Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for GCC Technologies LaserPro FMC280

- Page 1 www.delinit.by...

- Page 2 Dear Sir/ Madam, Thank you for choosing GCC and the LaserPro FMC280. You can be assured that this machine meets the highest safety standards while using technological innovations shared by no other laser engraver. The LaserPro FMC280 is backed by GCC, a truly international company that is dedicated to help your business grow.

-

Page 3: Table Of Contents

5.3.2 Color Management ..................85 5.3.3 Using the LaserPro FMC280 Print Driver ............ 86 5.3.3.1 LaserPro FMC280 Print Driver >> Options Page ......87 5.3.4.2 FMC280 Print Driver >> Pen Page ............ 91 5.3.4.4 LaserPro FMC280 Print Driver >> Paper Page ......... 97... - Page 4 8.2 Maintaining the Work table ................. 122 8.2.1 Cleaning the Work Table System .............. 122 8.3 Cleaning the Optics System ................122 8.3.1 Removing the Protection Window ............. 122 Chapter 9 .......................... 124 Appendix ......................... 124 9.1 LaserPro FMC280 Specification Sheet .............. 125 232002430G(02)

-

Page 5: Chapter 1

Chapter 1 Safety Principles of a DPSS & Fiber Laser Safety Ratings The Safety Interlock System Safety Labels Safety Measures Operating Environment www.delinit.by 232002430G(03) -

Page 6: Principles Of A Laser

1.2 Safety Ratings The LaserPro FMC280 is equipped with a DPSS laser that emits intense and invisible laser radiation with a wavelength of 10.6 microns in the infrared spectrum. The laser system is designated as a Class 1 laser device, meaning that the system is equipped with key safety features and an enclosed laser head to completely contain the laser under normal use. - Page 7 In compliance with CDRH standards, the required warning labels are affixed at the time of manufacture to the LaserPro FMC280, attached on appropriate locations. These labels are not to be modified in any way or removed for any reason. Please familiarize yourself with the specific labels and their locations on the machine.

- Page 8 CE Label This label indicates the class level of CE Warning Label Warning Label is written with all the necessary information to be aware of in every operation. 232002430G(03)

- Page 9 Laser Path Warning Label LaserPro machines are very safe under normal functioning conditions. However, as a precaution, Laser Path Warning Label are affixed on possible laser paths and operators should be aware of the possibility of injury while machine is operating Laser Path Danger label This label indicates the laser path.

-

Page 10: Safety Measures

Door open warning labels Protection Window Label This label indicates the protection wavelength. You can find this label in the lower middle of window. Machine Operation Warning Labels 1.5 Safety Measures • LASER RADIATION WARNING: Exposure to laser radiation may result in physical burns and severe eye damage. - Page 11 NOTE Each LaserPro FMC280 machine is shipped with a single pair of safety goggles. If additional safety goggles are required, please contact GCC directly or an authorized GCC distributor. If you wish to purchase one on your own, please make sure the safety goggles...

- Page 12 GCC FMC280 laser system. Hazardous or fire may occur if not follow 1.6 Operating Environment Please follow the guidelines when considering a suitable location to set the LaserPro FMC280. Improper work environments may lead to operational malfunction and/or unsafe working conditions.

-

Page 13: Assisted Air Safety And Setup Information

1.7 Assisted Air Safety and Setup Information Assisted Air Setup: Some assisted gas peripherals need to be prepared for assisted gas by your own before machine installation. 1. Gas Cylinder: Oxygen or 99.99% Nitrogen high pressure gas cylinder* 2. Cylinder Valve: To seal or open the gas cylinder. 3. - Page 14 Assisted Air Safety Notice: Only use Oxygen and Nitrogen with FMC280 laser system. Other gas is NOT allowed. Only qualified personnel should be allowed to adjust pressure-regulating equipment. Valves, gauges and other regulating devices should be installed on compressor equipment in such a way that cannot be made inoperative.

- Page 15 Regulator Valve – Adjust suitable gas pressure from gas cylinder for material processing. Recommended Regulator Valve specification: inlet pressure : 0~3500 psi ( 0~250 kgf/cm² ) Outlet pressure: 0~310 psi ( 0~22 kgf/cm² ) Flow volume: 140m³/hr NOTE 1. Make sure the high-pressure gas valves and connectors are tightly sealed without falling.

-

Page 16: Machine Turn-On/Off Procedures

1.8 Machine Turn-On/Off Procedures. Follow below Procedures to operate FMC280. Machine Turn-On Procedures: Power on FMC-280 Turn on the gas cylinder Adjust the gas regulator valve to proper air pressure Machine Turn-Off Procedures: Turn off the gas cylinder Click F4 then F2 on the control panel to enable AIR and release the remaining gas Turn off the regulator valve and confirm the cylinder gauge back to zero 232002430G(03) -

Page 17: Ec-Declaration Of Conformity

The manufacturer GCC Great Computer 4F-1., No.236, Fude 2nd Rd., Xizhi Dist., New Taipei City 22151, Taiwan hereby declares that the following product GCC LaserPro FMC280 Model Number Z1 has demonstrated conformity to the following guidelines: 2006/42/EC Machinery Directive 2006/95/EC Low Voltage Directive... -

Page 18: Chapter 2

Chapter 2 Unpacking& Contents Unloading and Unpacking Contents and Accessories Checklist www.delinit.by 232002430G(03) -

Page 19: Unloading And Unpacking

2.1 Unloading and Unpacking The LaserPro FMC280 is shipped in one crate that contains the machine, the software, and all of the necessary accessories. The following section shows detailed step-by-step instructions for unpacking and assembly of the machine. WARNING More than one person may be needed when loading and unloading the shipping crate in order to avoid body injury or damage to the machine. - Page 20 Step 3: Loosen the lock Step 4: Remove the top board and each sideboard 232002430G(03)

- Page 21 Step 5: Loosen and remove the pink packing strips by pushing the lock on the strip down and then pull it out towards the top before you can loosen the strips. Step 6: Unscrew the screws fastening the slide boards on the pallet 232002430G(03)

- Page 22 Step 7: Unscrew the screws fastening the slide boards on the pallet then pull them off to form ramps and fix it by screws. Step 8: Remove the wooden block from the crate base, and then unscrew the four holding stands so that they can be moved up.

- Page 23 Step 9: Position the ramps as shown below and the machine can now be pushed off the base board via the ramps. 232002430G(03)

-

Page 24: Contents And Accessories Checklist

Lens Tissue Lens Blower Power Cord (US/EU/AU) USB Cable Ethernet Cable Safety Goggles 4” Ventilation Pipe Connector Installation CD (LaserPro FMC280 user manual, driver) Lubrication Grease Warranty Card 1set Grounded Supporting Pins Magnetic Fixtures 3/8” High Pressure Air Tube Cutting Sample... -

Page 25: Chapter 3

Chapter 3 Mechanical Overview Front View Right ( Profile ) View Left ( Profile ) View Rear View www.delinit.by 232002430G(03) -

Page 26: Front View

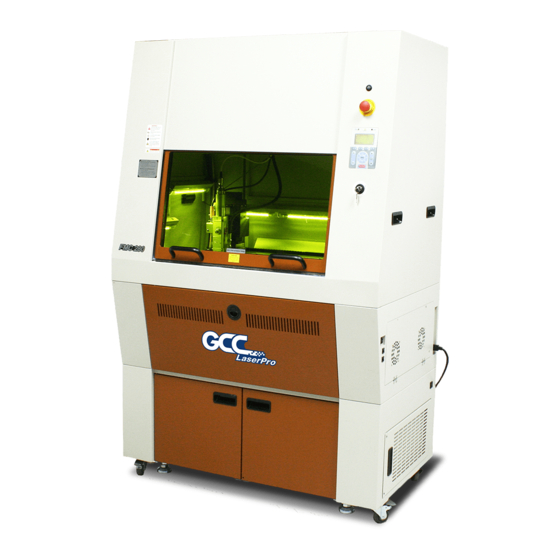

Please take some time to familiarize yourself with this section regarding the mechanical overview of the LaserPro FMC280. References will be made back to the different parts of the LaserPro FMC280 in later sections. 3.1 Front View LED light Switch... -

Page 27: Right (Profile) View

3.2 Right (Profile) View Ethernet Port Main Power Swiych USB Port Power Socket 232002430G(03) -

Page 28: Left (Profile) View

3.3 Left (Profile) View Water Inlet Water Outlet Assist Air Inlet 232002430G(03) -

Page 29: Rear View

3.4 Rear View 232002430G(03) -

Page 30: Chapter 4

Chapter 4 Setup and Installation Machine Setup Powering Up the Machine Connecting the Computer Graphics Software Setup Recommended Computer Configuration Installation of the LaserPro USB Driver Installation of the LaserPro Print Driver www.delinit.by 232002430G(03) -

Page 31: Machine Setup

4.1.2 Powering Up the Machine CAUTION Make sure both the LaserPro FMC280 and the computer are turned off before connecting either to a power source. Connect the male end of the power cord to a quality surge protector and then connect the surge protector to a properly grounded outlet. -

Page 32: Connecting The Computer

Follow below instruction for ethernet connectivity setup.. NOTE If you have purchased additional Optional Accessories for the LaserPro FMC280, please refer to chapter VII for instructions on how to properly setup your optional accessories. - Page 33 232002430G(03)

- Page 34 232002430G(03)

-

Page 35: Ethernet Connectivity Setup

4.1.3.2 Ethernet Connectivity Setup GCC laser engraver is built-in with LAN port to transmit data from PC to laser engraver with ease and higher speed instead of USB port option. Step 1. Connect LAN cable to the LAN port of GCC laser engravers and turn on machine Step 2. - Page 36 Step 5. Go to <Control Panel Network and Internet Network Connections> of computer, right click mouse on the connected internet device, and choose <Properties> Step 6. Choose the <Internet Protocol Version 4(TCP/IPv4)> and click <Properties> to open up the setting window. Step 7.

- Page 37 Step 8. Go to <Control Panel> <Device and Printers> of computer and right click on the laser machine printer, choose <Printer Properties>. Step 9. Select <Add Pot> under Ports tab, and follow the instruction to enter the TCP/IP information in laser machine’s control panel in step 4. 232002430G(03)

- Page 38 232002430G(03)

- Page 39 232002430G(03)

- Page 40 232002430G(03)

-

Page 41: Graphics Software Setup

• Illustrator • AutoCAD Other software such as EngraveLab and PhotoGrav may work with the LaserPro FMC280, but these are not officially supported. Any software that can output to the LaserPro Print Driver should work. NOTE Support will not be offered, if you experience output problems with non-supported graphics software. -

Page 42: Installation Of The Laserpro Print Driver

No if you want to use this printer as the default printer and click Next to continue. NOTE When working with the LaserPro FMC280 Print Driver within your graphics software, you will need to have the FMC280 set as the default printer to get proper output. If... -

Page 43: Parallels Desktops (Mac Os)

4.2.3 Parallels Desktops (MAC OS) MAC users can use GCC LaserPro machines by purchasing the Parallels Desktop software which allows you to install Windows OS in MAC computers and run Windows based software under MAC computer and output with GCC print driver. 1) Purchase Parallels Desktops on its official website. - Page 44 4) Enter your Mac OS X User Name and Password then press “OK” 5) Press “Active” 232002430G(03)

- Page 45 6) Press “OK” when activation is complete. 7) Register Parallels Desktop 232002430G(03)

- Page 46 8) Press “Register” and “OK” to complete the installation of Parallels Desktop. 9) Open Parallels Desktop (in the Applications folder) then choose File → New 232002430G(03)

- Page 47 10) Press “Install Windows from DVD or image file” then press “continue” to install windows OS 11) Select CD-ROM drive with the Windows installation CD 232002430G(03)

- Page 48 12) Enter the Windows OS product key 13) Select how you would like to run your Windows program. 14) After the prior setting is complete the windows OS installation procedure will start automatically. 232002430G(03)

-

Page 49: Using Autodesk Inventor With Gcc Laserpro Machine

15) Windows OS installation is complete then you can refer to “4.2.5 Installation of the LaserPro Print Driver” to install GCC LaserPro Print Driver. 16) Install the AP that you want to use after the above installation is complete. 4.2.4 Using Autodesk Inventor with GCC LaserPro machine 1. - Page 50 3. Set sheet size to match working area of engraver. Engraver working area can be found on the paper tab of the windows driver. 4. Start sketch. 5. Engraving a. Finish sketch. b. Right click on sketch and select properties. c.

- Page 51 6. Cutting a. Finish sketch. b. Right click on sketch and select properties. c. Line Type: Continuous d. Line Weight: .001 in. e. Set color to match one of the 16 colors available in the pen tab of the windows driver. NOTE All objects created in one particular sketch will have the same properties meaning all will engrave or all will cut.

-

Page 52: Chapter 5

- Page Setup and Orientation - Color Management - Using the LaserPro FMC280 Print Driver - LaserPro FMC280 Print Driver >> Options Page - LaserPro FMC280 Print Driver >> Pen Page - LaserPro FMC280 Print Driver >> Advanced Page - LaserPro FMC280 Print Driver >> Paper Page - LaserPro FMC280 Print Driver >>... -

Page 53: Using The Hardware

Once you have installed the LaserPro Print Driver, and have connected the LaserPro FMC280 to your computer, you will need to familiarize yourself with the LaserPro FMC280 control panel and LaserPro Print Driver. The print driver will be where specific laser parameters for your jobs are configured, while the control panel will allow you to set repeat times, manipulate file order, perform auto / manual focusing, and more. -

Page 54: Move Lens Carriage Correctly

LCD Display Screen Contrast Adjustment * This picture was taken with back door opened to clearly show the location of the contrast adjustment wheel. 5.1.3 Move Lens Carriage Correctly (1) Do move the lens carriage by holding the laser carriage and optical fiber to prevent the damage of machine. - Page 55 5.1.4 Work Piece Setup (1) Place the sheet metal piece to the work table on supporting bars. Supporting Bars (2) Arrange the magnetic fixtures to keep the sheet metal flat 232002430G(03)

-

Page 56: Setting Focus Position

NOTE 1. Proper grounding is critical for LaserPro FMC280 laser system proper operation. 2. Change the supporting bars if it’s rusted after time usage. Rusted supporting bars may affect the grounding of FMC280 and cause fault operation. 5.1.5 Setting Focus Position... -

Page 57: Graphic Control Panel Overview

5.1.6 Graphic Control Panel Overview The Control Panel The control panel on the LaserPro FMC280 provides an easy access to all the manual controls needed for cutting and engraving. The liquid crystal display (LCD), functional, directional and selection buttons make navigating through the machine’s manual controls easy to do. - Page 58 WARNING DO NOT attempt to remove or modify any component of the safety interlock system. If at any time, any of the access doors are open and the “laser” LED is illuminated, unplug the laser system IMMEDIATELY and contact GCC technical support for service instructions.

-

Page 59: Graphic Control Panel Navigation Chart Below

5.1.7 Graphic Control Panel Navigation Chart below Main Work Page Functions Page File Management Information Machine Setting Page Table Down File Information Page Red Beam Carriage Free Command Mode Save position Vector Mode File Save Mode Air Pressure detect HSU Setting LAN Setup Wizard Scaling Scaling... -

Page 60: Graphic Control Panel Function

Main Work Page The main work page is the page that the LaserPro FMC280 will default to upon startup and will be the “home base” for when navigating through the various functions of the control panel. This will be the page that is displayed when you are processing your jobs. - Page 61 Carriage/ Work Table Adjustment Page Navigating to this page: Main Work Page press, , , , or F3 Carriage / Work Table Carriage / Work Table Adjustment Page Adjustment Page The Carriage / Work Table Adjustment Page allow you to manually increase and decrease the height of the work table (Z-axis).

- Page 62 Functions Page Navigating to this page: Main Work Page press F4 Functions Page The Functions Page allows you to edit file management and machine settings. From this page, you will be able to access the File Management, Machine Setting, and Machine Information pages.

- Page 63 File Management Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Manage- ment>from the menu File Management Page The File Management Page allows you to manage the files that you have loaded onto the LaserPro FMC280. You can scroll through your jobs, delete a selected job, delete all jobs, and go to the Link / DLink Page to set and arrange multiple loaded jobs into a single job queue for processing.

- Page 64 Link / DLink Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Management >from the menu File Management Page press F2 Link / DLink Page The Link / DLink Page allows you to set, arrange, and remove loaded jobs to and from a job queue for processing.

- Page 65 File Information Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Management >from the menu File Management Page Select a job file and press Enter File Information Page The File Information Page allows you to view the speed, power, DPI, and Freq. settings of the selected job.

- Page 66 The File Edit Vector Page allows you to edit the vector pen, vector power, vector speed for the selected job. These settings correspond to the same settings found on the LaserPro FMC280 print driver. This page allows you to easily adjust these values to make immediate adjustments while processing your loaded jobs, even when you have disconnected your computer from the LaserPro FMC280.

- Page 67 Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<File Management>from the menu Machine Setting Page The Machine Setting Page allows you to access and modify various machine settings, including: Set Table Down, Set Red Beam, Carriage Free, Set Command Mode, Save Position, File Save Mode, Set Vector Mode, Other, and Reset.

- Page 68 Table Down Page>> Machine Setting Page Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Set Red Beam>from the menu Set Red Beam Page The Set Red Beam Page allows you to turn on or off the red dot laser pointer on the laser carriage. Enabling this function will indicate the exact area the engraving laser will fire upon.

- Page 69 Red Beam Page>> Machine Setting Page Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Set Red Beam>from the menu Set Red Beam Page The Red Beam Page allows you to turn on or off the red dot laser pointer on the laser carriage. Enabling this function will indicate the position where the laser will fire upon.

- Page 70 Carriage Free Page>> Machine Setting Page Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Carriage Lock>from the menu Carriage Lock Page The Carriage Free Page allows you to set whether the laser carriage is to be locked or free. If the Carriage Free setting is set to <YES>, then you will be able to manually move the laser carriage along the X and Y axis by hand with the top door open.

- Page 71 Command Mode Page>> Machine Setting Page Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Set Command Mode>from the menu Set Command Mode Page The Command Mode Page allows you to configure vector settings when outputting in Default or HPGL mode.

- Page 72 Save Position Page>> Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<Advanced Options>from the menu Advanced Options Select <SavePosition> from the menu The Save Position Function allows you to save the current X-axis and Y-axis positions of the laser carriage and sets this position to be the origin for subsequent jobs.

- Page 73 Vector Mode Page >> Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Vector Mode>from the menu Vector Mode Page There are three options under the V ector Mode Page: Acceleration Mode allows you to adjust and balance vector quality and speed settings based on your specific job.

- Page 74 Mode>from the menu Set File Save Mode Page The Set File Save Mode Page allows you to set whether or not the LaserPro FMC280 automatically deletes each job file after processing. Setting File Save to <NO> will automatically and immediately delete each job file from the LaserPro FMC280 after the engraving or cutting process.

- Page 75 Air Pressure Detect Page>> Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Air Pressure Detect >from the menu Air Pressure Detect Page Enable the Air Pressure Detect allows the laser machine to detect if the assisted gas is supplied or it’s run out of gas, the laser machine will show error message to remind when the assisted gas is not detected to ensure optimal cutting result.

- Page 76 LAN Setup Wizard Page>> Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<Ma chin e Se tting >from the menu Machine Setting Page Select<LAN setup wizard> from the menu LAN Setup Wizard Page The LAN Setup Wizard Page allows you to connect the laser machine with ethernet to transmit files from computer to laser machine for processing jobs.

- Page 77 HSU Setting Page>> Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<HSU Setting > from the menu HSU Setting Page There are two functions under HSU Setting page, one is HSU sensitivity, and the other is Travel Air. HSU Sensitivity function allows you to adjust the sensitive level of HSU laser cutting head to automatically detect the gap between working object and HSU laser cutting head to keep fixed focal distance for optimum processing result.

- Page 78 Scaling Page>> Machine Setting Page Navigating to this page: Main Work Page press F4 Functions Page Select<Ma chin e Se tting >from the menu Machine Setting Page Select<Scaling> from the menu Scaling Page The Scaling Page allows you to fine tune the laser machine output scale to precisely fit the original graphic file design scale when precision output is requried to your application.

- Page 79 Others Page>> Machine Setting Page Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Others >from the menu Others Page The Others Page allows you to change various settings that correspond to the control panel. The Language setting will allow users to change available languages displayed on the control panel.

- Page 80 Reset Page>> Machine Setting Page Main Work Page press F4 Functions Page Select<Machine Setting>from the menu Machine Setting Page Select<Reset>from the menu Reset Page The Reset Page will restore machine settings back to factory default. Press ENTER to confirm the change, and restart the machine.

- Page 81 Machine Information Page Navigating to this page: Main Work Page press F4 Functions Page Select<Machine Information>from the menu Machine Information Page The Machine Information Page provides you the information regarding the system such as the GCC logo, machine name, firmware version, and other information. Information Page Relevant Buttons Function...

- Page 82 5.2 Add Bridge to Cutting GCC LaserPro FMC280 fiber laser system comes with a node-bridge cutting function to help thin metal generate good cutting edge by assigning small bridges on the cutting path to prevent the cutout falling apart, and remove it manually after laser cutting.

- Page 83 Step 3. Click “Commands” and then “Macros” from the menu Step 4. Click and drag “Module1.Start” to the toolbar of CorelDRAW. 232002430G(03)

- Page 84 Step 5. Click “OK” to close the options window Step 6. The installation is completed, the node bridge icon will show on the toolbar of CorelDRAW. 232002430G(03)

- Page 85 5.2.2 Node Bridge Operation Step 1. Click the “Node Bridge” icon from CorelDRAW toolbar to launch the “Node Bridge Cutting” window the width setting of node bridge the length setting of node bridge Step 2. Using the “PICK TOOL” to select object. Step 3.

- Page 86 Step 4. Click the object to define node bridge location and its direction. The first click will assign its location to the node bridge, and the second click will define the inward or outward direction of the bridge. Outward bridge Inward bridge Step 5.

-

Page 87: The Laserpro Fmc280 Print Driver

Windows Control Panel → Printers and Faxes. If the LaserPro FMC280 is not selected as DEFAULT PRINTER, you may set it up through the graphics software as well. The following example takes CorelDRAW to demonstrate how to set up LaserPro FMC280 as the Printer. - Page 88 Height, you can simply click the Set From Printer function and CorelDraw will automatically set the proper orientation and dimensions based on the work table. (You MUST have the LaserPro FMC280 set as the default printer prior to doing this.)

-

Page 89: Color Management

In addition to having your Page Setup and Orientation properly set in your graphics software, you will also need to make sure Color Management is DISABLED prior to working with the LaserPro FMC280 Print Driver. From your graphic software’s Color Management page: •... -

Page 90: Using The Laserpro Fmc280 Print Driver

Now after you have properly set the Page and Layout and Color Management of your graphics software, you are ready to configure the details of your actual job through the LaserPro FMC280 Print Driver. The print driver allows you to adjust your engraving / cutting options. After you have setup your image, design, or text to be engraved in your software application, you can access the LaserPro FMC280 print driver by going to FILE →... -

Page 91: Laserpro Fmc280 Print Driver >> Options Page

T ip The following sections describe the specific functions for each of the settings found in the LaserPro FMC280 Print Driver. If you are new to laser cuttinng, it is recommended that you first familiarize yourself with the general principles of the laser process in Chapter 6. - Page 92 Print from your graphic software program. If Print Immediately is not checked, then selecting Print will transfer the job file to the machine and will need to be initialized from the LaserPro FMC280 control panel. File Function (Options Page) The file function section allows you to manage various laser parameters.

- Page 93 SmartACT (Options Page) SmartACT reduces the amount of time it takes to process a job, by eliminating unnecessary travel of the lens carriage at the expense of some quality. Usually the quality loss is minimal, but will depend on the image or design you are working with;...

- Page 94 After entering the filename and pressing “ok”, the Preview screen will be shown. The output file can be previewed and a simulated working time of the job is also displayed. 232002430G(03)

-

Page 95: Fmc280 Print Driver >> Pen Page

5.3.4.2 FMC280 Print Driver >> Pen Page The LaserPro FMC280 incorporates the use of 16 different colors to represent 16 different laser power and speed settings when cutting and engraving. These colors are referred to as “Pens”. Think of each pen as a designated laser setting, rather than as a color. - Page 96 NOTE The LaserPro FMC280 print driver cannot store more than 16 pen colors or different laser parameter Speed (Pen Page) The speed slider controls the laser’s speed during operation with settings ranging from 0.1 – 100%.Keep in mind, this is the speed the laser moves at when cutting or engraving straight lines. The machine will automatically slow down when processing curves.

- Page 97 PPI (Pen Page) PPI (pulses-per-inch) represents the number of times the laser pulses (fires) per linear inch, exclusive for vector cutting. Higher PPI settings will generate deeper, overlapping laser pulses, resulting in cleaner cuts. Lower PPI settings (lower than 150) will result in the individual laser pulses being spread apart, resulting in a perforated effect (similar to the perforation in the paper between mailing stamps).

- Page 98 Enter the repeat numbers to the function box, the laser will re-do the job for specified times. Some cutting may require multiple cut passes to cut through the materials with optimum quality. 5.3.4.3 LaserPro FMC280 Print Driver >> Advanced Page Scaling (Advanced Page) In some cases you may find a slight output inaccuracy in the actual output compared to what you have set in the computer.

- Page 99 • Center: Sets the current position of the laser head as the center point for your subsequent job. As an example, if the subsequent job is to vector cut a circle and you have the Position Mode set to Center, then the LaserPro FMC280 will vector cut a circle around the initial position of the laser head.

- Page 100 An example of an image that would benefit from the Cluster function would be: 2 squares to be engraved, side-by-side on the X-axis with a 20 cm gap in between them. In this scenario, you would want to enable the Cluster setting and set the distance to a value less than 20. By doing so, the laser will completely process one square and “leap-frog”...

-

Page 101: Laserpro Fmc280 Print Driver >> Paper Page

5.3.4.4 LaserPro FMC280 Print Driver >> Paper Page 232002430G(03) - Page 102 Unit (Paper Page) Here you can set your preferred measurement standard in which you would like to use with the LaserPro FMC280 print driver. You can choose between metric or imperial standards. Image Tuning (Paper Page) In the event that you are processing extremely fine and detailed designs requiring near- microscopic edge-to-edge precision, you will need to adjust the image tuning setting.

- Page 103 Rotary Fixture (Paper Page) NOTE This option is only to be used with the Rotary Chuck optional accessory properly set up. For instructions on how to set up the Rotary Chuck, please refer to Chapter VII of this manual. You will need to select this option when processing a job with the optional rotary attachment system to engrave on round or cylindrical objects.

-

Page 104: Spirit Series Print Driver >> Raster Page

5.3.4.5 LaserPro FMC280 Print Driver >> Language Page This page allows you to specify the language displayed by the LaserPro FMC280 Print Driver. Current language options available is English. 5.2.3.6 Spirit Series Print Driver >> Raster Page NOTE The Raster Page is only available when Black & White Mode Setting is selected from the Options Page, this page offers a number of advanced Raster Engraving output options. - Page 105 Halftone (Raster Page) This option controls the way a raster-engraved image is processed. The “digital image to engraved output” process can be processed via two methods: Dithering or Error Diffusion. Each offer additional output options yielding different output effects, style, and quality. •...

- Page 106 is broken down into for the dithering process. As an example, selecting 2 x 2 will shade with a 5-grade halftone, where as an 8 x 8 Dithering Matrix will dither with a 65-grade halftone. The following diagram is an example of the raster effects when using the different dithering matrices.

-

Page 107: Chapter 6

Chapter 6 Cutting Techniques Vector Cutting Cutting Large Work Piece 3D Tips Modify Image Settings of Picture for Better Engraving Quality 232002430G(03) -

Page 108: Vector Cutting

An example of a vector cut piece is cutting as shown below. The LaserPro FMC280 Print Driver determines which sections should be vector cut based on the outline width of that particular area or section of the design. In order to prep a particular section for vector cutting, you will need to set that object’s fill color to white and set its outline thickness between 0.001"... - Page 109 6.2 Cutting Large Work Piece When processing large piece materials than sheet metal like molded engineering parts, follow below procedures for setup. Youtube video is also available for quick reference https://www.youtube.com/watch?v=dEHyzKPzU_Q Step 1. Remove all the supporting bars on working platform with screw driver Step 2.

- Page 110 Step 3. Take out the grounding cable from accessory box. Attach one end of the cable to the metal frame of work table with screws and the other end to work piece to ensure proper grounding for machine protection. Attach the clip end of grounding cable to work piece.

- Page 111 6.3 Modify Image Settings of Picture for Better Engraving Quality Connect your digital camera to the computer by USB cable. Download the picture from the digital camera to the computer Select the picture that you want to engrave. Import the image from the folder where the picture is located by selecting File/Import Convert the image to Bitmap by selecting the image and click on Bitmaps/Convert to Bitmap 232002430G(03)

- Page 112 Change the Bitmap settings by setting “Color” to Grayscale (8-bit) and “Resolution” to 300 dpi and click OK. Finally, Invert the image by selecting Effects/Transform/Invert 232002430G(03)

- Page 113 Now you are ready to output the modified image by clicking File/Print 232002430G(03)

- Page 114 NOTE This instruction is a simple example for general use. There are many tips and tricks to achieve a good engraving quality. It takes a lot of practice and experience to achieve a good engraving quality. Different picture may need different modifications and different material may need different parameters.

-

Page 115: Chapter 7

Chapter 7 Optional Items Air Extraction System Option Rotary Chuck Option www.delinit.by 232002430G(02) -

Page 116: Fume Extraction System

In order to ensure personnel safety and legal compliance, GCC LaserPro FMC280 is required to connect with an explosion-proof fume extraction system. You can source fume extraction system locally meeting below specification with CE and ATEX Zone 22 compliance for Europe, and American Explosion regulation of Class 2 Division 2. - Page 117 3) Connect rigid and smooth walled tubing such as PVC or sheet metal with a 4” diameter to the ventilation opening located on the rear side of the LaserPro FMC280. (As shown in the picture below). Try to keep this tubing as straight as possible due to bended air tubing will reduce the exhaust efficiency.

-

Page 118: Rotary Chuck

7.2 Rotary Chuck The Rotary Chuck option provides the FMC280 laser system with the ability to engrave on cylindrical or spherical objects. In addition to the standard X, Y, Z axis, the rotary chuck allows for a fourth axis which rotates the working object up to 360° to allow for engraving & cutting on cylindrical or circular objects. - Page 119 3) Put the Rotary Chuck on top of the two Supporting Bars in step 2. Align and fix the Rotary Chuck to the No. 5 screw opening on the Supporting Bars. 4) Fix the other three screws accordingly. 5) Open the front door of the FMC280 laser machine and connect the Rotary Chuck cable to the connection port located on the machine chassis, and close the front door.

- Page 120 The Rotary Chuck now is properly installed. Power on the FMC280 laser system, the Rotary Chuck will be automatically detected, the working table will move to its proper position. CAUTION Please make sure that the laser cutting head will not collide with the Rotary Chuck prior to start work by lowering the work table down first.

- Page 121 The clamps on the Rotary Chuck can be detached and reverted for better fitting objects with different sizes. Note that the clamps should be assembled by lining up the correct numbers. Please remember to lubricate the detachable clamps along the groove with machine oil regularly after each use.

- Page 122 The rear end of the Rotary Chuck also can be locked or unlocked to slide its position by using an Allen key as shown below. Dial the lever indicated with red arrow below to move up or down the rear end which will adjust its leveling to match clamping end.

- Page 123 5) From the Paper Page, the first thing you must do is to check the Rotary Fixture. The Paper Size options and Rotary Parameter will change to allow for proper input based on your Rotary Chuck. Under Paper Size, the X value represents the length of your working piece. Enter the length of your work piece in this field.

-

Page 124: Chapter 8

Chapter 8 Basic Maintenance Suggested Cleaning and Maintenance Supplies Maintaining the Work table and Motion System - Accessing the Work table and Motion System Cleaning the Work table and Motion System Lubrication of the Y Rails Cleaning the Optics System - Removing the Mirrors - Cleaning the Mirrors - Removing and Cleaning the Focal Lens... -

Page 125: Suggested Cleaning And Maintenance Supplies

• Electrical shock may occur if you do not turn off and unplug the LaserPro FMC280 before cleaning. • Damage may occur to the system if you do not turn off and unplug the LaserPro FMC280 and turn off laser power supply by key before cleaning. -

Page 126: Maintaining The Work Table

Clean the working table on a frequent basis through the following steps: Turn the power off, release the gas, and unplug the LaserPro FMC280 before cleaning. Use a vacuum cleaner with a flexible nozzle to remove dust and debris from the work table. - Page 127 (2) Wash your hand before you doing any cleaning operation and all procedure need to process under clean environment with the air conditioner. (3) Use Lens Cleaning Blower in accessory box to blow away dust or residue from window surface. (4) Place a lens cleaning paper on the protection window then remove the cover slide from the drawer by applying pressure with your fingers to the surface with cleaning paper of the cover slide, opposite the seal ring.

-

Page 128: Chapter 9

Chapter 9 Appendix LaserPro FMC280 Specification Sheet www.delinit.by 232002430G(03) -

Page 129: Laserpro Fmc280 Specification Sheet

9.1 LaserPro FMC280 Specification Sheet Model Name FMC280 Model No. FMC280-Z1 Laser Source 1070nm fiber laser source, 1.5kW peak power Work Area 28 x 14.5 in. (712 x 370mm) Max. Part Size (W x L x H) 30.9 x 21.3 x 4.7 in. (786 x 542 x 120 mm) Dimensions 44.3 x 28.3 x 70.8 in.

Need help?

Do you have a question about the LaserPro FMC280 and is the answer not in the manual?

Questions and answers