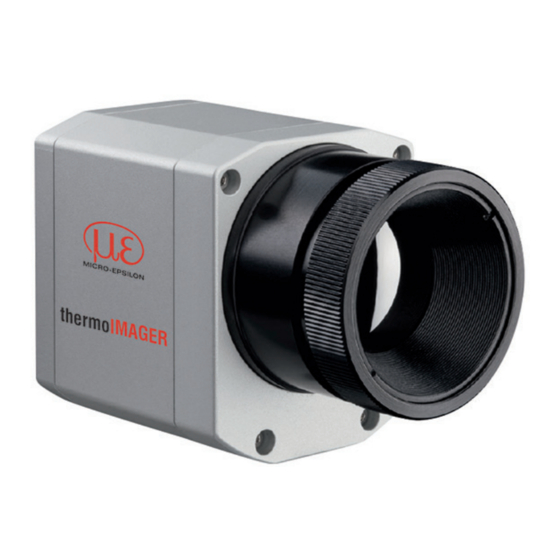

TIM 160S

TIM QVGA

TIM QVGA-HD

MICRO-EPSILON MESSTECHNIK GmbH & Co. KG

TIM QVGA-G7

Koenigbacher Str. 15 · 94496 Ortenburg / Germany

Tel. +49 (0) 8542 / 168-0 · Fax +49 (0) 8542 / 168-90

info@micro-epsilon.com · www.micro-epsilon.com

Your local contact:

Operating Instructions

thermoIMAGER

TIM 640 VGA

TIM VGA G7

www.micro-epsilon.com/contact/worldwide/

TIM

TIM M-1

TIM M-05

Advertisement

Table of Contents

Summary of Contents for MICRO-EPSILON thermoIMAGER TIM Series

- Page 1 TIM M-1 TIM QVGA-HD TIM VGA G7 TIM M-05 MICRO-EPSILON MESSTECHNIK GmbH & Co. KG TIM QVGA-G7 Koenigbacher Str. 15 · 94496 Ortenburg / Germany Tel. +49 (0) 8542 / 168-0 · Fax +49 (0) 8542 / 168-90 info@micro-epsilon.com · www.micro-epsilon.com Your local contact: www.micro-epsilon.com/contact/worldwide/...

- Page 2 Infrared camera MICRO-EPSILON MESSTECHNIK GmbH & Co. KG Koenigbacher Str. 15 94496 Ortenburg / Germany Tel. +49 (0) 8542 / 168-0 Fax +49 (0) 8542 / 168-90 e-mail info@micro-epsilon.com www.micro-epsilon.com...

-

Page 3: Table Of Contents

Contents Safety ............................7 Symbols Used ..............................7 Warnings ................................7 Notes on CE Marking ............................9 Intended Use ..............................9 Proper Environment ............................9 Technical Data ........................10 Functional Principle ............................10 Model Overview ............................. 11 General Specifications ........................... 12 Vibration / Shock ............................ - Page 4 Mechanical Installation ......................32 Dimensional Drawings ........................... 33 High Temperature Accessories - Cooling Jacket Advanced................. 40 Changing the Lens ............................40 Fixing the Focus of the Lens (only for TIM M-1 and TIM M-05) ..............41 Electrical Installation ......................43 PIN Assignment of Connectors ........................

- Page 5 Appendix Optional Accessories ......................62 Dimensions Cooling Jacket Advanced ................. 65 A 2.1 Standard Version ............................65 A 2.2 Extended Version ............................66 A 2.3 Laminar Air Purge for Cooling Jacket ......................67 Factory Settings ........................68 Emissivity Table Metals ......................69 Emissivity Table Non Metals ....................

- Page 6 thermoIMAGER TIM...

-

Page 7: Safety

Safety Safety System operation assumes knowledge of the operating instructions. Symbols Used The following symbols are used in the opeating instructions. Indicates a hazardous situation which, if not avoided, may result in minor or moder- ate injury. Indicates a situation that may result in property damage if not avoided. Indicates a user action. - Page 8 Safety Avoid shocks, impacts and vibration to the camera. > Damage to or destruction of the camera The supply voltage must not exceed the specified limits. > Damage to or destruction of the camera No solvent-based cleaning agents may have an effect on the camera (neither for the optics nor the housing). >...

-

Page 9: Notes On Ce Marking

Safety Notes on CE Marking The following apply to the thermoIMAGER TIM: - EU Directive 2014/30/EU - EU Directive 2011/65/EU Products which carry the CE mark satisfy the requirements of the EU directives cited and the relevant ap- plicable harmonized European standards (EN). The measuring system is designed for use in industrial and laboratory applications. -

Page 10: Technical Data

Technical Data Technical Data Functional Principle The thermoIMAGER TIM calculates the surface temperature based on the emitted infrared energy of objects, 10. The two-dimensional detector (FPA - focal plain array) allows a measurement of an area and will be shown as thermographic image using standardized palettes. The radiometric processing of the picture data enables the user to do a comfortable detailed analysis with the software TIM Connect. -

Page 11: Model Overview

Technical Data Model Overview The cameras of the TIM series are available in the following basic versions: Model Type Temperature range Spectral range Frame rate Typical applications TIM 160S -20 to 900 °C 8 - 14 μm 120 Hz Surface measure- 200 to 1500 °C ments in industrial (optional) -

Page 12: General Specifications

Technical Data General Specifications Model TIM 160S QVGA QVGA-HD QVGA-G7 640 VGA VGA G7 M-05 Protection class IP67 (NEMA-4) Operating 0 ... 50 °C 0 ... 70 °C 0 ... 50 °C 5 ... 50 °C temperature (+32 ... +122 °F) (+32 ... -

Page 13: Vibration / Shock

Technical Data Vibration / Shock 2.4.1 Used Standards IEC EN 60068-1: 1995-03 Environmental testing - Part 1: General and guidance IEC 60068-2-6: 2008-10 Environmental testing - Part 2-6: Tests - Test Fc: Vibration (sinusoidal) IEC 60068-2-27: 2010-02 Environmental testing - Part 2-27: Test Ea and guidance: Shock IEC 60068-2-47: 2006-03 Environmental testing - Part 2-47: Mounting of specimens for vibration, impact and similar dynamic tests... - Page 14 Technical Data Vibration, sinus shaped – testing Fc (acc. IEC60068-2-6) Frequency range 10 - 500 Hz Acceleration 29.42 m/s (3 g) Frequency change 1 octave/ min Number of axes Duration 1:30 h (3 x 0.30 h) Vibration, broadband noise – testing Fh (acc. IEC60068-2-64) Frequency change 10 - 2000 Hz Acceleration, effective...

-

Page 15: Electrical Specifications

Technical Data Electrical Specifications Model TIM 160S QVGA QVGA-HD QVGA-G7 640 VGA M-05 Power supply 5 VDC (powered via USB 2.0 interface) Current draw max. 500 mA Output Standard Process 0 - 10 V (Main measure area, measure area, internal temperature, flag status, Interface (PIF out) recording status, line scan status, alarm, frame sync, fail-safe, external... -

Page 16: Measurement Specifications

Technical Data Measurement Specifications Modell TIM 160S Temperature range -20 ... 100 °C; 0 ... 250 °C; 20 (150) ... 900 °C (scalable) additional temperature range: 200 … 1500 °C (optional) Spectral range 8 - 14 μm Detector UFPA 160 x 120 Pixel@120 Hz Lenses (FOV) 12°... - Page 17 Technical Data Model TIM QVGA QVGA-HD QVGA-G7 Temperature ranges -20 ... 100 °C; 0 ... 250 °C; (20) 150 ... 900 °C 200 ... 1500 °C (scalable) Option: 200 … 1500 °C 150 ... 900 °C Sighting range / low 0 ...

- Page 18 Technical Data Model TIM 640 VGA VGA-G7 Temperature range (scal- 20 ... 100 °C; 0 ... 250 °C; 200 ... 1500 °C able) (20) 150 ... 900 °C 150 ... 900 °C Option: 200 ... 1500 °C Sighting range / 0 ...

- Page 19 Technical Data Model TIM M-05 Temperature range … 1800 °C (27 Hz mode) 900 … 2450 °C (27 Hz mode) … 1800 °C (scalable) 950 … 2450 °C (80 Hz and 32 Hz mode) (80 Hz-Modus and 32 Hz mode) 1100 …...

-

Page 20: Microscope Lenses

Technical Data Microscope Lenses Model TIM 640 VGA Optical resolution 640 x 480 Pixel @ 32 Hz 640 x 120 Pixel @ 125 Hz Temperature ranges (scalable) -20 to 100°C, 0 to 250 °C, (20)150 to 900 °C Spectral range 8 to 14 μm Frame rate 125 Hz (switchable to 32 Hz) - Page 21 Technical Data Model TIM 640 VGA Shock / Vibration IEC 60068-2 Housing (size) 46 mm x 56 mm x 90 mm Weight 370 g, inkl. Objektiv Emissivity 0,100 … 1,10 1) Accuracy statement effective from 150 °C. 2) MFOV on TIM 450 is 2 x 2 pixels; on TIM 640 VGA 3 x 3 pixels 3) For more information, see 2.3, see 2.4 If you already have a TIM 640 VGA, the accessories kit without cameras is optionally available.

-

Page 22: Delivery

Delivery Delivery Unpacking 1 thermoIMAGER TIM inclusive 1 lens 1 USB cable (1 m 1 Table tripod 1 Process interface cable inclusive terminal block (1 m) 1 Software package TIM Connect 1 Operating Instructions 1 Aluminum case Carefully remove the components of the measuring system from the packaging and ensure that the goods are forwarded in such a way that no damage can occur. -

Page 23: Optical Charts

Optical Charts Optical Charts Notes on Focusing Make sure that the focus of thermal channel is adjusted correctly. If necessary, focus the thermal imaging camera with the optics, see Fig. The turning out of the optics leads to the focus setting near and the turning in of the lens to the focus setting infinity. - Page 24 Optical Charts Fig. 3 Measurement field of the infrared camera TIM 640 VGA representing the 33° x 25° lens HFOV Horizontal enlargement of the total measuring at object level VFOV Vertical enlargement of the total measuring at object level IFOV Size at the single pixel at object level DFOV Diagonal dimension of the total measuring field at object level...

- Page 25 Optical Charts Geometric resolution for ideal temperature measurement When designing optics for measuring IR cameras, special attention must be paid to the quality of detail contrast with which an object can be represented in the image. This is described by the modulation transfer function (MTF).

-

Page 26: Lenses Thermoimager Tim 160S

Optical Charts Lenses thermoIMAGER TIM 160S TIM 160S Distance to measurement object [m] 0.05 160 x 120 px 30° HFOV [m] 0.032 0.057 0.109 0.160 0.263 0.542 1.08 2.15 3.22 16.1 53.6 30° 23° VFOV [m] 0.024 0.044 0.083 0.122 0.201 0.397 0.79... -

Page 27: Lenses Thermoimager Tim Qvga / Tim Qvga-Hd / Tim Qvga-G7

Optical Charts Lenses thermoIMAGER TIM QVGA / TIM QVGA-HD / TIM QVGA-G7 TIM QVGA / Distance to measurement object [m] QVGA-HD / QVGA-G7 0.05 382 x 288 px 29° HFOV [m] 0.057 0.111 0.16 0.27 0.53 1.06 15.7 52.5 29° 22°... -

Page 28: Lenses Thermoimager Tim 640 Vga / Tim Vga-G7

Optical Charts Lenses thermoIMAGER TIM 640 VGA / TIM VGA-G7 TIM 640 VGA Distance to measurement object [m] / TIM VGA-G7 640 x 480 px 33° HFOV [m] 0.068 0.13 0.19 0.31 0.60 1.20 2.38 3.57 17.8 59.3 33° 25° VFOV [m] 0.051 0.09... -

Page 29: Microscope Optics Tim 640 Vga

Optical Charts Microscope Optics TIM 640 VGA TIM 640 VGA Distance to measurement object [m] 0.08 0.09 640 x 480 px 12° HFOV [m] 0.018 0.021 0.023 9° VFOV [m] 0.014 0.016 0.017 44.2 0.08 m Mikroscope optics 15° DFOV [m] 0.023 0.026 0.029... -

Page 30: Lenses Thermoimager Tim M-1 / Tim M-05

Optical Charts Lenses thermoIMAGER TIM M-1 / TIM M-05 TIM M-1 / Distance to measurement object [m] TIM M-05 382 x 288 px 20° HFOV [m] 0.07 0.11 0.18 0.36 0.72 1.43 2.15 10.7 35.8 f = 16 mm 15° VFOV [m] 0.05 0.08... -

Page 31: Lenses Thermoimager Tim M-1 / Tim M-05 With Vga Resolution

Optical Charts Lenses thermoIMAGER TIM M-1 / TIM M-05 with VGA Resolution TIM M-1 / Distance to measurement object [m] M-05 with VGA resolution 764 x 480 px 39° HFOV [m] 0.14 0.21 0.36 0.72 1.43 2.87 4.30 21.5 71.6 f = 16 mm 25°... -

Page 32: Mechanical Installation

Mechanical Installation Mechanical Installation The thermoIMAGER TIM is equipped with two metric M4 thread holes on the bottom side (6 mm depth) and can be installed either directly via these threads or with help of the tripod mount (also on bottom side). The tightening torque of the M4 screws for mounting the TIM camera should be between 1 ... -

Page 33: Dimensional Drawings

Mechanical Installation Dimensional Drawings Fig. 4 Dimensional drawing TIM 160S, dimensions in mm, not to scale thermoIMAGER TIM Page 33... - Page 34 Mechanical Installation Fig. 5 Dimensional drawing TIM QVGA / TIM QVGA-HD / TIM QVGA-G7, dimensions in mm, not to scale thermoIMAGER TIM Page 34...

- Page 35 Mechanical Installation Fig. 6 Dimensional drawing TIM 640 VGA / TIM VGA-G7, optics 29°/33° & 53°/60°, dimensions in mm, not to scale thermoIMAGER TIM Page 35...

- Page 36 Mechanical Installation Fig. 7 Dimensional drawing TIM 640 VGA / TIM VGA-G7, optics 13°/15°, dimensions in mm, not to scale thermoIMAGER TIM Page 36...

- Page 37 Mechanical Installation Fig. 8 Dimensional drawing TIM 640 VGA / TIM VGA-G7, optics 80°/90°, dimensions in mm, not to scale thermoIMAGER TIM Page 37...

- Page 38 Mechanical Installation Fig. 9 Dimensional drawing TIM 640 VGA, microscope optics 10°/12°, dimensions in mm, not to scale thermoIMAGER TIM Page 38...

- Page 39 Mechanical Installation Fig. 10 Dimensional drawing TIM M-1, TIM M-05, dimensions in mm, not to scale thermoIMAGER TIM Page 39...

-

Page 40: High Temperature Accessories - Cooling Jacket Advanced

Mechanical Installation High Temperature Accessories - Cooling Jacket Advanced The CoolingJacket Advanced is available as Standard Version and Extended Version. The IR camera can be used at ambient temperature up to 50 °C (up to 70 °C with TIM QVGA-HD / TIM QVGH-G7). -

Page 41: Fixing The Focus Of The Lens (Only For Tim M-1 And Tim M-05)

Mechanical Installation Fixing the Focus of the Lens (only for TIM M-1 and TIM M-05) With the TIM M-1 and TIM M-05, it is possible to fix the focus of the lens. To do this, unscrew the protective tube of the camera, see Fig. - Page 42 Mechanical Installation Fig. 15 Focusing screws for focus ring thermoIMAGER TIM Page 42...

-

Page 43: Electrical Installation

Electrical Installation Electrical Installation At the back side of the thermoIMAGER TIM you will find two connector plugs. Please connect the supplied USB cable with the left plug. The right connector plug is only used for the process interface. Fig. 16 Rear side of camera with connectors Plug for USB cable Plug for PIF cable thermoIMAGER TIM... -

Page 44: Pin Assignment Of Connectors

Electrical Installation PIN Assignment of Connectors SDA (I SCL (I DGND 3.3 V (Out) View on connector side Fig. 17 Pin assignment of rear side of camera In case you would like to connect the process interface of the camera directly to external hardware (with- out using the supplied PIF cable) you should activate the field “Support proprietary PIF cable”... -

Page 45: Process Interface

Electrical Installation Process Interface The TIM is equipped with a process interface (cable with integrated electronics and terminal block), which can be programmed via the software as an Analog Input (AI) and Digital Input (DI) in order to control the cam- era or as an Analog Output (AO) in order to control the process. -

Page 46: Industrial Process Interface (Optional)

Electrical Installation Fig. 20 Configuration process interface (PIF) The standard process interface offers the following inputs and outputs: Designation Description max. range status Analog input 0 - 10 V Digital input 24 V Analog output 0 - 10 V Alarm output 0/ 10 V The voltage levels for the DI are: LOW = 0 ... -

Page 47: Installation And Commissioning

Installation and Commissioning Installation and Commissioning All drivers are booted via Windows OS automatically. A driver installation is not necessary. By default the program starts automatically in the installed language. 1. Insert the included USB stick into the according port on your computer. 2. -

Page 48: Instructions For Operation / Cleaning

Instructions for Operation / Cleaning After the calibration files have been installed the live image from the camera is shown inside a window on your PC screen. 6. Choose the desired language in the menu Tools > Language. 7. Adjust the focus of the image by turning the exterior lens ring at the camera. Instructions for Operation / Cleaning Lens cleaning: Blow off loose particles using clean compressed air. -

Page 49: Software Tim Connect

Software TIM Connect Software TIM Connect Properties Fig. 22 Example window thermoIMAGER TIM Page 49... - Page 50 Further information regarding software installation as well as software features you will find in the opera- tin instructions. They are available online at: http://www.micro-epsilon.de/download/manuals/man--thermoIMAGER-TIM-Connect--en.pdf IR image from the camera Temperature profile: Shows the temperatures along max. 2 lines at any size and position in the image.

-

Page 51: Basic Features Of Software Tim Connect

Software TIM Connect Basic Features of Software TIM Connect Extensive infrared camera software - No restrictions in licensing - Modern software with intuitive user interface - Remote control of camera via software - Display of multiple camera images in different windows - Compatible with Windows 7, 8 and 10 High level of individualization for customer specific display - Various language option including a translation tool... - Page 52 Software TIM Connect Extensive online and offline data analysis - Analysis supported by measurement fields, hot and cold spot searching, image subtraction - Real time temperature information within main window as digital or graphic display (line profile, temperature time diagram) - Slow motion repeat of radiometric files and analysis without camera being connected - Editing of sequences such as cutting and saving of individual images...

-

Page 53: Basics Of Infrared Thermometry

Basics of Infrared Thermometry Basics of Infrared Thermometry 10.1 Introduction Depending on the temperature each object emits a certain amount of infrared radiation. A change in the tem- perature of the object is accompanied by a change in the intensity of the radiation. Searching for new optical material William Herschel by chance found the infrared radiation in 1800. - Page 54 Basics of Infrared Thermometry For the measurement of “thermal radiation” infrared thermometry uses a wave-length ranging between 1 μ and 20 μm. The intensity of the emitted radiation depends on the material. This material contingent constant is described with the help of the emissivity which is a known value for most materials, see Infrared thermometers are optoelectronic sensors.

- Page 55 Basics of Infrared Thermometry Object Lens Sensor Electronics Display Infrared system Fig. 25 Optical path The advantages of non-contact temperature measurement are clear - it supports: - temperature measurements of moving or overheated - objects and of objects in hazardous surroundings - very fast response and exposure times - measurement without inter-reaction, no influence on the - measuring object...

-

Page 56: Application Examples

Basics of Infrared Thermometry 10.2 Application Examples Monitoring of electronic Electronic development Process control extrud- Development of elec- cabinets ing plastic parts tronic components Monitoring of cables Development of me- Process control at calen- Process control in solar chanical parts dering cell production thermoIMAGER TIM... -

Page 57: Emissivity

Emissivity Emissivity 11.1 Definition The intensity of infrared radiation, which is emitted by each body, depends on the temperature as well as on the radiation features of the surface material of the measuring object. The emissivity (e – Epsilon) is used as a material constant factor to describe the ability of the body to emit infrared energy. -

Page 58: Determination Of Unknown Emissivity

Emissivity 11.2 Determination of Unknown Emissivity 3 methods: First of all, determine the current temperature of the measuring object with a thermocouple or contact sensor. The second step is to measure the temperature with the infrared thermometer and modify the emissivity until the displayed measuring value corresponds to the current tem- perature. -

Page 59: Characteristic Emissivity

Emissivity Fig. 30 Shiny metal surface Fig. 31 Blackened metal surface Afterwards, determine the temperature of a directly adjacent area and modify the emissivity until the measured value corresponds to the temperature of the colored surface. On all three methods the object temperature must be different from ambient temperature. 11.3 Characteristic Emissivity In the case that none of the methods mentioned above help to determine the emissivity you may use the... -

Page 60: Liability For Material Defects

The liability for material defects is 12 months from delivery. Within this period, defective parts, except for wearing parts, will be repaired or replaced free of charge, if the device is returned to MICRO-EPSILON with shipping costs prepaid. Any damage that is caused by improper handling, the use of force or by repairs or modifications by third parties is not covered by the liability for material defects. -

Page 61: Service, Repair

Service, Repair If the camera is defective, please send us the affected parts for MICRO-EPSILON MESSTECHNIK repair or exchange. GmbH & Co. KG Koenigbacher Str. 15 If the cause of a fault cannot be clearly identified, please send 94496 Ortenburg / Germany the entire measuring system to: Tel. -

Page 62: Appendix

Appendix | Optional Accessories Appendix Optional Accessories TM-MB-TIM Mounting base, adjustable in two axes TM-PH-TIM Protective housing, stainless steel, inclusive mounting base TM-CJAxxxx Further information on request, see 13 Cooling Jacket Advanced Dimensional drawing, see A 2 Dimensions in mm (inches), not to scale thermoIMAGER TIM Page 62... - Page 63 Appendix | Optional Accessories TM-NETBox-TIM Miniature PC for standalone installa- tion of TIM systems TM-USB-SGB-TIM USB server for cable extension via Ethernet TM-OPH24F-TIM Outdoor protective housing for TIM (suit- able for optics up to 90° FOV) with foils window TM-OPH24GE-TIM Outdoor protective housing for TIM (suit- able for optics up...

- Page 64 Appendix | Optional Accessories The infrared camera TIM and the USB server can also be used for outdoor applications by using the outdoor protective housing. The outdoor protective housing can be used for any TIM camera (lenses up to 90 ° FOV). In addition, the industrial PIF can be installed as an accessory without housing.

-

Page 65: A 2 Dimensions Cooling Jacket Advanced

Appendix | Dimensions Cooling Jacket Advanced Dimensions Cooling Jacket Advanced The CoolingJacket Advanced is available as a standard version and as an extended version. A 2.1 Standard Version Dimensions in mm, not to scale thermoIMAGER TIM Page 65... -

Page 66: A 2.2 Extended Version

Appendix | Dimensions Cooling Jacket Advanced A 2.2 Extended Version The Extended Version is provided for applications of the TIM series with the TIM Netbox and industrial PIF or the USB Server Gigabit and industrial PIF. Both TIM Netbox and industrial PIF or USB Server Gigabit and industrial PIF can be integrated in the CoolingJacket. -

Page 67: A 2.3 Laminar Air Purge For Cooling Jacket

Appendix | Dimensions Cooling Jacket Advanced A 2.3 Laminar Air Purge for Cooling Jacket Laminar air purge for front mounting of the CoolingJacket Advanced (Standard and Extended). Two different versions are available: One for standard IR camera applications (order no. TM-CJAAPLS-TIM, see Fig. -

Page 68: A 3 Factory Settings

Appendix | Factory Settings Factory Settings The devices have following presettings at time of delivery: Temperature range -20 ... 100 °C Emissivity 1.000 Process interface (PIF) inactive Interprocess Communication (IPC) inactive Measurement function Rectangle measure area thermoIMAGER TIM Page 68... -

Page 69: Emissivity Table Metals

Appendix | Emissivity Table Metals Emissivity Table Metals Material Typical Emissivity Spectral response 1.0 μm 1.6 μm 5.1 μm 8 - 14 μm Aluminum Non oxidized 0.1 - 0.2 0.02 - 0.2 0.02 - 0.2 0.02 - 0.1 Polished 0.1 - 0.2 0.02 - 0.1 0.02 - 0.1 0.02 - 0.1... - Page 70 Appendix | Emissivity Table Metals Material Typical Emissivity Spectral response 1.0 μm 1.6 μm 5.1 μm 8 - 14 μm Iron Non oxidized 0.35 0.1 - 0.3 0.05 - 0.25 0.05 - 0.2 Rusted 0.6 - 0.9 0.5 - 0.8 0.5 - 0.7 Oxidized 0.7 - 0.9...

- Page 71 Appendix | Emissivity Table Non Metals Material Typical Emissivity Spectral response 1.0 μm 1.6 μm 5.1 μm 8 - 14 μm Steel Polished plate 0.35 0.25 Rustless 0.35 0.2 - 0.9 0.15 - 0.8 0.1 - 0.8 Heavy plate 0.5 - 0.7 0.4 - 0.6 Cold-rolled 0.8 - 0.9...

-

Page 72: A 5 Emissivity Table Non Metals

Appendix | Emissivity Table Non Metals Emissivity Table Non Metals Material Typical Emissivity Spectral response 1.0 μm 2.3 μm 5.1 μm 8 - 14 μm Asbest 0.95 Aphalt 0.95 0.95 Basalt Carbon Non oxidized 0.8 - 0.9 0.8 - 0.9 0.8 - 0.9 Graphite 0.8 - 0.9... - Page 73 Appendix | Industrial Process Interface (Optional) Material Typical Emissivity Spectral response 1.0 μm 2.3 μm 5.1 μm 8 - 14 μm Sand 0.95 Snow Soil 0.9 - 0.98 Textiles 0.95 0.95 Water 0.93 Wood Natural 0.9 - 0.95 0.9 - 0.95 thermoIMAGER TIM Page 73...

-

Page 74: A 6 Industrial Process Interface (Optional)

Appendix | Industrial Process Interface (Optional) Industrial Process Interface (Optional) For use in industrial environment an industrial process interface with 500 VAC isolation voltage between TIM and process is available (connection box with IP65, 5 m, 10 m or 20 m standard or high temp cable for camera connection, terminal for process integration). - Page 75 Appendix | Industrial Process Interface (Optional) The industrial process interface offers the following inputs and outputs: Designation Description max. range / status A IN 1 / 2 Analog input 1 und 2 0 - 10 V D IN 1 Digital input (active-low = 0 ... 0.6 V) 24 V AO1 / 2 / 3 Analog output 1, 2 and 3 0/4 - 20 mA...

-

Page 76: A 6.1 Examples For A Fail-Safe Monitoring Of The Tim With A Plc

Appendix | Industrial Process Interface (Optional) A 6.1 Examples for a Fail-Safe Monitoring of the TIM with a PLC Fig. 37 Fail-Safe monitoring states Fail-Safe monitoring states [1] Breakdown of PIF power supply [2] Cable break of fail-safe cable [3] Interruption of cable TIM-PIF [4] Malfunction of camera [5] Breakdown of TIM power supply/ interruption of USB cable [6] Malfunction of TIM Connect software... - Page 77 Appendix | Industrial Process Interface (Optional) Fig. 38 Fail-Safe monitoring status Fail-Safe monitoring status [1] Breakdown of PIF power supply [2] Cable break of fail-safe cable [3] Short circuit of fail-safe cable [4] Interruption of cable TIM PIF [5] Malfunction of camera [6] Breakdown of TIM power supply/ interruption of USB cable [7] Malfunction of TIM Connect software thermoIMAGER TIM...

-

Page 78: A 7 Usb Cable Extensions

Appendix | USB Cable Extensions USB Cable Extensions The maximum USB cable length is 20 m. For greater distances between TIM and computer or for standalone solutions you should use the optional TIM NetBox or the USB-Server Industry Isochron: Fig. 39 Ethernet direct communication with TIM Netbox Fig. - Page 79 Appendix | USB Cable Extensions Fig. 41 Stand-Alone operation with TIM Netbox Fig. 42 USB Server Gigabit thermoIMAGER TIM Page 79...

-

Page 80: A 8 A Brief Overview To Serial Communication

Appendix | A Brief Overview to Serial Communication A Brief Overview to Serial Communication A 8.1 Introduction One of the features of the thermoIMAGER TIM Connect software is the ability to communicate via a serial comport interface. This can be a physical comport or a Virtual Comport (VCP). It must be available on the computer where the TIM connect software is installed. -

Page 81: A 9 A Brief Overview To Dll Communication (Ipc)

Appendix | A Brief Overview to DLL Communication (IPC) A Brief Overview to DLL Communication (IPC) The description of the initialization procedure as well as the necessary command list is provided on the CD and in the TIM Connect software under Help > SDK. 2 SDK packages are available. -

Page 82: A 10 Thermoimager Tim Connect Resource Translator

To limit this effort and to enable anybody to translate the resources of the TIM Connect application Micro-Epsilon has developed the small tool Resource Translator. This tool helps to translate any visible text within the thermoIMAGER TIM Connect application. -

Page 83: A 11 Process Interface

Appendix | Process Interface A 11 Process Interface A 11.1 Analog Output The maximum load impedance is 500 Ohm. The analog output can be used as a digital output too. The current value for no alarm and alarm on is set within the software. -

Page 84: Analog Input (Usable Voltage Range: 0

Appendix | Process Interface A 11.3 Analog Input (Usable Voltage Range: 0 ... 10 V) Fig. 45 Analog input thermoIMAGER TIM Page 84... -

Page 85: A 11.4 Relay Output At Industrial Pif (Part No.: Tm-Pifcxx-Tim)

Appendix | Process Interface A 11.4 Relay Output at Industrial PIF (Part No.: TM-PIFCxx-TIM) The analog output must be set to Alarm. The range for A01 - A03 can be set in the software: - No Alarm: 0 - 4 mA - Alarm: 10 - 20 mA REL1-3 (DO1-DO3): U = 30 VDC... - Page 86 MICRO-EPSILON MESSTECHNIK GmbH & Co. KG X9751206-E092100HDR Koenigbacher Str. 15 · 94496 Ortenburg / Germany Tel. +49 (0) 8542 / 168-0 · Fax +49 (0) 8542 / 168-90 MICRO-EPSILON MESSTECHNIK info@micro-epsilon.com · www.micro-epsilon.com *X9751206-E09* Your local contact: www.micro-epsilon.com/contact/worldwide/...

Need help?

Do you have a question about the thermoIMAGER TIM Series and is the answer not in the manual?

Questions and answers