Summary of Contents for KLR 930

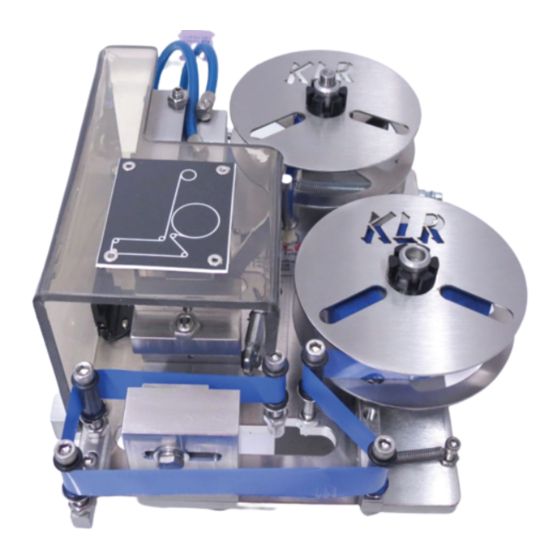

- Page 1 KLR 930 944, Des Hérons T : (450) 388-0404 info@klrsystems.com Saint-Pie, (Qc) Canada T : 1-800-918-8777 www.klrsystems.com J0H 1W0 D E P U I S / S I N C E 1977...

-

Page 2: Table Of Contents

KLR 930 Air Printer TABLE DES MATIÈRES IDENTIFICATION ........................4 Product number and type ....................4 Manufacturer name and adress ..................4 DECLARATION OF CONFORMITY ................4 SPECIFICATION ........................4 General fonction......................4 Dimensions and weight ....................4 Electrical and pneumatic specification ................4 SET UP BEFORE USING THE MACHINE ................. - Page 3 KLR 930 Air Printer PREVENTIVE MAINTENANCE AND REPAIR BY KLR SYSTEMS TECHNICIAN ....12 Technican address ......................12 ORDERING REPLACEMENT PARTS AND SUPPLY ..............12 KLR Printing supply ..................... 13 2016-04-11 Printed in Canada...

-

Page 4: Identification

Equipment described in this manual has been carefully designed and manufactured to high KLR standards. Special attention has been devoted to convenience of operation while simultaneously providing effective hazard protection for operating personnel. -

Page 5: Set-Up To Print

KLR 930 Air Printer SET-UP TO PRINT 1.1 Type Installation: Insert the desired type into the master plate as shown in the diagram below. Be sure the shoulder of the type is against the cavity of the master plate. All slots of the master plate must be filled with type (and spacers) to keep the type snug. - Page 6 KLR 930 Air Printer NOTE: During the machine installation, it may be necessary to adjust the position of tape guide roller (diagram 2 – number 1) for proper clearance between the printing tape and the closure track. Adjust the rollers so the tape is just clearing the closure track. If the tape hits the closure track, the ink surface of the tape may be scratched.

-

Page 7: Tape Feed Length

KLR 930 Air Printer 1.3 Tape Feed Length: The tape feed length is controlled by a screw between the stroke cylinder. Generally, use ¼’’ for one line of type, ¾’’ for two lines and 1’’ for three lines. To turn the screw adjustment to the desire setting, the print head must be in the out (or print) position. -

Page 8: Mechanical Setting

KLR 930 Air Printer Adjust this muffler until there is smooth and complete tape rewind. The rewind control may have to be readjusted when there is an air pressure setting change on the system. (Diagram 5) Instruction location The documentation is available with the product and on the web site www.klrsystems.com... -

Page 9: Automatic Compensator Drive The Tape

KLR 930 Air Printer 2- Loosen the two hex head screw under the frame block anvil. The block is on a pivot. (Diagram 6) 2.3 Automatic Compensator drive the tape: The rewind mechanic transfer drive from the tape feed roll to the rewind roll. The compensator... -

Page 10: Fonctions/Situations Exceptionnelles

KLR 930 Air Printer between the face of the type and the surface of the worktable. To set this .030’’, loosen hex lock nut. Fonctions/situations exceptionnelles Trouble Shooting TROUBLE PROBABLE CAUSE REMEDY Air pressure Reduce the air pressure if the type id Tape Breakage piercing through the tape. -

Page 11: Maintenance And Cleaning

KLR 930 Air Printer Rewind Spring Belt Check Ratchet bearing on rewinder tape or the mechanic actuator Water in the Air Valves Carefully disassemble the air valves Air System Not Functioning (actuator and main valve) and clean free of all water. -

Page 12: Preventive Maintenance And Repair By Klr Systems Technician

The KLR Service Department has a plan of periodic service covering all of our equipment. It is recommended that you investigate the benefits of participation in this equipment and continuous training of your personnel. -

Page 13: Klr Printing Supply

KLR 930 Air Printer The numbers moulded on casting should not be used to identify the casting for replacement. The same base casting may be machined as more than one finished part. Individual parts are furnished for replacement without screws, nuts, taper pins, cotter pins, oil cups, grease fittings, dowels, keys, spring posts, clamp studs, washers, ect., as... - Page 14 KLR 930 Air Printer BLUE MARKING TAPE FOR BAKERY TAPE.140 7/8'' x 1/2'' x 1000' rolls, packaged 36 rolls per case CHARACTER SCALE 2016-04-11 Printed in Canada...

- Page 15 Suggested Spare Parts ITEM PART DESCRIPTION QTY.PER PR-00014 Shaft - Clutch bearing actuating PR-00023 L-R Lever (L or R Printer) PR-00031 Rod adjust PR-00055 or A Cord Control Printer PR-00056 Cord Kwik Lok Connection 865 PR-00058 Cord Kwik Lok Connection 872 PR-00064 Cord Kwik Lok Connection 1087 PR-00068...

- Page 16 Exploded views ...

- Page 17 KLR.930-L PRINTER 12.882" 10.106" 11.297" Page: 17...

- Page 18 COVER PAGE 23 PRINTER MECHANIC PAGE COIL PAGE 21 TENSION SYSTEM PAGE 20 PR-00002 PNEUMATIC PAGE 19 Page: 18...

- Page 19 PRINTER MECHANIC PAGE PR-00002 PAGE 2 PR-00060 FOR KWIK LOK 865 PR-00061 FOR KWIK LOK 872,873 KLR.930-L # Document Title F10-190F12S SOCKET CAP 10-32 X 3/4" STAINLESS F10-190F14S SOCKET CAP 10-32 X 7/8" STAINLESS F10-190F20S SOCKET CAP 10-32 X 1 1/4" STAINLESS...

- Page 20 TENSION SYSTEM KLR.930-L # Document Title F01-190S FLAT WASHER #10 STAINLESS F03-190FS NUT 10-32 STAINLESS F03-250CS NUT 1/4 -20 STAINLESS F05-250-16 SHOULDER SCREW Ø 1/4'' X 1.00'' LG, 10-24 UNC F10-190F08S SOCKET CAP 10-32 X 1/2" STAINLESS F10-190F12S SOCKET CAP 10-32 X 3/4" STAINLESS F10-250C14S SOCKET CAP 1/4-20 X 7/8"...

- Page 21 COIL PRINTER MECHANIC PAGE KLR.930-L # Document Title F02-138S LOCK WASHER #6 STAINLESS F03-190FS NUT 10-32 STAINLESS F03-375CS HEX NUT 3/8-16 STAINLESS STEEL F06-190F04S SET SCREW 10-32 x 1/4" STAINLESS F10-138C16S SOCKET CAP 6-32 X 1" STAINLESS F10-190F14S SOCKET CAP 10-32 X 7/8" STAINLESS F11-138C03S BUTTON HEAD 6-32 X 3/16"...

- Page 22 PRINTER MECHANIC KLR.930-L # Document Title F01-190S FLAT WASHER #10 STAINLESS F01-250S FLAT WASHER # 14 STAINLESS F01-375S FLAT WASHER 3/8" STAINLESS F02-250S LOCK WASHER #14 STAINLESS F02-375S LOCK WASHER 3/8" STAINLESS F03-250CS NUT 1/4 -20 STAINLESS F03-312CS NUT HEX 5/16-18 STAINLESS F06-250C12S SET SCREW 1/4-20 x 3/4"...

- Page 23 MECHANIC PAGE PM-02108 RIVET PR-00016-A-L STAINLESS GUARD (OPTION) PR-00016-B STAINLESS GUARD (OPTION) PR-00002 PR-00033 GUIDE GUARD PROTECTOR PAGE 18 PR-00036 SAFETY DOOR BRACKET PR-00053L PLAN FOIL LEFT PRINTER PR-00055 FIL CONTROL PRINTER KLR 930 (R) AND (L) PR-00078 DEVIATOR Page: 23...

- Page 24 KLR.930-L OPTION 865L PR-00041 PR-00057 865L VIEW AND POSITIONING VIEW AND POSITIONING ON KLR.930-L ON KWIK LOK 865L Page: 24...

- Page 25 ACTUATOR PRINTER KLR 930 ACTUATOR KLR 930 # Document Title F06-250C05 SET SCREW 1/4-20 X 5/16 F11-112C04S BUTTON HEAD 4-40 X 1/4" STAINLESS F11-190F06 BUTTON HEAD 10-32 x 3/8 P31-00009 MAGNET PROXIMITY SWITCH PR-00055-A SWITCH PROXIMITY - SHORT PR-00069 ACTUATOR ARM...

- Page 26 PR-00011A PR-00011B PR-00011D PR-00011C PR-00040 PR-00150 PR-00151 PR-00152 PR-00040K PR-00153 Page: 26...

- Page 27 PR-00064 WIRE KWIK LOK 865 PR-00056 WIRE KWIK LOK 872 , 873 PR-00058 WIRE KWIK LOK 1081 , 1085 , 1087 PR-00035 PR-00046 Page: 27...

- Page 28 NOTES...

Need help?

Do you have a question about the 930 and is the answer not in the manual?

Questions and answers