Table of Contents

Advertisement

Quick Links

Hypro

Series 3377

®

Form L-1566

Rev A

Original Instruction Manual

KEEP FOR FUTURE REFERENCE

3377-1670 & 3377-1671

3377-1170 & 3377-1171

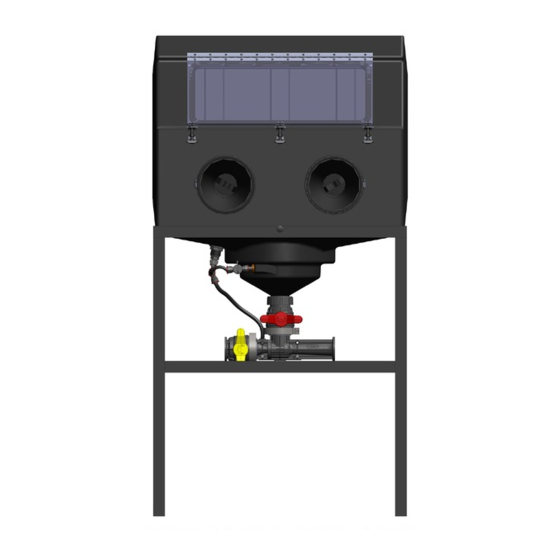

Framed & Unframed Closed System Cleanload

Pentair

Pentair

375 5th Ave., New Brighton, MN 55112

375 5th Ave., New Brighton, MN 55112

Phone: (651)766-6300 -OR-800-424-9776 Fax: 800-323-6496

Phone: (651)766-6300 -OR- 800-424-9776 Fax: 800-323-6496

www.hypropumps.com

www.hypropumps.com

Advertisement

Table of Contents

Summary of Contents for Pentair Hypro 3377 Series

- Page 1 Original Instruction Manual KEEP FOR FUTURE REFERENCE 3377-1670 & 3377-1671 3377-1170 & 3377-1171 Framed & Unframed Closed System Cleanload Pentair Pentair 375 5th Ave., New Brighton, MN 55112 375 5th Ave., New Brighton, MN 55112 Phone: (651)766-6300 -OR-800-424-9776 Fax: 800-323-6496 Phone: (651)766-6300 -OR- 800-424-9776 Fax: 800-323-6496 www.hypropumps.com...

-

Page 2: Table Of Contents

Contents Introduction.................................3 Description..............................3 Intended Uses................................3 Purpose of Manual..............................3 Misuses................................3 Product I dentification.................................4 Product Technical Data................................4 Fluid Pumping Application............................5 Tools................................5 Lifting, Transport, and Intermediate Storage......................5 Assembly and Installation................................5 Assembly............................5 Installation............................5 Control Systems.................................6 Commissioning, Start-Up, Operation, Shutdown........................7 Information.............................7 Start-Up, Operation, Shutdown...........................7 Maintenance and Servicing..............................8... -

Page 3: Introduction

Introduction Description Pentair Cleanload chemical eductors are designed to mix fluids and dry chemicals in a self-contained system. The inline eduction system allows the operator to mix chemicals quickly and safely. The Cleanload operates by receiving a fluid into the eductor where a fluid or dry chemical is mixed in. The mixture is then transferred into a holding tank to be used for spraying crops. Construction features a polypropylene venturi eductor and polyethylene hopper tank and FKM gaskets. Intended Uses The Cleanload is designed and constructed for incorporation into a large variety of applications that require the mixing of liquid and dry chemicals. -

Page 4: Product Identification

Product Identification Hypro uses serialized labeling to enable users to precisely identify the pump’s manufacturing date. Serial Number: First and second digits: year (12 = 2012) Third through fifth digits: consecutive day of the year the pump was manufactured. Sixth through eighth digit: unique system ID number. Product Technical Data Performance Charts General Cleanload Details... -

Page 5: Fluid Pumping Application

Fluid Pumping Applications Tools The Cleanload is designed using Imperial (inch) size bolts, but it can be mounted by metric (mm) tools as well. In most cases, an adjustable spanner wrench can be used to fit any size bolt. Lifting, Transport, and Intermediate Storage The packaging consists of a pallet for easy shipping and handling. During unpacking, inspect the contents of the packaging to ensure that all components are accounted for and undamaged. If there are damaged or missing components, please contact the dealer or Hypro. Dispose of the packaging materials properly according to local laws. -

Page 6: Control Systems

Standard Mounting • Place on flat even ground. Pump Plumbing • Typical tender application CLEAN WATER TANK BYPASS VALVE Control Systems • All pump systems with electric or hydraulic power sources are required to have a control system which meets all local and national standards. •... -

Page 7: Commissioning, Start-Up, Operation, Shutdown

Commissioning, Start-Up, Operation, Shutdown Before attempting to operate your Cleanload, the following must be understood and followed to ensure safe operation. Information Read the operating instructions (to follow) completely before using the Cleanload. • Always read and follow the chemical label instructions exactly. Understand safe practices for chemical handling, mixing, loading, cleaning, and first aid. •... -

Page 8: Maintenance And Servicing

Maintenance and Servicing Information ATTENTION: Divert or stop all flow to and from the Cleanload system before performing any service or maintenance procedures. ATTENTION: Always wear proper Personal Protective Equipment when handling chemicals including gloves, eye protection, respirator and safety shoes. ATTENTION: Always dispose of chemicals and contaminated water in accordance with national and local laws and statutes. -

Page 9: Troubleshooting

Troubleshooting When servicing of a Hypro Cleanload, be sure that all pumps are disconnected from energy sources Symptom Probable Cause(s) Corrective Action Replace 90-degree fittings with sweeping bends using reinforced hose, especially near the eductor outlet. Flow restrictions on outlet side Use 2” (51mm) or larger hose and fittings all the way of eductor. back to and into the tank. If sharp bends cannot be avoided, use oversized hose and fittings to minimize flow restriction. -

Page 10: Replacement Parts

Replacement Parts The following drawings show the Cleanload and their replacement parts. Only genuine replacement parts should be used. Failure to follow this warning can result in damage to property, serious injury or death. If the Cleanload malfunctions or is defective it should be sent back to Hypro for service. 3377-1670, 3377-1671, 3377-1170 &... - Page 11 Notes - 11 -...

-

Page 12: Warranty

Returns are to be shipped with the RMA number clearly marked on the outside of the package. Hypro shall not be liable for freight damage incurred during shipping. Please package all returns carefully. All products returned for warranty work should be sent shipping charges prepaid to: HYPRO / PENTAIR Attention: Service Department 375 Fifth Avenue NW...

Need help?

Do you have a question about the Hypro 3377 Series and is the answer not in the manual?

Questions and answers