Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ADENDORFF ELATHE-140

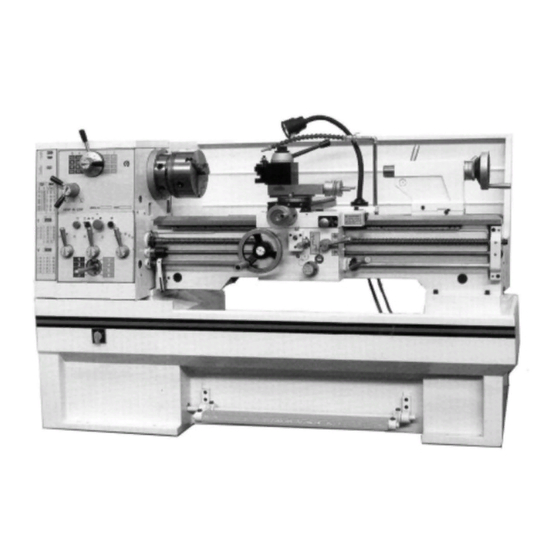

- Page 1 INSTRUCTION MANUAL & PARTS LIST...

-

Page 2: Table Of Contents

CONTENTS 1. General Safety Rules for Power Tools………………………2 2.Specification …………………………………………………3 3. Lifting……………………………………………………………3 4. Cleaning…………………………………………………………4 5. Installing…………………………………………………………4 6. Lathe Alignment Part.1………………………………………5 7. Lathe Alignment Part.2………………………………………6 8. Slide Ways Attention…………………………………………7 9. Cross-Slide Nut…………………………………………………7 10. Electrical Controls …………………………………………8 11. Speed Controls ………………………………………………9 12. Threading Dial Indicator ……………………………………10 13. -

Page 3: General Safety Rules For Power Tools

1.General Safety Rules for Power Tools Warning: Do not attempt to operate until you have read thoroughly and understand completely all instructions, rules etc. Contained in this manual failure to comply can result in accidents involving fire, electric shock, or serious personal injury. Maintain owners’... - Page 4 2.Specification Capacity Capacity Capacity Capacity Swing Over Bed 360mm(14") or 410mm(16") ") or 255mm(10") Swing Over Cross Slide 215mm(8 ") Swing In Gap Diameter×Width 540(21 /4)or (22")×190(7 ")or 205mm(8") Height of Center 185mm(7 Distance Between Centers 1000mm(40") Width of Bed 250mm(10") "×...

-

Page 5: Lifting

3.Lifting Use a sling-china to sling the lathe as in fig position the saddle and tailstock along the bed to obtain balance. I I I I mportant: mportant: mportant: mportant: the sling-chain should not touch the leadscrew or feed-shaft to avoid damage. Unloading of the machine. -

Page 6: Installing

5.installing Locate the machine on a solid foundation, allowing sufficient area all around for easy working and maintenance (see foundation plan).the lathe may be used freestanding or bolted to the foundation. Freestanding: position lathe on foundation and adjust each of the six mounting feet to take equal share of the load. -

Page 7: Lathe Alignment Part.1

Construction of the ground Due to the recent tendency of utilizing ultra-hard alloy steel tools, it surely increases the speed of heavy cutting comparing to the previous steel tool. But, in the mean time, it easily happens to the vibration of the machine. For assuring better cutting result, it requires as very strong and steady construction of ground. -

Page 8: Lathe Alignment Part.2

The importance and methods of spindle leveling adjustment 1.switch on to make the spindle turn while the spindle is set up at 1170 r.p.m .by putting the palm of the left hand on the headstock cover to fell its chatter. An unrevealing spindle will lead to lathe chatter.move leveling block (either “A”... -

Page 9: Slide Ways Attention

8.slide ways attention tapered gib strips are fitted to slideways od saddle cross-slide and top (compound) slides so that any slackness, which may develop can be rectified. Ensure that slideways are thoroughly cleaned and lubricated before attempting adjustment. Then rest the gib screw ans tightening the front screw, a little at a time check constantly for smooth action throughout full slide... -

Page 10: Electrical Controls

10.electrical controls the power switches are fitted on the face electrical box in back of the bed and below the headstock. 1. move the power switch set at ON position then the indicator lamp glows. 2. press the GREEN buttom. The main drive motor can be running with moment( with the main motor rotation lever is set in the neutral position.) 3. -

Page 11: Speed Controls

11.speed controls (2 speed moto) spindle speeds: selected by the two lever controls and electrical switch, on the headstock and stand. The sixteen available speeds are shown directly on the data plate. While the electrical switch set are position, the small lever rotated right-hand side, it provides speeds from 1800-510 r.p.m., and rotated to left-hand side, it provides speeds from 330-90 r.p.m. -

Page 12: Threading Dial Indicator

12.threading dial indicator A. A. A. A.whitworth whitworth whitworth whitworth threads threads threads threads located on right-hand side of the apron on lathes having an imperial leadscrew. Engage the indicator in engagement. To cut threads of an even number per inch, close the leadscrew nut as ANY line on the dial passed the datum mark, to cut threads of odd numbers per inch, close the leadscrew but at any numbered line. -

Page 13: Chucks And Chucks Mounting

Each graduation on the dial is marked with a letter, which indicates the points at which the half nuts may be engaged for certain threads. A diagram is supplied with the thread dial to show which gear and graduations must be used for each pitch of metric screw thread. 13.chucks and chucks mounting when fitting chucks or faceplates, first ensure that spindle and chuck tapers are scrupulously clean and that all cams lock in the correct... -

Page 14: Electric Circuit Control

14.Electric Circuit Control... - Page 15 Electric Board Diagram...

- Page 16 Code Code Name Name Function Function Electric Electric Rating Rating Code Code Name Name Function Function Electric Electric Rating Rating YD132M-8/4 3/4KW AC 3PH Motor Spindle 400V 50HZ Pump Coolant AB25 90W 400V 50HZ Fuse Main Circuit Protection RT18 32A Fuse Control Circuit Protection RT18A 5A...

- Page 17 Bed Gssembly Gssembly Gssembly Gssembly1/3...

- Page 18 Gssembly Bed Gssembly Gssembly Gssembly2/3...

- Page 19 Bed Gssembly Gssembly Gssembly Gssembly3/3...

- Page 20 Bed Gssembly(1) code code code code name name name name S S S S pecification pecification pecification pecification Notes Notes Notes Notes 1 1 1 1 .01-002 .01-002 .01-002 .01-002 Bridge Bridge Bridge Bridge 1 1 1 1 2 2 2 2 .01-037 .01-037 .01-037...

- Page 21 Bed Gssembly(2) N N N N code code code code name name name name Specification Specification Specification Specification Notes Notes Notes Notes o o o o .03-094 .03-094 .03-094 .03-094 Cover Cover Cover Cover 1 1 1 1 .01-038 .01-038 Block Block Chip...

- Page 22 Bed Gssembly(3) code code name name S S S S pecification pecification pecification Notes Notes code code name name pecification Notes Notes .01-102 .01-102 Belt Belt Pulley Pulley 1 1 1 1 .01-102 .01-102 Belt Belt Pulley Pulley .01-102 .01-102 .01-102 .01-102 Motor...

- Page 23 Bed Gassembly(4) Code name Specification Notes GB/T301-95 Shaft 51103 17×30×9 GB/T77-2000 Screw M6×6 .01-012 Light Bar .01-014 Circlip .01-019 Cover GB/T77-2000 Screw M12×8 .01-020 Sleeve .01-107 GB/T77-2000 Screw M8×8 .01-020 Lever GB/T77-2000 Screw M10×10 5×45 GB/T879.2-2000 .01-013 Clutch GB2089-94 Spring 1.2×6×46 GB308-89 Steal Ball...

- Page 24 Distance Institution Set...

- Page 25 Distance Institution Set code N N N N ame specification Notes code code code specification specification specification Notes Notes Notes 1 1 1 1 0.1-033 0.1-033 0.1-033 0.1-033 Shaft Shaft Shaft Shaft 1 1 1 1 2 2 2 2 .01-034 .01-034 .01-034...

-

Page 26: Headstock Assembly

Headstock Assembly(1/3) - Page 27 Headstock Assembly(2/3)

- Page 28 Headstock Assembly(3/3)

- Page 29 Headstock Assembly(1) code code code code name name name name S S S S pecification pecification pecification pecification Notes Notes Notes Notes 1 1 1 1 .02-001 .02-001 .02-001 .02-001 Headstock Headstock Headstock Headstock 1 1 1 1 2 2 2 2 .02-002 Screw 2 2 2 2...

- Page 30 Headstock Assembly(2) code name specification Notes code code code name name name specification specification specification Notes Notes Notes .02-023 Spacer 1 1 1 1 .02-023 .02-023 .02-023 Spacer Spacer Spacer 3 3 3 3 0 0 0 0 × × × × 3.55 3.55 3.55 3.55...

- Page 31 Headstock Assembly(3) code name S S S S pecification pecification Notes code code code name name name pecification pecification Notes Notes Notes .02-048 .02-048 .02-048 .02-048 Gear Gear Gear Gear 1 1 1 1 m m m m 2.5 2.5 z43 GB/T894.2-86 GB/T894.2-86 GB/T894.2-86...

- Page 32 Headstock Assembly(4) code name S S S S pecification pecification Notes code code code name name name pecification pecification Notes Notes Notes .02-074 .02-074 Plug Plug 2 2 2 2 .02-074 .02-074 Plug Plug 1 1 1 1 5 5 5 5 × × × × 2.65 2.65 2.65 2.65...

-

Page 33: Gear Box Control

Gear Box Control(1/4) - Page 34 Gear Box Control(2/4)

- Page 35 Gear Box Control(3/4)

- Page 36 Gear Box Control(4/4)

- Page 37 Gear Box Control(1) code code N N N N ame specification specification Notes Notes code code specification specification Notes Notes M M M M 8 8 8 8 × × × × 35 35 35 35 1 1 1 1 GB/T70.1-2000 GB/T70.1-2000 Screw...

- Page 38 Gear Box Control(2) C C C C ode N N N N ame specification Notes specification specification specification Qty Notes Notes Notes Ⅱ Ⅱ Ⅱ Ⅱ - - - - Ⅰ Ⅰ Ⅰ Ⅰ Gear .03-018 .03-018 .03-018 .03-018 Gear Gear Gear 1 1 1 1...

- Page 39 Gear Box Control(3) C C C C ode name name name name specification specification specification specification Notes Notes Notes Notes Ⅲ Ⅲ Ⅲ Ⅲ Gear 36、 、 、 、 m125z20 .03-043 .03-043 Gear Gear 1 1 1 1 .03-043 .03-043 Gear m.25z m.25z...

- Page 40 Gear Box Control (4) code name specification Notes GB3452.1-82 O-Ring 10×2.65 GB3452.1-82 O-Ring 17×2.65 .03-070 Washer GB/G1096-79 4×12 .03-071 Washer GB/T70.1-2000 Screw M5×12 .03—072 Handle .03-073 Shaft .03-074 .03-075 Washer GB/T77-2000 Screw M8×8 GB308-89 Steal Ball .03-076 1-8 Plate .03-077 Sleeve .03-078 Top Plate...

-

Page 41: Apron (L.h.)

Apron(1/2) - Page 42 Apron(1/2)

- Page 43 Apron (1) code name specification Notes 0.4-001 Apron casting M3×6 GB/T70.1-2000 Screw M8×6 GB/T77-2000 Screw 1×5×15 GB/T2089-94 Spring GB-308-89 Steal Ball .04-040 Shaft .04-016 Handle .04-057 Spacer .04-036 Nameplate GB1160.1-89 Oil Standard Q/ZB285.3 Plug R3/8” .04-003 Nameplate .04-048 Cover GB/T70.1-2000 Screw M5×16 0.4-049...

- Page 44 Apron (2) code name specification Notes .04-007 Handwheel .04-008 Scale Ring GB/T1096-79 5×5×20 .05-117 Screw GB/T70.1-2000 Screw M6×25 GB/2089-94 Spring 0.5×4×12 GB308-89 Steal Ball GB/T1096-79 Screw M5×25 .04-004 Shaft .04-002 Gear ml.5 z18 .04-023 Plug 0.4-009 Gear ml.5 z18 GB/T1096-79 5×5×18 GB/T879.2-2000 5×35...

- Page 45 Apron (3) code name specification Notes .04-037 0.4-025 Shaft 0.4-030 Plate GB/T41-2000 GB/T77-2000 Screw M5×16 5 ×40 GB/T879.2-2000 .04-026 Head of Handle .04-027 Handle GB/T879.2-2000 5×30 .04-041 Fork GB/T3452.1-82 O-Ring 16×1.8 GB/T3452.1-82 O-Ring 28.5×3.55 .04-021 Shaft .04-022 Flange .04-020 Nameplate .04-044 Shaft .04-019...

- Page 46 Carringe (1/2)

- Page 47 Carringe (1/2)

- Page 48 Carringe (1) code name specification Notes GB1155-89 Oil Cup .05-130 .05-140 Sign GB/T77-2000 Screw M6×10 GB/T70.1-2000 Screw M8×70 GB/T118-2000 8×70 GB1155-89 Oil Cup .05-101 Bed saddle .05-138 Wiper .05-139 Wiper Cover GB/T818-2000 Screw M5×10 .05-102 C over-cross Sliding .05-136 Wiper .05-137 Wiper Cover GB/T70.1-2000...

- Page 49 Carringe (2) code name specification Notes GB/T819.1-2000 Screw M4×6 .05-124 Wiper Cover .05-126 Iron Block .05-123 Iron .05-122 Wiper Cover .05-111 Copper Bush GB/T41-2000 GB/T97.1-2000 Washer .05-112 Seat .05-110 Seat GB/T301-95 Thrust Bearing 51100 .05-120 .05-121 C onditioring B loclc GB/T77-2000 Screw M8×20...

- Page 50 Compound...

- Page 51 Compound code name specification Notes .05-001 Compound Rest .05-002 Swivel Table GB/T879.2-2000 Cyliudrical Pin 5×30 .05-010 Screw .05-013 Tool Post GB93-83 Screw M10×50 .05-012 Washer 0.5-015 Clamping Handle 0.5-016 Clamp Headle GB11500-89 Oil Cup GB/T2089-94 Spring 0.5×4×12 GB308-89 Steel Ball .05-007 Sleeve .05-006...

-

Page 52: Lubrication

Lubrication... - Page 53 Lubrication code name specification Notes Tie-In. Tie-In. Double Cone Ring 直径 4×0.75 Lubrication tube (Qty) .05-149 Oiler .05-147 Bolt .05-148 Distributoy GB/T77-2000 Screw M4×6 GB/T77.1-2000 Screw M6×12 One-way Valve 直径 6 Single taperSheath 直径 6 Tie-In. 直径 6 Pouble taperSheath Tie-In GB3452.1-82 O-Ring...

- Page 54 Tail Stock Assembl (1/2)

- Page 55 Tail Stock Assembl (2/2)

- Page 56 Tail Stock Assembl (1) code name specification Notes .06-001 Tail Stock .06-002 Tail Stock Bose GB//T5780-2000 Screw M10×70 GB/T95-2000 Retaining Ring GB/T93-87 Spring Washer .06-003 Bedway WiperPlate GB/T5780-2000 Screw M12×100 GB/T95-2000 Retaining Ring .06-004 Bedway WiperPlate GB/T5780-2000 Screw M12×130 GB/T56-88 HexagonThick Nut .06-005 .06-006...

- Page 57 Tail Stock Assembl (2) code name specification Notes .06-015 Feed Screw .06-016 Feed Nut GB/T70.1-2000 Screw M6×16 GB/T894.1-86 Retaining Ring .06-017 Retaining Ring GB308-89 Steel Ball GB/T2089-94 Spring 06×5×16 .06-018 Dial GB/T1096-79 5×5×16 GB/T78-2000 Screw M6×16 .06-019 Screw .06-020 Hand wheel .06-021 Handle .06-022...

-

Page 58: Steady Rest

Steady Rest... - Page 59 Steady Rest code name specification Notes .08-201 Upside of Steady Rest .08-202 Downside of Steady Rest GB/T119.1-2000 10m6×50 .08-203 Sleeve .08-204 Bush .08-205 Screw Shaft .08-206 Sleeve GB/T77-2000 Screw M6×6 .08-207 Bracket GB/T119.1-2000 6m6×20 GB278-94 Shaft 6×19×6 .08-211 Sleeve 0.8-208 Screw GB879.2-2000 5×12...

- Page 60 Follow Rest...

- Page 61 Follow Rest code name specification Notes GB/T5782-2000 Bo l t M10×10 GB/T97.1-2002 Washer .08-301 Follow Rest GB/T119.1-2000 6m6×6 GB/T77-2000 Screw M6×6 .08-302 Sleeve .08-303 Screw Shaft .08-204 Bush Borrow .08-203 Rotate Handle Borrow GB/T78-2000 Screw M6×8 GB879.2-2000 5×26 .08-208 Limited Screw .08-304 Support Shaft...

- Page 62 Chuck Guard Cover...

- Page 63 Chuck Guard Cover code name specification Notes .08-903/1 Plate .08-903/2 Plate .08-903/3 Plate .08-903/4 Plate .08-903/5 Qu ill C6241-8904 Cover Bracket Borrow GB/T70.1-2000 Screw M6×30 GB/T78-2000 Screw M6×10 C624-8905 Borrow GB/T70.1-2000 Screw M6×20 GB/T70.1-2000 Screw M8×20 GB/T6175-2000 GB/T79-2000 Screw M6×20 GB/T6175-2000 08-902 Shaft...

Need help?

Do you have a question about the ELATHE-140 and is the answer not in the manual?

Questions and answers